Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.11 Johannesburg Nov. 2015

http://dx.doi.org/10.17159/2411-9717/2015/v115n11a8

SURFACE MINING CONFERENCE PAPERS

Determining settlement rates and surface stability using in situ density of backfill as a proxy for displacement

D. FennI; A. du KandaI; D. DukhanII

IApplied Rock Engineering cc working on behalf of GIBB Engineering and Architecture

IIEskom Line Engineering Services

SYNOPSIS

Gibb Consulting Services was contracted by Eskom Line Engineering Services to conduct an investigation to determine the absolute displacement to date and infer the current rate of displacement of unsurveyed colliery backfill.

At the test site, where a 400 kV power line is to be constructed, neither the surface nor the backfill material had been monitored and it was not possible to state whether the surface will be subject to future settlement that may compromise surface infrastructure. Therefore indirect methods of estimating current and future displacements needed to be found to act as a proxy for a comprehensive long-term settlement monitoring exercise and provide a reasonable estimate for the settlement that has occurred in the decades of mining.

The innovative solution was to recover essentially undisturbed core from backfill using a sonic drill rig and use the measured dry density values from the samples as a proxy for the rate and absolute displacement in the backfill.

The success in obtaining an essentially undisturbed backfill core and the clear relationship of the backfill density with age and depth allowed the conclusion to be issued that the power line infrastructure can be constructed over the backfill; with a warning that once the water table recovers after mining ceases some collapse settlement may occur.

With this method, the amount of settlement can be predicted and, if proven conclusively, provides a way to confidently release huge areas of currently waste ground for future surface infrastructural development.

Keywords: settlement, subsidence, mine backfill, undisturbed backfill core, sonic drilling, bulk density, surface infrastructure construction over backfill

Introduction

In coal mining, it is normal mining practice to backfill the newly mined-out voids with the excavated waste rock and soils. As there is no requirement for the mining companies to uniformly compact the spoil or accurately monitor surface or inter-backfill displacement, these backfilled voids are prone to differential compaction and consolidation settlement. They are therefore avoided as sites for future surface infrastructure work, especially for linear structures such as roads, railways, and power lines.

Eskom planned to construct a new 400 kV power line from Hendrina to Gumeni , which would cross several areas of backfill in the heavily mined areas around the Witbank Coalfield.

Since no survey monitoring data was available, Gibb Consulting Services was tasked with developing methodologies for estimating current and future displacements in the backfill, which would substitute for a long-term settlement monitoring exercise.

Methodology

Initially, applied geophysics was to be used, but both literature sources and experts in these fields concluded that it would probably not yield useful data as the 'noise' generated by the very heterogeneous soils mix could be greater than the difference in the material properties being measured.

Since geophysics and monitoring could not be used, an innovative methodology was derived that used in situ dry density, obtained from essentially undisturbed core from the backfill, as a proxy for settlement. This was based on the assumption that that the increase in soil density over time and depth could be measured sufficiently accurately to allow for a correlation between the backfill age, depth, and settlement to be found.

To the authors' knowledge, this has never been attempted before, mainly due to the practical difficulties of drilling undisturbed samples from an open cast mine backfill material that ranged from solid sandstone boulders and cobbles to shales and clays.

Most drilling methods would either require fluid flushing or would not be able to penetrate the soil mass to the depth required. Only sonic drilling offered the promise of triple tube wireline drilling without the need to flush or even rotate.

The Sonic Drill Section of Boart Longyear International was approached for their opinions and guidance due to their experience in this field.

Their enthusiasm and insight was invaluable to the success of this project. Experienced drillers from Europe were used for the duration of this project. A novel addition to this project was to use transparent Perspex inner tubes, so the core could be inspected in the field and methodology adjustments made immediately.

Another area where partners to this project were instrumental to its success was the Optimum Colliery personnel who unstintingly constructed roads, removed overburden, gave up their time, knowledge and databases and smoothed out a thousand potential problems and without whom this project could not have been a success.

