Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.11 Johannesburg Nov. 2015

http://dx.doi.org/10.17159/2411-9717/2015/v115n11a17

SANCOT CONFERENCE PAPERS

A review of current tunnelling technology and boring applications in mining and infrastructure development - An EPCM perspective

S.C. Gouws

Worley Parsons, South Africa

SYNOPSIS

Sustainable infrastructure development has long been identified as a key enabler for socio-economic growth and poverty reduction in societies globally. Twenty-one years into the young South African democracy, economic prospects are fragile and unemployment statistics are high. According to Trading Economics (2015) the GDP growth rate in South Africa averaged 3.07% from 1993 until 2015.

Through the National Development Plan 2030, the government has responded by instituting the Presidential Infrastructure Coordinating Commission (PICC) to direct national growth and drive job creation by effecting a long-term infrastructure investment programme. The Commission is mandated by Cabinet to coordinate, integrate, and accelerate implementation of more than 150 individual social and economic infrastructure plans.

In the civil infrastructure development sector, increased urbanization is compelling governments and the public sector to expand safe and reliable public amenities, but the availability of real estate for construction in congested cities is a challenge. Within the mining infrastructure construction industry safe, rapid, and efficient mine extraction strategies are imperative to realize increased production, business hurdle rates, and stakeholder expectations.

Asset owners and stakeholders are obliged to consider advanced mechanized underground excavation and support technologies in order to present feasible solutions timeously. From an engineering design, procurement, and construction management (EPCM) perspective tunnelling technology and boring applications have a distinct advantage over conventional excavation techniques. These solutions may enhance commerce and transportation by expanding infrastructure in concentrations of national economic activity, providing crucial linkages with rural areas, between cities, and across international borders.

This paper explores the contribution by mechanized tunnelling technology and boring applications applied in conjunction with digital and automation technologies compared with conventional methodologies. The technological expertise, combined with a paradigm shift in delivery of project objectives, will promote economic growth, aid recovery from the economic downturn, and improve social development.

Keywords: sustainable health and safety, productivity, efficiency, project delivery, mechanization, tunnelling technology, rock cutting and boring

Introduction

There are a number of new tunnel projects in the pipeline in South Africa for water transfer schemes, metro rail extensions, and for rapid mine access, which are well suited to tunnel boring machines. Government has recognized mineral resource and civil infrastructure investment as a key priority and acknowledges the challenges to implement strategic projects.

The National Planning Commission states that South Africa has a relatively good core network of national economic infrastructure.

The challenge is to maintain and expand the infrastructure in order to support economic growth and social development goals.

Government envisages the implementation of the social and economic infrastructure plans by 2030. As a result of a number of recent high-profile project overruns, achieving predictable project outcomes in safety, cost, and schedule is paramount for the success of future projects.

Through effective pre-feasibility and options analyses studies, higher levels of confidence and integrity will be gained in support of the investment proposal. In the mineral resource and civil infrastructure sectors, companies are starting to action these challenges through the application and development of sustainable technology.

The main challenges to achieving sustainable safe, cost-efficient, and timely project outcomes in South Africa can be summarized broadly in two key performance areas namely Sustainable health and safety performance and Productivity and delivery performance.

Sustainable health and safety performance

Fundamentally all stakeholders agree; underground work must and can be executed safely. Zero harm to people, assets, and the environment remains a key success factor. There have been shafts completed without a single lost time incident, and then there have been subsequent shafts completed with multiple fatalities. The civil construction sector continues to contribute a disproportionate number of fatalities and injuries relative to other sectors, and this must be addressed.

Sustainable health and safety has long been the focus of attention, and while it is acknowledged that many industry associations and professional societies, contracting organizations, and others have made significant efforts to improve health and safety, there is still much work to be done to reach the target of 'zero harm' (COMSA, 2015)

Both the mining and civil infrastructure industries have recently undertaken significant actions towards achieving sustainable safety performance.

► Project incident review boards have presented analyses of incidents and near misses, enabling joint ownership and understanding of incident root causes. With this better understanding, participants have been able to implement engineering and procedural controls

► Industry networks such as the Shaft Sinking HSE Network have been created, which provides input and technical guidance in attending to poor safety performance. This forum brings together the CEOs of the key shaft-sinking organizations to commit to, sponsor, and direct action for ongoing safety improvement.

Cross-industry collaboration and learning is delivering sustainable safety performance, demonstrated by the improvements in safety statistics. A zero harm mindset and culture is a key enabler to sustainable safety in both mining and civil infrastructure project development.

