Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.5 Johannesburg May. 2015

GENERAL PAPERS

Equipment selection based on the AHP and Yager's method

M. Yavuz

Eskisehir Osmangazi University, Mining Engineering Department, Turkey

SYNOPSIS

One of the challenging problems for optimization in mining operations is to choose the best equipment among the alternatives. Equipment selection is an important task for mine management due to its operational cost, and is also an integral part of mine planning and design. Equipment selection is not a well-defined process because it involves the interaction of several subjective factors or criteria. Besides, decisions are often complicated and may even embody contradictions. Therefore, equipment selection is considered as a multi-criteria decision-making process, and suitable decision-making methods should be employed in this process. In this study, the loader selection for Aegean Lignite Colliery was made by using both the analytic hierarchy process and Yager's method. Owing to the misusage of Yager's method in the past, a new procedure is proposed in this paper for making proper decisions. It is highly recommended in this purposed method that criteria or alternatives should be grouped so as not to exceed the limitations of human performance (nine criteria/alternatives). The most appropriate solution for the loader selection was investigated by obeying this limitation for each method, and the results were compared. At the end of the decision-making process, a sensitivity analysis was applied for each method in order to see how a criterion affects the final decision. The advantages and disadvantages encountered during the application of each decision-making method are presented.

Keywords: AHP, Yager's method, decision making, loader selection

Introduction

Multiple-criteria decision-making (MCDM) is one of the most considered branches of operation research. MCDM refers to making decisions that involve multiple, usually conflicting, criteria. The problems in MCDM are classified into two categories: multiple-attribute decision-making (MADM) and multiple-objective decision-making (MODM). However, the terms MADM and MCDM are often used to indicate the identical class of models and are confused in practice. Usually, MADM is used when the model cannot be stated in mathematical equations, otherwise MODM is used (Hwang and Yoon, 1980).

Decision-making is an important task in mining engineering projects, as in other engineering branches. Every mining engineer makes several decisions in daily mining applications. Most of the decisions made by mining engineers are completely instinctive, drawing from their past experience; therefore no decision-making method is applied.

Equipment selection is one of the most prominent problems in mining engineering. Mining engineers have to make difficult decisions during the equipment selection stage. As the decisions have a strong influence on the economic life of any mining scenario, they are considered as complex MADM problems. Therefore, the decision-maker can evaluate the subjective criteria concerning the problem of equipment selection. The decision-maker wishes to consider more than one objective criterion for the equipment selection stage. Among the number of alternatives, the most suitable equipment must be selected according to the objectives and alternatives. MADM applications can assist the decision-maker in achieving the optimal solution. In the mining industry, MADM methods can be applied for equipment selection because these methods include subjective and objective criteria that affect the selection among alternatives.

A review of the literature reveals that decision-making techniques have been used in different types of mining applications (Acaroglu, Feridunoglu, and Tumac; Alpay and Yavuz, 2007, 2009; Ataei, 2005; Ataei et al., 2008; Bitarafan and Ataei, 2004; Elevli and Demirci, 2004; Kazakidis, Mayer, and Scoble, 2004;, Kesimal and Bascetin, 2002; Kluge and Malan, 2011; Namin et al., 2008; Yavuz, 2008; Yavuz and Alpay, 2008; Yavuz, Iphar, and Once, 2008).

In this paper, two different MADM methods - the analytic hierarchy process (AHP) and fuzzy multiple-attribute decisionmaking (FMADM) - are applied to select the loader for an open pit mine, and the solutions are compared.

Method

Equipment selection is important and difficult task to perform because of the need for handling many criteria simultaneously in the decision-making process. The number of criteria is important for arriving at the right decisions. A maximum of nine criteria can be handled in decision-making problems because of the general limitations of human performance (Saaty and Ozdemir 2003). These limits are widely reported in the literature as the 'memory span', 'attention span', 'central computing space', and 'channel capacity' (Ozdemir, 2005). If the pairwise comparison matrixes are formed without considering these limits, then inconsistencies will likely occur. Even when the matrix is consistent, the matrix will likely not be valid. Therefore, the correct usage of the selected decision-making method is important to ensure the proper decisions. Because of the limitations mentioned in the AHP method, the total number of criteria for the Yager's method should also be less than nine (Yavuz and Alpay, 2007).