Optimum was chosen as a site due to its repetitive geology, unvarying hydrology, and long mining history of consistent dragline opencast mining method. This consistency reduced the number of variables, allowing a full graph of the settlement versus depth and age to be produced.

Finally, the completed, waxed, and sealed sample cores were transported for testing to SoilLab in Pretoria, who are acknowledged to be the leading soil testing laboratory in South Africa.

The dry density test results were compared to backfill displacement measurements obtained from the literature locally and internationally. The comparison included empirical calculations for expected settlement, and these were compared to the results of the core density analysis and recent survey profile levels from Optimum Colliery.

Sonic drilling

After comparing various drilling methods, it was realized that only sonic drilling would produce core samples that were essentially undisturbed and not affected by flushing, contamination, and excessive core loss (Figure 1).

One of the advantages of sonic drilling is its ability to continuously core unconsolidated and some consolidated formations with a minimal amount of disturbance and compaction.

High-frequency mechanical oscillations, developed in a special drill head, are transmitted as resonant vibrations, along with a rotary action, through the tooling to the bit. The vibratory action fluidizes the soil particles, destroying their shear strength, pushing the particles away from the drill bit and along the sides of the drill string.

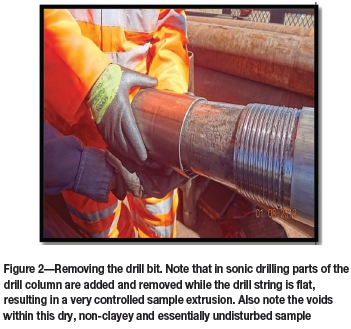

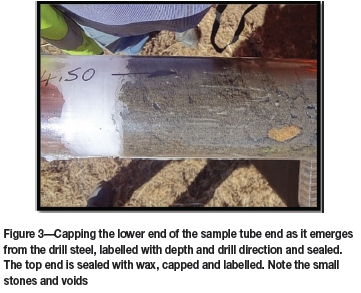

With the outer casing left in place to hold the borehole open the 3.0 m core barrels were extracted (Figure 2) and the 1.5 m long Perspex sample tubes were immediately sealed with wax (Figure 3).

It became apparent that much beyond 40 m depth, especially in the more sandstone- (boulder)-rich formations, some water had to be used to reduce barrel friction and cool the bit, flushing away part of that sample. Drilling muds were considered in order to reduce this effect, but this idea was rejected to prevent sample contamination. Total core loss was estimated to be less than 5% of the total core, thus not affecting the overall quality of the data.

Mine settlement theory

Researchers have investigated and attempted to predict soil (backfill) settlement for decades, with various levels of success.

In the literature survey, all relatively successful attempts to investigate and predict the settlement of backfill involved the monitoring of actual settlement profiles over years, and even decades.

Internationally, a number of rehabilitation guidelines have been produced and in 2007 the South African Chamber of Mines (COM) sponsored a new set of guidelines. It allows the mining companies to produce backfilled ground that is suitable for agricultural use, but does not require the mine to produce an engineered, compacted soil suitable for engineered structures such as buildings, roads, or pylon-suspended power lines. Nor does the ground need to be subject to rigorous surveying, although surface profiling is becoming more common.

Until recent times, there was little pressure to produce expensive engineered backfill, as land use and land costs were not an issue. However, today the pressures for redevelopment are increasing, while the availability of unmined ground, especially for linear structures (roads railways, and power lines), is decreasing. As more opencast coal operations coalesce, this will add to this pressure.

An important fact underpinning this investigation was that the backfill composition was relatively unknown; especially with regards to compaction and soil parameters such as friction and cohesion.

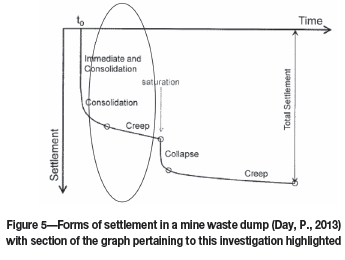

Figure 5 (Day, P., 2013) summarizes the various forms of settlement. Initially, during the backfilling, immediate settlement occurs without altering the mass of the backfill. Soon thereafter, volume changes occur during consolidation settlement as the excess air and water pressures dissipate. This trends into a more gradual creep stage, which was the main settlement stage that was planned to be measured in this project. Finally, if the water table recovers, post-mining collapse settlement could occur, accelerating the creep process. This stage could not be measured in the investigation as the water table had not recovered.

