Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 no.11 Johannesburg Nov. 2015

http://dx.doi.org/10.17159/2411-9717/2015/v115n11a18

SANCOT CONFERENCE PAPERS

Sprayed concrete for underground excavations - A status report

B.C. Viljoen

SMEC South Africa Consulting Engineers

SYNOPSIS

Commencement of the next phase of the Lesotho Highlands Water Project is a year or so away from becoming reality. Some 50 km of tunnels in the form of access adits, shafts, diversion tunnels, and main waterways will be constructed. Sprayed concrete will form an integral part of the temporary and permanent rock support systems that will be installed. Furthermore, the use of sprayed concrete as a final tunnel lining solution was proposed as a viable alternative to concrete linings in the feasibility studies that preceded the forthcoming implementation phase.

The aim of this paper is to make the reader aware of all the sprayed concrete related issues that engineers tend to grapple with during the design and construction of tunnel projects and other underground works. Primarily, these issues would include selection of applicable design parameters, technical specifications, construction application methods, quality control and, most importantly in the context of final or permanent linings, the durability of sprayed concrete.

The International Tunnelling Association (ITA) Working Group (WG) 12 has been tasked specifically to publish a set of recommendations on the Quality and Control of the Application of Sprayed Concrete and the Testing of Sprayed Concrete for Durability. These tasks were also further explored at the recent World Tunnel Congress (WTC 2015) that was held in Dubrovnik, Croatia at the end of May 2015.

Keywords: sprayed concrete, shotcrete, quality control, durability

Introduction

Sprayed concrete is presented in a variety of shapes, designs, forms, application methods and accompanying terminologies including shotcrete, gunite, pneumatically applied concrete, and the like. The International Tunnelling Association (ITA) decided to standardize on a single terminology, namely 'sprayed concrete', in order to simplify specification, interpretation of guidelines, and codes of practice.

Sprayed concrete structures are also increasingly being regarded as permanent structures, thereby implying the need for long-term durability testing and assessment. Durability is not only dependent on selecting the appropriate materials and the mix design, but also on the standard of workmanship employed during application. All the effort in ensuring appropriate materials selection and mix design can be nullified if the end product lacks homogeneity, has voids or laminations, and is unduly permeable. Such deficiencies can usually be attributed to poor workmanship of the sprayed concrete operator. A substantial amount of research and development work has also been done in trying to develop specifications that should ensure that the sprayed concrete can withstand aggressive service conditions. More work still needs to be done in establishing simple routine quantitative testing of the durability of the in-place sprayed concrete. Mechanization has helped in achieving consistency of the end product.

ITA Working Group (WG) 12, under the leadership of Professor Eivind Grøv, Chief Scientist and Professor at the University of Science and Technology in Trondheim (NTNU), has been tasked to publish a set of recommendations on Quality and Control of the Application of Sprayed Concrete and the Testing of Sprayed Concrete for Durability. The sub-group working on the Quality and Control aspects is led by Mr. Volker Wetzig based at the VersuchsStollen Hagerbach underground research facility in Flums Hochwiese, Switzerland. The durability sub-group was initiated and led by Mr. Tony Boniface (Gibb South Africa) and was recently taken over by the author after Mr. Boniface's retirement. The goal of WG 12 is to have these guidelines ratified and published as ITA reference documents within the next year or two.

Challenges

The principal methods of excavation in the underground construction environment would be by drill and blast and mechanized methods including tunnel boring machine (TBM) systems, and in particular, in horizontal and sub-horizontal excavations. In the mining environment mechanized methods, especially in vertical and sub-vertical excavation (shafts), are much more prevalent, but similar principles will apply with respect to the use of sprayed concrete. The main challenges facing sprayed concrete solutions are:

► Working environment (health and safety)

► Quality and control

► Remedial measures

► Durability.

Durability has perhaps more relevance in the civil engineering industry, where project design life is significantly longer and where the impact of non-ideal implementation of maintenance procedures tend to be more visible to the public eye. Sprayed concrete soil nail walls in road cuttings or linings in metro subways are good examples where durability is an essential characteristic.

