Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.115 n.2 Johannesburg Feb. 2015

GENERAL PAPERS

'Salem Box Test' to predict the suitability of metallurgical coke for blast furnace ironmaking

K.B. Nagashanmugam; M.S. Pillai; D. RavichandarI

IR & D Centre & Coke Ovens, JSW Steel Ltd, Salem Works, Salem, India

SYNOPSIS

Blast furnace performance depends strongly on the coke reactivity index (CRI) and coke strength after reaction (CSR) properties. An innovative and cost-effective method, known as the Salem Box Test, has been developed to prevent the mass production of inferior coke unsuitable for blast furnace use. This method consists of coal carbonization on a micro-scale and involves charging approximately 18 kg of coal blend in a stainless steel box, carbonizing it together with coal cake in the plant coke ovens, and testing the coke produced for CRI and CSR to determine its suitability for blast furnace use. Only coal blends that yield coke with CRI <25% and CSR >64% are permitted for mass production, and other coal blends are either rejected or the blending ratios adjusted in an attempt to upgrade them. The experimental results reveal that, for a given coal blend, the quality of coke produced by the Salem Box Test is comparable with that produced by bulk production, indicating that the test is acceptable as a screening tool for regular use.

The present paper describes the methodology and application of Salem Box Test to predict the suitability of coke for blast furnace use at JSW Steel Limited, Salem Works (JSWSL), and illustrates its advantages in adjusting the coal blending ratio to produce superior coke, in detecting coal contamination, and in preventing bulk production of inferior coke.

Keywords: coke-making, blast furnace, metallurgical coke, Salem Box Test, coke reactivity index (CRI), coke strength after reaction (CSR).

Introduction

The dominant ironmaking process in the world today is the blast furnace process, and the most important raw material fed into the blast furnace in terms of operational efficiency and hot metal quality is metallurgical coke. Inside the blast furnace, coke performs three functions:

➤ Thermal: as a fuel providing the energy required for endothermic chemical reactions and for melting of iron and slag

➤ Chemical: as a reductant by producing reducing gases for iron oxide reduction

➤ Mechanical: as a permeable medium providing passage for liquids and gases in the furnace, particularly in the lower part of the furnace.

When coke passes through a blast furnace, it degrades and generates fines which affect bed permeability and the process efficiency. Coke quality is often characterized by the hot and cold strength, ash composition (Mayaleeke et al., 2009; Nagashanmugam and Reji Mathai, 2012), and chemistry, which are largely dictated by the coal properties (Grosspietsh et al., 2000). Unfortunately, cold strength and hot strength are not clearly defined, and the methods used for quantifying these parameters by experimental measurement vary (Van Niekerk and Dippenaar, 1991). A range of laboratory tests and procedures have been developed to characterize the physical and chemical properties of coke and gauge their potential effects in blast furnaces. The most commonly used and well-known tests are the coke reactivity index (CRI) and coke strength after reaction (CSR) developed by Nippon Steel Corporation in Japan in early 1970s to assess the effect of CO2 reactions on coke. Generally, a high CSR is believed to prevent the coke from breaking down, improve the permeability, and increase the productivity of the ironmaking process as well as decrease the specific coke consumption (Grosspietsh et al., 2000). However, there is no international consensus on an ideal way to determine the quality of coke, as each industry relies on empirical experience for its interpretation. These laboratory tests are designed to test coke properties under a specific set of conditions, which might not be universally suitable. The reproducibility of CRI and CSR values also varies considerably between different laboratories (Arendt et al., 2001).