Creep and (post-mining) collapse settlement are irreversible and are the most significant forms of settlement affecting any structures built on the fill.

Hill (1994) stated that the mechanism for creep settlement is one of gradual rearrangement of the material fragments, resulting in a reduction in void ratio due to crushing at highly stressed contact points, increasing the dry density of the material. Compressive stresses within a body of fill are concentrated at the contact points between material fragments.

The Sowers method (Sowers, Williams, and Wallace, 1965) is currently the most widely used and accepted method for estimating settlement in the geotechnical engineering community. It separates the calculation of primary and secondary settlement. Equation [1] calculates primary settlements in each distinct layer.

where sis the creep settlement expressed as a percentage of the fill height (creep strain) that occurred between times t1 and t2from the beginning of the period of creep settlement, and a is the creep compression rate parameter.

Difficulty arises in determining the time at which creep settlement began (tzero), with layers placed first clearly beginning to settle before the placement of later layers. Sowers, Williams, and Wallace (1965) took this time to be the date when half the fill was completed.

Note that these investigators were working with a variety of materials, most of which were laid over a period of time, usually months or even years. In the case under investigation and for normal dragline mines, the creation of the low-wall backfill is very quick, occurring over a matter of hours or days. Therefore the issue of where tzero starts is null. In this investigation, it was assumed throughout that the age of the backfill was the same as the mining date, which was only recorded to the nearest month.

Other authors examining the behaviour of creep settlement in rockfills include Soydemir and Kjaemsli (1979) and Clements (1984). Soydemir and Kjaemsli examined the post-construction performance data for 23 rockfill dams, and observed both displacement/time and displacement/dam height relationships. In an attempt to combine these relationships, equations were produced for the displacement/dam height relationship for different time periods of the form:

where S is crest settlement, H the dam height, and ß and δ constants dependent upon the time period for which settlement is to be estimated and the method of dam construction, as shown in Table I.

This investigation hoped to overcome the difficulties inherent in making absolute measurements of settlement in models by directly measuring the densities in the material and relating these to assumed, calculated, and measured settlements.

The investigation would be considered a success if the data resulted in density versus age and depth graphs that were comparable to graphs of measured displacement against age and depth.

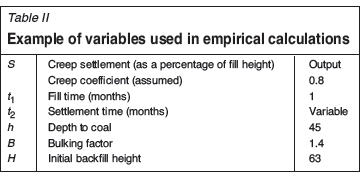

When utilising Sowers Method the following variables were utilised, each variable chosen after careful consideration and comparison to the existing circumstance (Table II).

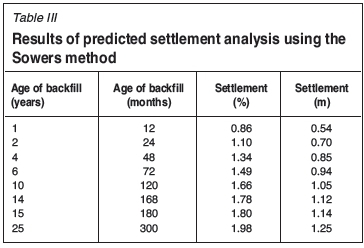

The results in Table III were found for settlement as a percentage of backfill height (H). Furthermore, expected settlement was found for all boreholes across the various mine backfill ages.

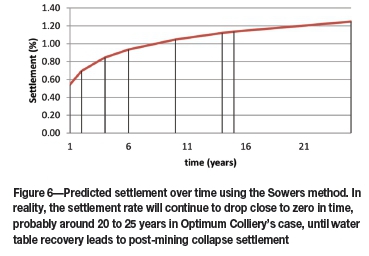

It can be seen from the initial results obtained using Sowers's method that over extensive periods (Figure 6) the rate of settlement decreases or stabilizes as the void ratio decreases with weathering of the backfill and with the filling of the voids during collapse settlement. Note that the Sowers equation is not able to accurately predict the initial settlement.