AHP method

The AHP method developed by Saaty represents the interaction of multiple factors in complex unstructured situations (Triantaphyllou, 2000). This method is based on the pairwise comparison of components with respect to attributes and alternatives. A pairwise comparison matrix, nxn, is constructed, where n is the number of elements to be compared. This method is applied for hierarchical problem structuring. The problem is divided into three levels: the problem statement, the object identification to solve the problem, and the selection of the evaluation criteria for each object. After structuring the hierarchy, the pairwise comparison matrix is constructed for each level in which a nominal discrete scale from 1 to 9 is used for the evaluation (Table I) (Saaty, 1980, 2000).

The next step is to determine the relative priorities of the criteria or the alternatives implied by this comparison. The relative priorities are determined using eigenvectors. For example, if the pair comparison matrix is A, then the following can be written:

To calculate the eigenvalue ƛmaxand eigenvector w=(w1, w2,..., wn), the weights can be estimated as relative priorities of the criteria or alternatives.

Because the comparison is based on a subjective evaluation, a consistency ratio is required to ensure the accuracy of the selection. The consistency index (CI) of the comparison matrix is computed as follows:

where ƛmaxis the maximal or principal eigenvalue, and η is the matrix size. The consistency ratio (CR) is calculated as:

where RI is the random consistency index. Random consistency indices are given in Table II (Saaty, 2000).

In general, a consistency ratio of 0.10 or less is considered acceptable. In practice, however, consistency ratios exceeding 0.10 occur frequently.

FMADM method

FMADM methods have been developed because of the lack of precision in assessing the relative importance of attributes and the performance ratings of alternatives with respect to an attribute. This imprecision may arise from a variety of sources, such as unquantifiable information, incomplete information, unobtainable information, and partial ignorance (Chen and Klein, 1997).

The main problem of a fuzzy MADM is to select/prioritize/rank a finite number of courses of action (or alternatives) by evaluating a group of predetermined criteria. Thus, to solve this problem, an evaluation procedure rating and ranking (in order of preference) of the set of alternatives must be constructed. The fuzzy MADM problem is described below:

1. A set of m possible courses of action (referred to as alternatives):

A = {A1, A2,.....Ai,....., Am}

2. A set of n attributes (or criteria):

C = {C1, C2,....., Cj,....., Cn} with which alternative performances are measured

3. A performance rating of alternative Aí with respect to attribute (or criterion) Cjwhich is given by the nxm fuzzy decision matrix:

R= {Rij| i= 1, 2,.....m; j = 1, 2,...., n},

where Rijis a fuzzy set (or fuzzy number)

4. A set of n fuzzy weights:

W = [Wj iWj=1, 2,.....n}

where Wjis also a fuzzy set (or fuzzy number) and denotes the importance of criterion j, Cj, in the evaluation of the alternatives (Chen and Klein, 1997).

Although a large number of FMADM methods have been addressed in the literature, the focus of this paper is mainly on Yager's method (Yager, 1978). This method is sufficiently general to address both multiple objectives and multiple attribute problems. Yager's method follows the max-min method of Bellman and Zadeh (1970) with the improvement of the Saaty's method, which considers the use of a reciprocal matrix to express the pairwise comparison criteria and the resulting eigenvector as subjective weights. The weighting procedure employs exponentials based on the definition of linguistic hedges as proposed by Zadeh (1973).

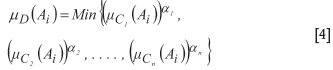

When describing MADM problems, only a single objective is considered, namely the selection of the best alternative from a set of alternatives. Yager's method assumes the max-min principle approach. The fuzzy set decision is the intersection of all criteria:μD(A) = Min [μC1(Ai),μC2(Ai),...,μCn Aí)}. For all (Ai) ε A, the optimal decision is yielded by μD) (A*) = Max μD,(Ai)), where A* is the optimal decision.

