Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.4 Johannesburg Apr. 2015

SPECIAL ARTICLES

Handover of model stope to Wits School of Mining Engineering

09 March 2015 - Johannesburg: A life-size mining stope panel was handed over by New Concept Mining (NCM) to the Wits School of Mining Engineering on 6 March 2015, to help students learn about stoping activities through a better visualization of how a real mine looks.

The stope panel - sponsored to the tune of R250 000 by NCM - is part of a range of simulated facilities sponsored and developed at the School's premises on West Campus, in partnership with companies active in the mining sector such as Aveng, Gold Fields, and Sibanye. These include a mine tunnel, mine shaft steel work, and a lamp room.

Professor Cuthbert Musingwini, newly appointed Head of the School of Mining Engineering at Wits, said: 'We are delighted to add this new facility to our School's resources and grateful to be partnering with far-sighted stakeholders like NCM who share our dedication to skills and technology development.'

NCM marketing director Brendan Crompton said the sponsorship of the model stope panel was driven by NCM's commitment to safety, efficiency, and productivity in South African mines. The SA-based company is a market leader in narr0w-reef stope support products, and has expanded into a number of countries worldwide.

'As a quality-focused company rooted in South Africa, we recognize that the future of our mining sector is built on the calibre and skills of graduates from institutions like Wits University,' said Crompton. 'Partnering with the School of Mining Engineering at Wits is one of the ways that we contribute to sustainability and safety in mining, especially as we both prioritize technological innovation as a key factor in the success of the sector.'

Measuring some seven metres in length, the model stope was constructed from a metal framework, mesh, and concrete. Sculptor Russell Scott used various materials and techniques, including hand-packed cement and layers of paint, to achieve the realistic effect of a working stope face in an underground platinum mine.

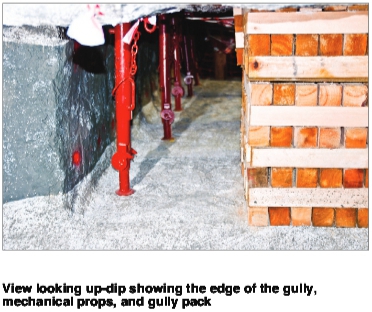

The panel dips at 10 degrees, has a stoping width of one metre, and extends some three metres on strike. It has been equipped with various items of support infrastructure to demonstrate to students the variety of technologies employed underground. These include timber props, timber packs, rockbolts, and safety nets suspended near the working face.

NCM has contributed roof support equipment both from its own range of products and from other sources. It is also making available some of its electronic monitoring and warning devices in the stope, augmenting the School's focus on digital remote monitoring technologies to enhance safety on mines.

Like the recently completed model mine tunnel, the stope panel is situated in the basement of the School of Mines premises, where it incorporates one of the building's beams as a geological feature.

Professor Fred Cawood, former Head of the School, initiated construction of the stope panel as part of his digital mine research at Wits Mining. These simulated facilities form part of the 'digital mine' environment which is providing invaluable tools for learning and research, bringing a real mine experience to mining engineering students at Wits.

'Most of the 200 first-year students we welcome each year are straight from school and have never been in a mine before,' said newly appointed Head of School Professor Cuthbert Musingwini. 'Although mine visits are arranged from time to time, this facility gives easy access to students - so that they can visualize and test what they are studying theoretically.'

'While the facility is invaluable for our teaching work, it will also be made available to our research students as they push the boundaries of productivity with digital and other technology in mining,' said Professor Cawood. 'Now more than ever, South Africa needs to encourage and facilitate research that can stimulate our mining sector; through facilities like these, Wits School of Mines is showing its commitment to doing that.'

S. Braham