The introduction of mechanized tunnelling technology and tunnel boring is bound to improve safety performance. The focus has been on the elimination of hand-held drilling, improved ground and material handling techniques, removal of people from the most dangerous areas, and reducing the overall number of people working underground.

Productivity and delivery performance

In 2012 and 2013 the South African mining sector, on a nominal basis, directly accounted for 8.6% and 8.3% of GDP respectively. This represents a significant reduction from the industry's peak in 1970 when the mining sector produced 21% of the GDP (COMSA, 2013).

The decline has been matched with a decline in the number of persons employed underground and the annual tonnage hoisted to surface. Linked to that is the decline in shaft-sinking performance rates. The mining and civil industries nevertheless continue to make a valuable contribution to the economy in terms of foreign exchange earnings, employment, and economic activity.

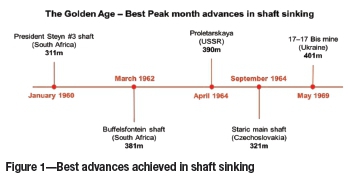

Figure 1 depicts some heritage shaft-sinking performances. Peak month performance on a few sinking projects has shown us what was possible 50 years ago. Current shaft-sinking projects achieve less than 50% of those peak performances.

The low performance rates in shaft sinking have led to a decrease in project efficiencies and increasing capital costs. In addition:

► Civil infrastructure projects are developed underground as a result of real estate constraints, and on mining projects, orebodies are located at even greater depths

► Low investor confidence and low project delivery certainty are resulting in fewer projects being approved

► Safety performance improvements combined with increased regulatory constraints have contributed to reductions in productivity compared to previous methods.

The critical path of an underground project will always remain with the establishment of main access infrastructure.

Projects require shorter schedules and this can be achieved only through continuous mining operations and by utilizing a one-pass in-line equipping process. To realize a business case with improved certainty around safety, reliability, and production performance requires a fresh approach.

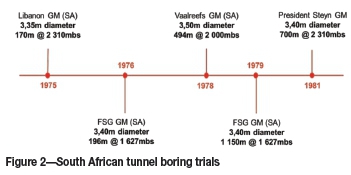

History has shown that the use of tunnel boring machines (TBMs) for mining projects in South Africa has not been without its fair share of challenges, and the potential the technology offers in the civil infrastructure sector has recently been recognized. In the mere six years that TBMs were trialled from 1975, only four machines were trialled in South African gold mines, operating in quartzites with a UCS of 150 to 250 Mpa (Figure 2).

Although TBM technology was proven to be technically feasible in South African hard-rock conditions, all four trials were regarded as failures in economic terms (Taylor et al., 1978). No further trials have been considered in the past 34 years.

The main challenges during the FSG tunnel boring trials in 1976 stem from limitations in the muck-handling systems with large rocks generated in the cutter head and tungsten carbide button cutter failure. Requirements were to operate with curves of 30 m radius and several short conveyors were employed, which led to excessive spillage.

Machine design inhibited support installation close to the face. A performance of 6 m over a 16-hour double shift was achieved, indicating the potential technical viability, but was constrained through delays in the system. Machine availability was measured at 65% and utilization at a mere 26%, resulting in excessive unit costs (Taylor et al., 1978).

Technological advances and case studies

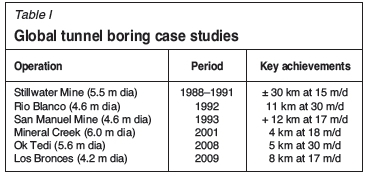

Globally, there are many hard-rock tunnelling success stories and any simplified perception that TBMs cannot be used for mining projects is false, as it is subject to geological risk. TBM technology has advanced since 1981 and we can leverage on the lessons learned on successful applications in the mining and civil industries around the globe (Table I).

A notable current use of a TBM outside of South Africa is at the Stillwater Mine in Montana, a platinum group metals (PGM) operation, where additional tunnels are being constructed as part of the mine expansion. TBMs were first used at this mine for the development of nearly 30 km of tunnels for the main mine access in the late 1980s and 1990s.

In the early 1990s, a TBM was used for the development of more than 12 km of tunnels at the San Manuel Mine in Arizona. A 4.6 m diameter open main beam type of TBM was used and was mobilized underground into the mine via a shaft and launched from an underground chamber.

