Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.3 Johannesburg Mar. 2015

GENERAL PAPERS

Avoiding structural failures on mobile bulk materials handling equipment

M.J. SchmidtI; B.W.J. van RensburgII

IAnglo American Coal

IIDepartment of Civil Engineering, University of Pretoria

SYNOPSIS

Bulk materials handling systems are extensively used in the mining and minerals industry, where a fairly high incidence of structural failure is experienced, notwithstanding design compliance with appropriate standards. A number of case studies are explored to demonstrate how insufficient controls or protection systems have contributed to structural failures on mobile bulk handling equipment. The importance of design integration across engineering disciplines is highlighted. The revision of ISO 5049-1 (1994) is proposed to provide specific rules and guidelines pertaining to machine protection systems. It is further recommended that the structural design engineer of the original equipment manufacturer (OEM) fulfils a more prominent role during the final acceptance and handover of mobile bulk handling equipment, with specific reference to protection systems.

Keywords: continuous bulk handling equipment, machine protection system, structural failure, ISO 5049-1 (1994).

Introduction

Unfortunately. a fairly high incidence of structural damage or failure of bulk materials handling systems is experienced in the mining industry (Krige, 2012), notwithstanding design compliance with appropriate standards. Improved structural safety is in the interest of all employees and also facilitates steady company earnings. Catastrophic failures may cause injuries or fatalities and inevitably cause significant business interruptions since bulk materials mines are usually operated on a continuous basis with scheduled maintenance intervals.

This paper specifically addresses rail-mounted mobile bulk materials handling (BMH) equipment such as stackers, reclaimers, and ship loaders, and focuses on design shortcomings pertaining to controls, protection systems, and integration across engineering disciplines. ISO 5049-1 (International Organization for Standardization, 1994) is internationally recognized and utilized throughout the industry (Krige, 2012) for the design of mobile BMH equipment. Compliance with this standard means that the designer has met the design obligation, notwithstanding that the limitations of the standard are widely recognized (Krige, 2012; Morgan, 2012). Where equipment damage or failure occurs, potential disputes between the owner and supplier are not easily resolved when the latter can prove that the equipment design met the requirements stipulated in the standard or client specification.

Although highly skilled and experienced design engineers are usually involved in the delivery of mobile BMH equipment, recent failures of machines designed in first-world countries by reputable original equipment manufacturers (OEMs) support claims in the literature that the skills shortage crisis in the engineering industry is yet to be resolved (Hays, 2012; Kaspura, 2011; Gardner, 2011). Failures cannot always be attributed to design-related issues only. A wide range of factors may contribute to failures, including material quality, manufacturing, commissioning, abuse, etc. The fast-track nature of most mining projects nevertheless puts pressure on equipment suppliers to provide new designs with a minimum of engineering effort, and this may be exacerbated by the scarcity of design engineering resources. The drive towards more cost-effective designs may result in less conservative designs which leave little tolerance for unexpected loading conditions or possible future upgrades. Furthermore, the lack of a proper systems design approach restricts the extent of integration between protection systems limits and structural or mechanical strength. The risk of failure is often not understood when controls are wilfully over-ridden or have not yet been commissioned.

The aim of this paper is to recommend actions to improve the overall safety of mobile BMH equipment by focusing on aspects specifically related to the design integration and commissioning of protection systems and controls. Three typical case studies have been selected from an assortment of mobile BMH machine failures in order to illustrate the significant impact that inadequate protection systems and lack of design integration across engineering disciplines had on these failures.

Design standards

Standards related to the design of mobile MBH include:

1. ISO 5049-1 (1994) Mobile equipment for continuous handling of bulk materials - Part 1 Rules for the design of steel structures (International Organization for Standardization, 1994)

2. FEM SECTION II (1992) 2 Rules for the design of mobile equipment for continuous handling of bulk materials, Document 2.131 / 2.132 (De La Federation Europeenne de la Manutention, 1992)

3. AS 4324.1 (1995) Mobile equipment for continuous handling of bulk materials - General requirements for the design of steel structures (Standards Association of Australia, 1995)

4. DIN 22261 (2006) Excavators, spreaders and auxiliary equipment in opencast lignite mines (German Institute for Standardization, 2006).

