Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.114 n.12 Johannesburg Dec. 2014

A SOUTHERN AFRICAN SILVER ANNIVERSARY MEETING, 2014 SOMP

Mining off-Earth minerals: a long-term play?

G. A. CraigI; S. SaydamI; A.G. DempsterII

ISchool of Mining Engineering, The University of New South Wales, Australia

IIThe Australian Centre for Space Engineering Research, The University of New South Wales, Australia

SYNOPSIS

The Moon, asteroids, and planets of the solar system represent the most distant caches of wealth that humanity has ever considered recovering. Yet, in addition to the potentially recoverable values represented there, harvesting off-Earth resources has a second, almost incalculable sustainable benefit in that they can be retrieved with absolutely no damage to Earth.

Previous research mostly assessed the potential of asteroids and the Moon for mining purposes from a theoretical and scientific point of view. These studies investigated drawbacks that could be experienced in this type of operation, but no detailed economic evaluation that is meaningful for mining project management has been conducted and the parameters that are most likely to make an operation feasible are unknown. This paper provides a preliminary economic and sensitivity analysis of a possible off-Earth mining business extracting minerals from an existing asteroid.

Keywords: off-Earth mining, space mining, in situ resource utilization, future mining.

Background

As history has repeatedly shown, where there are valuable minerals to be mined, adventurous humans will arrive in droves -even if it means battling extreme conditions and excessive risks. The motivation for off-Earth mining is clear: an abundance of valuable resources that can feed our technologically-driven society, the necessity of discovering new places that our society can colonise, and the development of new technologies and processes to enable these missions, which will generate spin-off technologies that can be used in fully-automated terrestrial mining endeavours.

By widening the scope of mining engineering to incorporate off-Earth opportunities, the mining industry can be sustained from an economic standpoint. In a similar way, the increased costs of mining and diminishing natural resources available close to the surface of the Earth may soon support the idea that off-Earth resources are more profitable.

Limited research has been conducted in this area. O'Leary (1988) initiated one of the first off-Earth mining studies and identified that the surfaces of the Earth's Moon, Mars's two moons, and an asteroid named 1982 DB have the potential for developing missions for space mining. However, he focused on a manned mission, which entails high operational and safety risks. Duke et al. (1997) designed three operational scenarios to extract water ice at the lunar poles, using microwave energy for heating the ice, thermal processing and steam pipe transportation, and using a dragline with thermal processing. Their designs were conceptual and did not consider the economic feasibility of the operations.

Sonter (1997) investigated the design process for feasibility studies of off-Earth mining operations and developed a net present value (NPV) analysis including variables based on orbital mechanics, rocket fuel requirements, mining and processing methods, product mass returned, and duration of the return trip. A new analysis concept was also utilized by Sonter (1997; 2001), the 'mass payback ratio', which illustrates the need to expend mass in the form of propellants, rocket bodies, and mining consumables in order to return product mass to the market. Moreover, Sonter (2001) applied a scenario where resources obtained from asteroids are brought into low Earth orbit (LEO) and sold as construction material for LEO infrastructure. These materials include water to make propellant, nickel and iron for construction, and semiconductors to make solar cells. Sonter's studies (1997; 2001) were the first that considered the economic viability of such missions.

Ross (2001) published a report on the important factors in determining the feasibility of an asteroid mine. This report considers the extraction of several commodities from asteroid orebodies, including water and volatiles, precious metals, rare earth metals, refractory material, and iron and nickel. Ross's study, like Sonter's, used NPV analysis as the primary tool. Ross also outlines the market demand, which is subject to continual iteration due to its size and nature. Notably, geological characteristics were not mentioned and the actual analysis stage was not undertaken. This limits the credibility of the study, in that it suggests principles without testing. However, Blair et al. (2002) from the National Aeronautics and Space Administration (NASA) Jet Propulsion Laboratory (JPL) investigated the feasibility of off-Earth mining for water extraction. A simple NPV analysis was found to be insufficient to make an investment decision, due to the high capital and research investment required for a start-up operation, creating unpredictable risks and uncertainties in the business model.

