Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.12 Johannesburg Dec. 2015

http://dx.doi.org/10.17159/2411-9717/2015/V115n12a3

PAPERS - CHEMICAL ENGINEERING & METALLURGY AT WITS

The impact of coal quality on the efficiency of a spreader stoker boiler

R.L. Taole; R.M.S. Falcon; S.O. Bada

School of Chemical and Metallurgical Engineering, Faculty of Engineering and the Built Environment, University of the Witwatersrand, Johannesburg

SYNOPSIS

This research establishes the combustion characteristics and efficiencies of South African coals of different qualities and their impact on the performance of a grate spreader stoker boiler. Four different coal samples were tested in the particle size range 6.25 x 25 mm. A detailed investigation involving the boiler operating conditions associated with the physicochemical characteristics of the coals, petrographic properties, and temperature profiles from a thermal camera was conducted. The thermal analysis indicates that there is a strong correlation between thermographic data (combustion behaviour and maximum flame temperatures) and petrographic composition of the coals. This association is not reflected in calorific values and proximate analyses of the coals. In terms of combustion efficiencies, all coals yielded relatively high amounts of unburnt carbon in the fly ash (about 36.90%). The highest steam output obtained was 41.76 t/h at the highest combustion efficiency of 79.13%. The thermographic results obtained from this study led to the conclusion that South African low-grade Gondwana coals undergo delayed ignition and burn at unusually high temperatures (1500-1800°C), which is in contrast to the original belief that the combustion temperature is around 1400°C.

Keywords: coal, combustion, macerals, thermographic camera, travelling grate.

Introduction

There are about 6000 industrial-scale boilers in South African industries today, all using lower grade coals than they were initially designed for (Johns and Harris, 2009). The travelling grate spreader stoker boiler is one of the oldest combustion technologies that have been in use since the beginning of the twentieth century (Giaier and Loviska, 1997). However, these traditional coal-fired boilers are still widely used for electricity generation in South African industries. The pulp and paper, sugar, cement, and many other industries use steam to generate power, consuming approximately 9 Mt of coal per annum (SANEDI, 2013). Numerous investigations have also been conducted on the competitiveness of using existing convectional coal-fired utilities, such as grate stoker boilers, in firing and co-firing a wide range of fuels (Li, et al., 2009; Thai, et al., 2011; Sheng et al., 2012). Despite having been in the market for many years, coal-fired spreader stoker technology still presents challenges in regard to inefficient combustion of coal (Lin et al., 2009). This has always been regarded as a technical operational problem, rather than being due to the inherent characteristics of coal. This investigation is aimed at the study of feed coals utilized in a specific boiler and the effects of their properties on the efficiency of combustion.

Most of the previous research in the field of industrial stoker-fired boilers, including spreader stokers, has been undertaken in Europe and America (Falcon, 2010).The results of these studies reside with boiler manufacturers, who rarely publish their findings. The only published results that can be found locally using South African coal (SAC) are limited to investigations conducted mostly by the sugar, pulp, and paper industries (Falcon, 2010). These studies focus mainly on the effect of operating conditions on boiler performance, and not specifically on the impact of coal quality. There is thus little or no knowledge on the compatibility of SACs and stoker fired boilers in this country. There is virtually no published information which clearly draws the relationship between coal quality, technical operational conditions, and the efficiency of spreader stoker boilers for SACs. In addition, the characteristics of coals should also be well understood if retrofitting of the existing boilers is to be successful (Falcon and Ham, 1988). It is important that this standpoint be fully embraced, especially in the South African context because the majority of the old boilers were designed by overseas manufacturers (mostly American and British), using their own types of coal and hardly any local coals (Falcon, 2010). This implies that original designs of most of the old boilers did not necessarily match SAC types.

This paper attempts to refine the current understanding of the effect of varying coal qualities and operating conditions on boiler efficiency in one particular travelling grate spreader stoker boiler. The study focuses on the combustion characteristics of four different coal samples and their impact on boiler efficiency. An advanced thermographic visual testing system in the boiler is used to interpret the results, together with petrographic techniques and conventional physical and chemical analyses (proximate and ultimate analyses).