ISO 5049-1 (1994), FEM SECTION II (1992), and AS4324-1 (1995) focus on the design of the steel structures and some mechanical aspects associated with mobile BMH equipment. Although additional parts were initially planned for all of these standards, which would address mechanical, electrical, and other aspects, these were never published. With the exception of DIN 22261, which is not commonly utilized (Schmidt, 2014), the standards available to the mobile BMH equipment industry are therefore silent on rules and requirements for machine protection systems. By implication, it is therefore left to the equipment supplier to provide protection systems that are deemed adequate to ensure the safety of any equipment supplied.

AS 4324-1 (1995) is currently under revision and it is envisaged that the revised standard will be published in May 2015 (George, 2014). Additional parts, which will address electrical and controls aspects, are planned for publication within the next two years.

Case studies

Case study 1 - collapse of a portal reclaimer

Background

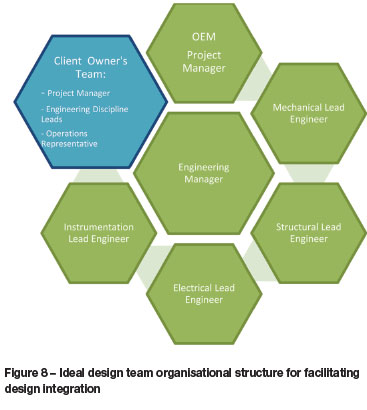

Prior to failure, the machine had been in production use for several months, although commissioning of the collision protection system had not been completed. The general arrangement of a typical portal reclaimer is shown in Figure 1.

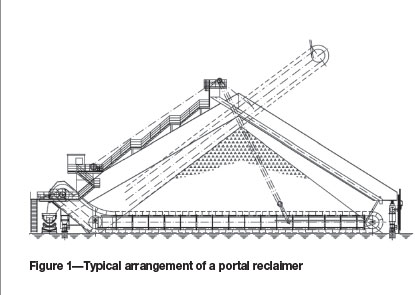

At the time of the collapse, the designed reclamation rate was exceeded by approximately 30%. The stockpile proximity probes appeared to not be working, resulting in unexpectedly high digging forces which led to the failure of major structural connections as shown in Figure 2.

Key findings from the investigation

The lateral resistance of the machine was insufficient to withstand the forces generated within the structure when excessive digging was experienced. Proximity probes, detecting the stockpile height, are fitted to ensure that the digging depth of rake buckets is maintained within the prescribed limits. These devices did not function properly or had not yet been commissioned, so were switched off, resulting in excessive digging forces (Anon., 2007; Krige, 2012).

Electric drive motors are equipped with protection relays to limit the electrical current that can be drawn during operation, i.e. the applied system torque can be limited. Industry practice suggests that the overload protection is set to a value of 5-10% above the peak system design load (Bateman, 2013). The protection study report, compiled subsequent to the failure, indicated that the motor protection relay setting on the reclamation drives was at a default value of 2 instead of 1.05 (Anon., 2007). Furthermore, the mechanical design for the scraper drive system dictated an installed motor power requirement of 154 kW, which implies that the next size up of 160 kW was specified. During procurement, 185 kW motors were supplied due to the unavailability of the 160 kW motors. This decision was made without consultation with the relevant design engineers.

Upon investigation, it was also found that the fluid couplings installed between the drive motors and reducers were rated at service factors such that a reclamation drive torque could be delivered that was only marginally below the maximum electric motor torque. Torque transfer through fluid couplings can be limited according to the design requirement by reducing the percentage oil fill, which is normal practice. The commissioning data revealed that the fluid coupling was overfilled by approximately 15%. Small amounts of oil at high percentage fill levels will lead to a significant increase in torque transfer capacity (Anon., 2007).