Working environment

The occurrence of dust is inevitable for any of the types of sprayed concrete applications (which may be principally divided between wet and dry application methods), but the quantities and types of dust can differ considerably. Dust can occur in the form of cement paste/particles (aggressive), water droplets, aggregate (silica dust), or in combination, all with varying degrees of impact on the workmen and machinery inside the workspace. Much attention has been paid to this problem and specifications, application guidelines, and codes of practice have been developed that cover the full spectrum of interventions, ranging from ventilation and safety equipment to materials, mix design, and application procedures and associated sprayed concrete equipment.

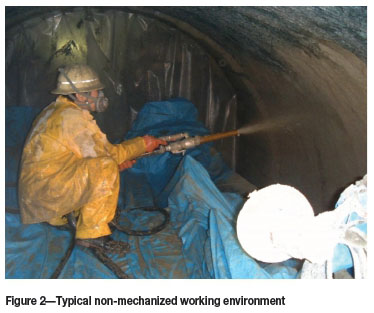

Clearly the most obvious solution is to mechanize, thereby removing the workmen from the immediate workspace. Mechanized applicators are fairly common these days and more so with the increasingly onerous occupational health and safety regulations being promulgated. Typical examples of the working environment and mechanized application solutions are shown in Figures 1 and 2. In spite of this, one cannot ignore the fact that manual or hand-held spraying has its particular application and is still in common use.

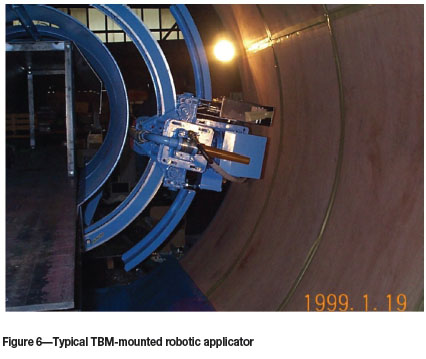

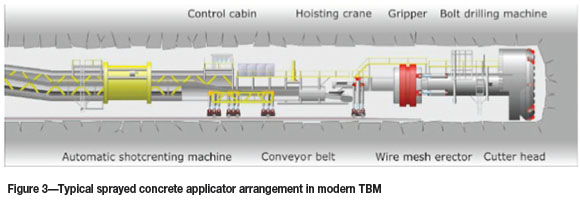

TBM operators generally try to avoid the use of sprayed concrete at the excavation face because of the adverse impact dust has on the mechanical systems and the staff working in these confined spaces. Rearward application (if it can be tolerated from a rock support point of view) resolves some of these issues, but creates new problems with regard to ventilation and logistics. An example of a modern TBM sprayed concrete arrangement is shown in Figure 3.

Mechanized solutions raise another issue, namely the purpose of the sprayed concrete application. Sprayed concrete can be used very effectively as a temporary sealing layer in the case of deteriorating rock types or as initial support measure at the excavation face to deal with unstable ground conditions. For this type of application durability would not be an issue, and quality and control would be focused on environmental conditions rather than long-term performance criteria because this type of sprayed concrete application would be later included in a permanent concrete or sprayed concrete lining.

Quality and control

Appropriate quality control measures must be in place at the batch plant, during transport, in the application equipment chain, and at the application workplace. Quality control at the workplace must be based on quick and simple assessments of the work done. Many specifications have been developed over the years, some of which may not necessarily comply with the concept of evaluating quality of work without significant delay to the progress of excavation. Quality and control guidelines will typically deal with:

► Requirements for design, materials, equipment, and workmanship

► Quality control plan to be prepared by the contractor

► Preconstruction testing in the laboratory and on site

► Qualification and certification of sprayed concrete operators

► Testing during construction.

Test methods, frequency, and periods for interpretation and evaluation should be appropriate for the environment in which they are conducted.

In water tunnels with sprayed concrete final linings, the issue of exposed surface roughness and the impact it will have on hydraulic conductivity of the tunnel also needs to be considered in the design and quality plans.