Figure 7 shows that displacement monitoring over long periods yields actual displacements at those points monitored (Hills, 1994). Note that the only dragline operation measured, Clockfields (point 8 in the figure), showed by far the most settlement and the highest rates of settlement when compared with engineered and compacted backfills. This is a dragline-made backfill that has similar ground properties to those found at Optimum Mine - depths of 20 m to 50 m, uncompacted dry mudstone and clay fill.

Significantly, the curves for density shown in the Results section of this paper are very similar to the curve for Clockfields at a depth of around 40 m. The curves indicate a rapid initial displacement for Clockfields and increase in density for Optimum, tapering off at around year 2 or 3 and trending into a flat line at around year 4 for Clockfields and year 5 for Optimum Mine.

Investigation methodology and results

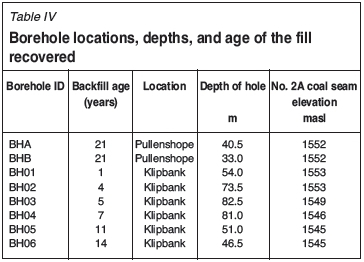

Table IV shows the boreholes drilled and the ages and depths of backfill in the respective logs.

Boreholes BHA and BHB were drilled 20 m apart as a control to determine if they yielded similar results for similar drilling conditions, which was found to be the case. They were not used as part of the data-set as the ground and drilling technique differed from the other boreholes (practice was to vary rotation and flushing to establish the most efficient drilling method, with the finding that 45 r/min gave the best results without affecting compaction), which reduced the value of the data obtained. However, as these holes were situated close to the proposed power line, they provided valuable data on actual conditions at the site.

The Klipbank array of holes was drilled roughly along a line in the direction of the face advance. Therefore the holes yielded samples that were very similar in nature, but differed in age (Figure 8).

Hills (1994) and Hills and Denby (1996) found that settlement profiles often do not match the profile of the underlying ground surface, with the settlement profile tending to be displaced away from the pit walls; which they considered was probably due to lateral shear movements in the fill. For this reason, the sides of backfill were avoided to negate this variable.

The backfill density was initially determined using the wax density method, where representative samples of each borehole were extracted from the protective Perspex inner tubes and coated with paraffin wax. The waxed sample was weighed in air and water, and the bulk density, dry density, and specific gravity were calculated.

Dry density values were obtained for each borehole with this method, samples being taken from varying depths and lithologies across each borehole. A number of dry density values were compared at various depths within each borehole. Dry density values across all the boreholes at comparable depths were cross-checked to determine if the density altered with age.

Through the use of transparent sample tubes it was proved visually that the sonic drilling produced essentially undisturbed core by volume and density (Figure 9). However, many of the sand-rich samples were seen to have a short unfilled section at the top of the tube. This 'core loss' was ascribed to:

► Friction from the Perspex 'dragging' the drier material down the tube. This effect has been reported by others, especially when using Shelby tubes and other more friction-based sampling methods

► Hard, unweathered rocks could be pushed to one side instead of being cored. To reduce this effect, a uniform minimal drill rotation of 45 r/min was used throughout

► Drill fluid washing away the fine material. In the test holes, up to 100% of the sample was lost to flushing, highlighting the need to dry drill. Note that even using the sonic drill, which should keep drill fluid separated from the sample, this was still problematic

► The shaking and vibrations from the drilling action

► Actual voids within the material, especially under large boulders. Two short voids were reported in BH 2, both around 30 cm long. The material above then slid down the tube, leaving core loss at the top.

It was not possible to determine which of the above reasons were responsible for the drill core loss and to what extent. Therefore the following policy was adopted: all suspect core was rejected where the core recovery was less than 90% or where water was used as flushing and recovery dropped below 66% or was 'wet'. Since it could not be determined if the 'core loss' or 'gap' was due to actual loss or compaction, it was decided that it would be treated as 50% loss and 50% compaction. This was applied equally to all samples and did not alter the shape of the output graphs or unduly affect the conclusions.