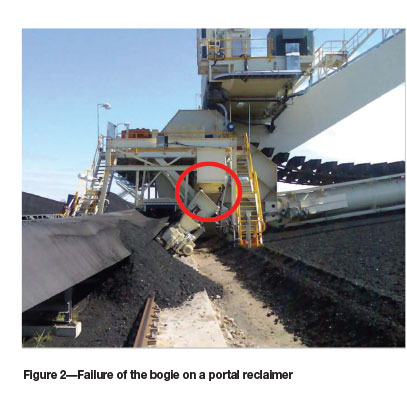

The machine could not withstand the motor starting torque as prescribed for the abnormal digging resistance criteria as outlined in ISO 5049-1 (1994). Depending on start-up torque control, the motor torque during start-up could exceed twice the operating torque on the motor, depending on the motor type selection, as shown in Figure 3. (Curves B and C represent a typical conveyor drive selection).

Multidisciplinary design integration - scraper drive system

The lack of proper design integration between mechanical, structural, electrical, and control and instrumentation engineering disciplines was revealed during the investigation (Anon., 2007). It is essential that the structural design engineer understands the effect and magnitude of forces that could be exerted on machine structures under abnormal conditions. The mechanical, and likewise the electrical, design engineer must understand how the selection and commissioning of equipment such as fluid couplings and electric motors could have an adverse effect on structural design parameters. The importance of interaction between the control and instrumentation and the structural and mechanical designers to ensure that alarm levels and limits are correctly designed and commissioned cannot be overemphasized.

Final acceptance and approval of the machine, and more specifically the validation of protection systems by the OEM's structural design engineer or representative who understands the structural limitations of the equipment, are crucial. This collapse highlighted the importance of understanding the additional risks associated with the production use of a machine that has not been fully commissioned, and where protection systems may be inoperative and stockpile volumes have not yet been fully calibrated. The operation of machines that have not been fully commissioned must be prohibited, regardless of production pressures.

Case study 2 - Collapse of a slewing stacker

Background

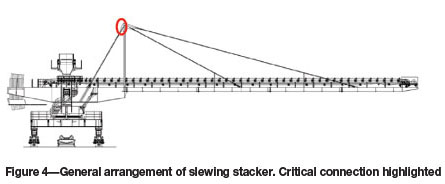

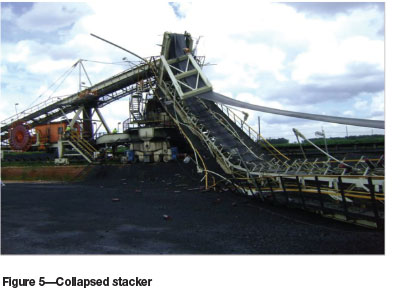

The machine was successfully operated for approximately a year before collapsing completely. An incident in which the boom conveyor belt was overloaded preceded the failure event. The failure of a critical tie-beam connection, which is highlighted in Figure 4, initiated the collapse of the boom and ultimately ruined the entire machine.

The extent of the damage can be seen in Figure 5.

Key findings from the investigation

Loading conditions were underestimated because an incorrect material bulk density was used in the design. The incorrect commissioning of the speed switch settings associated with the boom belt contributed to the structural overloading of critical tie-beam connections when slippage of the boom belt occurred.

Based on the design requirements of ISO 5049-1 (1994), critical tie-beam connections were overloaded, although the ultimate carrying capacity exceeded the most severe design load combination. The design of these connections is therefore considered to be marginal. The tie-beam connections utilized bolts in double shear in such a way that fastener threads intercepted a shear plane. Furthermore, high-strength electro-galvanized fasteners, which are susceptible to hydrogen embrittlement (Erling, 2009), were used in this critical tie-beam connection. The topic of corrosion and embrittlement is discussed at length in the American Institute of Steel Construction (AISC) Guide to design criteria for bolted and riveted joints (Kulak et al., 1987). From laboratory tests referenced, Kulak et al. note '... it became apparent that the higher the strength of the steel, the more sensitive the material becomes to both stress corrosion and hydrogen stress cracking. The study indicated a high susceptibility of galvanized A490 bolts to hydrogen stress cracking.' It is ultimately concluded that 'galvanized A490 bolts should not be used in structures. The tests did indicate that black A490 bolts can be used without problems from brittle failures in most environments.' (A490 bolts are the direct equivalent of the Class 10.9 bolts used in South Africa). High hydrogen contents were confirmed by the metallurgical examination of the fasteners, while surface cracks were noted at the thread roots of some specimens. Through the application of fracture mechanics, it can be demonstrated that the load carrying capacity of the tie-beam connection fasteners may have been reduced by hydrogen effects to a value far below what would be required to sustain a boom load associated with the luffing operation of an overloaded stacker boom (Schmidt, 2014).

