Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.116 n.4 Johannesburg Apr. 2016

http://dx.doi.org/10.17159/2411-9717/2016/v116n4a5

STUDENT EDITION - METALLURGY

Slurry abrasion of WC-4wt%Ni cold-sprayed coatings in synthetic minewater

N.B.S. MagagulaI; N. SacksII; I. BotefIII

ISchool of Chemical and Metallurgical Engineering, University of the Witwatersrand, Johannesburg, South Africa

IIDST-NRF Centre of Excellence in Strong Materials, South Africa

IIISchool of Mechanical, Aeronautical and Industrial Engineering, University of the Witwatersrand, Johannesburg, South Africa

SYNOPSIS

Low-pressure cold gas dynamic spraying was used to deposit WC-4wt%Ni and WC-4wt%Ni-1wt%Mo coatings onto mild steel. Dense coatings with very low porosities were produced. No decarburization occurred during deposition and no deleterious phases were formed. The coatings were subjected to standardized material characterization tests, as well as slurry abrasion testing to assess their wear behaviour. The wear tests were conducted in synthetic minewater-silica slurries, while distilled water-silica slurries were used as a control. The hardness of the coatings, 512HV03 and 458HV03 for WC-4wt%Ni and WC-4wt%Ni-1wt%Mo respectively, are comparable to those achieved using high-temperature coating processes. The abrasion wear rates for both coatings were less than 5 mg/min and 10 mg/min in the distilled water-silica and synthetic mine water-silica slurries respectively. The approximately 50% increase in wear rate in the synthetic minewater slurry is attributed to a synergistic corrosive wear mechanism. The predominant wear mechanisms were identified as binder smearing and delamination, with carbide grain fracture and pull-out.

Keywords: tungsten carbide, nickel, cold spray, coatings, abrasion, minewater

Introduction

Slurry abrasion is a common phenomenon in mining operations, particularly in pipelines transporting, for example, sand-water slurries. This type of wear can cause pipeline fracture, shortened operational lifetimes, and impede pipeline efficiency. To reduce or limit abrasion, thermally sprayed tungsten-carbide-based coatings are often used as pipe linings (Kanchan et al., 2010). This is due to their attractive mechanical properties, which include high wear resistance, stiffness, hardness, compressive strength, and tensile strength. These properties are provided by the coating microstructure and composition, which is a blend of hard, wear-resistant tungsten carbide (WC) particles embedded in a fracture-tough metallic binder phase (Brookes, 1997). Cobalt (Co) is the most commonly used binder due to its excellent wetting of the WC phase and moderate mechanical properties; however, its application is limited to non-corrosive environments as it has a low corrosion and oxidation resistance (Andren, 2001). Nickel (Ni) may also be used as a binder, and has been shown to have superior oxidation and corrosion resistance, but in some applications may not have the required mechanical properties (Kim et al., 2006).

The WC-based coatings are generally deposited by flame, arc, plasma, or highvelocity oxy-fuel (HVOF) spraying, all of which require melting or partial melting of the feedstock powder constituents (Jacobs et al., 1998; Kear et al., 2000; Zikin et al., 2012). These high-temperature deposition processes may adversely affect the properties of the coating, as oxidation, decarburization, unwanted phase transformations, and tensile residual stresses may occur. An alternative deposition method that claims to reduce and/or eliminate these undesirable effects is the cold-gas dynamic spray process (CGDS) (Champagne, 2007). In this technique, the feedstock powders are heated only to low temperatures which are below the melting points of the constituent materials. This process has been shown to produce coatings with low porosity and good wear and corrosion resistance, comparable to HVOF coatings, and may have compressive residual stresses which could improve the coating's mechanical properties (Lima et al., 2002). Due to the low temperatures employed, this cold spray technique also has significantly lower energy requirements compared to the high-temperature deposition processes, which make it attractive in an energy-conscious society (Papyrin et al., 2006).

In the current study, the use of a low-pressure cold gas dynamic spray system to produce WC-4wt%Ni coatings was investigated. The aim of the research was to produce coatings that have a good resistance to slurry abrasion, and which may find application in a mining environment. Nickel was selected as the binder due to its superior corrosion properties compared to Co, which would make it more suitable for mining applications. In addition, a small amount of molybdenum (Mo) was added to investigate its effect on the coating properties. A brief review of the cold spray process will be given first, followed by the methodology and results of the research.