Initial results considered the stratigraphic composition of each borehole log as per British Standard 5930 ( British Standards Institute, 2007) separating hard rock such as sandstone and softer materials such as shale within each borehole. Material was initially tested according to geological consistency at certain predetermined depths. It was expected that density would slowly increase over time and with increasing depth due to creep settlement. However, the results indicated that the density of the backfill at any given depth did not alter appreciably over time, which was unexpected.

It was found that the more consolidated material samples had been selected for the wax density tests rather than the less consolidated, loose backfill. It was therefore decided that supplementary testing would be needed, using an alternative method of sampling, which would provide a more representative set of data.

The second series of laboratory tests was conducted on complete 1.5 m long samples, disregarding the soil composition. These were dried in an oven and then weighed to determine their dry density for a larger sample volume than was possible by the wax density tests. This was considered to be more representative of the backfill as each 1.5 m run of core contained a variety of particle sizes and took into account the natural voids. Using this method, utilizing the simple principle that dry density is equal to the dry mass divided by the volume of the sample, another set of results was produced.

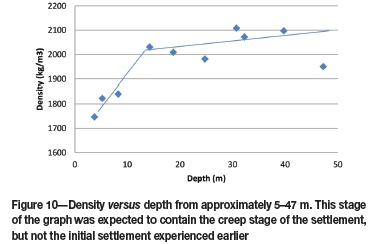

Figure 10 shows that the density from around 5 m below surface to 47 m increased with depth, as expected. However, while a straight line may have been expected, the graph depicts two distinct data-sets. The first set near surface from 5-9 m was highly variable, possibly due to the amount of surface disturbance over the years, suggesting that this method cannot provide reliable results near the surface. The second data-set shows that the in situ density increased gradually with depth, as expected. The density at the last data point (47 m) was slightly lower than expected, possibly due to greater levels of weathering encountered at this point, erosion due to footprint rainwater, or the effects of autocompression, which is described in more detail later in this paper.

The graph, while raising questions, suggested that the results from the measurement of dry density of larger dried samples could be used to describe the settlement process and warranted further attention.

The principal aim of testing was to define a correlation between age of backfill, depth of backfill, and density, whereby density or changes in density would act as a proxy indicator of settlement. The results indicated that the densities could be separated according to depth below surface:

► Near surface, within 9 m

► Shallow depths, between 9 m and 30 m

► Medium depths, from 30 m to 50 m

► Large depths, from 50 m to 80 m (the maximum drilled).

Note that recently, the seam being mined dipped so that only the very young samples were located at the deepest depths. This explains the lack of medium to deep data from the older, shallower holes.

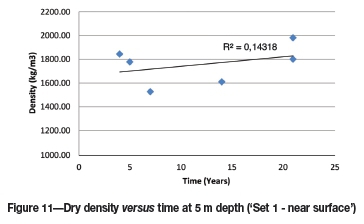

The dry density analysis at 5 m delivered the results shown in Figure 11.

As expected, due to repeated surface disturbance such as levelling and backfill compaction as part of the rehabilitation process, the correlation R2 between age and density was only 0.143. This indicates that densities attained using this method at shallow depths cannot be utilized as an accurate method to predict rate of settlement.

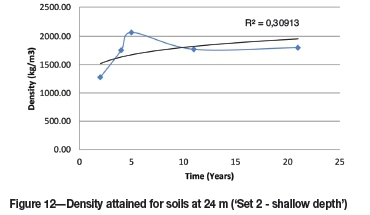

The soil behaviour and densities of samples at shallow depths between the 9 m and 30 m levels are of more significant interest, typified by the results from 24 m. This depth represents the bulk of backfilled material in older coal mines in South Africa.

Figures 12 demonstrates the expected steep initial settlement with increasing density for around the first five years after mining, followed by a much slower creep phase. These results correlate well with the published literature for monitored settlements in mine backfill in both rate and magnitude.