Supervisory control and data acquisition (SCADA) recordings revealed that the boom loading significantly exceeded the intended design parameters prior to the collapse. The alarm set-point to alert a boom overload condition was specified at a level that was too high to prevent structural overload. The machine could therefore be exposed to severe loading conditions without any operator abuse. The probability that operator abuse contributed to the failure could not, however, be ruled out altogether.

The protection systems on the machine were found to be inadequate to ensure that structural loading remained within the intended design parameters. At the time of the collapse, the machine had not been formally handed over to the operations team.

The root cause of the stacker collapse can therefore be summarized as follows.

Design deficiencies contributed to a marginal design of critical connections, which was further exacerbated by defective bolts, adversely affecting the carrying capacity. The absence, malfunctioning, and incorrect commissioning of machine protection systems allowed an overload condition to develop, which led to the catastrophic collapse of the stacker.

Case study 3 - structural damage to a drum reclaimer

Background

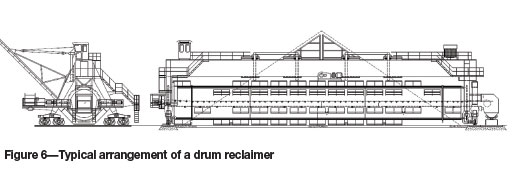

Although no failure occurred as such, significant damage was done to the support legs of a drum reclaimer when the control system of one of the long travel drives malfunctioned, resulting in a skewing action that imposed excessive loading which was not considered in the original design. A typical arrangement of the machine is shown in Figure 6.

Key findings from the investigation

The overall machine control system was originally configured without interlocks between the independent long travel drive systems located on adjacent bogie wheel sets. When the control system for the drives at the one end malfunctioned, the drives on the opposite end continued with the long travelling sequence until the drives tripped on overload as a consequence of the skewing of the machine. Severe local damage and permanent deformation were caused to the boxed plate structural section of the fixed legs. The machine, as shown in Figure 7, had been in service for decades.

Discussion

Skew control can be achieved by comparing signals from incremental encoders on both sides of the machine (McTurk, 1995). Skew should occur only if one side of the machine cannot travel for accidental reasons, e.g. an obstacle on the rails, and if this happens a signal must trigger the immediate shutdown of the machine. The control systems associated with the long travel of the machine were not fail-safe. Abnormal loads, not anticipated in the original structural design, were subsequently exerted on major structural members. The equipment was nevertheless operated successfully for many years prior to the skewing incident. Insufficient design integration existed between the OEM's structural, mechanical, electrical, and control and instrumentation engineering disciplines during the detail design phase of the original project. The damage could have been avoided by the incorporation of additional protection instrumentation for negligible additional capital cost.

The lack of interdisciplinary design integration, as discussed in the above case studies, is of concern. This is probably a highly controversial topic which design engineers would generally not want to embark upon. Of course, some BMH equipment OEMs will address this engineering challenge better than others. Unfortunately, the facts presented in the above case studies demonstrate that design engineers often design with an engineering discipline-specific approach, without the required understanding of design details from counterparts representing other engineering disciplines. This may have a direct influence on the overall performance of the equipment. The author acknowledges that discipline-specific specialists are nevertheless required for the successful design of mobile BMH equipment. The appeal is merely for better design integration, which is not based on perception but rather on a thorough understanding of interdependence between engineering disciplines. Although the competitive nature of the mobile BMH industry generally leads to a tendency amongst OEMs not to openly share design content with their client representatives, it would be advantageous to both parties, especially where the client appoints a third-party design auditor. While it is more common for larger corporate clients to have skilled engineering staff assigned to capital projects for the purposes of engineering oversight, smaller enterprises generally rely entirely on the OEMs for the successful delivery of functional mobile BMH equipment as specified in the supply contract. Liaison between the OEM's design engineers and the client's engineering discipline leads is invaluable for ensuring successful project delivery. Furthermore, larger corporate clients often have a number of operations where the same or similar mobile BMH equipment may be utilized in ways other than was envisaged under the supply contract. The input from operational personnel, who are responsible for the daily operation and general maintenance of existing equipment, must not be underestimated, but the ability of such individuals to influence new designs remains largely dependent on their skill and experience.

