Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.8 Johannesburg Aug. 2015

http://dx.doi.org/10.17159/2411-9717/2015/V115N8A8

Mine Occupational Safety and Health Leading Practice Adoption System (MOSH) examined - the promise and pitfalls of this employer-led initiative to improve health and safety in South African Mines

M. HermanusI; N. CoulsonI; N. PillayII

ICentre for Sustainability in Mining and Industry University of Witwatersrand

IIIndependent Consultant

SYNOPSIS

This paper assesses the effectiveness of the Mine Occupational Health and Safety Leading Practice Adoption System (MOSH) and its potential to improve mine health and safety in South African mines. Developed by the Chamber of Mines, which represents the majority of the country's large scale mining employers, MOSH was devised to accelerate progress towards achieving health and safety milestones, which were set by tripartite agreement in 2003. The paper documents and builds on the findings of a study conducted by the Centre for Sustainability in Mining and Industry (CSMI) in 2011 that evaluated MOSH strategy, structures, and process of implementation. The study found that MOSH operated across the mining sector, was directed and dominated by experts and, despite best efforts to include other stakeholders, was led by employers. Statutory worker health and safety representatives and structures were not integrated into the complex change process developed by MOSH. The Mine Health and Safety Inspectorate (MHSI) and organized labour were ambivalent about direct involvement in MOSH and preferred regulatory measures to enforce the participation of mines. MOSH interventions were not targeted at mines with a poor health and safety record, and MOSH lacked a baseline from which to track impacts on sector-wide health and safety performance. The leading practices most widely adopted by mines were designed to improve, rather than fundamentally alter, existing practice. Although the depth of engagement with MOSH among stakeholders and on mine sites varied, mining companies, labour representatives, and the Mine Health and Safety Inspectorate (MHSI) saw the programme as significant.

Keywords: health and safety, regulatory framework, best practice, milestones

Introduction

In 2011, the Chamber of Mines commissioned the Centre for Sustainability in Mining and Industry (CSMI) to evaluate the progress and effectiveness of the rollout of the Mine Occupational Health and Safety Leading Practice Adoption System (MOSH). CSMI, based in the School of Mining Engineering at the University of the Witwatersrand, is an independent research centre conducting health and safety research relevant to all major stakeholders in the mining sector. The purpose of the evaluation was to identify the factors that enabled or hampered the adoption of new technologies or practices. The timing of the evaluation, two years before the deadline for the 2013 safety and health milestones, allowed time for adjustments to be made. This paper summarizes the results of the evaluation and includes further analysis and discussion of the nature of the programme and the conditions that act to advance it or it hold back.

Background

Health and safety in the South African mining sector is governed by the Mine Health and Safety Act (MHSA). The MHSA reflects an outcomes approach to regulation, based on risk assessment and risk management. It provides for extensive dialogue and consultation between the Mine Health and Safety Inspectorate (MHSI), which represents government, employers and organized labour on matters of policy, regulation, research, and the state of health and safety in the sector. The MHSA also authorizes the MHSI to enforce the provisions of the Act through issuing directives to take corrective action, halting activities that pose imminent and high levels of risk to health and safety, and administering fines. In addition, the MHSI is charged with the responsibilities of promoting health and safety through investigations and inquiring into the causes of accidents, initiating research, making health and safety data public, and issuing advice.

Tripartite engagement is formalized in the Mine Health and Safety Council (MHSC). This is a national structure established by the MHSA that considers the state of health and safety in the sector, proposes policy and legislation, commissions research, and provides advice to the Minister of Mineral Resources. Through the MHSC, organized labour, government, and employers come together to undertake their mandated joint responsibilities, which include a biennial review of health and safety. The review takes the form of a convention called the Mine Health and Safety Summit. At the Summit of 2003, the tripartite partners agreed to establish targets for health and safety, and intermediate milestones for the period 2003 to 2013 (DMR, 2013) (Table I). The 2010 Summit launched a framework that included guiding principles, commitments and action points, to shift health and safety culture, referred to in the sector as the Culture Transformation Framework.

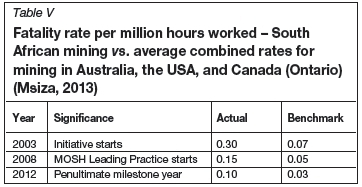

As seen in Table I, the goals for 2013 involved reducing the number of fatalities to levels attained by the mining sectors of Australia, the USA, and the Ontario province of Canada; and from 2013 onwards, eliminating new cases of silicosis and noise-induced hearing loss. The attainment of these milestones represented a considerable challenge.

Before MOSH began piloting leading practices to address health and safety challenges in 2008, the sector relied solely on the individual efforts of mining companies to achieve the milestones. MOSH represented a shift to collective and informed effort, active promotion of promising interventions, and engagement of the entire sector, across all commodities and all regions of the country.

The MOSH Leading Practice Adoption System

MOSH centred on the uptake of leading practices to address health and safety priorities and included both improved technology and procedures. The practices addressed four challenges in keeping with 2013 health and safety milestones, namely falls of ground; transport and machinery, relevant to the reduction of mine fatalities; and dust and noise, relevant to the elimination of silicosis and noise-induced hearing loss respectively. Table II summarizes seven leading practices promoted through MOSH at the time of the CSMI process evaluation.