The older backfill often appeared in the results to exhibit a slight loss in density. This is possibly due to the rainfall infiltration washing away fine material or the boulders weathering over time. It is not thought to be due to an upwards (heave) movement caused by the clay fraction swelling, and if found to be consistent in other investigations can be treated by a suitable correction factor and hence discounted.

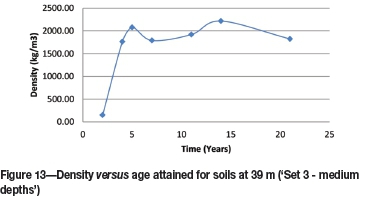

The pattern for densities obtained up to 39 m depth (Figure 13) appears to conform to the previous pattern for shallow depths, but with only a single 'young' hole exhibiting a very low density (possibly a core loss error in the laboratory as the sample tube appeared full when drilled).

The remaining data from samples ranging from 4 to 21 years in age shows a more consistent density in a range from around 1800 to 2200 kg/m3. This is close to the average expected density range of the in situ sandstone-shale mix prior to mining and indicates that the creep phase at this depth is largely complete by around 5 years.

Most of the solid overburden was between 35 m and 45 m in depth. However, the topography sloped gently upwards, increasing the strip ratio and depth of solid overburden in the final few mine cuts.

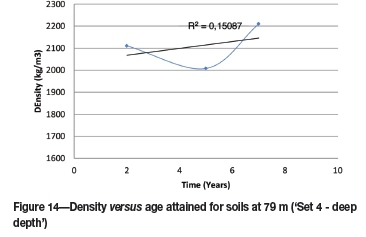

Finally, deep sample densities, where samples were taken from depths greater than 50 m below surface, were evaluated. It should be noted that due to site topography and drill depths the range of samples available at this depth was small, therefore while reasonable conclusions were found the sample set size was limited.

The investigation was able to source limited data from 50 m to 80 m depth, and only in backfill aged from 2 to 4 years. This data was used to compare the density trends attained at depth (Figure 14). These graphs show that the initial settlement reaches densities very close to that expected for the host rock mass prior to mining. This is a very high initial settlement, possibly indicating that the deeper backfill had suffered high initial compression.

The high initial compression with densities equivalent to the initial in situ rock mass could be attributed to a combination of four factors:

► Assuming the dragline bucket collects newly blasted material high up from the muckpile and traverses on a flat trajectory, the material dropped onto the lower levels of the low wall would have high velocity impact leading to lower initial void ratios

► Infiltration of fines from the overlying backfill

► Some or much of the lower level of the new low wall spoil would have been thrown by the blast, thereby having a high kinetic energy and resulting in a low void ratio

► Autocompression from the >40 m waste overburden would provide over 1 MPa of pressure, leading to a reduced void ratio.

Whichever of the four factors are predominant, the results suggest that the initial compression is relatively high in the lower portion of the deep backfill, and the resultant creep is correspondingly reduced.

This view is supported by Scott (1989), who noted that many other researchers have observed a linear relationship between autocompression and log time (Leigh and Rainbow, 1979; Riker et al., 1978; Hankins, 1984). This type of settlement continues longer in the top layers of spoil, since here ground stresses are not large enough to accelerate settlement (Ferguson, 1984).

From the above results and corresponding analysis it can be seen that backfill material at depths between 10.0 m and 40.0 m can be considered as the key or vital elements to be taken into account when considering creep settlement. It is within these bounds that the most significant change in material density and compaction occurs; therefore it follows that materials within these limits will contribute the most to creep settlement and its effects on surface.

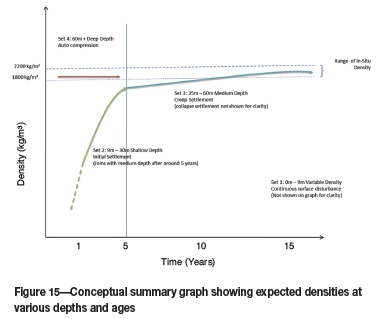

Figure 15 shows a conceptual graph of expected and realized densities at various depths and ages, based on collected data. In other cases, the backfill may exhibit slightly different values, but is expected to follow the general pattern. Note that in this investigation, post-collapse was not measured. Once the water table recovers it would be expected in the creep settlement stage. Figure 15 should be compared to the theoretical graph shown in Figure 5. As they are very similar in shape, it strongly suggests that this method mimics the graph that would be produced by monitoring, thus satisfies the criteria for declaring this method and investigation a success.