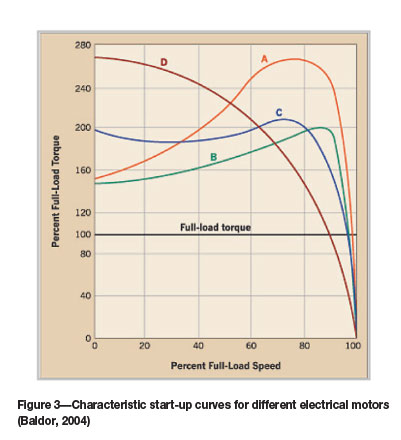

A typical integrated design team organization structure that is conducive to a high level of design integration with a systems design approach is depicted in Figure 8. The following aspects characterize such a team structure:

> Within the OEM's design team organizational structure, there is a free flow of information directly related to design interfaces between engineering disciplines without interference in discipline-specific matters

> Design interfaces are approached as an integrated system with input from relevant role-players as a team effort across engineering disciplines

> The respective engineering disciplines have a sound understanding of how equipment selection and systems dictated by engineering counterparts influence their individual designs

> The client owner's team participates in the design scope definition and design risk assessment with specific reference to machine protection and controls. Engineering input, oversight, liaison, and progressive review are provided by relevant representation from the client

> Specific design requirements are agreed between the OEM and client owner's team within the agreed contractual arrangement

> There is a free flow of information between the discipline-specific engineers from the owner's team and their OEM counterparts responsible for the design, without compromising the latter party's intellectual property rights.

Although it is expected that most OEMs will embrace and advocate the integrated model, case studies unfortunately suggest that a low level of design integration is often encountered within the industry.

Conclusion

The brief case studies as discussed have highlighted past incidents where incorrect commissioning or inadequate protection systems and controls contributed significantly to the collapse or severe damage of mobile BMH equipment. Deficient protection systems can often be linked back to the lack of design integration across engineering disciplines.

Although the end-user may be inclined to assume that a high level of interdisciplinary engineering integration is exercised, the studies demonstrate that this is not necessarily the case, which subsequently necessitates that the matter receives greater focus during current and future machine designs.

While a design standard can never be a substitute for a pragmatic design approach, the only international design standard available for the design of mobile bulk handling equipment, ISO 5049-1 (1994), does not address rules pertaining to machine protection systems. The case studies discussed demonstrate the industry's need for an updated standard to facilitate safe BMH designs in this regard.

A design team organization structure is proposed to facilitate an integrated systems design approach.

Recommendations

A technical committee should be appointed to review the ISO 5049-1 (1994) standard to include rules and guidelines regarding machine protection systems. Consideration should be given to the revisions envisaged to the AS 4324-1 (1995) standard facilitated by the Australian Standards Committee ME43 in this regard. Although this paper focuses on machine protection systems, there is an opportunity to consider the use of alternative lightweight and compound construction materials, as well as new rope technology for tie systems, while revising the ISO 5049-1 (1994) standard. It is furthermore recommended that guidelines are provided for designers who wish to follow a limit-state design approach, since there are a number of reputable OEMs in the mobile BMH industry who do not follow allowable stress principles.

It is recommended that the structural design engineer be closely involved with the verification of alarms and set-points associated with machine protection systems, in conjunction with other specialists responsible for the design and commissioning thereof, to make absolutely certain that these systems and controls comply with the design intent before final handover.

A high level of interdisciplinary design integration must be pursued with specific reference to machine protection systems and controls. A risk-based design approach should be mandatory.

