Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 no.8 Johannesburg Ago. 2015

http://dx.doi.org/10.17159/2411-9717/2015/V115N8A12

Evaluating the coal bump potential for gateroad design in multiple-seam longwall mining: A case study

X. WangI; J. BaiI; W. LiI; B. ChenI; V.D. DaoI, II

ISchool of Mines, China University of Min &Tech, China

IIHanoi University of Mining and Geology, Vietnam

SYNOPSIS

This study proposes a methodology for evaluating the risk of coal bumps in multiple-seam longwall mining. Both the stress field and the total energy release (TER) during retreat were evaluated in the specified case involving multiple-seam mining using the LaModel program. The results of numerical simulations indicated that both the peak vertical stresses on the panel edges and the peak TERs in the outby longwalls increased significantly as the horizontal offsets were reduced from 60 m to zero. With the comprehensive consideration of the stress field and TERs, a conservative offset of 60 m was ultimately adopted when developing the gateroads of the lower panel in the field. The field measurements indicated that coal bumps were avoided completely by employing the proposed design, and the maximum roof-to-floor and rib-to-rib convergences of the tailgate during retreat were only 360 mm and 576 mm, respectively.

Keywords: coal bump; total energy release (TER); longwall mining; multiple-seam

Introduction

Coal bumps - sudden, violent bursts of coal -pose a serious threat to the safe excavation of coal. Their occurrence depends on the properties of the surrounding rocks, stress field, and dynamic disturbance. The complexity of the mechanism of coal bumps is further enhanced in multiple-seam mining due to seam interaction. Multiple-seam mining is most frequently found in the coalfields in eastern China, such as Xuzhou, Xinwen, Zaozhuang, and Huainan. In the past, due to issues of availability, economics, and ignorance of the potential risk in multiple-seam mining, coal seams in such conditions were mined without proper planning to account for seam interaction. Fortunately, studies published over the past three decades have raised awareness of the problems associated with multiple-seam mining, and indicated that the ground control issues induced by multiple-seam mining can be avoided and/or minimized with proper planning.

A number of technical studies pertaining to the design of multiple-seam mines have been published. These studies can be divided into two groups based on their methodologies of design: empirical (Chekan and Listak, 1993; Haycocks and Zhou, 1990, Matetic et al.; 1987a, 1987b) and numerical approaches (Li et al., 2000; Maleki, 2007; Mark, 2007; Peng, 2007; Zipf, 2005). The majority of the extant studies on the interaction mechanisms in multiple-seam mining have focused on the load transfer during operation, resulting in the proposal of the pressure bulb theory (Forrest et al., 1987; Haycocks and Karmis, 1983; Peng, 2008; Peng and Chandra, 1980) and pressure arch theory (Holland, 1973; Oram and Ponder, 1997) to guide multiple-seam mine design. However, neither, of these theories can be used to evaluate the potential for coal bumps.

Recent studies have indicated that coal bumps might occur when inappropriate designs are employed in multiple-seam mining (Peng, 2008). Past studies suggest that a great amount of energy is more likely to accumulate in pillars in the upper coal seam, and disturbances from drives and stopes in lower seams enhance the incidence of sudden breaks, which may also result in a coal bump. Thus, research focused on load transfer in multiple-seam mining cannot effectively prevent the potential bump from occurring. Instead, reasonable operation of roadways is an effective approach to weakening the accumulation of energy in pillars and the disturbance from drives and stopes in lower seams, thus reducing the risk of coal bumps in multiple-seam mining.

This paper evaluates the risk of a coal bump in multiple-seam longwall mining based on numerical modelling of the total energy release (TER).

Geological background

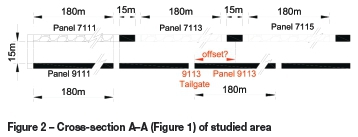

Zhuang Shuanglou coal mine is located in Xuzhou, Eastern China. Panels 7111, 7113, and 7115, which are flat and 3.8 m thick, were extracted from the No. 7 coal seam, whereas panels 9111 and 9113, also flat and 3.7 m thick, were extracted from the No. 9 coal seam.