Experimental

Coal selection and sample preparation

Four coal samples, identified as A, B, C, and D, of similar calorific value and different abrasive indexes, were used in this study. The coals were sourced from separate mines in the Witbank area of South Africa, except for coals A and D which were both from the same mine. The coals were crushed to the standard designed size specified for a spreader stoker boiler at 6.25 x 25 mm. The coal samples were sampled in accordance with ISO 18283:2006 (E) guidelines in order to obtain the most representative coal fed into the boiler furnace. The particle size distributions (PSDs), Hardgrove indexes (ASTM D3402), and abrasive indexes (Eskom standard) of the samples are presented in Table I. The design coal specification for the spreader stoker boilers utilized in this study is 6.25 x 25 mm size fraction. The PSDs (Table I) below indicates that coal D has the lowest proportion of finer particles at 16.47% <6.25 mm, while coal A contained the highest amount of finer particles at 29.62% <6.25 mm.

Physicochemical analyses

Proximate analysis was conducted to determine the total moisture (ISO 589: 2008); inherent moisture (SABS 925:1978); volatile matter (ISO 562: 1998); ash content (ISO 1171: 1997); and fixed carbon (by difference). The ultimate analysis (ASTM D 5373), along with the calorific value, which is the measure of the heat content, was determined in accordance with ASTM D5865-04. The total sulphur (ASTM D4239:1997) and species of sulphur (ISO 157) were also determined. Both the bottom ash and fly-ash samples were analysed for unburnt carbon (UBC) using the standard ASTM D4239:199 to determine the total carbon concentration. Ash fusion temperature (AFT) was determined for all samples in accordance to ISO 540, and the results are shown in Table II.

Petrography and analysis of combustion gases

The coals were prepared according to ISO 7404/2 (1998). A Leica DM4500P petrographic microscope was used for the optical determination of the organic, inorganic, and associated components by analysing the microlithotypes, including the carbominerites and minorities analyses. The rank, as indicated by the mean random reflectance, Rr%, is of the order of 0.61 to 0.76%, as seen in Table III. In terms of rank, all coals are of the bituminous C category, with coals A and D slightly lower in maturity. The flue gas was analysed using an Orsat apparatus. The gases measured were carbon dioxide (CO2), carbon monoxide (CO), and oxygen (O2). The concentration of other gases, such as NOx and SOx, in the flue gas was analysed using a gas chromatograph in the laboratory after capturing the flue gas in a gas pipette and Tedlar bags.

Thermography with furnace camera

The thermographic furnace camera is the main analytical tool in this study. The technique uses infrared radiation to acquire and analyse thermal information using a non-contact thermal imaging device. This provides the capability to differentiate between the thermal characteristics of different coal samples during combustion. The furnace temperature profiles and the sample flame morphology were studied to understand the thermal behaviour of the samples according to different colours emitted during combustion. The video (DURAG type D-VTA 100-10 series) and thermography system utilized allows for the analysis of the furnace conditions and the visualization of the flame temperature profiles during coal combustion in real time. In addition, the camera provides for temperature determinations at individual points; such as thermal analysis of local temperature distribution, classification of temperature-definable measuring windows and lines, referred to as regions of interest (ROIs). The thermographic camera D-VTA100-10 has the following technical output:

Optical field of view 72° horizontal, 54° vertical, and 90° diagonal

Thermography from a total radiation range: 1000-1800°C Cooling water volume 350 l/h

Compressed air volume max. 25 Nm3/h.

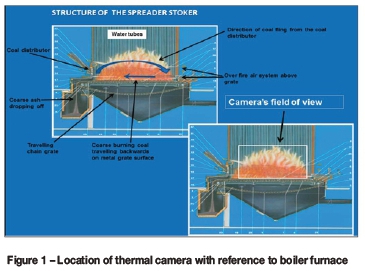

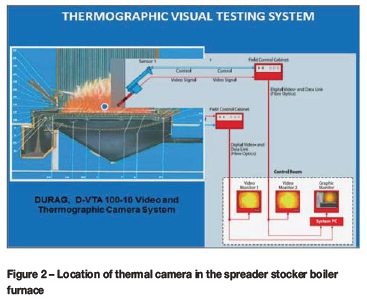

The location of the thermal camera field of view with reference to the boiler furnace is depicted in Figure 1. The figure illustrates a typical arrangement of the thermographic system for data capturing in the boiler furnace and conveyance to a programmable logic controller (PLC) system for operator control and monitoring. In order to perform a thermographic test for furnace temperature profiling, the positioning of the video camera was first defined and used as a reference to the extent of the optical field viewed and of data captured. The camera was placed about 1 m above the boiler grate level and from the furnace arch where the coal was fed into the boiler (Figure 2). This arrangement allowed for coverage of almost the entire furnace area of interest, based on an optical field of view of 72°.