Acknowledgements

Anglo American plc for permission to use the material published. The opinions expressed are those of the author and do not necessarily represent the policy of Anglo American plc

Dr G.J. Krige for input into this study topic and my career

Sandvik Mining and Construction for valuable input into the study

OEMs who participated in the study survey.

References

Anonymous. 2007. Reclaimer incident analysis reports and letter. Documentation compiled by a professional investigation team. [ Links ]

AS 4324-1. 1995. Mobile equipment for continuous handling of bulk materials. Part 1: General requirements for the design of steel structures. Standards Association of Australia, New South Wales, Australia. [ Links ]

Baldor Electric Co. 2004. Understanding induction motor nameplate information, electrical construction and maintenance. http://ecmweb.com/motors/understanding-induction-motor-nameplate-information [Accessed 10 Oct. [ Links ] 2013].

Bateman, P. 2013. Principal Electrical Engineer, Anglo American Thermal Coal. Personal communication. [ Links ]

DIN 22261. 2006. Excavators, spreaders and auxiliary equipment in opencast lignite mines - Part 1 to 6. German Institute for Standardization, Berlin, Germany. [ Links ]

Erling, S. 2009. Methods of preventing hydrogen embrittlement in hot dipped galvanized high strength steel fasteners. Hot Dip Galvanizing Today, vol. 6, no. 2. pp. 21-21. [ Links ]

Feger, F. 2013. Surface Mining (IPCC) & Materials Handling, R&D/Engineering Manager, Sandvik Mining and Construction. Personal communication. [ Links ]

Fem Section II. 1992. Rules for the design of mobile equipment for continuous handling of bulk materials. De La Federation Europeenne de la Manutention, Brussels, Belgium. [ Links ]

GEORGE, G. 2014. SIS Coordinator. Standards Australia. Personal communication. [ Links ]

Gardner, M. 2011. Industry complains of skills shortage. University World News, 27 March, no. 164. http://www.universityworldnews.com/article.php?story=20110325204522328&query=Industry+complains+of+s kills+shortage [Accessed 8 August 2013]. [ Links ]

Hays. 2012. Hays Global Skills Index [produced in partnership with Oxford Economics, London]. http://www.oxfordeconomics.com/publication/open/222621 [Accessed 10 Oct. [ Links ] 2013].

ISO 5049-1 1994. Mobile equipment for continuous handling of bulk materials - Part 1: Rules for the design of steel structures. International Organization for Standardization, Geneva, Switzerland. [ Links ]

Kaspura, A. 2011. Skills shortage claims backed up by surveys. Engineers Australia, June 2010. pp. 74-75. [ Links ]

Kulak, G.L., Fisher, J.W., and Struik, J.H.A. 1987. Guide to design criteria for bolted riveted joints. 2nd edn. American Institute of Steel Construction Inc., Chicago, Illinois, USA. [ Links ]

Krige, G.J. 2012. Learning from structural failures of material handling equipment. Australasian Structural Engineering Conference 2012: The Past, Present and Future of Structural Engineering, Barton, Australia. Engineers Australia. pp. 130-137. [ Links ]

Krige, G.J. 2013. WAH Engineering Consultants CC. Personal communication. [ Links ]

McTurk, J.R. 1995. Portal and bridge scraper reclaimers - a comparison. Beltcon Conference 1995. South African Institute of Materials Handling, Johannesburg, South Africa. [ Links ]

Morgan, R. 2012. Design of materials handling machines to AS4324.1. Australasian Structural Engineering Conference 2012: The Past, Present and Future of Structural Engineering, Barton, Australia. Engineers Australia. pp. 138-145. [ Links ]

Morgan, R. 2013. Revision to Australian Standard AS4324.1-1995 for materials handling of bulk products. 2013 Northern Regional Engineering Conference Structural Engineering Conference, Townsville, Australia. [ Links ]

Schmidt M.J. 2014. Avoiding structural failures on mobile materials handling equipment. MSc dissertation, University of Pretoria, South Africa. [ Links ]

Paper received Dec. 2013

Revised paper received Sep. 2014.