Charging an inferior coke to the blast furnace poses problems such as high dust generation, poor permeability, hanging, slips, high fuel consumption, reduction in the quantity of coal injection, low productivity etc. To avoid such a scenario, a novel technique, known as the 'Salem Box Test', which employs micro-level carbonization of the coal blend in a stainless steel box, was developed at JSW Steel Limited's Salem Works (JSWSL). The coke obtained by the box test is then tested for CRI and CSR to determine its suitability for blast furnace operation. Only those coal blends that produce coke with a maximum of 25% CRI and a minimum of 64% CSR, are used for mass production in the coke oven plant. This method avoids the mass production of coke unsuitable for blast furnace operation and ensures the manufacture and consistent supply of suitable coke. Coke with a maximum of 25% CRI and a minimum value of 64% CSR was found to be suitable for the JSWSL blast furnaces. This paper describes the use of the Salem Box Test to predict the suitability of coke for ironmaking in a blast furnace.

Material and method

At JSWSL, it is a normal practice to blend various types of coal, viz. hard coking coal, semi-hard coking coal, and non-coking coal in the required proportions such that the volatile matter and ash content of the blended coal are less than 26% and 9% respectively. These coals are blended so as to minimize the use of scarce hard coking coal and also to minimize the cost of coke production, as the profitability of a steelmaking operation depends directly on the cost of coke.

Procedure for Salem Box Test

The Salem Box Test (patent under application) is a cost-effective method for evaluating the suitability of different coal blends before mass production of coke. At JSWSL, this method is used for selection / optimization of coal blends that would produce coke with the required CRI and CSR in the real operating environment.

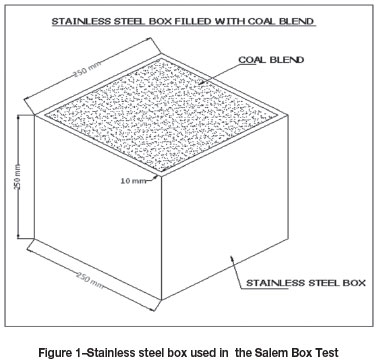

Samples of various coals, which constitute the coal blend, are collected and crushed to below 3 mm in size. The coal samples are mixed in the required proportions to prepare the coal blend, the required quantity of water is added to maintain approximately 10% moisture, and the sample is then homogenized by manual mixing. The coal blend placed inside a stainless steel box (size 250 mm χ 250 mm χ 250 mm, wall thickness 10 mm) in three to four increments and stamped with a metal stamper until approximately 18 kg of coal blend is compacted. The sample is now ready for carbonization. As the box needs to remain uncovered, a lid is not provided. The box is placed over the 'ready-to-charge' stamped coal cake by removing a portion of the cake at the center of its width to accommodate the box. The coal cake is then charged into the oven for carbonization, together with the box of test blend (Nagashanmugam et al., 2012). After carbonization, the coke cake is pushed onto the quenching car and is water-quenched. The box is then removed and the coke obtained is air-cooled, crushed, and sieved to 19-21 mm size. The sized coke is analysed for CRI and CSR (ASTM D-5341-99, 2004) using equipment from M/s. Naskar Instruments Ltd, Kolkata, India. The test results determine the suitability of the coal blend for mass production in coke ovens. Only those coals / coal blends that yield coke (by the Salem Box Test) having CSR >64% and CRI <25% are be considered for mass production at JSWSL.

Determination of CRI and CSR

About 10 kg of coke is crushed and screened to 20 ±1 mm. A 200 g sample of coke is placed in the reaction tube and heated to 1100°C in an inert atmosphere of nitrogen. Pure carbon dioxide gas is then passed through the sample. The reaction is sustained for 2 hours. The reacted coke is then cooled and weighed to determine the CRI (Nagashanmugam and Reji Mathai, 2012). The strength test is performed by placing the sample in an I-shaped drum and rotating it at 20 r/min for 30 minutes. The coke is then weighed to determine the CSR (Nagashanmugam and Reji Mathai, 2012).

Results and discussion

Before the introduction of the Salem Box Test, testing of coals/coal blends for bulk manufacture of coke was carried out in large-scale oven trials. Although such a method has obvious advantages, it also has several disadvantages. For example, oven trials must not interfere with the usual routine of the plant, but must await a convenient time. Sometimes, due to a considerable time lag between the arrival of the coal at the plant and its use at the ovens, serious deterioration of the coking properties occurs through weathering. Furthermore, the full oven test becomes quite expensive (assuming it results in an inferior coke), hence obtaining the required information by simpler means leads to cost savings. Large-scale tests are needed only to confirm the result obtained by the Salem Box Test.