Leading practices promoted by MOSH were already established in industry, not yet widely used across the sector, and judged to offer significant health and safety hazard mitigation potential. Identifying leading practice was the first step. The site at which a leading practice was first found was called the 'source' mine. The next major step involved piloting the leading practice in a second mine site, referred to as the 'demonstration' mine. To support piloting at the demonstration mine, research into the knowledge, attitudes, and values of workers, supervisors, and managers responsible for implementation was conducted, to inform subsequently developed behavioural communication and leadership plans. This research was referred to as understanding the 'mental models' of workers, supervisors, and management. The adoption process at the demonstration mine site was carefully documented and recommendations made about the process of adoption based on this experience. Once successfully demonstrated, the leading practice was then actively promoted for adoption across the industry as a whole.

The MOSH leading practice adoption system was systematically documented in a handbook which described the structures required for driving the programme, provided tools and advice for overseeing implementation, and documented processes for conducting workshops and other key activities. Other materials were also developed to support the adoption process, which included documentation on the MOSH portal, DVDs, and brochures.

The organizational structures of MOSH

The organizational structures for MOSH in 2011 (and which were still in operation at the time of writing of this paper) included Adoption Teams, a MOSH Task Force, a Learning Hub, and communities of practice. These structures provide strategic and operational focus, enable learning within the system, and guide and encourage implementation at mine sites. At the time of the evaluation the structures were constituted as follows:

> MOSH Adoption Teams existed for each area of leading practice aligned with the four priority health and safety challenges. These were led by one or two technical specialists, often seconded to the Chamber of Mines by industry for a minimum of six months (at the time of the evaluation). Rollout of leading practice across the industry proceeded under the leadership of the Adoption Teams

> The MOSH Task Force provided governance and oversaw the adoption activity. High-level industry representatives served on the MOSH Task Force. The responsibilities included ensuring that Adoption Teams were well aligned to industry needs, and that the needs of the teams were communicated to industry

> The MOSH Learning Hub, at the Chamber, was responsible for managing the MOSH Adoption Teams to maximize industry ownership, exposure, and buy-in

> Communities of practice were ad hoc structures that met to disseminate information on leading practices. Management, technical, and health and safety staff from mine sites were invited to attend a specific community of practice (also known as COPA) for a specific adoption practice. COPAs were facilitated in mining regions and often involved participants from across different mining companies and operations learning together.

Methodology of the evaluation study

Leading practices were largely piloted in demonstration mines in 2008 and rolled out across the industry from 2009 onwards. Although MOSH was designed to increase uptake though the active promotion and guided adoption of leading practices, the programme progressed slowly and unevenly, prompting the evaluation study conducted by CSMI. The evaluation was conducted between August and November 2011 by a multidisciplinary team of researchers from CSMI, including researchers with backgrounds in mining engineering and geology, health and safety regulation, public health, and sociology. The team included an experienced researcher fluent in indigenous languages.

The evaluation was a three-tiered study of the MOSH intervention. Data was collected and organized under three main themes: (i) oversight and governance, (ii) resourcing and capacity, and (iii) operational or mine-site level intervention. The study involved the collection of qualitative data through key informant interviews and focus group discussions. Data was collected from all levels of the MOSH intervention from senior industry leaders and technical experts through to teams of employees involved with the implementation of specific adoption methodologies. Underground/on-site visits at operations were also conducted to explore the specific context for leading practice adoption. The evaluation included an extensive review of MOSH documentation, including reports, minutes of meetings, and education and communication tools. In total fifteen people were interviewed about oversight and governance, and twenty individuals were interviewed about resourcing and capacity. The majority of these interviews involved officials and representatives from industry and the Chamber of Mines with direct responsibility for MOSH. Representatives from organized labour and the MHSI were also engaged for their perspectives on the governance of MOSH. Eight site visits to mines were conducted involving discussions with 119 individuals. Of this number, a total of 55 workers were reached through focus group discussions.

Three of the seven leading practices promoted by MOSH were selected for in-depth investigation by the research team. This was because they represented leading practices where there was greater uptake, documentation, and access to sites that could be followed from source to adoption mines. Table III summarizes in generic terms the selection of mines for participation in the evaluation. However, it also shows that at the time of the evaluation, only two of these practices actually followed the MOSH process to conclusion, from the source mine to the adoption mine.

The key evaluation questions and sub-questions considered by the research team are listed below.

How is the process of MOSH adoption happening at a site level? With a focus on:

> Understanding the MOSH process as it unfolds in practice from the source mine through to implementation at the adoption mine

> Assessing the key factors which facilitate and/or limit adoption

> Understanding how the process is currently monitored and evaluated

> Understanding the rollout of leading practices across industry using the adoption teams.

Assess the appropriateness and success of the existing MOSH structures, with a focus on:

> Assessing the performance to date of the Learning Hub, other key role-players, and other component structures

> Evaluating the governance and accountability structures of the Learning Hub

> Understanding the Learning Hub's relationships with key stakeholders and other bodies in the implementation of the MOSH leading practice system

> Understanding the division of labour between all the key role-players with regard to the implementation of the MOSH adoption system.

> Reviewing the capacity of the Learning Hub, other key role-players, and other component structures within a changing mining environment for meeting the MOSH mandate in future.

A limitation of the study was that the sample of leading practices examined largely represented the success stories of the MOSH leading practice adoption system. The motivation and resources at participating mine sites may not be representative of the sector as whole. Mines that were not participating in the MOSH intervention were not included in the evaluation and hence their accounts are absent from the findings and analysis.

Findings of the evaluation study

The findings of the evaluation point to MOSH success at a mine-site level with some serious gaps at other levels of the programme, including in some cases mine-site level gaps. The findings are presented under five headings, with quotes taken from the research interviews to illustrate the points made.