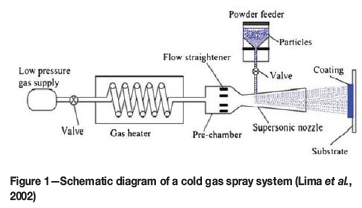

Cold gas dynamic spraying

Cold gas dynamic spraying (CGDS) is a process whereby metal powder particles are utilized to form a coating by means of ballistic impingement upon a suitable substrate (Champagne, 2007). The fine powder particles, usually 5-45 μΐη, may be accelerated at supersonic speeds of 3001200 m.s-1 towards the substrate, using air or a suitable carrier gas (Figure 1). The process was first developed in the mid-1980s at the Institute for Theoretical and Applied Mechanics of the Siberian Division of the Russian Academy of Science in Novosibirsk (Stoltenhoff et al., 2002). The discovery began as a study of the erosive behaviour of particle-laden flow on an object in a wind tunnel. Above a certain minimum particle velocity, the particles adhered to the target rather than abrading it, leading to the formation of coatings; a trend found to be characteristic for each of the metal powders tested. Further depositions were then made of a wide range of pure metals, metallic alloys, polymers, and composites onto a variety of substrate materials.

Since its initial discovery, CGDS has developed into two fundamental deposition methods, namely high-pressure cold gas spraying and low-pressure cold gas spraying, in which the operational parameters such as pressure, temperature, and the carrier gases differ (Villafuerte, 2010). High-pressure systems typically use nitrogen or helium gas with pressures reaching approximately 7 MPa to accelerate the gas flow to the supersonic regime. Low-pressure systems typically use air (sometimes nitrogen) with pressures between 0.5500.695 MPa. Due to the low temperatures used, limited or no melting occurs during deposition, so that the chemical composition of the coatings typically remains identical to the feedstock powders (Papyrin et al., 2006).

In order to achieve sufficient adhesion and coating buildup, the powder particles must undergo severe plastic deformation on impact; hence the successful deposition of ductile metals such as nickel, copper, and aluminium. According to Hussain et al. (2009), during impact the pressure that is generated causes material interlocking and mechanical bonding. The deposition of ceramic materials such as WC is difficult. Due to their hard and brittle nature, such materials tend to shatter on impact, often leading to erosion of the substrate and previously deposited layers (Karthikeyan, 2007; Ang et al., 2011). For successful deposition, hard materials must be co-deposited with ductile binders (Wang and Villafuerte, 2009; Lioma et al., 2015).

An additional advantage of the CGDS process over many high-temperature processes is that it may be applied by means of a portable system, which enables on-site repairs to be done. This is more cost-effective than having components disassembled and shipped off-site for repairs.

Materials and methodology

In this study two different coatings were investigated, namely a WC-4wt%Ni coating and a WC-4wt%Ni-1wt%Mo coating. The coatings were deposited onto mild steel substrates, 20 χ 20 mm in size, which were grit-blasted with -300+100 pm alumina grit prior to the deposition process in order to facilitate adhesion of the coatings. A low-pressure cold spray machine (Centreline Series P SST) was used to deposit the powder blends onto the mild steel using air as the carrier gas. Following deposition, the coatings were polished to a 1 μΓη surface finish for material characterization tests. The microstructure was studied using a Carl Zeiss Sigma field emission scanning electron microscope (FESEM) coupled with an energy dispersive X-ray spectrometer (EDS), which was used for elemental composition analysis and mapping. The coating thickness, porosity, WC grain size, and Ni binder mean free path were measured using lineal analysis on the FESEM images. Phase identification was done using a BRUKER D2 X-ray diffraction (XRD) instrument with Co-Ka radiation and PANalytical X'Pert High Score software. Vickers micro-hardness tests were done according to ASTM E384 (2011).

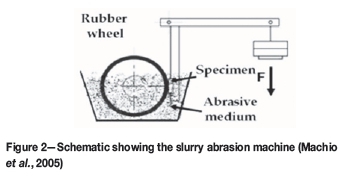

Slurry abrasion testing of the coatings were conducted using a modified ASTM G105 (2002) machine. A schematic diagram of the machine is shown in Figure 2. Three samples were tested simultaneously using an applied load of 22 N per sample, with the abrasion wheel rotating at 0.66 m.s-1. Silica sand with an angular morphology and an average hardness of 1084 ± 156HV was used as the abrasive medium. The silica was mixed with two different liquid media, namely distilled water and synthetic minewater. The composition of the synthetic minewater was 37 ppm Ca2+, 1500 ppm Cl-, 40 ppm Mg2+, 980 ppm SO2-, and 943 ppm Na+ (Machio et al., 2005). The distilled water slurry was used as a control to assess the aggressiveness of the synthetic minewater slurry. The test duration was 60 minutes, with the mass loss of each coating being measured at 5-minute test intervals for the first 20 minutes, and thereafter in 10-minute intervals. The abrasion wear rate was calculated as mass loss as a function of time. The abraded surfaces were examined using electron microscopy (FEI SEM Quanta 200) in order to identify the wear mechanisms.