The main difference in this approach compared with other approaches is that the importance of the criteria is represented as exponential scalars. This representation is based on the idea of linguistic hedges. The rationale behind using weights (or importance levels) as exponents is that as the importance of a criterion increases, the exponent should increase, providing the minimum rule. Conversely, the less important a criterion, the smaller the weight. This process seems intuitive. Formally, this method can be written for a>0 (Bascetin and Kesimal, 1999):

Modified Yager's method

Because of the limitations mentioned in the 'Methods' section, the total number of criteria for Yager's method should be less than nine (Yavuz and Alpay, 2007). Therefore, a new procedure for Yager's method is proposed in this paper for making proper decisions by taking into consideration the fact that the criteria or alternatives should be grouped so as not to exceed the limitation of human performance (nine criteria/alternatives). In this method, the following steps should be applied to solve the problem in question with Yager's method:

> Group the criteria into clusters with less than nine criteria

> Perform Saaty's method for the main groups and calculate the weights for each group

> Perform Saaty's method for all criteria in each group and calculate the weight of each criterion in the group

> Calculate the final weights of the criteria by multiplying the criteria weights with their own group weights.

An application for loader selection

Description of the study site

In Turkey, coal production units controlled by the Etibank Company were transferred into Turkish Coal Enterprises (TKI) in 1957. In accordance with the Government's general energy policy, TKI was assigned to produce lignite and other types of coal to satisfy the country's coal demand, contribute to the economy, prepare and execute plans and programmes, determine application strategies, and to realize the strategies. The lignite reserves in Turkey total 13 billion tons, 4.5 billion tons of which are controlled by TKI. In total, 46 per cent of lignite production in Turkey is by TKI. TKI's production depends on the requirements of the power generation companies and the demands from heating and industry. TKI produced 26.2 Mt of marketable coal in 2007 and 3.6 Mt through license. In 2007, TKI produced a pickling of 268 million m3. In total, 79 per cent of the coal sold in 2007 (31.6 Mt) was supplied to the thermal plants operated by the electricity generation company.

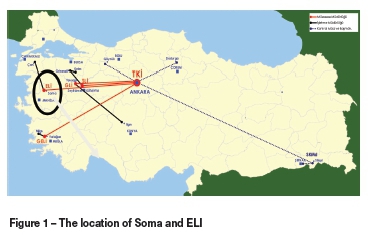

Mining in the Aegean Lignite region has been ongoing since 1913. This region depended on the Western Lignite Colliery (GLI) from 1939 until 1978, and then operated under GLI until 1995. After 1995, the mines were operated by the Aegean Lignite Colliery (ELI). TKI received a regional directorate, operation directorate and was re-established as a legal entity in April 2004. After 2004, TKI established activities at the centre of the largest entity, Soma, and 90 miles away in Manisa (Figure 1).

In the township of Manisa, Soma has 610 Mt of lignite reserves with lower heating values between 2080-3150 kcal/kg. TKI holds these reserves, which are spread over 24.4 thousand hectares, and 71 per cent of these reserves are licensed to be exploited with underground operations by TKI.

Approximately half of the total sales of heating and industrial coal sold by TKI originate from this region. In addition, coal preparation and coal extraction plants are located in Soma. Opencast mining uses large-capacity excavators and heavy trucks. Underground mining is performed for the tender and the period of royalty; the annual production is 5.2 Mt. The total production of this establishment was 9.6 Mt in 2011.

Defining the equipment selection process

The AHP technique was used for wheel loader selection according to the criteria established by ELI. Selection criteria affecting the decision-making process should be considered in the AHP technique. The criteria used in this work to select the best alternative for a loader are the required technical features:

> Operating weight between 80 and 90 t

> Diesel engine with a net power exceeding 650 horsepower and suited for heavy working conditions

> Rated bucket capacity exceeding 12 cubic yards

> 45° discharge height exceeding 4 m

> Breakout force exceeding 60 000 kg

> Lifting capacity exceeding 17 500 kg

> Static tipping load exceeding 45 000 kg

> Articulating angle exceeding 30°

> Tyre protection chain should be available

> Rops-type operator cabin suited for all types of climate conditions

> L-5 class tubeless tyres resistant to wearing

> The machine should be equipped with a torque converter, full power shift, and four-wheel drive.