Success at mine-site level relied on interpretation and a customized fit

Successes at mine-site level were found to rely on both the ability of Adoption Team Leaders, as well as mine management to interpret, distil and tune the MOSH Adoption System for site-specific conditions (see Table IV).

At the level of mine site implementation, when mines had successfully committed to the adoption process there was often genuine engagement with the MOSH process. At the mines visited it was clear that management had invested significant resources in meeting the implementation requirements. This involved:

> Addressing problems arising during implementation

> Seeking, listening to, and acting on feedback

> Being prepared to go back to the drawing board when initial efforts failed

> Collecting data to support whether a leading practice was working or not

> With the exception of one site included in the evaluation visits, the communities of practice were described as a useful structure through which to share experiences.

It was at the level of the mine-site that the expertise and wisdom of the Adoption Team Leaders were widely appreciated. One of the key findings at mine-site level was that workers, supervisors, and mine management accepted and embraced the MOSH leading practices.

Responses to particular leading practices varied across mine sites as indicated in the accounts in Table IV. Certain leading practices were much easier to introduce. Entry examination and making safe far outstripped the progress made with other leading practices with respect to the number of mines adopting a leading practice. Investments in technology such as the Fogger dust suppression system or proximity detection systems presented much more complex challenges, both in terms of capital outlay and alignment with existing systems of risk management.

A gap in the MOSH process at the time of the evaluation was that MOSH did not provide guidance on when and how to engage with suppliers and original equipment manufacturers (OEMs). This was found to be particularly problematic when only one or two suppliers are available for a particular technology ('... there are not enough technicians to attend to its failures') and when technologies are being transferred across commodities and the supplier or OEMs are working out of their normal context.

The MOSH process was overly technical and complex

The overly technical and complex process of adoption implementation attracted a fair measure of criticism. The 48 steps of the MOSH adoption process captured in a complex handbook that includes 16 sections and 52 two worksheets and reference documents resulted in many individuals, even those intimately involved with the intervention, being unable to state clearly 'what is MOSH?' The various elements and steps clouded the central objective as the statements below attest.

'It's too many steps and the challenge is to make it much simpler. Mining people are simple people - we don't need laborious procedures. Decide what we are going to do and we do it and measure our progress. We are adding too much complexity to a simple matter.' 'The management steps can be put in a nutshell. We did this and did not fixate on a piece of paper.'

The complex process also meant that common-sense steps in a change management process, such as 'buy-in' for a new initiative, did not happen optimally. Rather, 'engagement' tended to be codified in the process of understanding 'mental models' and the preparation of 'communication and leadership plans.'

'Is it possible to use other terms than mental models "getting understanding of how people think" or "perception survey"?'

Workers and other role-players felt marginalized by the MOSH process

Codification also meant that labour representatives and other actors felt left out or excluded from important activities.

'With hindsight we should have involved the engineering and health/medical sections of our mine in the MOSH project.'

'I would say buy-in from underground teams is critical. This was made clear to me in the failure in ... leading practice. There is sometimes a fine line between consultation and buy-in. A pilot shouldn't be in one area but rather in a shaft or across a level because this is a better platform to roll out from. I don't have a recommendation to the MOSH process other than don't rush it and don't force feed . we followed the steps but we did not use the templates. Actually we used a mass meeting to kick-start the whole process.'

On paper, a strength of the MOSH process is its commitment to worker involvement; however, in practice this commitment and the activities designed to foster involvement (such as mental models referenced above) did not always translate into a whole-hearted experience of participation. Workers were prepared for the introduction of changes through MOSH through a combination of demonstration, one or more days of training, and on-the-job coaching. Workers did not recognize the informal on-the-job coaching as training.

'Demonstrationfor one day! You can't call that training!'

'We train ourselves ... I talk to my team mate.'

Evaluation respondents used the term 'resistance' fairly loosely to describe all the concerns, fears, and objections to the MOSH process. The basis for this resistance could be well-founded. For example, leading practices can interfere with the pressure to meet production targets. Entry examination and making safe can and did result in longer periods of time spent securing the work area at the start of a shift, as the following quote from an underground supervisor indicated.

'Although we were not very supportive at the introduction stage of the practice, as it affected our production rate, we can see the benefits now: it gives a clear message to the workforce that we care for their safety. The unions and associations are supportive.'

There was an absence of a cogent strategy

The MOSH Task Team, constituted by industry representatives, was considered as the primary structure involved with MOSH governance.

Respondents reported that MOSH did well in breaking down traditional hierarchical and inter-company barriers and helped to raise the profile of occupational health and safety issues in the workplace. However, elsewhere in the evaluation findings it was also reported that the biggest obstacle to widespread support for MOSH was the 'not invented here' mentality that results in disinclination at lower levels to implement the strategy.

'The silo mentality is starting to disappear; we are in this as an industry together.'

'At least the CEOs are starting to singfrom the same hymn sheet - we face the same challenges and are starting to get solutions.'

Given the scope of the programme and the tasks involved, the evaluation team found, surprisingly, that MOSH lacked a cogent strategy. Dissimilar ideas about the intention(s) of MOSH surfaced in the responses of individuals at different levels of the programme to the question, 'what is MOSH?' At the operational site level, MOSH practitioners talked about 'finding leading practice' or 'sharing leading practice.' In contrast, role-players at the level of governance and oversight placed more emphasis on the change management component of MOSH.

'MOSH is a comprehensive change management system.' 'MOSH changes the occupational health and safety culture in the industry.'