Results and discussion

Materials characterization

Figure 3 shows the FESEM images of the two coating microstructures adjacent to their respective XRD patterns. An inhomogeneous distribution of the WC carbide phase within the Ni matrix was observed for both coatings. The smaller WC particles are due to fracturing of the carbide phase during deposition as the particles impact the substrate. Similar observations have been made by other authors (Bhaumik et al., 1991). The XRD patterns show the main phases of WC, Ni, and Mo, and it is noted that no decarburization occurred. A summary of the coating properties is listed in Table I. The WC-4wt%Ni coating has a higher average hardness than the WC-4wt%Ni-1wt%Mo coating. This is due to the smaller average WC grain size measured for the WC-4wt.%Ni coating. It is well known that cemented tungsten carbide materials with finer WC grain sizes have higher hardness values (Brookes, 1997). It was noted that the addition of 1wt %Mo to the WC-4wt%Ni coating reduced the hardness by 10.5%, which is quite significant given the small amount of Mo added. The reason for this effect is as yet unclear. Despite the differences in the carbide grain sizes, the Ni binder mean free path and wt% retained WC of both coatings were similar. The average amount of WC retained in the coatings was 41wt%, which is low given the original feedstock powder composition of 95-96wt%. This is a common phenomenon in cold-spray coatings when hard ceramic particles are deposited as mentioned earlier. Due to their hard and brittle nature, a certain percentage of the particles will bounce off the substrate during deposition, while some particles fracture on impact. The porosity of both coatings is very low and acceptable, suggesting that fairly dense coatings were produced.

Slurry abrasion wear

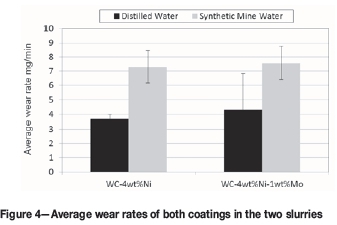

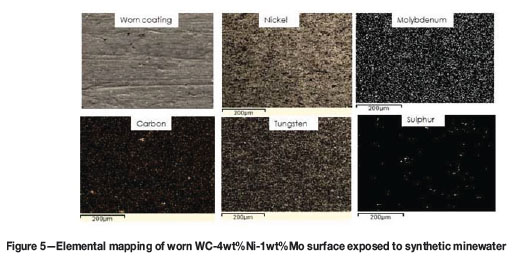

The slurry abrasion wear rates of the two coatings are shown in Figure 4. The average wear rate of the WC-4wt%Ni coating is slightly lower than that of the WC-4wt%Ni-1wt%Mo coating in both slurries tested. This concurs with the higher average hardness of the WC-4wt%Ni coating, which aligns with well-established theory that a higher hardness should provide better resistance against wear (Hutchings, 1992). The wear rates of the coatings in the synthetic minewater slurries are approximately 50% higher than those in the distilled water slurries. This large increase was unexpected given that the pH of the distilled water was 7, while that of the synthetic minewater was only 6.2. However, these wear rates indicate the extent to which synergistic action between wear and corrosion can lead to high material removal rates. While abrasion may be the dominant degradation mechanism based on the direct contact between the silica abrasive particles and the coating, the breakdown of the coating surface provides access for the liquid medium to attack the subsurface material. Thus while abrasion proceeds on the coating surface in contact with the silica, corrosion of the coating occurs simultaneously at subsurface level. This corrosive process facilitates material removal by preferentially attacking the binder phase, thereby weakening the bonding between binder and carbide, and subsequently making it easier for larger volumes of material to be removed as abrasion continues. Figure 5 is an elemental mapping of one of the WC-4wt%Ni-1wt%Mo coating surfaces exposed to synthetic minewater. Apart from the expected coating elements, traces of sulphur were found on the surface, which are remnants of the chemical salts used to produce the synthetic minewater solution.