The spreader stoker boiler study

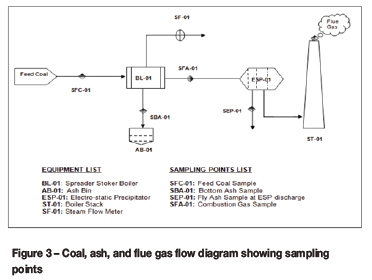

The water-tube spreader stoker boiler used in this investigation has a heating surface area of 169.5 m2, mean height of 9.98 m, width of 4 m, effective length of 4.8 m, a grate area of about 19.3 m, and sample feed rate capacity of about 42.43 t/h. The boiler has a steam generation capacity of 45 t/h, producing saturated steam at 31 bar gauge (barg) pressure. The boiler consists of a negative pressure furnace house, an economizer, and an electrostatic precipitator (ESP) for capturing particulates as seen in the layout shown in Figure 3. The full details of the spreader stoker boiler have been reported elsewhere (Taole, 2015). The coal is fed through coal feeders at the front of the furnace. Lighter coal particles burn in suspension and the heavier ones fall onto the grate, burning on it. The grate travels from the back of the furnace towards the front, where the ash is discharged.

The boiler was operated under a steady load conditions as far as possible during the test period, i.e. operations were allowed to stabilize at least an hour prior to commencement of the tests. Steady-state conditions were determined from the analysis of combustion gases in the flue gas stream. All boiler operating conditions, i.e. the grate speed, coal feeder stroke rate, and the under-grate air (UGA) system, which conveys primary combustion air to the overlying coal bed, were kept constant during the trials, in order to establish the impact of coal quality on combustion performance. The tests were performed under full-scale operation. Fluctuations in operating conditions were occasionally experienced, mostly the grate speed. This led to tests being run on each sample over a two-day period to constitute two separate sample batches for the same coal in order to allow for repeatability of the results.

Results and discussion

Physciochemical properties of the coal

The calorific value (CV) of the coals ranges from 25.54 to 27.00 MJ/kg. Coal C has the highest CV of 27 MJ/kg and lowest volatile matter content of 23.50%. All four coal samples are considered to be of reasonably low ash, ranging from 14.70 to 17.30%. All the coals utilized contain about 0.02%. sulphate sulphur. Pyritic sulphur is higher in coals A (0.78%) and D (0.71%) compared to coal B (0.13%). The highest fraction of organic sulphur is also found in coal A at 0.66%, while coal B has the lowest proportion at 0.24%. The ultimate analysis results show that the fraction of nitrogen for the four coals is fairly similar, with the lowest value being 1.59% for coal D and the highest being 1.66% for both coals A and C. This indicates that coals A and C are likely to produce higher proportions of fuel NOxcontributing to the total NOxemissions.

The HGI values for the coals in this study range from 52 to 70, while the AI values vary from 54 to 246. Coal A was the hardest sample, with an HGI of 52 and AI of 246, while coal sample D was the softest with an HGI value of 70 and AI of 54. It was noted that coal A and coal C, with an HGI of 52 and 59 respectively, have similar HGI values but clearly different AI values of 246 for coal A and AI of 99 for coal C. This distinctive difference in AI might be a positive influence on the grindability and thermal shattering of coal C in the freeboard of the spreader stoker furnace, compared with coal A.

The propensity of the four coals to slagging and clinker formation on the grate and furnace heat transfer equipment was also investigated. The flow ash fusion temperatures (AFTs) for the four coals ranged from 1400°C to 1500°C. The highest values were recorded for coals A and C, both at 1500°C, while the lower ash fusion temperatures were detected in coals B and D at around 1400°C.

Petrography

The overview of the petrographic results for the four coals is presented in Table III. Coals A and D are vitrinite-rich, at 47% and 44%, respectively, whereas coals B and C have significantly high proportions of inertite at 68% and 70% respectively. Total reactive macerals for the four coals range from 54 to 64%. Coal D has the highest proportion of total reactive macerals at 64%, while coal C shows the lowest fraction at 54%. Coal D appears to have a slightly higher proportion of abnormal (weathered) constituents than the other three coals, at 25%. This indicates the organic components in coal D are more extensively cracked, weathered, and oxidized than in the other three coals. The mean random reflectance values (Rr%) for the four coals range between 0.61 to 0.76%. In terms of rank, all coals are the bituminous C, with coals A and D slightly lower in maturity.