Although most respondents agreed that the MOSH initiative was in part a response to the 2013 milestones and that the impact of MOSH should be benchmarked against them, no hard success measures were applied to MOSH at the time of the evaluation. The 'number of mines adopting' was the most frequently quoted measure of MOSH progress, with little or no reference to the limitations of such a measure. Other potential measures quoted by interviewees were reducing fatalities, creating a single industry standard, enhancing the skills of workers, and serving as a culture transformation framework.

The absence of a well-articulated strategy also meant that the Adoption Teams were faced with issues that they were unable to resolve. For example, it was acknowledged by the Dust Adoption Team that some of the leading practice technologies promoted through MOSH sat low down in the hierarchy of controls and posed a dilemma for practitioners who understand first principles. Over-simplifying the strategy or target setting for MOSH could result in leading practices being taken off-the-shelf rather than being an integral component of a well-reasoned health and safety risk management system at a specific mine site. If the adoption of leading practice was not based on risk management principles, MOSH could be accused of simply 'selling' leading practice. The inclusion of MOSH in the amended 2010 Mining Charter (refer to the Discussion section) was cited as an illustration of this problem.

'Mining Charter both a driver and now a threat (compliance thereof). Not based on risk management but expectations of implementing a leading practice.'

The lack of cogent strategy also meant that decisions about targeting priority environments and/or mining commodities for leading practice were not made. The Transport and Machinery Adoption Team had an overwhelming task demonstrating the proximity device in three different setting: coal and hard rock trackless and hard rock railbound machinery.

'We felt people will respond negatively to us if we just select hard rock and railbound transport, although this is where the number of fatalities are found - we haven't targeted our intervention.'

It was striking how little power the existing structure felt it had to influence strategy. MOSH governance could be concluded to be 'everybody else's business.' Problem companies with poor health and safety records could not be targeted by the existing MOSH structures; a point that is returned to in the discussion below.

'There is no process for targeting problem companies.'

The most constructive suggestions regarding the way forward were that the tripartite MHSC should develop strategy and that the 2013 milestones could be used as a basis to set further targets for the next decade.

MOSH was industry- and expert-led rather than led by tripartite partners

While MOSH made provision for the input of government and labour representatives at all stages of the MOSH process, such involvement was patchy and particularly superficial in planning workshops and decision-making structures of the programme. This underpined the observation that the Chamber of Mine largely drove the programme on its own. Consequently, technical expertise and employer leadership characterized the MOSH intervention, and this steered the evaluation team to describe the intervention as 'expert-led.'

'As labour we were brought in very late. Labour needed to be part of the research process.'

'... has been searchingfor experts, a range of experts who can bring different expert dimensions to bear.'

'If a person is not a recognized leader in the industry then you can't succeed.'

The MHSI expressed ambivalence about MOSH for a number of reasons. First, it would prefer to engage with the programme though the MHSC, and secondly it was uncomfortable with the idea of promoting practices low down the hierarchy of controls. The MHSI also felt that the Chamber of Mines should act against its members with the worst health and safety performance. The fact that the Chamber of Mines is not representative of all mines was also a challenge to the MHSI.

Organized labour regarded the impact of MOSH as significant at some mine-site levels but negligible in the mining sector as a whole. Trade unions regarded the involvement of workers in making informed decisions as an important outcome of MOSH. Labour felt they had an important role to play at all levels of the MOSH intervention, but recognized their limited capacity to do this. Like the MHSI, they also felt unable to resolve and articulate their own role within MOSH and that the MHSC is the correct place for strategic discussions about MOSH.

Discussion

What is the 'promise' MOSH represented? Evidence at a site level is that MOSH leading practices would be transferred between different sites, and where successfully transferred, could have beneficial effects. However, as shown in the evaluation, not all practices were easily replicated on different mines, and relevant leading practices or technologies were not necessarily taken up where they were most needed. This meant that the potential of MOSH was not fully realized. The MOSH evaluation study found that the programme did not target specific mines where improvements in health and safety performance would be of most significance for the entire sector. Thus the fundamental logic that runs through MOSH -change your health and safety culture, introduce effective technology and procedures, and improve the sectors' health and safety performance - seemed to falter at the first post.

This begs the question as to whether there were gaps in the underlying or prevailing wisdom that were pertinent to the prospects of MOSH as a premier vehicle for improving health and safety. This is particularly important in the light of the new health and safety milestones that were set for the South African industry in 2014. In addition, what other considerations would make MOSH worthy of continued support and investment of time and resources?

The discussion here explores these questions by considering three areas that represent both the promise and the pitfalls of MOSH. These are the contribution of MOSH in the present climate of health and safety improvement; the exercise of leadership for MOSH within the health and safety regulatory framework; and readiness for change and worker participation in MOSH at the mine-site level.

The contribution of MOSH to sector-wide health and safety performance

The data in Table V summarizes the fatality data at the start, mid-term, and the year preceding the end of the period for which the milestones apply. It was estimated that the safety performance of the South African mining industry, measured as fatality rate per million hours worked, must have improved by at least 20% per year to reach the average combined fatality rates of Australia, the USA, and Ontario (Canada) by 2013, (DMR, 2011; van der Woude et al., 2004, p. 6). While the South African mining sector had significantly closed the gap between itself and the benchmark countries in terms of fatality rates, the actual number of fatalities remained high, at 112 in 2012; and the year-on-year improvements were more modest than planned. The most significant reductions in the actual numbers of fatalities were achieved on coal mines (-30%) followed by gold mines (-18%).