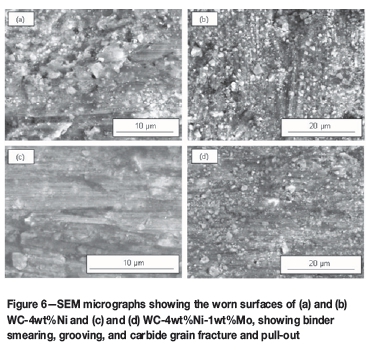

According to Hutchings (1992), when the ratio of the hardness of the abrasive to the hardness of a surface is greater than 1.2 (Ha/Hs >1.2) then hard abrasion associated with plastic indentation is expected to occur on the surface. In this research, the Ha/Hs ratios for both coatings were 2.1 and 2.4 for WC-4wt%Ni and WC-4wt%Ni-1wt%Mo respectively. Thus both coatings experienced hard abrasion, with the silica particles indenting the coating surface. The precise mechanisms of material removal were identified using SEM, and examples of the worn surfaces are shown in Figures 6 and 7. The predominant mechanisms observed were carbide grain cracking, chipping, and removal, with extensive binder smearing and delamination. Grooving of the surfaces was also observed, which indicates the path followed by the silica particles and wear debris. These wear mechanisms are similar to those typically observed for cemented WC materials subjected to abrasion (Larsen-Basse, 1985). The angularity of the hard silica particles facilitated the preferential removal of the softer nickel binder phase from between the carbide grains. This leaves the carbide grains unsupported, making their removal easier as abrasion proceeds. The removed material tends to form hard micro-abrasives which then subject the coating to additional wear, causing fracture of the embedded carbide grains. The wear mechanisms were similar for both slurry types, although larger volumes of material were removed from the coatings subjected to the synthetic minewater.

Conclusion

This research showed that a low-pressure cold gas dynamic spray system could be used to deposit WC-4wt%Ni and WC-4wt%Ni-1wt%Mo coatings onto mild steel. Dense coatings exhibiting very low porosities, an average of 41wt% retained WC, and hardnesses comparable to high-temperature deposited coatings, were produced. No decarburization or deleterious phases were formed in the coatings. The addition of 1wt% Mo to the WC-4wt%Ni coating did not improve the hardness or abrasion resistance. Both coatings showed an approximate 50% increase in abrasion wear rate when subjected to a synthetic minewater-silica slurry. This was attributed to a synergistic corrosive-wear mechanism. The predominant wear mechanisms for both coatings are those typically experienced by cemented tungsten carbide coatings when subjected to abrasion.

Future work

Although the coatings have shown good abrasion resistance under laboratory conditions, further detailed research needs to be undertaken to determine their suitability for industrial application. This should include field testing on carefully monitored slurry transportation pipelines to observe the performance of the coatings. As slurries may also have a corrosive nature, corrosion testing should be done on the coatings, with exposure to varying media found in mining operations. Pipelines have elbows which experience eccelerated erosion, often leading to pipe failure, and therefore the coatings should be subjected to erosion testing at various impact angles and using different slurry media. Finally, an in-depth financial analysis should be done to assess the viability of substituting the cold spray process for some of the high-temperature processes currently being used to produce wear-resistant pipe linings.

Acknowledgements

The authors wish to acknowledge the financial support received from the Department of Science and Technology and the National Research Foundation in South Africa. The assistance of Ms D. Lioma, Mr N. Nelwalani, Mr S. Maqobelane, Professor A. Ziegler, and the workshop staff of the School of Chemical and Metallurgical Engineering, University of the Witwatersrand, is greatly appreciated.

References

Andren, H-O. 2001. Microstructures of cemented carbides. Materials and Design, vol. 22, no. 6. pp. 491-498. [ Links ]

Ang, A.S.M., Berndt, C.C., and Cheang, P. 2011. Deposition effects of WC particle size on cold sprayed WC-Co coatings. Surface and Coatings Technology, vol. 205, no. 10. pp. 3260-3267. [ Links ]

ASTM E384. 2011. Standard Test Method for Knoop and Vickers Hardness of Materials. ASTM International, West Conshohocken, NJ. [ Links ]

ASTM G105-02. 2002. Standard Test for Conducting Wet Sand/Rubber Wheel [ Links ]

Abrasion Tests. ASTM International, West Conshohocken, NJ. [ Links ]

Bhaumik, S.K., Upadhyaya, G.S., and Vaidya, M.L. 1991. Properties and microstructure of WC-TiC-Co and WC-TiC-Mo2-Co(Ni) cemented carbides. Materials Science and Technology, vol. 7. pp. 723-727. [ Links ]

Brookes, K.J.A. 1997. Hardmetals and other Hard Materials. 6th edn. International Carbide Data, UK. [ Links ]