Key findings

A methodology that is rugged and simple in concept and execution has been demonstrated to describe the settlement in a non-engineered and uncontrolled dragline-produced coal mine backfill. Significantly, the method does not rely on detailed knowledge of the backfill composition or on actual displacements based on years or decades of laborious measurements, with the results being available within days of the final drilling programme.

The main finding is that the graph produced from comparing the dry density of sample versus age and depth closely mimics the graphs produced from actual survey monitoring data.

As expected, the method is unable to produce meaningful data close to ground surface (<9.0 m) as this ground has been disturbed repeatedly due to rehabilitation work. It could be that this material has not been compacted by the fill above it and is therefore highly variable in void content.

Between 9 m and around 30 m, the dry density was initially low at around 1100 kg/m3, but rapidly undergoes initial consolidation to around 2200 kg/m3, peaking at year five. Thereafter, the rate of consolidation slows and creep settlement continues more gradually as described in the literature.

Between 30 m and 50 m there appears to be autocompression and reduced subsequent creep. This indicates that the main area of interest lies above this height. The graphs produced of measured density versus depth within this range mimic the settlement graphs produced by various authors for dragline fill.

From 50 m to the bottom of the fill at 80 m, the graphs show very high autocompression levels and little or no subsequent compression. This indicates that the settlement expected in dry conditions will be minimal and there will be little benefit in costly monitoring or digging out the uncompacted backfill and replacing it with an engineered compacted backfill from these depths.

It should be noted that the area under investigation has been mined continually by dragline for the entire 21-year period and the backfill should therefore be considered not to have suffered from post-collapse settlement as the fill has always been drained, except for footprint rainwater infiltration. The amount and rate of post-collapse settlement that will occur when mining ceases and water table recovers were estimated using published empirical methods, but could not be verified in this investigation. This should be taken into account prior to any design decisions based on this work.

Many other interesting factors were found in this investigation, but owing to space constraints cannot be discussed at length in this paper. For example, by comparing the height of the current backfill against the original height of the in situ rock and coal, the bulking factor of the backfill after creep settlement was found to be 1.2, which is in line with values from the literature.

Models of expected settlement profiles were generated from published empirical formulae and were compared to the investigation results.

The investigation indicates that the creep phase of the backfill settlement was largely complete by the fifth year.

Recommendation

Due to the successes of using density as a proxy for settlement it is recommended that this method is repeated on sites where long-term survey monitoring data is available. It should then be possible to determine the accuracy and repeatability of the method and perhaps a direct correlation factor between settlement and density can be found. This could lead to this method being used as a simple proxy to determine settlement in unsurveyed backfill.

Future data should be compared to the current conclusions to update the validity and usefulness of this method to determine the settlement amount and rate by comparison of material density with age. Other test sites may have more variable geology, mining, and backfill/compaction sequencing, thus complicating the data obtained.

Conclusion

This investigation shows that density of mined backfill can be used as a proxy for settlement when correlated with age and depth of recovered core samples. This is demonstrated by good correlation between the graphs produced and the data suggested by the existing literature and empirical calculations (comparing Figures 5 and 15).

Acknowledgements

The work undertaken and the resulting outcome of such an ambitious and largely undocumented research proposal could not have been achieved without the support and assistance of the following key participants; Eskom Lines Engineering Services, GIBB Consulting Services, Optimum Colliery, Boart Longyear, and SoiLab.