Geological surveys showed that both the No. 7 and No. 9 coal seams were uniform and their average overburden depths were 772 m and 787 m, respectively. According to the core logs from exploration in these areas, shown in Table I, the interburden of the No. 7 and No. 9 seams was 15 m thick and consisted of a 0.89 m thick shale underlain by a 14.11 m thick fine sandstone. The mechanical properties of these layers, shown in Table I, refer to laboratory test results.

All three panels in the No. 7 seam were mined out and sealed by the end of 2010; the panel layouts are shown in Figure 1. In the beginning of 2012, the same panel layout as 7111 was proposed for panel 9111 (see Figures 1 and 2) to begin the development and retreat in No. 9 seam; however, a slight bump occurred at the pillar 20 m outby the longwall face during panel retreat. Strong pillar spalling and floor heave were observed, and the averaged roof-to-floor convergence reached 1.2 m. Due to safety concerns, panel 09111 was subsequently abandoned. Fortunately, this accident did not result in any fatalities.

Another mine, the San Hejian coal mine, was extracting the No. 7 and No. 9 seams to the southeast of Zhuang Shuanglou. The two mines are separated by a normal fault, with the San Hejian mine on the footwall side. The average fault offset in a vertical direction is 128.5 m. Hence, the overburden depths of the flat No. 7 and No. 9 coal seams in San Hejian Mine were 643.5 m and 658.5 m, respectively. The panels of the No. 7 and No. 9 seams in this mine were in the same layout and the upper longwalls were superimposed precisely on the lower ones. Note that both seams in the blue highlighted area in Figure 1 were mined out by 2007. No bump occurred in this mine during the extraction process. The differences in the ground response between these two mines during operation may thus be attributed to the different overburden depths.

Knowing the lower seam was mineable in the San Hejian mine, the owners of the Zhang Shuanglou mine proposed attempting to extract the No. 9 seam by arranging appropriate horizontal offset of the longwall panels. A schematic diagram of the idea to offset the lower panels is shown in Figure 2. The problem thus became one of finding the proper offset to avoid potential coal bumps.

Numerical modelling

LaModel program

The boundary element model (BEM) program LaModel was employed to evaluate the stress distribution and TERs when the lower seam was extracted. LaModel was originally written in 1994 by Dr Keith Heasley (1998), and experience showed that it could be used for structural mine planning and analysis (Heasley et al., 2003; Stemwart et al., 2006). In 2009, energy release rate calculations were incorporated into LaModel 3.0, and a number of case studies indicated that the energy release rate calculation module was fairly reliable for evaluating mine design in bump-prone areas (Sears and Heasley, 2009). Note that LaModel assumes a frictionless coal/rock interface, which may be an unwarranted assumption for coal bump prediction. However, in the present study the model was carefully calibrated to offset this disadvantage.

Model details

For the LaModel simulation, the coal seam was discretized with 2 m2 elements in a 250 χ 500 element grid with the model boundary shown in Figure 1. The thickness and Young's modulus of overburden rock in LaModel need to be calibrated before reasonably accurate results can be produced.

Due to the difficulty of measuring the distribution of longwall abutment pressures, the following empirical equation (Peng, 2008) illustrating the extent of the side abutment (or the influenced zone) after retreating of panel 7111 was used to calibrate to the inputs in LaModel.

where Wsis the width of the side abutment (or influenced zone) in feet, and h is the overburden depth in feet.

Note that the US unit used in above equation was mathematically converted into SI. Since the overburden depth of Panel 7111 was 772 m, the width of the side abutment after panel retreating would be 143 m. The rock mass in the overburden was simulated with a modulus of 20.7 GPa and laminations 10 m in thickness. The profile of the side abutment pressure predicted by LaModel is shown in Figure 3. The data indicates that zone of influence of the side abutment pressure reaches 148-150 m, which agrees well with the result calculated using Equation [1]. From this point of view, the selected numbers for the Young's modulus and thickness of rock mass in the overburden were acceptable.