Boiler performance related to rates of steam output, combustion efficiencies of the coals, and determinations of boiler efficiency

Table IV presents the results obtained from the performance of the test equipment in the form of the rates of steam output and combustion efficiencies of the coals. Sampling was performed throughout the testing period as the boiler loading or operating steam output was confirmed steadied for about three hours. This test provides an insight into the conditions of flue gas exiting the boiler furnace and before entering the economizer section, in terms of exit temperatures and combustion gases. The readings recorded indicate averaged values over the four-hour testing period for each coal sample. The indications are that coal C, with the highest O2content and the lowest CO2fraction of the flue-gas, exhibits poor combustion as evidenced by the relatively high amounts of unburnt carbon (UBC) reported in the ash. Coal D, with the lowest O2content and the highest proportion of CO2in the flue gas, displays improved combustion considering the comparatively low amount of UBC in ash.

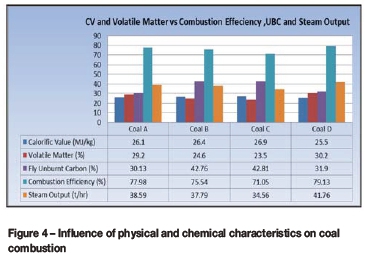

The impact of the physicochemical properties of the coal samples utilized in this study on the boiler performance and efficiency is further elucidated in Figure 4. The performance of the boiler during the combustion of each coal sample was determined by monitoring the proportion of carbon loss in the fly ash as well as the steam output. Figure 4 also depicts how the physical and chemical properties of coal, namely the calorific value and volatile matter content, possibly affected the coals during combustion. It was observed that the combustion efficiency increases with decreasing amounts of unburnt carbon in the fly ash and increasing volatile matter content, but does not appear to correlate with the calorific value. Increasing combustion efficiency correlates with increasing volatile matter and decreasing fixed carbon, and inversely with the unburnt carbon.

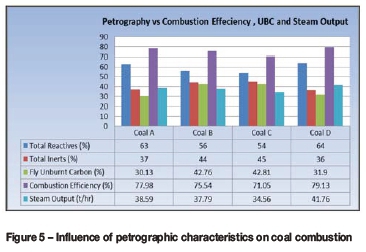

However, the petrographic analysis provides vital information for the holistic understanding of the combustion behaviour of the coals. The analyses and associated combustion profiles of the four coals are illustrated in Figure 5. The results indicate that higher combustion efficiency is correlated with higher vitrinite content and total reactive macerals. Coals D and A had higher combustion efficiencies of 79.13% and 77.98%, and total reactivities of 64% and 63%, respectively, compared to coals C and B. Coal D produced the highest steam output (41.76 t/h) and combustion efficiency (79.13%), while coal C yielded the lowest steam output (34.56 t/h) and lowest combustion efficiency of 71.05%. It was also noted that higher amounts of unburnt carbon corresponded with higher quantities of inertinite and lower combustion efficiency.

Boiler performance related to proximate analysis, calorific value, and petrographic composition

The primary objective of this investigation was to establish the combustion characteristics and efficiencies of four coals and their impact on the performance of one specific spreader stoker boiler. In seeking to determine the dominant parameters influencing combustion efficiency and boiler performance, a detailed investigation involving the boiler operating conditions associated with physical and chemical characteristics of the coals, petrographic properties, and thermographic data as observed in the boiler was conducted. From Table V, it is noticeable that coals B and C, with the highest calorific values and lowest volatile matter contents, yielded the lowest steam outputs and combustion efficiencies. In contrast, coals A and D, with the lowest calorific values and highest volatile matter contents, produced higher steam outputs and combustion efficiencies. It was also observed that for coals with the closest similarities in physical and chemical properties, such as coals A and D, there were noteworthy differences in the boiler performances under matching operating conditions, as marked by varying steam outputs and combustion efficiencies. The superior performance of coals A and D, compared to coals B and C, may be attributed partly to higher volatile matter contents, as this would imply the coals were easier to ignite. In terms of boiler performance based on proximate analyses, the highest steam output of 41.76 t/h and highest combustion efficiency of 79.13% was observed for coal D, which had the highest volatile matter content and lowest fuel ratio (FR) value. The lowest steam output at 34.56 t/h and lowest combustion efficiency at 71.05% were yielded by coal C, with the lowest volatile matter content and highest FR value. However, the high steam output correlated with high volatile matter and high combustion efficiency, but correlated inversely with fuel ratio and unburnt carbon, as shown in Table V. The fuel ratio is determined from the ratio of fixed carbon to volatile matter and is used to approximate the ease of ignition and burnout for a given coal sample.