References

British Standards Institute. 2007. British Standard 5930 Code of Practice for site investigation updated 2007. [ Links ]

Campbell, G. 2013. Personal Communication. Consulting Geophysicist, GAP Geophysics (Pty) Ltd. [ Links ]

Charles, J.A., Hughes, D.B., and Burford, D. 1984. The effect of a rise of water table on the settlement of backfill at Horsley restored opencast coal mining Site, 1973-1983. Third International Conference on Ground Movements and Structures, Cardiff, UK. [ Links ]

Charles, J.A., Naismith, W.A., and Burford, D. 1977. Settlement of backfill at Horsley restored opencast mining site. 1st Conference on Large Scale Ground Movements and their Effect on Structures, UWIST, Cardiff, UK. [ Links ]

Clements, R. 1984. Post-construction deformation of rockfill dams. ASCE Journal of Geotechnical Engineering. pp. 821-840 [ Links ]

Day, P. 1992. Determination of settlement parameters for open cast pit backfill by means of large scale tests. Symposium of Construction over Mined Areas, Pretoria, South Africa. [ Links ]

Day, P. and Wardle, G. 1996. Effects of water on settlement of opencast pit backfill: case histories of investigation and performance. SAICE Seminar on Hydrology of Made Ground, Johannesburg, South Africa. [ Links ]

Day, R. 2013. Personal Communication. Consulting Geophysicist for Engineering & Exploration Geophysical Surveys. [ Links ]

Day, P. 2013. Personal Communication. Chairman, Jones and Wagner Consulting Services (Pty) Ltd. [ Links ]

Fenn, D. and Du Kanda, A. 2013. Undermining and Surface Subsidence for the Zeus Kusile 400 kV power line. Phase 2 - Backfill Investigation and Risk Assessment. Unpublished report for Eskom Lines Engineering Services -Transmission (LES). The Umbani JV. [ Links ]

Ferguson, D. 1984. Reclaimed and backfilled areas. Preprint: Third International Conference on Ground Movements and Structures, UWIST, Cardiff, 9-12 July 1984. 20 pp. [ Links ]

Hankins, P. 1984. Predictive settlement analysis of mine spoil at an open pit coal mine. MSc thesis, University of Alberta, Edmonton, Alberta. 174 pp. [ Links ]

Heymann, G. 2013. Personal communication. Geotechnical lecturer, Department of Civil Engineering, University of Pretoria. [ Links ]

Hills, C.W.W. 1994. The Examination and Prediction of Opencast Backfill Settlement. PhD thesis, University of Nottingham, UK. [ Links ]

Hills, C.W.W. and Denby, B. 1996. The prediction of opencast backfill settlement. Geotechnical Engineering, vol. 119, July. [ Links ]

Leigh, W.J.P. and Rainbow, K.R. 1979. Observation of the settlement of restored backfill of opencast mine sites. Symposium on the Engineering Behaviour of Industrial and Urban Fill, University of Birmingham. pp. E 99-E 127. [ Links ]

Scott, J.D., Zinter, G., Pauls, D.R., and Dusseault, M.B. 1988. A Review of the International Literature on Mine Spoil Subsidence. Report no. RRTAC 88-12, Alberta Land Conservation and Reclamation Council. 36 pp. [ Links ]

Sowers, G.F. 1973. Settlement of waste disposal fills. 8th International Conference on Soil Mechanics and Foundation Engineering, Moscow, 6-11 August 1973. [ Links ]

Sowers, G.F., Williams, R., and Wallace, T.S. 1965. Compressibility of broken rock and the settlement of rock fill. Proceedings of the Conference on Soil Mechanics and Foundation Engineering, Montreal. vol. 2. [ Links ]

Soydemir, C. and Kjaernsli, B. 1979. Deformations of membrane-faced rockfill dams. Proceedings of the 7th European Conference on Soil Mechanics and Foundation Engineering, Brighton. vol. 3. pp. 281-284. [ Links ]

Tanner, P. 2007. Guidelines for the Rehabilitation of Mined Land. Chamber of Mines of South Africa and Coaltech Research Association. [ Links ]

This paper was first presented at the, Surface Mining 2014 Conference, 16-17 September 2014, The Black Eagle Room, Nasrec Expo Centre, Johannesburg, South Africa.