On the other hand, the strain-softening material model was used for both coal seams, and the element strengths were determined using the in-situ coal strength of 6.2 MPa in conjunction with the Mark-Bieniawski pillar strength formula as implemented in the coal material 'wizard' in LaModel (Heasley and Agioustantis, 2007). The coal elastic modulus was set at 2.07 GPa, and the residual seam stress and strain values of coal materials were approximated based on the method of Karabin (1994). In addition, the gob was assumed to be a strain-hardening material and its stress-strain relationship followed Salamon's gob model equation (1990). Rigid seam boundary conditions were implemented on the north, south, and west sides of the grid, while a symmetrical boundary condition was implemented on the east side.

The remaining barrier pillars between the adjacent two panels in the upper seam were 15 m wide. The interburden of the two seams was 15 m thick, and all of the longwall panels were 180 m wide, which was determined by mine regulations. A total of eight plans were proposed for the horizontal offsets of panel 9113 (see Figure 2 and Table II).

The development and retreat of the upper three longwalls were run as the first to sixth steps in the LaModel simulation, followed by development and retreat of panel 9113 with strategies no. 1 through 8 in turn, as shown in Figure 4.

Model results

Vertical stress distribution

The eight plans were performed separately in turn in the LaModel simulation. Figure 5 shows the vertical stress distribution in 3D during the retreat of panel 9113. Clearly, in Figure 5(a), the offset is 60 m, i.e., the headgate and tailgate of panel 9113 are developed beneath the upper gobs, which may lead to less vertical stress (54.1 MPa,) distributed on the panel edges. In addition, because the interburden is only 15 m thick and the upper remaining pillars may cave down as the longwall 9113 retreats, there is no stress concentration in the middle of the panel 9113 gob.

If the offset distance is equal to zero, however, as shown in Figure 5(b), the maximum vertical stress distributed at the edges of the gob may reach 70.9 MPa. Meanwhile, because the headgate and tailgate are located beneath the upper remaining pillars, the maximum vertical stress distributed at the edges of the entries in the outby longwall will reach 39.4 MPa. This is not a desirable outcome given that the in-situ vertical stress is only 19.6 MPa.

Empirical criterion for TER

When operating panel 9113 with different offsets, the TER must also be evaluated because a minor coal bump occurred in panel 9111. It is accepted that in order to prevent bumps from occurring, the TER should be smaller than the minimum energy release that may lead to a coal bump. However, there is no consensus among researchers (Dou and He, 2001), on the ideal value of the limited energy release for specific mining conditions. Fortunately, the San Hejian mine has safely and successfully mined both seams with lower overburden depths due to the fault throw. Thus, the empirical methodology can be used in this case to propose the TER criteria for coal bump control.

The numerical model employing LaModel 3.0 was developed as the longwalls retreated successfully in the San Hejian mine. Figure 6 shows the TER after the longwall retreat. Note that the peak TER is 34.8 MJ and is located at the centre of the panel. Experience shows that there will be no bumps under these conditions, therefore in this study 34.8 MJ is selected as the conservative criterion for the offset of longwalls needed to keep the TER less than 34.8 MJ after retreat.

TER of different offsets

Figure 7 shows the TER when retreating panel 9113 with different offsets. It can be seen that:

> There are two peak TERs distributed at the two sides of each entry, and the TERs gradually increase as the offsets decrease from 60 m to zero

> When the offsets are less than 40 m, the TERs at the panel edges are greater than those at the panel centre, indicating that the upper remaining pillars will significantly influence the gateroads as the offsets decrease

> There is always a peak TER in the centre of panels, no matter what the offset

> The peak TERs are 24.3, 28.6, 35.8, 45, 54, 64.2, 73.7, and 83.5 MJ when offsets of 60, 50, 40, 30, 20, 10, 5 m, and zero are employed, respectively.