Erickson (2006) studied asteroid mining with a particular focus on optimal return on investment (ROI) from near-Earth asteroids (NEAs), and stressed the cost efficiency and risks of a possible operation. He further recommended that the mining equipment to be used at such an operation should be flexible, adaptable, and re-usable to handle a variety of NEA conditions. He particularly pointed out that robotics with artificial intelligence is essential to stage such a mission.

Zacharias et al. (2011) compared feasibility studies of potential mining projects on asteroids, the Moon, and Mars based on each of their dynamic locations. They conducted an NPV analysis of possible 10-year mining operations for an arbitrary mineral and found that the Moon returned the most favourable NPV compared to Mars and two selected asteroids. Based on their assumptions, both the Moon and Mars provided positive NPVs, but the asteroids had negative NPVs. However, a possible asteroid-mining operation would be expected have a much longer lifespan than a typical Earth-based operation, so the economic analysis could be quite different considering all the variables and risks associated with the operation.

Pelech (2013) studied an economic evaluation of mining comets and the Moon for an off-Earth water market. He developed four water-mining scenarios to supply a H2/LOx propellant market in LEO and established a ratio, named 'propellant payback ratio', inspired from Sonter's studies (1997; 2001), which indicates the economic return on the forgone opportunity to launch the propellant directly from the Earth. He used the opportunity cost concept considering infrastructure and equipment launched from Earth. In this study, for every kilogram of mining equipment and infrastructure launched into LEO, the opportunity to launch a kilogram of propellant has been forgone.

Gertsch and Gertsch (2003) applied terrestrial surface mine design and planning techniques to the production of lunar regolith for extracting gases for life-support for 100 people at a lunar base. They discussed various hypothetical scenarios with basic assumptions for mining regolith from five large cold trap craters near south lunar pole. Muff et al. (2004) conducted a study at NASA that includes a prototype design of a bucket wheel excavator to be used on the surface of the Moon and Mars to extract surface regolith. Both studies focused on using similar excavation techniques and equipment to those that are used in terrestrial mining operations.

Schmitt et al. (2008) summarized the vision for space exploration, determining that the first stage would incorporate the development of mining initiatives on the Moon to extract life-sustaining elements such as H, He, C, N, and O. These elements are all available in various concentrations in the lunar regolith or surface rock. They proposed that a base would be needed on the Moon to provide an extensive refuelling and life-support system.

Yoshikawa et al. (2007) and Raymond et al. (2012) studied asteroid characteristics providing valuable information. Subsequent spacecraft missions reduced the geological uncertainty surrounding this analysis.

Karr et al. (2012) from NASA studied the potential of using ionic liquids (ILs) to dissolve metal-bearing regolith in order to exploit the water and metal present within it. Acidic IL was used to dissolve small samples of a nickel/iron meteorite (named Campo del Cielo) and the metals were recovered by electrowinning. When the voltage was slowly raised from an initially low level, it was possible to recover the different metals separately at the anode. The water was removed using a micro-distillation apparatus. This represents the first extraction of oxygen, in the form of water, from an extraterrestrial source, as well as a possible method of processing metals in space. The authors also mentioned that this dissolution technique in prospector drilling could be used for the analysis of regolith.

Balla et al. (2012) discussed the use of direct laser fabrication technology to mine off-Earth minerals. The feasibility of this method was evaluated through a series of experiments using lunar regolith simulant. The experiments were able to demonstrate that this method is able to produce bulk amounts of mineral products through the melting and re-solidification of regolith. The laser absorption of materials is directly proportional to electrical resistivity, therefore the lunar regolith melted completely with a laser power as low as 50 W. However, they noted that more work will be needed before the process can be regarded as feasible on a large scale.

Buet et al. (2013) developed a robotic mining system for rapid Earth orbit capture of asteroid resources. They aimed to capture and bring asteroid regolith to the Earth's surface. Prado (2013) evaluated terrestrial mining systems such as strip mining, but the problem in using this system off-Earth in an extremely low-gravity situation is that the dust and rock would be expelled into space above the surface, obscuring and inhibiting the mining operation.