Benefits of innovative mechanization with advanced technology

From an EPCM perspective it has become increasingly clear that the rapid development and application of technologies, automation, and mechanization is fundamental to unlocking the economic value potential within both the mining and infrastructure sectors of South Africa's economy. Our industry and country need new solutions to realize our value potential. We need to simultaneously achieve the following:

► Improved and predictable safety performance

► Significantly improved tunnelling productivity and capital efficiency

► Predictable project delivery durations and affordability.

We must seek to find holistic and systematic approaches for implementing projects with advanced technology that provide increased clarity for complex capital decisions coupled with increased stakeholder confidence in decision-making processes and ability. Mechanized tunnel boring is part of such a holistic and systematic approach which needs to be evaluated through the detailed engineering, design, and planning phases.

We need to employ lessons learned and consider mechanization technology in the front end loading (FEL) phase of projects, with an acute understanding of the terrain, rock mass characteristics, machine limitations, extraction strategy, support methods, and engineered infrastructure requirements.

Shaft and infrastructure development projects are major capital items. Underground mining projects dictate that the critical path is through shaft sinking and the underground development before production can commence. These two aspects must be seen as mutually dependent. To move forward we must address the following constraints and perceptions:

► TBMs are considered to be in the research and development phase for hard-rock boring

► Automation is not widely accepted or fully applied

► Different projects have different risk profiles

► The perception of TBMs failing to deliver in hard-rock deep-level mines in South Africa.

Engineering procurement and construction management (EPCM) perspective

Where government and asset owners do not have sufficient in-house capability and experience with implementing advanced technology in South Africa, lessons learned across the globe on similar applications can be implemented. Many asset owners have made significant advancements in automation and optimization globally. This approach could be applied more widely across asset development in South Africa.

Our industries require innovative solutions upfront in the early design phases of projects and onward. What differentiating activities do we need to engage to turn the vision into reality and how do we capitalize on benefits achieved elsewhere in the world? Independent expert decision support for 6 in the past and with a predictable safety outcome of zero harm.

Approach to realizing the vision

While we would like to believe that we operate in a technically sophisticated industry, there are industries where project delivery and engineering is further advanced. We have all witnessed industries such as aerospace, automotive, defence, and nuclear go through transformative reengineering of their processes.

There is certainly an opportunity to extract learnings from these industries as they have seen improved performance across the entire asset life-cycle with the appropriate application of technology. Consider our own rich South African history and some achievements of the past, including lessons learned around the globe.

Consider technological advances made in the oil and gas, coal, and civil engineering sectors, developments in other industries and lately in mining with regard to tunnel boring mechanization. What is 'The Art of the Possible' and how do we need to approach the mechanized strategies in a sustainable way? It is through upfront lateral thinking in our studies, planning, and engineering designs.

Mechanized underground tunnelling and civil development projects have comparative applications in portions of their life cycle. In mining the excavation is a means to an end whilst in most civil applications the excavation is the end product. Consider the 'Pit to Port' or 'Mine to Market' project value chain (Figure 3) which depicts the various value adding phases to realizing the full mining project objectives.

The exploration, evaluation and planning for development projects are right up front in the value chain. We deliberately need to be more focused on the front end loading (FEL) or early development phases of our projects.

A significant amount of project spend precedes execution, when one needs to meticulously explore, evaluate, engineer, design, plan, and recommend appropriate mechanization technology (Figure 4).

With the FEL strategy an acute understanding of the rock mass characteristics, limitations of the extraction methodology, and engineered infrastructure requirements can be gained.

There is more potential to realize project objectives as the plan progresses through all phases in the project life-cycle, which facilitates opportunity and risk identification to provide value with respect to infrastructure requirements to realize the vision.

Key technical considerations for TBMs

A thorough evaluation of the project location and anticipated ground conditions should be performed when considering a TBM for a mining or a civil infrastructure project. Appropriate geotechnical investigations are necessary to provide key information on the subsurface conditions to enable planning and design of the proposed tunnel alignment.

The designs include the following considerations:

► Geological issues - rock type, alteration, strength, abrasivity, durability, and groundwater inflows. Varying rock conditions will impact on the TBM design to adopt for a specific project

► Depth of cover and the potential for overstressing or rockbursts will inform geotechnical and support requirements

► Project location and remoteness - site access and terrain, portal locations, TBM constraints, tunnel size, and support requirements are key logistical considerations

► Contractor and workforce experience, training, and project schedule demands are vital in competency and selection evaluations.