The results in Table VI indicate that increasing combustion efficiency correlates with increasing total reactivity. Conversely, high combustion efficiency proves to be inversely proportional to the amount of unburnt carbon and total inertinite. With regard to steam production, the highest steam outputs correlate with high vitrinite content, higher combustion efficiency, and lowest unburnt carbon. Coal D, with the second highest vitrinite content of 44% mmf and lowest inertinite content of 47% mmf, produced the highest steam output at 41.76 t/h. The association between steam output and petrographic composition was also consistent for the other three coals B, C, and D, which yielded steam outputs paralleling their respective petrographic compositions in terms of total reactive and inert maceral contents. These results show that the impact of petrographic characteristics is crucial in understanding the combustion behaviour of coal. It can further be asserted that for combustion behaviour of any particular coal sample to be wholly known, there has to be an equally comprehensive study of the petrographic characteristics of the coal.

Comparison of thermographic characteristics of the four coals

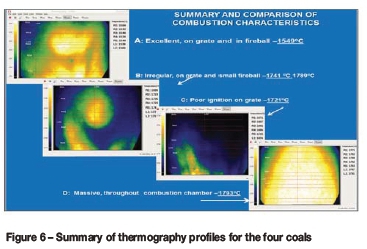

The investigation into the combustion behaviour of the four coals tested was based on thermographic analysis and temperature profiling of the furnace during combustion. Thermography provides insight into the thermal behaviour of the different coals tested by showing maximum combustion temperatures in the flames and the characteristics of ignition combustion. A summary of the thermographic temperature profiles is presented in Figure 6, and the behaviour of each coal is illustrated in terms of flame characteristics and associated temperature readings. All four coals showed significantly different combustion characteristics despite having comparable calorific values, volatile matter contents, and ash contents. The results indicate that there is a strong correlation between combustion efficiency, unburnt carbon, and petrographic composition of the coals. There is a correlation between the combustion efficiency and the total reactive macerals, i.e. the highest combustion efficiency and the lowest unburnt carbon correlate with a high content of reactive organic materials. Low combustion efficiency and high unburnt carbon correlate with high-inertinite coals. This association is not reflected in calorific values or data from the proximate analysis. In addition, according to Table V, there is a correlation between the combustion efficiency, fixed carbon, and volatile matter. The lower the fixed carbon of the samples, the higher the combustion efficiency, and the higher the volatile matter, the higher the combustion efficiency The different thermographic trends observed in coals A and D from the same colliery illustrate the lack of a clear correlation between flame temperature, calorific value, combustion efficiency, and ash and volatile matter content. Despite having fairly similar proximate analyses and calorific values, the two coals burnt at notably different flame temperatures under similar operating conditions. Coal A burnt with the lowest maximum flame temperature of all the four coals at ROI5 = 1549°C, while coal D recorded the highest maximum flame temperature amongst the four coals at ROI5 = 1793°C.

Coal A, with 14% weathered oxide content, has similar petrographic properties to coal D, which is relatively fresh and unaltered and therefore is likely to burn in its normal condition. Coal B was noted as the coal with the second highest flame temperature at ROI5 = 1741°C. Although this coal possesses the highest calorific value, its flame characteristics did not exhibit good combustion or ignition as the flame burnt irregularly and was segregated to discrete parts of the furnace. This observation further confirms that there is no correlation between flame temperature, calorific value, and proximate analysis data. With the exception of coal B, which produced highest temperature in the middle of the furnace (the desirable combustion zone), all other coal samples tended to yield higher flame temperatures both on the grate and in the upper fireball zones of the furnace where the boiler heat-exchangers (steam drum) are located. This indicates delayed combustion at the back end of the boiler. Such conditions are undesirable as they imply loss of efficiency due to combustion in regions outside of the furnace heat transfer zones, leading also to fouling of the heat exchange surfaces and blocking of convective passes by ash deposits. High flame temperatures pose a greater risk of soot formation due to volatile matter components of the coal, especially tar, undergoing secondary reactions at high temperature (Fletcher et al., 1997).

Conclusion

This research compared the combustion performance of the four coals with their physicochemical properties and their petrographic characteristics. This information provided valuable insight into the differences in combustion behaviour.