In addition to these technical features, the wheel loader should be able to operate in local conditions such as 1000 m of altitude, ambient temperatures of -25 to +40°C, and soil densities of 1.1 to 1.8 t/m3.

The criteria and sub-criteria were assessed by an expert team consisting of one mechanical engineer (the manager of the firm, with 10 years of experience in the mining industry) and two mining engineers with 20 years of experience in the mining industry. All decisions have a common hierarchical structure whereby options are evaluated against the various criteria to promote the ultimate decision objective. The problem of the loader selection was structured in a hierarchy of different levels constituting goals, criteria, sub-criteria, and alternatives (Figure 2).

The AHP solution

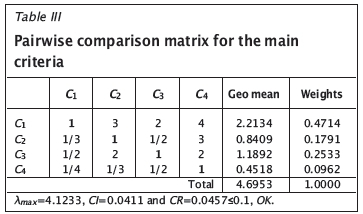

After structuring a hierarchy, the pairwise comparison matrix for each level is constructed. During the pairwise consideration, a nominal scale is used for the evaluation (Table I). As shown in Table III, each main criterion affecting the loader selection was compared, and the pairwise comparison matrix was constructed. The expert team performed these comparisons. The Economic Main criterion is the most important factor (priority 0.4714).

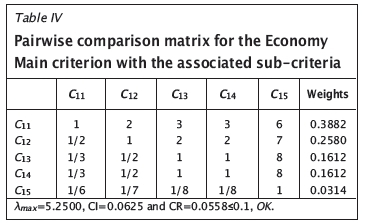

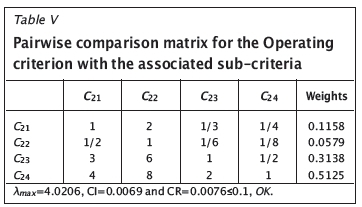

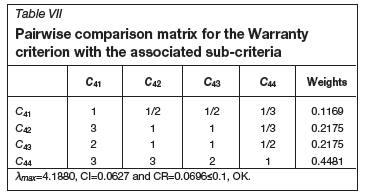

After constructing the pairwise comparison matrix for the main criteria, all subgroups of each main criterion should be compared (Tables IV, V, VI, and VII).

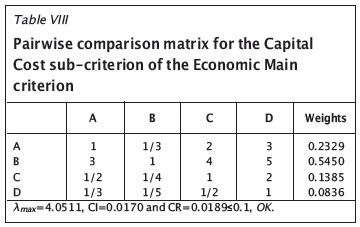

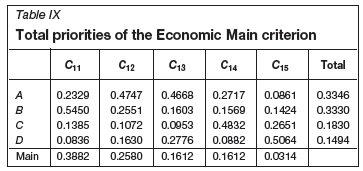

The pairwise comparison matrices are constructed by comparing each loader alternative with each sub-criterion in all of the main criteria. The comparison matrix for the Capital Cost sub-criterion in the Economic Main criterion is given in Table VIII as an example, and the general evaluation of the Economic Main criterion is given in Table IX. An identical procedure was applied for the other main criteria and associated sub-criteria.

The total priorities of the Economic Main criterion are calculated by summing the product of the relative priority of each sub-criterion and the eigenvalues considering the corresponding Economic Main criterion. The total priorities are calculated as the following: (0.2329x0.3882) + (0.4747x0.2580) + (0.4668x0.1612) + (0.2717x0.1612) + (0.0861x0.0314) = 0.3346 (Table IX).

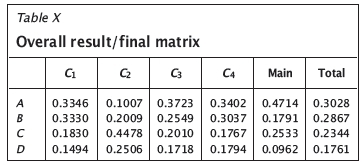

The overall rating for each alternative is calculated by summing the product of the relative priority of each criterion and the alternatives considering the corresponding main criteria. For example, the overall rating of 'Alternative A is calculated as the following: (0.3346x0.4714) + (0.1007x0.1791) + (0.3723x0.2533) + (0.3402x0.0962) = 0.3028. Similarly, the constructed final matrix is shown in Table X.