Minimum specifications for TBMs are necessary, such as length of development, radii, and alignment in order to prevent the incorrect type of TBM from being used. The overall site and geological conditions associated with some projects may suggest that it is not appropriate to use TBMs due to higher perceived risk.

Suitable project application criteria

► Greenfield projects - new infrastructure developed from surface

► Brownfield projects - if supporting infrastructure will permit performance

► Orebodies of shallow to intermediate depth are feasible

► Straight conveyor belt declines with minimum radii of 250-300 m

► Homogeneous rock conditions with a low percentage of faults/shears and/or highly altered rock determine TBM cutter selection, including hard rock 150 MPa to 250 Mpa

► Vertical tunnel alignment below a maximum grade of 3% is typical, but if above 3% then special braking systems are required. Notable inclined examples for TBMs include 35° upward shafts for hydropower projects in Switzerland and India and downward 30° escalator tunnels in Moscow.

Conclusions

Globally there are hard-rock mechanized tunnelling and boring application success stories and TBMs are a proven technology. There is an opportunity to extract learnings from other industries, our own rich South African history, and some achievements of the past, including lessons learned around the globe where improved performance has been realized across the entire asset life-cycle with the appropriate application of technology.

We need to integrate the rapid development, application, and automation of mechanized equipment in our upfront approach to mine and infrastructure project design and development to enable sustainable safety and capital efficiency on our projects.

Projects must seek to find holistic and systematic approaches for implementation and control of equipment with advanced technology that provide increased clarity for our complex capital decisions and increase owner/shareholder confidence in our decision-making processes and ability.

In the appropriate application combined with a paradigm shift in delivery of project objectives, TBMs have the potential to change our industries dramatically, which is crucial in supporting economic growth in South Africa and to achieving social development goals.

Acknowledgements

The author wishes to thank WorleyParsons for allowing this paper to be published, and acknowledges information provided by Murray and Roberts Cementation, Aker-Wirth, Herrenknecht, Mitsubishi, The Robbins Company, Rowa, and Seli SpA.

References

Chamber of Mines of South Africa. 2015 http://www.chamberofmines.org.za/media-room/facts-and-figures.htm [Accessed 9 June 2015]. [ Links ]

Construction Industry Development Board. 2009. Construction Health and Safety in South Africa; Status and Recommendations June 2009. http://www.cidb.org.za/Documents/KC/cidb_Publications/Ind_Reps_Other/ind_reps_ construction _h_s_in_SA_status_recommendations.pdf [Accessed 9 June 2015]. [ Links ]

Development Bank of Southern Africa and the Presidency, South Africa. The State of South Africa's Economic Infrastructure: Opportunities and challenges 2012. http://nepadbusinessfoundation.org/index.php/regional-integration-and-infrastructure-publications/299-the-state-of-south-africa-s-economic-infrastructure-opportunities-and-challenges-2012 [Accessed 9 June 2015]. [ Links ]

SouthAfrica.info. 2015. Mining Operation Phakisa gets going. http://www.southafrica.info/business/economy/development/phakisamining-150515.htm [Accessed 24 July 2015]. [ Links ]

South Africa. 2014. Department of Mineral Resources. Annual Report 2013-14. http://www.dmr.gov.za/publications/annual-report/summary/26-annual-reports/1219-annual-report-20132014.html [Accessed 9 June 2015]. [ Links ]

South Africa. National Development Plan 2030. Our Future - make it work https://nationalplanningcommission.wordpress.com/the-national-development-plan/downloads/ [Accessed 9 June 2015]. [ Links ]

South Africa. National Planning Commission, National Development Plan, Economic Infrastructure https://nationalplanningcommission. wordpress.com/economic-infrastructure/ [Accessed 9 June 2015]. [ Links ]

Taylor, J.G., Taylor, R.N., and Hall, A.E. 1978. The introduction of a tunnel borer into a South African gold mine. Journal of the South African Institute of Mining and Metallurgy, vol. 78, no. 2. pp. 188-198. [ Links ]

Trading Economics. Not dated. South Africa GDP Growth Rate. http://www.tradingeconomics.com/south-africa/gdp-growvth [Accessed 24 July. [ Links ] 2015].

This paper was first presented at the, Mechanised Underground Excavation in Mining and Civil Engineering Conference 2015 (SANCOT), 23-24 April 2015, Elangeni Maharani Hotel, Durban, South Africa.