Remedial works

The main difference between ordering remedial works for a concrete structure and a sprayed concrete structure is that a concrete structure does not immediately become load-bearing (apart from self-weight) and can often be supported during the time required for remedial measures. Sprayed concrete in underground excavations becomes part of the temporary or permanent rock support system virtually immediately. Measures that include removal and re-spraying of unacceptable portions of the sprayed concrete can materially affect the safety of the works and may therefore not be practical. Solutions that include over-spraying and chemical treatment could therefore be more appropriate. Fundamentally, the principle should be to avoid getting into this situation by ensuring good and proper quality and control.

Excavation faces, especially in the case of TBM excavations, move relatively fast and the logistics involved with the instruction of remedial work can become very time-consuming and costly, frequently resulting in costly delays of the works.

Durability

General considerations

Mix design has been extensively covered in many publications, specifications, guidelines, and testing methods and will be comprehensively encapsulated in the ITA WG 12 guidelines dealing with Quality and Control. Unfortunately, not as much work has been done on those construction parameters that can have an even greater effect on the long-term durability of the applied sprayed concrete. Such parameters include the permeability and denseness of the applied sprayed concrete and the role of curing (Boniface, 2009). Much of the work of ITA WG 12 dealing with durability will focus on this aspect.

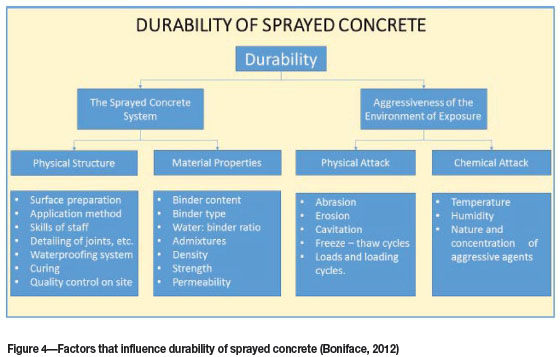

In the case of permanent sprayed concrete structures the fundamentals of durability are shown in Figure 4. The most significant factors influencing the durability of sprayed concrete are considered to be the following;

► Buildable designs-shapes to be formed and joint location

► Modern relevant specifications-materials, equipment, methods, acceptance testing, environment control, health and safety

► Capable and trained applicators-certification, training, and re-evaluation

► Wet or dry application method-equipment, mix designs, methodologies, and applicationenvironment.

► Hand or mechanized application-workplace environment, volume of work, consistency of application, quality and control measures

► Correct mix design and accelerator choice-rebound, layering, adhesion, stiffness, and strength development

► Surface preparation-cleaning methods, quality of the surface with respect to proper and reliable long-term bonding with the substrate, time interval between applications, use of curing compounds

► Curing methods-relative humidity in excavation, multiple applications, and curing compound properties

► Ground and water conditions acting on the structure during construction-seepage weakening adhesion, leaching out of cementitious product, and infiltration with deleterious chemicals and other pollutants

► Site control-monitoring and corrective or remedial actions

► Future environment and loading regime-the physical environment would cover all forms of mechanical surface damage and also damage resulting from unanticipated load cases. The chemical environment would include any agent that will have a negative impact on the behavioural properties of the sprayed concrete.

Taking all these factors into account, the durability of sprayed concrete is dependent on two aspects:

► The design of the sprayed concrete mix (taking into account the physical and chemical characteristics of each and every constituent), to match the needs of the chemical and physical exposure conditions to which the sprayed concrete will be subjected to

► The actual physical (and chemical) properties of the in situ sprayed concrete.