Bernold (2013) developed a method and machine to 'vacuum up' regolith material as a form of material collection. This machine has been tested with the lunar simulant developed by the research team (Creagh, 2013). To overcome the lack of atmosphere, two concentric tubes were used. A gas is forced through the outermost tube and regolith dust is removed inside the inner tube, suspended within the gas.

Lucas and Hagan (2014) conducted a study to analyse and compare the feasibility of conventional pick cutting systems and pneumatic excavation systems in an off-Earth environment. The samples tested were the Australian Lunar Regolith Simulant-1 (ALRS-1), designed by Bernold (2013). While more research and development is required on the prototype pneumatic excavation system to determine the rate of excavation and other factors that would assist with assessing the mining efficiency of this system, it was determined that both machines were capable of excavating lunar regolith at any relative density. It was also concluded that although neither system was feasible for lunar excavation with current technology, the pneumatic excavation system was superior under the lunar conditions analysed.

Owing to the rapid development of the private commercial space industry, continual iteration is required to keep the results of these investigations relevant. There has not been a concentrated effort to reduce costs through investigation of alternative capital expenditure models. None of the previous investigations have taken the geological characteristics of each deposit into account. Almost all mine design and planning activity on the Earth is heavily influenced by geology and the knowledge gained from previous experience. A lack of sufficient geological information is one of the most detrimental uncertainties in making investment decisions.

The previous studies indicate that bodies in NEOs are the most likely to be economically viable, while the more distant comets are unlikely to support a positive cash flow. These results appear to be heavily dependent on the accessibility of each deposit by a spacecraft. Crucially, they also do not quantify the geological characteristics or extractability of each deposit as a cost factor in the analysis.

There are some USA-based companies intending to mine asteroids for volatiles and metals (Belfiore, 2013) due to the perceived accessibility. However, the Moon, and importantly (in terms of suitability of human colonization) Mars, must be given a fair trial and compared with asteroid resources in order to determine the most economically viable strategic business plans.

A case study for asteroid mining

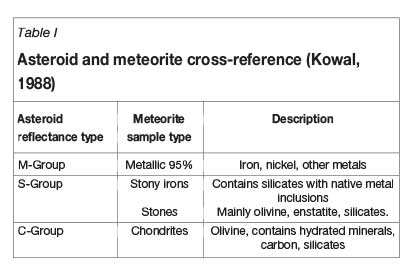

Current knowledge of asteroids is derived from meteorite samples, long-range electromagnetic spectrum observations, and spacecraft observations and sampling. The asteroids are categorized by the spectral signatures from long-range observations (Price, 2004). The spectral signatures are divided into the categories given in Table I and referenced with respect to different composition characteristics found in meteorites. It should be noted that there are many more subclasses within each of these groups.

Launching a payload from the Earth's surface into space is generally considered one of the higher costs in space development (Ross, 2001); hence by starting a mining industry in space early in the space development phase, unnecessary costs can be avoided. To develop such an industry, a certain level of pre-existing space industry is required so as to provide fuelling services and/or energy sources for the mining operations, as well as a market for the raw materials so that payload values are not undermined by the costs of re-entry to Earth to access the terrestrial mineral market.

Astronauts walking on the Moon found that the regolith is very fine grained and possesses an electrostatic charge. This charge causes the dust to stick to equipment and astronaut suits. It is expected that the surface of many asteroids would be similar (Slezak, 2013).

Sonter (2013) described a typical target asteroid body and estimated that this target may contain approximately 10% Ni-Fe, 10% magnetite, 10% water, and 50 ppm platinum group elements. He further mentioned that in 2020, the value contained in this type of material could be over US$1 million per ton in space, but only US$4 000 per ton if the platinum was brought to the Earth's market.