Initially, the box tests were performed in cube-shaped mild steel box with a thickness of 7 mm and dimensions of 300 mm x 300 mm x 300 mm. This was later optimized to 250 mm x 250 mm x 250 mm and 10 mm thickness to facilitate manual handling and increase the service life of the boxes. As boxes of both dimensions were found to give consistent results, trials with other dimensions were not conducted. Although the size of the box is not critical, it is better to have the box dimension at least 10 times the size of coke (19-21 mm) used for CRI and CSR analysis. Although boxes made of mild steel gave satisfactory results, the results were occasionally found to be inconsistent. Subsequently, this was found to be due to corrosion of the mild steel. It was suspected that iron oxide, the product of corrosion, might initiate the gasification reaction at low temperature and hence affects the CRI and CSR indices of the coke. In order to confirm this supposition, two box tests were carried out with the same coal blend, one in presence of iron oxide and the other in its absence, and the resultant cokes were tested for CRI and CSR. The results of the test are presented in Table I.

Table I reveals that the CRI and CSR values of coke obtained by carbonization in the absence of iron oxides were suitable for blast furnace, as they meet the JSWSL specification of CRI <25% and CSR >64%. The coke obtained from the same coal blend in the presence of iron oxides was found to have deteriorated in quality to a larger extent with respect to CRI and CSR, thus becoming unsuitable for blast furnace use. It is also clear that, even though the coal blend is good, the presence of iron oxide has spoiled the quality of the coke. The coal blend, being of very good quality, would have yielded better coke (suitable for the blast furnace) in actual ovens, had it not been affected by corrosion of the mild steel box. The stainless steel boxes were found to yield highly consistent results, and therefore boxes made of other materials were not tested.

Figure 1 shows a schematic of the stainless steel box used in the Salem Box Test, and Figure 2 illustrates the flow diagram depicting various steps in performing the test.

A large number of box tests have been carried out to date, the results of which have proved to be highly satisfactory for the prediction of the coke quality that would be obtained by mass production in coke ovens. Table II presents few examples of box tests conducted with various coals / coal blends.

Those coal blends that yielded CRI values below 25% and CSR values above 64%, were passed for mass production, and other coal blends were either rejected or further tested by varying the blending ratios.

In order to determine the applicability and suitability of the Salem Box Test, the coal blends that were found to yield the required CRI and CSR were carbonized in coke ovens for mass production as per normal procedure and the resultant coke was subjected to CRI and CSR analysis. The CRI and CSR values of coke obtained from box tests and those obtained from coke ovens using same coal blends are compared in Table III.

It can be seen from Table III that the CRI and CSR values of coke obtained from box tests and bulk tests for the same coal blends correlate well, and the variation is insignificant. This indicates that the coke obtained from the box test could be considered to represent coke that would be obtained by bulk production using the same coal blends. Thus, the Salem Box Test becomes an effective screening tool for selecting or rejecting a given coal blend for bulk coke manufacture.

Prior to the introduction of the Salem Box Test, there were numerous instances where coke was rejected for use in the blast furnace owing to poor quality. After the introduction of box tests, such instances have been avoided as the box test gives a clear indication as to the suitability of a particular coal blend for producing blast-furnace quality coke. Furthermore, a continuous supply of suitable coke is also ensured.

Salem Box tests are also helpful in making minor adjustments in the coal blend compostion in order to produce better coke. There are instances where coal blends / coal mix were changed based on the results of box tests. Table IV illustrates typical examples where the proportions of the coal blend were changed or modified suitably such that box tests yielded better CRI and CSR results.