Because the comparison is based on a subjective evaluation, a consistency ratio (CR) should be calculated from Equation [3] to ensure the accuracy of the selection. From TableS III to VIII, the maximum eigenvalues (ƛmax) are nearly the size of the matrix (in Table III, the size of the matrix is 4x4, and the mean value of ƛmaxis 4.1233), and the CR values are less than 0.1 (in Table III, the mean CR value is 0.0457). These values are in the desired range. Therefore, this decision is selected without repeating the procedure.

Considering the overall results in Table X, Alternative A must be selected as the optimum loader selection to satisfy the goals and objectives of the TKI management because the priority of this alternative (0.3028) is the highest among all options.

For the loader selection, the proposed AHP model is unique in its identification of multiple attributes, minimal data requirement, and minimal time consumption. However, the most substantial general disadvantage of the AHP method is developing a large number of pairwise comparison matrixes. Pairwise comparisons are often a stressful process for decision-makers.

The solution by Yager's method

The calculation procedure by Yager's method is identical to the AHP method both for the main criterion and sub-criteria in the problem in question.

The main criterion and sub-criteria weights are calculated identically as in the AHP method. The combined weights for the 21 sub-criteria are then calculated by multiplying each main criterion weight and each sub-criterion weight separately. The combined weights for each sub-criterion are given in Table XI.

The sum of the weights of this sub-criterion weight is 1. The calculated weight values for each sub-criterion are taken as membership functions of each sub-criteria. The exponential weights for each sub-criterion are given as follows:

α11=0.1831, α12=0.1216, α13=0.0760, α14=0.0760, α15=0.0148

α21=0.0207, α22=0.0104, α23=0.0562, α24=0.0918 α31=0.0355, α32=0.0830

α33=0.0355, α34=0.0118, α35=0.0201, α36=0.0201, α37=0.0355, α38=0.0118

α41=0.0112, α42=0.0209, α43=0.0209, α44=0.0431

The general weight values for each sub-criterion obtained from expert opinions are given as the 'decision matrix' in Table XII. The weights of each alternative for the sub-criteria are selected using fuzzy numbers ranging from 0 to 1.

By using membership levels of alternatives and the weight of criteria for each criterion, the following conclusions were reached using Equation [4]:

μD(Alternαtive A)=min{0.40.1831, 0.20.1216, 0.20.0760, 0.40.0760,080.0148 0.40.0207,040.0104 0.20.0562,0.20.0918, 0.40.0355, 0.20.0830, 0.40.0355, 0.40.0118, 0.60.0201, 0.20.0201, 0.20.0355, 0.20.0118, 0.20.0112, 0.40.0209, 0.20.0209, 0.40.0431}=0.822.

μD(Alternative B)=min{0.20.1831, 0.40.1216, 0.60.0760, 0.60.0760, 0.60.0148, 0.20.0207, 0.60.0104, 0.60.0562, 0.40.0918, 0.80.0355, 0.60.0830, 0.20.0355, 0.20.0118, 0.20.0201, 0.40.0201, 0.40.0355, 0.60.0118, 0.40.0112, 0.60.0209, 0.80.0209, 0.20.0431}=0.745.

μD(Alternative C)=min{0.60.1831, 0.80.1216, 0.80.0760, 0.20.0760, 0.40.0148, 0.80.0207, 0.20.0104, 0.80.0562, 0.80.0918,0.60.0355, 0.40.0830, 0.60.0355, 0.60.0118, 0.40.0201, 0.80.0201, 0.80.0355, 0.10.0118, 0.60.0112, 0.80.0209, 0.40.0209, 0.60.0431}=0.656.

μD(Alternative D)=min{0.80.1831, 0.60.1216, 0.40.0760, 0.80.0760, 0.20.0148, 0.60.0207, 0.80.0104, 0.40.0562, 0.60.0918, 0.150.0355, 0.80.0830, 0.60.0355, 0.40.0118, 0.80.0201, 0.60.0201, 0.60.0355, 0.40.0118, 0.80.0112, 0.20.0209, 0.60.0209, 0.80.0431}=0.707.