Quality control testing

Quality control testing in the laboratory and on-site test panels are extensively covered in the literature and in practice. One can control aggregates, water, mix design, water/cementitious content ratios, admixtures, batch plant operation, equipment, and application procedures. The question that is not fully answered is how does one readily monitor the quality of the finished product? Density testing alone has proved unreliable, and classic forms of permeability testing are generally unsuitable for regular day-to-day routine site testing of finished work. Four approaches are worth noting:

► Penetration, hardness, and UCS (coring) testing. Strength testing is commonly specified, is easily undertaken, and does not have much impact on excavation progress, but is sometimes seen as a normal quality control measure and not necessarily a good indicator of durability

► Permeability testing. Some specifications require the permeability to be less than 10-12 m/s. This is much the same as that achieved with dense in situ concrete. It has been suggested that sprayed concrete yielding permeability test result figures below this, in the range of between 10-8 m/s to 10-10 m/s, should be considered as having a high permeability (Thomas, 2009)

► Water penetration testing. Some specifications refer to the use of the simplified permeability test (actually a water penetration test) described in DIN 1048-5, which has been incorporated into BS EN 12390-8:2000. EFNARC's Sprayed Concrete specification makes reference to EN 7031 and allows a maximum penetration of 50 mm, but requires a mean average value of 20 mm

► Boiled absorption (BA) and volume of permeable voids (VPV) testing. These make use of the standard test procedures described in ASTM C 642-06. This approach has been adopted by the American Concrete Institute (ACI) in their 2009 Guide for Specifying Underground Shotcrete. These tests continue to be used for the routine monitoring of the durability potential of in-place sprayed concrete in North America and southern Africa (Morgan 1994). In contrast, the 3rd edition of the British Tunnelling Society/Institution of Civil Engineer's Specification for Tunnelling makes no mention of BA or VPV testing.

A number of criticisms have been raised against the BA and VPV testing approach.

► Water penetration tests only give an empirical indication of permeability; and BA/VPV tests only give an indication of capillary absorption. While BA/VPV testing has its uses, poor results are not necessarily an indication of poor durability

► ASTM C642 requires samples to be oven dried at 100 to 110°C for not less than 24 hours. The sample is then boiled for 5 hours. This is probably not representative of in situ conditions that the sprayed concrete may be subjected to

► Another important aspect is that when cement replacements (PFA, GGBFS, silica fume) are incorporated into sprayed concrete mixes for durability reasons, the hydration process continues long after 28 days. By boiling a sample at 28 days of age, this later hydration (and densification) of the sprayed concrete will be destroyed and the sample will be unrepresentative of the ultimate condition and performance of the in situ sprayed concrete.

It has been well documented that porosity and permeability are not related, as was demonstrated in the UK Concrete Society Technical Report 31 - Concrete Permeability.

It is clear that there are still wide-ranging views on this issue, but it should be possible at least to agree on routine in situ testing methods that can provide a good indication of the durability potential of applied sprayed concrete.

Available reference specifications

The most commonly used international technical specifications are listed below. Domestic specifications use these specifications as basis with a blend of local requirements and constraints.

(i) EFNARC, European Specification for Sprayed Concrete, 1996

(ii) ACI 506.5 R-09, Guide for Specifying Underground Shotcrete, August 2009

(iii) ACI 506.2-95, Specifications for Materials Proportioning and Application of Shotcrete

(iv) BTS/ICE Specification for Tunnelling, British Tunnelling Society/Institution of Civil Engineers, 3rd edition 2010.

Commonly used materials testing methods include:

(i) BS EN 12390-8:2000; EN 7031 - Water penetration

(ii) ASTM C114 and C1602/3 - water quality

(iii) ASTM C403 (BS 4550) - setting times

(iv) ASTM C642-06&82 - Boiled Absorption and Volume of Permeable Void.

(v) ASTM C1116 - Fibre Reinforced Concrete

(vi) ASTM C1140 - Test panels

(vii) ASTM C1141 - Admixtures

(viii) ASTM C1436 - Materials

(ix) ASTM C1604, ASTM C42, SANS 5865 - Beam and core testing

(x) ASTM C1609, C1116 and C78 - Fibre Reinforced Concrete Beams (note that ASTM C1018 was withdrawn in 2006).

Closing

In conclusion, it appears that sprayed concrete as a permanent component of civil and mining engineering structures has developed very far in gaining acceptance among the owners, designers, and constructors of these structures. A large amount of substantive work has been done on the material properties aspects of sprayed concrete, as is demonstrated by the wide selection of guidelines, codes of practice, test methods, and publications that are available. We can expect high confidence levels when it comes to pre-construction laboratory mix design and testing as well as on-site panel testing. Proven quality and control procedures have been developed and strength testing methods and procedures during construction are in place.