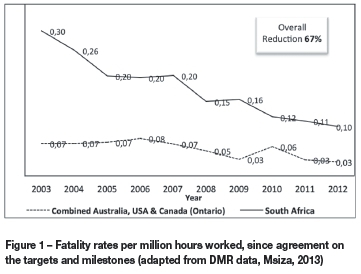

Figure 1 shows how the rate of fatalities in South African mines improved over time relative to the benchmark over the period 2003 to 2012 (Msiza, 2013).

Fatality figures were the starting point for the risk assessments that illustrated the importance of specific leading practices. Using fatality figures from 2009 for falls of ground, it was estimated that appropriate interventions could save up to 129 lives per year. However, although the goal of MOSH is to impact on industry-wide health and safety performance, the improvements that have been achieved across the sector have not been attributed (other than in general terms) by the Chamber of Mines or the MHSI to any specific interventions promoted through MOSH, such as netting and bolting safety systems (Creamer, 2013; DMR, 2012).

Data of similar detail was not available for health, but progress was described as follows. Exposures to crystalline silica reported to the MHSI were all less than the occupational exposure limit of 0.01 mg/m3, but cases of silicosis continued to be diagnosed among miners. Whether the target of no new cases among previously unexposed individuals was achieved was unclear. In 2012, 1075 miners were diagnosed with noise-induced hearing loss of occupational origin, and the largest numbers were associated with gold and platinum mining (422 and 368 respectively). According to the MHSI, there was 'no significant improvement on occupational disease' (Msiza, 2013).

The difficulty of attributing safety improvements to MOSH was compounded by the fact that other major developments were unfolding at the same time, such as an initiative to change the culture of the mining sector, efforts to increase training of safety representatives, pressure from MHSI on mines to implement the outcomes of research undertaken through the MHSC, and the MHSI's more forceful approach to enforcement (Vogt, et al., 2011; Creamer, 2012). In addition, various companies had embarked on their own initiatives to improve health and safety (Faurie, 2011). Without an established baseline and mechanisms to track improvements at site level, the impact of MOSH could not be ascertained reliably against this backdrop. The problem was identified in the evaluation study and persists, although other measures of MOSH progress have subsequently been embraced.

For example, the indicator for the number of adopting mines was poorly selected and the reach of the programme into the industry could not be assessed. The underlying reasoning for this was that individual mine sites were at different stages of adoption, some of which were complex and took months, if not years, to resolve, rendering the indicator 'number of mines adopting meaningless over time. An exception was the leading practice for 'entry examination and making safe', which far outstripped other leading practices in terms of its spread into the industry. Notably, this practice necessitated a change in procedure rather than the introduction of new technology.

In addition to parallel initiatives and the absence of baseline data, the impact of MOSH was also obscured by changes in reporting requirements in the amended Mining Charter in 2010 (DMR, 2010), the subsequent 2012 Industry Mining Charter Health and Safety Report (Chamber of Mines, 2012), and an 'Adoption Scorecard' introduced by the Adoption Teams within MOSH. Mines were required to report at first the number of mines adopting leading practice, and thereafter the proportion of adopting workplaces relative to the number of workplaces at which leading practices should be adopted.

However neither the Charter and nor the scorecard provided the necessary baseline to support meaningful measures of outcome and impact. The number of work sites adopting, number of teams trained, and units installed among others were the only measures of progress within MOSH. Appropriate outcome measures could be expected to include relevant health and safety leading indicators, and impact measures relevant lagging indicators of health and safety performance. However, none of this was possible without a baseline that enables tracking.

MOSH and the exercise of leadership within the health and safety regulatory framework

The inception, implementation, and growth of MOSH should be understood within the context of health and safety regulation in the mining sector in South Africa.

South Africa's health and safety legislative environment in the mining sector is guided by outcomes-based legislation that embodies general responsibilities for employers to provide safe and healthy workplaces, self-regulation, and participatory arrangements, allowing employers through engagement with workers to determine how particular outcomes are to be achieved. 'A performance standard specifies the outcome required but leaves the concrete measures to achieve that outcome up to the discretion of the regulated entity.' (Coglianese et al., 2002, p. 3) In other words, it is not prescriptive. 'In contrast to a design standard or a technology-based standard that specifies exactly how to achieve compliance, a performance standard sets a general goal and lets each regulated entity decide how to meet it' (Coglianese et al., 2002, p. 3). Outcomes-based legislation creates space for national health and safety strategy. The 2013 health and safety milestones are an example of this.

South Africa is not alone in adopting an outcomes-based approach to health and safety legislation. The Mine Health and Safety Act (MHSA) 29 of 1996 is shaped by the approach to health and safety accredited to the British 'Robens Committee' (Robens, 1972) that concluded that 'apathy', both on the part of employers and employees, was significantly contributory to poor health and safety outcomes. The recommendations of this Commission ushered in an era of health and safety practice that arises from the idea the there is a 'natural identity of interests between employers and employees' (Robens, 1972, p. 21) on issues of health and safety. The main features of the Robens model are that employers have primary responsibility for risk management, and that workers are party to decisions about how best to address health and safety risks through elected health and safety representatives and structures such as employer-employee health and safety committees. All of these are features incorporated into the MHSA. Although widely applied, the Robens model is also criticized as being too business-friendly, institutionalizing of the concept of self-regulation, and glossing over fundamental social conflict (Tombs and Whyte, 2012). The last point, about overlooking conflict, seems to have particular relevance for the South African mining sector, in which both class and racial divisions, often coinciding, play out.