Using the Bellman-Zadeh max-min rule, the structure of a decision is reached as follows:

μD(A)={Alternative A/0.822, Alternative B/0.745, Alternative C/0.656, Alternative D/0.707}

The optimal solution is found as follows: μD(A*)=max{μD(Alternative A1)}=0.822. Therefore, 'Alternative A' is found to be the most appropriate wheel loader because it displays the highest membership function value.

Yager's method consists of the identical order of operations as the AHP method, up to the calculation of all criterion weights. The most substantial difference between Yager's method and the AHP is achieving the final solution using only one decision matrix. Therefore, Yager's method involves fewer processing steps and fewer pairwise comparisons than the AHP method. Although not used in this study, decision-makers can include linguistic expressions in the decision-making process in the application of Yager's method (Yavuz, 2008). This feature facilitates decision-making in a fuzzy environment.

Sensitivity analysis for each method

A sensitivity analysis must be performed to determine how the alternatives will change with the importance of the criteria. As the priority of one of the criteria increases, the priorities of the remaining criteria must decrease proportionately, and the global priorities of the alternatives must be recalculated. A sensitivity analysis can also be used to determine the most important or critical criterion by computing the absolute or percentage amount by which the weight of any criterion must be changed to cause a switch in the ranking of the top alternative or in any pair of alternatives (Triantaphyllou and Sanchez, 1997).

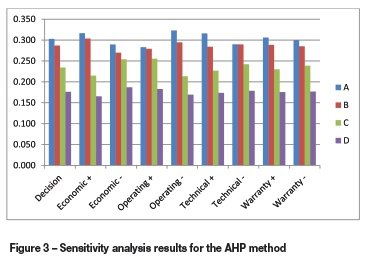

The values of the eigenvector for the main criterion in the pairwise comparison matrices simulated were increased or decreased for several scenarios in the AHP and FMADM methods. No change was noted in the judgment evaluations in the final priority ranking when the eigenvector value of each criterion increased/decreased up to 44 per cent in the AHP method (Figure 3). Therefore, 'Alternative A can always be selected as the most convenient alternative for the decision-making process, and 'Alternative B', 'Alternative C, and 'Alternative D sequentially followed in the final priorities. From the sensitivity analysis, the final result of the proposed AHP model is mainly sensitive to decreases in the Technical Main criterion.

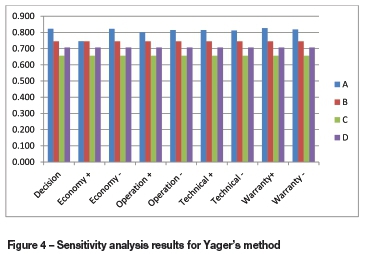

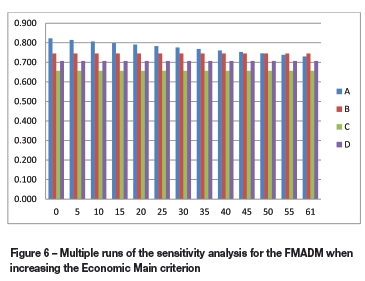

However, the final decision found by the proposed FMADM model was compared with the simulated scenarios in Figure 4. When the priority of the all criteria increased or decreased by 50 per cent, the present decision does not change. Therefore, 'Alternative A' can always be selected as the most convenient alternative for the decision-making process, and 'Alternative B', 'Alternative C', and 'Alternative D' sequentially followed in the final priorities. From the sensitivity analysis, the final result of the proposed FMADM model is mainly sensitive to increases in the Economic Main criterion.