> The quality of coal proved to significantly influence the combustion performance in the stoker boiler under investigation. This was best reflected in the petrographic composition of the coals and the thermorgaphic results as indicated by flame temperatures and combustion flame characteristics

> The most relevant results were observed fro the combustion performance of coals A and D, both from the same colliery. These coals had the same proximate analyses, calorific values, and ash contents, but differed significantly in combustion temperatures, flame shapes, as well as petrographic composition

> In terms of efficiency, coal A produced the second highest combustion efficiency and steam output, and burnt at the lowest flame temperatures of all four coals. Coal D, on the other hand, while producing the highest steam output and combustion efficiency, burnt at the highest flame temperatures of all four coals, with a massive flame that encompassed virtually the entire freeboard above the grate as well as on the grate. Under these conditions, extensive thermal damage of boiler plant equipment could be expected

> The reasons for the difference in combustion performance between coal A and coal D were revealed in part by petrographic analyses, which showed that coal A was a fresh coal and coal D comprised 25% oxidized and weathered organic matter. This was supported by an unusually high Hardgrove index (soft grindability), a particularly low abrasion index (AI), and a lower than normal ash fusion temperature (AFT) relative to the values found in coal A

> The massive fireball and high temperatures in the freeboard produced by coal D are interpreted to be due to the presence of friable weathered coal material that underwent intense thermal shattering as the particles entered the hot zone and were lifted up and thrown across the boiler chamber

> The combustion characteristics of coals B and C were found to differ significantly from those of coals A and D. Both coals exhibited limited ignition, reduced flames, and poor burnout characteristics leading to higher unburnt carbon contents in the fly ash. These results occurred despite these coals having the highest calorific values and nominal ash contents. The lower combustion efficiencies of these coals can be attributed to increased proportions of relatively inert forms of organic components (inertinite)

> Coal A would be the preferred feed for the boiler under investigation, owing to its lower propensity to slagging due to the lowest flame temperatures of all four coals, its high AFT, second highest combustion efficiency and steam output, and the lowest flame temperatures of all four coals.

References

Falcon, R.M.S. and Ham, A.J. 1988. The characteristics of Southern African coals. Journal of the South African Institute of Mining and Metallurgy, vol. 88, no. 5. pp. 145-161. [ Links ]

Falcon, R.M.S. 2010. Internal unpublished reports. School of Chemical and Metallurgical Engineering, Faculty of Engineering and the Built Environment, University of the Witwatersrand. [ Links ]

Fletcher, T.H., Ma, J., Rigby, J.R., Brown, A.L., and Webb, B.W. 1997. Soot in coal combustion system. Progress in Energy and Combustion Science, vol. 23, no. 3. pp. 283-301. [ Links ]

Giaier, T.A. and Loviska, T.R. 1997. Vibrating grate stokers for the sugar industry. Proceedings of the Annual Congress of the South African Sugar Technologists Association, vol. 71. pp. 172-175. [ Links ]

Johns, A.R. and Harris, M. 2009. Boiler Efficiency Calculations. Lecture notes: Coal Combustion and Power Generation course, University of Witwatersrand, Johannesburg, 31 August 2009. [ Links ]

Li, Z., Zhao, W., Li, R., Wang, Z., Li, Y., and Zhao, G. 2009. Combustion characteristics and NO formation for biomass blends in a 35-ton-per-hour travelling grate utility boiler. Bioresource Technology, vol. 100. pp. 2278-2283. [ Links ]

Lin, P, Ji, J, Luo, Y., and Wang, Y., 2009. A non-isothermal integrated model of coal-fired travelling grate boilers. Applied Thermal Engineering, vol. 29. pp. 3224-3234. [ Links ]

SANEDI. 2013. Overview of the South African Coal Value Chain. South African Coal Roadmap. http://www.sanedi.org.za/archived/wpcontent/uploads/2013/08/sacrm%20value%20chain%20overview.pdf [Accessed 26 May 2015]. [ Links ]

Sheng, J.S. Wang, B.B., and Li, W.J. 2012. A study on structural characteristics of biomass briquette boiler. Applied Mechanics and Materials, vol. 197. pp. 211-215. [ Links ]

Taole, R.T. 2015. The Impact of Coal Quality and Technical Operating Conditions on the Efficiency of a Spreader Stoker Boiler. http://wiredspace.wits.ac.za/handle/10539/17553 [ Links ]

Thai, S.M., Wilcox, S.J., Chong, A.Z.S., Ward, J., and Proctor, A. 2011. Development of fuzzy based methodology to commission co-combustion of unprepared biomass on chain grate stoker fired boilers. Journal of the Energy Institute, vol. 84, no. 3. pp. 123-131. [ Links ]

Paper received May 2015

Revised paper received Nov. 2015