To elaborate, South African outcomes-based health and safety legislation was introduced into a mining context shaped by apartheid and a skewed economic system that marginalized and divided people on racial grounds. Mining was at the heart of the apartheid economy, and mining-related legislation until the late 1980s formally discriminated against black South Africans, who make up the majority of the population, by restricting them to manual work at the bottom of the employment hierarchy. Black mineworkers were confined to hostels and inferior rates of compensation were paid to black miners for occupational injury or ill-health. Estimates are that over 70 000 black miners died in mine accidents since the inception of mining, and an even larger number contracted silicosis. The 1994 Leon Commission of Inquiry into Safety and Health in the Mining Industry (Leon Commission, 1995) and the subsequent MHSA were early advancements associated with the postapartheid Mandela government. Sector-wide studies show that the apartheid legacy is still felt by workers (Hermanus et al., 2010; Shaw et al., 2010, 2011), especially with respect to racism, the practice of bonus payments, and a culture of blame. It is within this context that the South African experience of health and safety outcomes-based legislation is operative.

The MOSH initiative is in essence a voluntary industry-level action, which the Robens Committee regarded as having high potential for improvements:

'Progressive employers recognise that firms within an industry should work towards higher standards collectively, so that progress is not impeded by fear of unfair competitive advantage. There is virtually unlimited scope for practical work by industry-based safety bodies which can collate and interpret statistics, publish information, undertake technical surveys and research, and provide advisory services to individual firms, and liaise with government departments and inspectorates. Through these means each industry can work towards the solution of its own special problems.' (Robens, 1972, p. 15)

However, in the South African context, as MOSH sought to shift industry practices, it required the support and cooperation of labour and the state. Yet the initiative was conceived and promoted outside of the tripartite forums that enable government, labour, and the employers to work together. Both organized labour and the MHSI expressed a desire for MOSH strategy to be resolved through the MHSC, although this could change the voluntary status of the initiative. Nevertheless, as conceived in legislation, the MHSC's functions are consistent with Robens Committee's ideas.

The insistence of both labour and MHSI, that participation in MOSH should not be voluntary, was subsequent to the 2011 evaluation, and achieved by incorporating MOSH leading practices into the Mining Charter. The Charter is a regulatory instrument for 'transforming' the mining sector in South Africa. The scorecard and associated reporting template require companies to report on both the consideration and uptake of MOSH leading practices (DMR, n.d. (a), (b)). Thus the problem posed by the voluntary nature of MOSH of uptake at poorly performing mines was offset by developments in the regulatory environment.

The translation of a voluntary initiative into a regulatory requirement underscores a difficulty at the heart of the South African tripartite system, namely that the main employer body is not trusted (Shabangu, 2011) and has difficulty taking forward major voluntary initiatives without the expressed endorsement of stakeholders. Changes to the mandate of the MHSC, in which the role of the Minister of Mineral Resources (rather than the tripartite MHSC) is central to policy-making, reflect these dynamics (Odendaal, 2013). In addition, stakeholders prefer an arms-length relationship with employers, as one way of being seen to preserve their own integrity. This has meant that MOSH is endorsed through enforcement rather than ongoing engagement over the content and impact of the programme.

Subsequent to the completion of the CSMI evaluation, the Learning Hub established, in addition to MOSH Task Team, the 'MOSH Advisory Group' to specifically include representatives from labour and the MHSI. However, this does not necessarily strengthen engagement. MOSH needs to deal with the problem of engagement and involvement of other stakeholders within the MHSC, rather than bypass it through establishing non-mandatory advisory structures.

Readiness for change, worker participation, and MOSH at the mine-site level

The MOSH initiative reflects the Robens Committee's assertion that '7he primary responsibilityfor doing something about present levels of occupational accidents and disease lies with those which create the risks and those who work with them' (Robens, 1972, p. 7), but runs into difficulties to those experienced elsewhere in respect of fully engaging the workforce. This is evident at both the national level of MOSH leadership (as discussed above) and at minesite implementation level as reflected in the findings. It is the latter that is discussed here.

One of the underlying assumptions of MOSH was that the MOSH process of engagement could induce a process of change. Numerous steps and templates in the MOSH handbook codified a process of engagement that encouraged practitioners to get in touch with what workers specifically were thinking and to ensure that mine-site leadership carried an appropriate message. However, findings in the evaluation point to the difficulty of achieving this without reference to the specific environment in which MOSH was being introduced. The contexts of each mine site varied, and hence the call by mines themselves for guidance about basic principles, and not ever-increasing detail. Therefore more flexibility was required which allowed mines to interface with the MOSH process differently, based on the level of readiness to embrace change.

Readiness is shaped by a number of factors (Hopkins, 2012; Novatis et al., 2012) It is shaped by whether managers at every level in an organization recognize the importance of dealing with health and safety risks and make this a priority; whether organizations have properly engaged workers to obtain their support and cooperation for efforts aimed at improving health and safety; and whether the experience and knowledge of workers of health and safety risks is understood and appreciated. It further extends to ensuring that processes are in place to secure and maintain the appropriate skills that are important in addressing health and safety risks. This also applies to different levels in an organization, so that workers, supervisors, managers, and technical support teams have complementary and integrated responsibilities for health and safety. Related factors that are equally important to an organization's ability to address health and safety risks are quality of leadership, culture (especially a sense that organizational culture is just), trust, engagement, and worker participation (Gunningham, 2008; Dekker, 2008). These have specific relevance in South African mining, as discussed earlier.