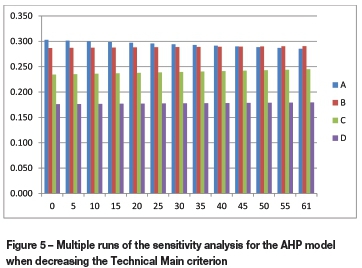

In the sensitivity analysis, by increasing or decreasing the values of the eigenvector of the main criterion, the variability limit is calculated as 61 per cent. After this limit, the Warranty Main criterion takes a negative value, increasing the Economic Main criterion. As previously mentioned, the AHP model is mainly sensitive to decreases in the Technical Main criterion, and the FMADM model is mainly sensitive to increases in the Economic Main criterion. Figure 5 and Figure 6 show respectively multiple runs of the sensitivity analysis for every 5 per cent change of the AHP and FMADM models according to its most sensitive criterion. These figures also indicate the accuracy of the applied decision-making process in both methods.

Conclusions

Mining engineers frequently have to select an optimum option among alternatives related to the mining operation. Each mining engineer might make precise decisions in all mining operations, and the decision-maker must use a suitable technique to make proper decisions. A number of techniques are available for solving different types of decision problems. In this study, the AHP and Yager's methods, which are two similar MADM techniques, are used to solve an equipment selection problem.

Equipment selection involves the interaction of several subjective and objective factors or criteria. Decisions are often complicated and many even embody contradictions. The AHP and Yager's method models, which contain four main criteria and 21 sub-criteria, were developed. Among the four alternatives under consideration, 'Alternative A is the most acceptable option identified for both methods when considering all main and sub-criteria in the analysis.

Unlike the traditional approach for loader selection, decision-making methods are more scientific, providing integrity and objectivity in the estimation process. Both the AHP and Yager's method models are transparent, easy to comprehend, and applicable by the decision-maker.

The AHP and Yager's method-based applications can be utilized in different sectors of the mining industry. The number of criteria and alternatives in the AHP and Yager's method applications should be determined by the decisionmaker because of the consistency and validity of the decision-making process (Saaty and Ozdemir, 2003; Ozdemir, 2005). The number of alternatives should be less than nine, otherwise a grouping method should be applied following the instructions presented in this study.

Finally, the result of this study shows that AHP and Yager's method applications can assist engineers in effectively evaluating the alternatives available in mining engineering.

References

Acaroglu, O., Feridunoglu, C., and Tumac, D. 2006. Selection of roadheaders by fuzzy multiple attribute decision making method. Transactions of the Institute of. Mining and Metallury A, vol. 115, no. 3. pp. A91-A98. [ Links ]

Alpay, S. and Yavuz, M. 2007. A decision support system for underground mining method selection. Lecture Notes Artificial Intelligence, vol. 4570. pp. 334-343. [ Links ]

Alpay, S. and Yavuz, M. 2009. Underground mining method selection by decision making tools. Tunnelling and Underground Space Technology, vol. 24, no. 2. pp. 173-184. [ Links ]

Ataei, M. 2005. Multicriteria selection for alumina-cement plant location in East-Azerbaijan province of Iran. Journal of the South African Institute of Mining and Metallurgy, vol. 105, no. 7. pp. 507-514. [ Links ]

Ataei, M., Jamshidi, M., Sereshki, F., and Jalali, S.M.E. 2008. Mining method selection by AHP approach. Journal of the Southern African Institute of Mining and Metallurgy, vol. 108, no. 12. pp. 743-751. [ Links ]

Bascetin, A. and Kesimal, A. 1999. The study of a fuzzy set theory for the selection of an optimum coal transportation system from pit to the power plant, International Journal of Surface Mining, Reclamation and Environment, vol. 13, no. 3. pp. 97-101. [ Links ]

Bellman R.E. and Zadeh L.A. 1970. Decision making in a fuzzy environment. Management Science, vol.17, no. 4. pp. 141-164. [ Links ]

Bitarafan, M.R. and Ataei, M. 2004. Mining method selection by multiple criteria decision making tools. Journal of the South African Institute of Mining and Metallurgy, vol. 104, no. 9. pp. 493-498. [ Links ]

Chen, C. and Klein, C.M. 1997. An efficient approach to solving fuzzy MADM problems. Fuzzy Sets and Systems, vol. 88, no. 1. pp. 51-67. [ Links ]