Champagne, V.K. 2007. The Cold Spray Materials Deposition Process: Fundamentals and Applications. Woodhead Publishing, Cambridge. [ Links ]

Hussain, T., McCartney, D.G., Shipway, P., and Zhang, D. 2009. Bonding mechanisms in cold spraying: the contributions of metallurgical and mechanical components. Journal of Thermal Spray Technology, vol. 18, no. 3. pp. 364-379. [ Links ]

Hutchings, I.M. 1992. Tribology: Friction and Wear of Engineering Materials. Edward Arnold, London. [ Links ]

Jacobs, L., Hyland, M.M., and De Bonte, M. 1998. Comparative study of WC- cermet coatings sprayed via the HVOF and the HVAF process. Journal of Thermal Spray Technology, vol. 7, no. 2. pp. 213-218. [ Links ]

Kanchan, K., Anand, K., Bellacci, M., and Giannozzi, M. 2010. Effect of microstructure on abrasive wear behaviour of thermally sprayed WC- 10Co-4Cr coatings. Wear, vol. 268, no. 11-12. pp. 1309-1319. [ Links ]

Karthikeyan, J. 2007. The advantages and disadvantages of the cold spray coating process. The Cold Spray Materials Deposition Process. Champagne V.K. (ed.). Woodhead Publishing Series in Metals and Surface Engineering, Woodhead Publishing, Cambridge. pp. 62-71. [ Links ]

Kear, B.H., Sadangi, R.K., Jain, M., Yao, R., Kalman, Ζ., Skandan, G., and Mayo, W.E. 2000. Thermal sprayed nanostructured WC/Co hardcoatings. Journal of Thermal Spray Technology, vol. 9, no. 3. pp. 399-406. [ Links ]

Km, H-J., Lee, C-H., and Hwang, S-Y. 2005. Superhard nano WC-12%Co coating by cold spray deposition. Materials Science and Engineering A, vol. 391, no. 1-2. pp. 243-248. [ Links ]

Km, H-C., Shon, I-J., Yoon, J-K., and Doh, J-M. 2006. Comparison of sintering behaviour and mechanical properties between WC-8Co and WC-8Ni hard materials produced by high-frequency induction heating sintering. Metals and Materials International, vol. 12, no. 2. pp. 141-146. [ Links ]

Larsen-Basse, J. 1985. Binder extrusion in sliding wear of WC-Co alloys. Wear, vol. 105. pp. 247-256. [ Links ]

Lima, R.S., Karthikeyan, J., Kay, C.M., Lindemann, J., and Berndt, C.C. 2002. Microstructural characteristics of cold-sprayed nanostructured WC-Co coatings. Thin Solid Films, vol. 416, no. 1-2. pp. 129-135. [ Links ]

Lioma, D., Sacks, N., and Botef, I. 2015. Cold gas dynamic spraying of WC-Ni cemented carbide coatings. International Journal of Refractory Metals and Hard Materials, vol. 49. pp. 365-373. [ Links ]

Machio, C.N., Akdogan, G., Witcomb, M.J., and Luckyx, S. 2005. Performance of WC-VC-Co thermal spray coatings in abrasion and slurry erosion tests. Wear, vol. 258. pp. 434-442. [ Links ]

Papyrin, Α., Kosarev, V., Klinkov, S., Alkhimov, Α., and Fomin, V. 2006. Cold Spray Technology. 1st edn. Elsevier Science. [ Links ]

Stoltenhoff, T., Kreye, H., and Richter, H.J. 2002. An analysis of the cold spray process and its coatings. Journal of Thermal Spray Technology, vol. 11, no. 4. pp. 542-550. [ Links ]

Villafuerte, J. 2010. Recent trends in cold spray technology: looking at the future. Surface Engineering, vol. 26, no. 6. pp.393-394. [ Links ]

Wang, J., and Villafuerte, J. 2009. Low pressure cold spraying of tungsten carbide composite coatings. Advanced Materials and Processes, vol. 167, no. 2. pp. 54. [ Links ]

Zikin, Α., Ilo, S., Kulu, P., Hussainova, I., Katsich, C., and Badisch, E. 2012. Plasma transferred arc (PTA) hardfacing of recycled hardmetal reinforced nickel-matrix surface composites. Materials Science (Medziagotyra), vol. 18, no. 1. pp. 12-17. [ Links ]

Paper received Feb. 2016.

Paper written on project work carried out in partial fulfilment of BSc. Eng. (Metallurgical and Materials Engineering)