Although MOSH embodied tools to address leadership practice, communication, worker perceptions, and attitudes, the problem of deep-rooted mistrust and all that flows from it were not specifically acknowledged or addressed. This could be achieved by linking to the industry-wide 'Culture Transformation Framework' (MHSC, 2011) which supports initiatives to shift the culture of the industry.

Linked to the issue of organizational readiness for change is the observation that the MOSH process did not incorporate the role of workers in health and safety as envisaged by the MHSA. At the site level, the expert-led paradigm of MOSH kept labour at the edge rather than central to improved health and safety. Worker health and safety representatives and employer-worker health and safety committees were not central to the MOSH process at the site level. Engagement with the site level health and safety committee and/or training of health and safety representatives specifically were not a feature of MOSH activities on site, but could be. During the evaluation, respondents from organized labour reported being brought into the MOSH process at a late stage. Meeting with the health and safety committee should be at an early stage of engagement and a key step in establishing buy-in at a mine.

MOSH collapsed the process of engagement with workers, to focus mainly on the collection of data to support the development of mental models about specific health and safety concerns and interventions. These models profile the knowledge, attitudes, and perceptions of workers and are used to shape behavioural communication and leadership behaviour plans. These types of studies can be time-consuming and require that interviewers are properly trained to conduct interviews. One of the recommendations of the evaluation was that this type of study could be commissioned at a national/regional and/or commodity level rather than having to be repeated at each mine site. Communication and leadership plans could be adapted for specific mine sites. However, more importantly this type of approach is fundamentally focused on building a process for change through understanding individual behaviour, when in fact health and safety is fundamentally about building an effective system (in which, obviously, consideration of individual behaviour has a role, but is not the driver).

Without sufficient integration into the existing health and safety system, MOSH effectively minimised the opportunity for engagement with labour. Engagement with workers should include active engagement with health and safety worker representatives and labour structures at the mine site, as well as with regional and national labour structures.

The extent to which the present MOSH initiative misread the process of engagement is further evidenced in the introduction to MOSH, subsequent to the 2011 evaluation, of 'simple leading practices.' Simple leading practices are examples of technology changes that can be made without needing to engage, such as winch covers to minimize dust. This new focus was presented as 'quick wins', but also perpetuated a legacy of an industry unable to resolve issues of engagement and fundamental change, albeit in a difficult and complex environment.

Conclusions

MOSH is an ambitious initiative with complex technical, structural, and procedural elements. It was clear the mining industry as a whole engaged with MOSH to various degrees, and labour and the MHSI saw MOSH as significant.

The full impact of MOSH and its sustainability across the mining sector was not clear. It was evident that where MOSH worked well, mines usually considered and implemented several leading practices simultaneously. This was particularly the case when a mine subscribed to a broad strategy of improvement and culture change. In these instances there appeared to be greater capacity to absorb the processes and technologies of the MOSH adoption system. Difficulties in assessing the impact of MOSH arose from many quarters within the MOSH programme itself, which did not clearly define and measure its impact, and the fact that MOSH was one of many initiatives to improve health and safety in South African mines. Many of these were launched and operated simultaneously, and the effect of one on the other was never considered. An example of this was how a tough new regulatory approach, the culture transformation framework, and the MOSH processes could be expected to interact.

There are also factors that hamper MOSH which are specific to the operational environment of South African mines and the nature of the Chamber of Mines.

> Although the Chamber represents the majority of mine employers, it is unable on its own to take forward national-scale decisions even when these may be in the best interests of the workers and people affected by mining. Thus one of the unspoken challenges associated with MOSH at the time of the evaluation was that it was championed by an employer body with primarily an advocacy role, which relied solely on voluntary uptake by mining companies

> As found in the evaluation, the Chamber, as a voluntary organization representing employers, could not set hard performance targets for mines. Consequently the costs and resources necessary to sustain MOSH over time were likely to have diminishing returns because the initiative could not target companies with the poorest health and safety records, which in turn could chose not to adopt MOSH for their own reasons

> While the MHSI chose not to participate in the design and planning of MOSH, or actively lead the uptake of leading practices, two years after MOSH's establishment it provided indirect support through regulation. The incorporation of MOSH into the Mining Charter and related scorecard introduced pressures to comply, something that the Chamber was unable to do. The effect of this might still be, ironically, to mask and diminish the problem of not being able to target mines where performance is wanting.

Another factor that affects MOSH was that the programme did not formally recognize that different organizations were not able to initiate and absorb change in the same way. However, in the Adoption Teams and on mine sites, the organizational context of health and safety did come into play, and found expression in the concerns raised over the complexity and highly-structured nature of the process, and the adaption of the process on site.

Finally, it is apparent that the MOSH process unfolded outside the formal health and safety system described in the MHSA. Whether mines can find ways of drawing health and safety committees and health and safety representatives into the programme is a matter worthy of further consideration.