Elevli, B. and Demirci A. 2004. Case study: multicriteria choice of ore tranport system for an underground mine: application of PROMETHEE methods. Journal of the South African Institute of Mining and Metallurgy, vol. 104, no. 5. pp. 251-256. [ Links ]

Hwang, C.L. and Yoon, K. 1980. Multi Attribute Decision Making: Methods and Applications. Springer-Verlag, Berlin, [ Links ]

Kazakidis, V.N., Mayer, Z., and Scoble, M.J. 2004. Decision making using the analytic hierarchy process in mining engineering, Transactions of the Institute of. Mining and Metallury A, vol. 113, no. 1. pp. A30-A42. [ Links ]

Kesimal, A. and Bascetin, A. 2002. Application of fuzzy multiple attribute decision making in mining operations. Mineral Resources Engineering, vol. 11, no. 1. pp. 59-72. [ Links ]

Kluge, P. and Malan, D.F. 2011. The application of the analytical hierarchical process in complex mining engineering design problems, Journal of the Southern African Institute ofMining and Metallurgy, vol. 111, no. 12. pp. 847-855. [ Links ]

Namin, E.S., Shahriar, K., Ataee-Pour, M., and Dehghaniet, H.A. 2008. New model for mining method selection of mineral deposit based on fuzzy decision making. Journal of the Southern African Institute ofMining and Metallurgy, vol. 108, no. 7. pp. 385-395. [ Links ]

Ozdemir, M.S. 2005. Validity and inconsistency in the analytic hierarchy process. Applied Mathematics and Computation, vol. 161, no. 3. pp. 707-720. [ Links ]

Saaty, T.L. and Ozdemir, M.S. 2003. Why the magic number seven plus or minus two. Mathematical and Computer Modeling, vol. 38, no. 3-4. pp. 233-244. [ Links ]

Saaty, T.L. 2000. Fundamentals of Decision Making and Priority Theory with the Analytic Hierarchy Process. RWS Publications, Pittsburgh. [ Links ]

Saaty, T.L. 1980. The Analytic Hierarchy Process: Planning, Priority Setting. McGraw-Hill, New York. [ Links ]

Triantaphyllou, E. and Sanchez, A. 1997. A sensitivity analysis approach for some deterministic multi-criteria decision making methods. Decision Sciences, vol. 28, no. 1. pp. 151-194. [ Links ]

Triantaphyllou, E. 2000. Multi Criteria Decision Making Methods: A Comparative Study. Kluwer Academic Publishers, Dordrecht. [ Links ]

Yager, R.R. 1978. Fuzzy decision making including unequal objectives. Fuzzy Sets and Systems, vol. 1, no. 2. pp. 87-95. [ Links ]

Yavuz, M. and Pillay, S. 2007. Comment on: Mining method selection by multiple criteria decision making tool, by M.R. Bitarafan and M. Ataei. in the Journal of SAIMM, vol. 104, no. 9, pp. 493-498. Journal of the Southern African Institute ofMining and Metallurgy, vol. 107, no. 2. p. 137. [ Links ]

Yavuz, M. and Alpay, S. 2008. Underground mining technique selection by multicriterion optimization methods. Journal ofMining Science, vol. 44, no. 4. pp. 391-401. [ Links ]

Yavuz, M. 2008. Selection of plant location in the natural stone industry using the fuzzy multiple attribute decision making method. Journal of the Southern African Institute ofMining and Metallurgy, vol. 108, no. 10. pp. 641-649. [ Links ]

Yavuz, M., Iphar, M., and Once, G. 2008. The optimum support design selection by using AHP Method for the main haulage road in WLC Tuncbilek Colliery. Tunnelling and Underground Space Technology, vol. 23, no. 2. pp.111-119. [ Links ]

Zadeh, L.A. 1973. Outline of a new approach to the analysis of complex systems and decision process. IEEE Transactions, vol. SMC-3, no. 1. pp. 28-44. [ Links ]

© The Southern African Institute of Mining and Metallurgy, 2015. ISSN2225-6253. Paper received Jan. 2013 and revised paper received Apr. 2014.