Appropriate offset

The peak TERs and predetermined criteria for bump control in panel 9113 in the Zhang Shuanglou mine are plotted in Figure 8. Evidently, peak TERs decrease as the offsets of panel 9113 increase; more importantly, the offsets of panel 9113 need to be at least 50 m to prevent coal bumps according the empirical criteria proposed in the previous section.

Hence, to be more conservative, an offset of 60 m was finally adopted when developing the gateroads of panel 9113 in the field.

Field measurements

The roof-to-floor and rib-to-rib convergences in the tailgate of panel 9113 were monitored during the retreat, as shown in Figure 9. It can be seen that (1) the maximum roof-to-floor and rib-to-rib convergences were only 360 mm and 576 mm, respectively; (2) 90% of the entry convergences occurred within the 40 m outby distance to the the longwall face; (3) no violent entry convergence occurred during the longwall retreating. Hence, the proposed design for the gateroad layout was appropriate and successfully avoided a coal bump.

Conclusions

The majority of prior studies of the interaction mechanisms in multiple-seam mining focused mainly on load transfer during operation. However, recent studies have indicated that coal bumps may occur when the longwall layouts in multiple-seam mining are improperly designed. Hence, in this study, the boundary element model (BEM) program LaModel was employed to evaluate the stress analysis and total energy release (TER) in the specified case when the longwalls of the lower seam were extracted.

A total of eight strategies were proposed for the horizontal offsets of panel 9113. The model results indicated that the peak vertical stress on the edge of panel 9113 might drop from 70.9 MPa (zero offset) to 54.1 MPa (offset 60 m). In addition, the TER criterion for bump control in this study was set at 38.4 MJ based on the empirical approach. The TER analysis indicated that the peak TERs decreased as the offsets of panel 9113 increased; more importantly, the offsets of panel 9113 needed to be at least 50 m to prevent coal bumps according the empirical criteria proposed in this paper. Hence, to be more conservative, an offset of 60 m was ultimately adopted when developing the gateroads of panel 9113 in the field. Field observation showed that coal bumps were avoided successfully and the maximum roof-to-floor and rib-to-rib convergences were only 360 mm and 576 mm, respectively.

In this study, the use of TER for evaluation of coal bump potential was validated, based on past experience of successful working. However, the method was unsuccessful regarding coal bump potential in Crandall Canyon Mine in Utah (Sears and Heasley, 2009; Sears, 2009).Notwithstanding, the use of TER for coal bump risk assessments shows promise.

Acknowledgments

This work was supported by the Self-research Program of the State Key Laboratory of Coal Resources and Safety Mining of China through contract no. SKLCRSM08X04, the National Natural Science Foundation of China through contracts no. 51204166 and 51174195, and the Priority Academic Program Development of Jiangsu Higher Education Institutions through contract no. SZBF2011-6-B35. This support is gratefully acknowledged. The authors also wish to thank Dr. Keith Heasley (West Virginia University) for his valuable comments on this paper during its preparation.

References

Chekan, G.J. and Listak, J.M. 1993. Design Practices for Multiple-Seam Longwall Mines. IC 9360. US Bureau of Mines. [ Links ]

Dou, L. and He, X. 2001. Theory and Technology of Rock Burst Prevention. China University of Mining and Technology Press, Xuzhou. [ Links ]

Forrest, P., Haycocks, C., and Zhou, Y. 1987. Design of lower seam longwall operations in multiple seam mining. Proceedings of the 6th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. Peng, S.S. (ed. [ Links ]).

Haycocks, C. and Karmis, M. 1983. Ground Control Mechanisms in Multi-Seam Mining. Final report submitted to US Bureau of Mines, Office of Mineral Institutes. [ Links ]

Haycocks, C. and Zhou, Y.X. 1990. Multiple-seam mining - a state of-the-art review. Proceedings of the 9 th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. Peng, S.S. (ed. [ Links ]).