However, some inconsistencies still exist with the verification of the sprayed concrete application process and assessing the performance of the final product. Issues such as applicable in situ testing methods and interpretation of the results to arrive at higher confidence performance values for structural capacity and long-term durability still need some further work. Aspects that perhaps need further integration include:

► Quantitive proof of consistency of application -variations in the application density, porosity, and permeability. Mechanixation increases such confidence levels

► Applicator performance - even in a mechanized environment there will still be the need for an experienced operator

► Use of batch plant records to prove consistency of delivery and compliance with mix designs

► Type and frequency of strength and materials testing during construction - balancing the need to prove the work done without undue impact on construction (excavation) production rates

► Long-term performance monitoring of the end product

► Linking all of the above together to yield definitive durability validation procedures.

ITA WG 12 will attempt to expand on these issues in collaboration with experts in this field and with the goal of arriving at an integrated solution that can be applied with a high level of confidence.

References and bibliography

References used to compile the text and a selection of useful publications are listed below. Some of the authors are also members of ITA WG 12.

Ballim, Y. and Basson, J.J. 1994. Durability of concrete, Fulton's Concrete Technology. 7th edn. Addis, B.J. (ed.). Portland Cement Institute. Chapter 9. [ Links ]

Boniface, A. 2012. International Tunnelling and Underground Space Association, Working Group 12: Use of Sprayed Concrete. Draft Report on the Testing of Sprayed Concrete for Durability, May 2012. Unpublished. [ Links ]

Boniface, A. and Morgan, D.R. 2009. Durability and curing of shotcrete. ITA/SAIMM/SANCOT 'Shotcrete for Africa' Conference, Johannesburg, 2-3 March 2009. [ Links ]

Franzen, T., Garshol, K.F., and Tomisawa, N. 2001. Sprayed Concrete Linings: ITA Working Group Report, Tunnelling and Underground Space Technology, vol. 16. pp. 295-309. [ Links ]

Haglia, P. 2008. Deterioration mechanisms and durability of sprayed concrete in Norwegian tunnels. Proceedings of the 5th International Symposium on Sprayed Concrete, Lillehammer, Norway, 21-24 April 2008. [ Links ]

Hilar, M., Thomas, A., and Falkner, L. 2005. The latest innovation in sprayed concrete lining - the lasershell method, Tunel (Magazine of the Czech Tunnelling Committee and the Slovak Tunnelling Committee ITA/AITES), vol. 4. pp. 11-19. [ Links ]

Jolin, M., Bolduc, L-S., Bissonette B., and Power, P. 2011. Long term durability of sprayed concrete, 6th International Symposium on Sprayed Concrete, Tromso, September 2011. pp. 212-225. [ Links ]

Malmberg, B. 1993. Shotcrete for rock support: a summary report on the state of the art in 15 countries. Tunnelling and Underground Space Technology, vol. 8, no. 4. pp. 441-470. [ Links ]

Melby, T., Dimmock, R., and Garshol, K.F. 2006. Sprayed Concrete for Rock Support, BASF. 11th edn. [ Links ]

Morgan, D.R. 1994. Transfer Tunnels - Evaluation of Shotcrete. HBT Agra Ltd. Report No 157/856 - Lesotho Highlands Consultants, April 1994. [ Links ]

Thomas, A. 2009. Sprayed Concrete Lined Tunnels, Taylor and Francis. [ Links ]

Yun, K-K., Namgoong, K., Choi, S-Y., and Kim, Y-G. 2011. Field application of high performance wet mix shotcrete for rehabilitating and landscaping a reservoir spillway. 6th International Symposium on Sprayed Concrete, Tromso, September 2011. pp. 453-463. [ Links ]

This paper was first presented at the, Mechanised Underground Excavation in Mining and Civil Engineering Conference 2015 (SANCOT), 23-24 April 2015, Elangeni Maharani Hotel, Durban, South Africa.