References

Chamber of Mines. Not dated. MOSH - Learning From Each Other by Learning Practice Adoption. http://www.mosh.co.za/ [Accessed 13 January 2014]. [ Links ]

Chamber of Mines. 2012. Mining Charter, 2012 Health and Safety Report. Chamber of Mines of South Africa, Johannesburg. [ Links ]

Coglianese, C. and Lazer, D. 2003. Management-based regulation: prescribing private management to achieve public goals. Law and Society Review, vol. 37, no. 4. pp. 691-730. [ Links ]

Coglianese, C., Nash, J., and Olmstead, T. 2002. Performance-Based Regulation. Prospects and Limitations in Health, Safety, and Environmental Protection. Regulatory Policy Report no. RPP-03. Harvard Kennedy School, Harvard University, Cambridge MA. [ Links ]

Creamer, M. 2012. Section 54 stoppage issue dominates Shabangu media conference. Mining Weekly, 20 March 2012. wwww.miningweekly.com [Accessed 17 January 2014]. [ Links ]

Creamer, M. 2013. SA mines Installing 170 000 safety bolts a day, 200 km safety netting. Mining Weekly, 27 November 2013. www.miningweekly.com [Accessed 10 December 2013]. [ Links ]

Dekker, S. 2008. Just Culture. Who gets to Draw the Line? Springer-Verlag, London. [ Links ]

DMR (Department of Mineral Resources). 2010. Amendment of the Broadbased Socio-Economic Empowerment Charter for the South African Mining and Minerals industry. Pretoria. [ Links ]

DMR (Department of Mineral Resources). 2011. Mineral resources - about mine heatlh and safety. http://www.dmr.gov.za/mine-health-a-safety.html [Accessed 15 January 2014]. [ Links ]

DMR (Department of Mineral Resources). 2012. Annual Report 2011/2012. Mine Health and Safety inspectorate, Pretoria. [ Links ]

DMR (Department of Mineral Resources). 2013. Mineral resources - about mine health and safety. http://www.dmr.gov.za/mine-health-a-safety.html [Accessed 11 December 2013]. [ Links ]

DMR (Department of Mineral Resources). Not dated (a). Mining Charter Reporting Template, Final. Pretoria. [ Links ]

DMR (Department of Mineral Resources). Not dated (b). Scorecard for the Broad-Based Socio-Economic Empowerment Charter for the South African Mining industry. Pretoria. [ Links ]

Faurie, J. 2011. SA faces challenges in entrenching safety culture. Mining Weekly, 22 July 2011. www.miningweekly.com [Accessed 15 November 2013]. [ Links ]

Gunningham, N. 2008. Occupational health and safety. Worker participation and the mining industry in a changing world of work. Economic and Industrial Democracy, vol. 29, p. 336. [ Links ]

Hermanus, M., Coulson, N., and Magner, C. 2010. Creating a Shared Approach to Improving Safety in Mining "A White Flag Every Day". CSMI, University of the Witwatersrand and REOS, Johannesburg [ Links ]

Hopkins, A. 2012. Disastrous Decisions -The Human and Organisational Causes of the Gulf of Mexico Blowout. CCH, Australia. [ Links ]

Leon Commission. 1995. Report of the Commission of Inquiry Vols 1 and 2. Department of Mineral Resources, Pretoria. [ Links ]

Mine Health and Safety Council. 2011. Zero Harm through Action - Culture Transformation Framework for the South African Mining Sector. Johannesburg. [ Links ]

Msiza, D. 2013. A Reflection of the Progress on the 2003 OHS Milestones. MineSafe 2013. Mine Health and Safety Inspectorate, Department of Mineral Resources, Pretoria. [ Links ]

Novatis, E., McCormick, P., Woodside, E., and Lardner, R. 2012. Beyond Bulletins and Presentations: Use of Scenarios to Learn from Accidents. The Keil Centre, UK. [ Links ]

Odendaal, N. 2013. New mine health and safety act raises questions. Mining Weekly, 25 November 2013 www.miningweekly.com [Accessed 25 November 2013]. [ Links ]

Pienaar, G. J. and du Plessis, J.J. 2009. Meeting and exceeding the occupational hygiene milestones. Hard Rock Safe Safety Conference 2009. Southern African institute of Mining and Metallurgy, Johannesburg. pp. 231-234. [ Links ]

Robens, L. 1972. Safety at Work. Report of the Committee. Government Report, United Kingdom. Health and Safety Executive, Bootle, Merseyside, UK. [ Links ]

Shabangu, S. 2011. Keynote Address by Ms S Shabangu, Minister of Mineral Resources, at the Mine Health and Safety Council (MHSC) Summit at Emperor's Palace, 17 November 2011. [ Links ]

Shaw, A., Blewett, V., and Schutte, S. 2011. International Frameworks, National Problems: Mining OHS regulation in South Africa and Australia. 34th International Conference of Safety in Mines Research Institutes, New Delhi, India, 7-10 December 2011. pp. 545-554. [ Links ]

Shaw, A., Schutte, S., Cox, S., Blewett, V., Milanzi, L., Moraba, T., Formanowicz, A., and Mokoena, A. 2010. Changing Minds, Changing Mines: Final Report to the Mine Health and Safety Council. Mine Health and Safety Council, Johannesburg. [ Links ]

Tombs, S. and Whyte, D. 2012. Reshaping health and safety enforcement: better regulation. Making Employment Rights Effective. Dickens, L. (ed.). Hart Publishing, Oxford, UK. pp. 67-86. [ Links ]

Van der Woude, S. 2014. Employer Summit 2006, Improvment Required for Milestones. [ Links ]

Van der Woude, S., Stewart, J., Ally, I., and Leburu, T. 2004. Strategies for Sustainable Improvement in Safety Performance. 0141206-COM-Safety paper-final 6 Dec 04- SvdW-c7. Chamber of Mines, Johannesburg. [ Links ]

Vogt, D., Durrheim, R, and McGill, J. 2011. Submisson: State Intervention in the Mining Industry. Prepared for the African National Congress. CSIR,.Johannesburg. [ Links ]

Paper received May 2014

Revised paper received Dec. 2014