Table IV illustrates three cases in which the designated coal blends produced coke with inferior CRI and CSR values. However, slight modification in the weight percentage of individual coals (especially Indonesian coal) led to an improvement in coke quality, making it suitable for blast furnace use. It can be seen that, even by maintaining the total weight fractions of hard coking, semi-hard, and non-coking coals constant, it becomes possible to obtain coke of the required quality. Subsequent investigation revealed that high volatile matter and alkali content (Na2O + K2O) in Indonesian hard coking coal in examples 1 and 2 and Australian semi-hard coking coal B in example 3 were responsible for the poor coke quality.

The results in Table IV reveal that by suitably changing the blending ratio of individual coals it is at times possible to obtain the required coke quality.

The Salem Box Test also serves to reject / screen out an individual coal or coal blends that are unsuitable for bulk coke manufacture. Table V illustrates few typical instances where the bulk production of an inferior coke was averted by using box tests.

Based on the composition and properties of these coals, it was expected that both the coal blends should yield coke with the required CRI and CSR properties, but the results obtained negated the expectation. Detailed investigation and analysis revealed that Australian hard coking coal E was contaminated at the loading port (example 1) and Australian semihard coking coal C was contaminated with other non-coking coals at the unloading port (example 2). This contamination was found to be the root cause for the poor quality of coke. Thus, based on the results of box tests, the mass production of inferior coke was averted.

Conclusions

➤ The quality of coke produced by the Salem Box Test is comparable with that produced by bulk production, indicating that the test is acceptable as a screening tool for regular use

➤ The Salem Box Test serves to reject an individual coal or coal blend as unsuitable for coke production and prevents bulk manufacture of inferior coke

➤ The Salem Box Test is also an effective method for detecting contamination in coal, and can be used to indicate where coal blending ratios can be adjusted to yield a coke product with suitable CRI and CSR properties.

➤ The Salem Box Test has been successfully used for more than 7 years at JSWSL to avoid the mass production of unsuitable coke and ensure the manufacture, availability, and consistent supply of coke suitable for blast furnace operation. This has resulted in better productivity and cost savings in blast furnace operation.

Acknowledgement

The authors are thankful to the management of M/s. JSW Steel Limited, Salem Works, for granting permission and for providing facilities to carry out the research work in JSWSL, R&D centre and coke ovens.

References

Arendt, P., Huhn, F., and Kuhl, H. 2001. CRI and CSR - a survey of international round robins. Coke Making International, vol. 2. pp. 50-53. [ Links ]

ASTM D-5341-99, Reapproved 2004. Standard test method for measuring Coke Reactivity Index (CRI) and Coke Strength after Reaction (CSR). pp. 1-4. [ Links ]

Grosspietsh, K.H., Lyngen, H.B., Dauwels, G., Karjalahti, T., Van der Velden, B., and Willmers, R. 2000. Coke quality requirements by European blast furnace operators in the turn of the millennium. Proceedings of the 4th European Coke and Ironmaking Congress, Paris La Defense, 19-21 June 2000. Vol. 1. pp. 1-11. [ Links ]

Mayaleeke, A.H., Adlleke, A.O., and Dashak., D.A. 2009, Studies on the ash chemistry of Nigerial Enugu Coal as a blend component in metallurgical coke making. Pacific Journal of Science and Technology, vol. 10, no. 2. pp. 782-787. [ Links ]

Nagashanmugam, K.B. and Reji Mathai. 2012. The influence of coal ash chemistry on the quality of metallurgical coke, Coromandal Journal of Science, vol. 1, no. 1. pp. 60-64. [ Links ]

Nagashanmugam, K.B., Sathaye, J.M., Pillai, M.S., and Bhattacharya, H. 2012. A method for testing / screening the suitability of coke for blast furnace iron making (Salem Box test), complete specification. Application. no.811/CHE/2012, www.ipindia.nic.in 30 August 2013. pp. 1-13. [ Links ]

Van Niekerk, W.H. and Dippenaar, R.J. 1991. Blast-furnace coke: a coal-blending model. Journal of the South African Institute of Minerals and Metallurgy, vol. 91, no. 2. pp. 53-61. [ Links ]