Heasley, K.A. 1998, Numerical Modeling of Coal Mines with a Laminated Displacement-Discontinuity Code. PhD dissertation, Colorado School of Mines. [ Links ]

Heasley, K.A., Worley, P., and Zhang. Y. 2003. Stress analysis and support design for longwall mine-through entries (a case study). Proceedings of the 22nd International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. [ Links ]

Heasley, K.A. and Agioustantis, Z.G. 2007. LaModel: a boundary-element program for coal mine design. Proceedings: New Technology for Ground Control in Multiple-seam Mining. IC 9495. National Institute for occupational Safety and Health, Washington, DC. [ Links ]

Holland, C.T. 1973. Mine pillar design. SME Mining Engineering Handbook, vol. 1, section 13.8. AIME. [ Links ]

Karabin, G. and Evanto, M. 1994. Experience with the boundary-element method of numerical modeling to resolve complex ground control problems. Proceedings of the 18th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. [ Links ]

Li, H., Liu, M., Kang, Q., and Zhai, X. 2000. Optimization of district mine layout in multi-seam mining: a case study. Proceedings of the 19th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. Peng, S.S. and Mark, C. (eds). [ Links ]

Maleki, H.N., Stewart, C., and Stone, R. 2007. Three-seam stress analyses at Bowie Mines, Colorado. Proceedings of the 26th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. Peng, S.S. et al. (eds). [ Links ]

Matetic, R.J., Chekan, G.J., and Galek, J.A. 1987a. Design considerations for multiple-seam mining with case studies of subsidence and pillar load transfer. Proceedings of the 28th US Symposium on Rock Mechanics, University of Arizona, Tucson, AZ. [ Links ]

Matetic, R.J., Chekan, G.J., and Galek, J.A., 1987b. Pillar Load Transfer Associated with Multiple-Seam Mining. RI 9066. US Bureau of Mines. [ Links ]

Mark, C. 2007. Multiple-seam mining in the Central Appalachian coalfields. Proceedings of the New Technology for Ground Control in Multiple-Seam Mining. IC 9495. National Institute for occupational Safety and Health, Washington, DC. [ Links ]

Oram, J.S. and Ponder, C.G. 1997. Measurement of effects of interaction and influence on mine layout design at Maltby Colliery. Proceedings of the 16th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. Peng, S.S. (ed. [ Links ]).

Peng, S.S. and Chandra, U. 1980. Getting the most from multiple seam reserves. Coal Mining and Processing, vol. 17. pp. 78-84. [ Links ]

Peng, S.S. 2007. Ground Control Failures - a Pictorial View of Case Studies. University pf West Virginia, Morgantown, W.V. [ Links ]

Peng, S.S. 2008. Coal Mine Ground Control. 3rd edn. University pf West Virginia, Morgantown, WV. [ Links ]

Salamon, M.D.G. 1990. Mechanism of caving in longwall coal mining. Rock Mechanics Contribution and Challenges. Proceedings of the 31st US Symposium on Rock Mechanics, Golden, CO. CRC Press, Boca Raton, FL. [ Links ]

Sears, M. and Heasley, K.A., 2009. An application of energy release rate. Proceedings of the 28th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. Peng, S.S. (ed. [ Links ]).

SEARS, M. 2009. Implementing Energy Release Rate Calculations into the LaModel Program. MS thesis, West Virginia University, Morgantown, WV. [ Links ]

Stewart, C., Stone, R., and Heasley, K.A., 2006. Mine stability mapping. Proceedings of the 25th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. [ Links ]

Zipf, R.K. 2005. Failure mechanics of multiple seam mining interaction. Proceedings of the 24th International Conference on Ground Control in Mining, West Virginia University, Morgantown, WV. Peng. S.S. (ed. [ Links ])

Paper received Aug. 2014

Revised paper received Jun. 2015