In this case study, an M-type asteroid was chosen as the target for the mining operation. A high percentage of nickel and iron, which can be used for construction materials in orbit, was assumed. A number of M-type asteroids were identified but the one chosen has higher radar reflectivity compared to other asteroids (Ostro et al., 1991), hence its mineral composition is widely accepted in the scientific community. 1986 DA is an NEA that is assumed to be 0.5 astronomical units (AU) away from the Earth and has a delta-V (a standard measure of the energy needed to complete space manoeuvres) value of 7.195 km.s-1 (Benner, 2013). This means that it is only slightly less accessible than the Moon - a round trip between the Earth and 1986 DA could take approximately one year.

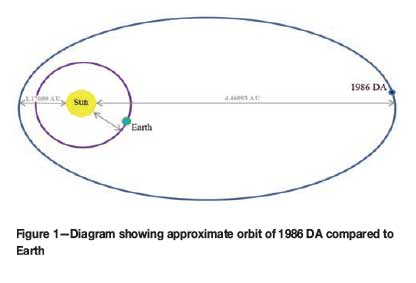

It is already known that 1986 DA's orbit around the Sun passes within Mars' orbit, therefore at some points it is relatively close to the Earth, approaching as close as 0.2 AU (Yeomans et al., 1987), but only for a very short time. The minimum distance between the asteroid and the Sun (the perihelion) is 1.17 AU, while the maximum distance is 4.46 AU. Since the distance between the Earth and the Sun is 1 AU, it is assumed that the distance between the Earth and asteroid is between 0.17 AU and 3.46 AU. For the purposes of this study, 1986 DA is assumed to be about 0.5 AU from the Earth, or the same distance as Mars from the Earth. In this respect, the time to travel to the asteroid would be comparable to the time taken to reach Mars. Figure 1 indicates a simplified possible orbital path of 1986 DA and the Earth. This diagram was constructed based on the abovementioned information and was used to make the assumption of the distance between the Earth and the asteroid.

1986 DA has the composition of naturally occurring stainless steel, or 88% Fe, 10% Ni, and 0.5% Co (Ross, 2001; Ingebretsen, 2001) making it a perfect resource to mine. This composition is assumed to be uniform throughout the asteroid, and hence the entire asteroid is considered as an orebody and therefore the reserve is equal to the resource. The mean density of the asteroid is assumed to be 5 g.cm-3 (Ostro et al., 1991) and this equates to a total reserve of 20 Gt of raw stainless steel. If the minerals were to be processed and sold separately, it would be necessary to provide reserve estimates for each mineral. For 1986 DA, therefore, reserves of 17.6 Gt of iron, 2 Gt of nickel, and 100 Mt of cobalt were assumed. The remaining 300 Mt could be made up of a combination of gold and platinum, which together constitute 1% of the asteroid's reserve.

Possible mining methods

Since this study focuses on the economic analysis of such an operation, it was important to consider possible mining methods in order to make relevant assumptions. Therefore, two mining methods were investigated for extracting the metal from the asteroid: an open cut method and an underground method.

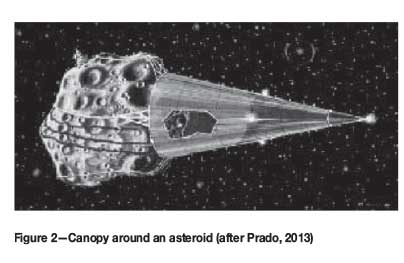

The open cut method is similar to terrestrial opencast methods, apart from any necessary surface securing systems. The near-zero gravity would mean that all equipment needs to be anchored to the surface of the asteroid. Mined material also needs to be prevented from leaving the mining area. This could be achieved through the addition of a canopy or 'mining cover', which is described by Prado (2013). A typical canopy system can be seen in Figure 2.

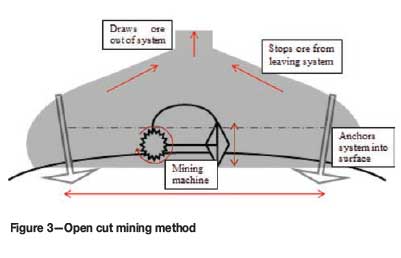

The mining system drills or breaks the ore and the broken material is released into the space above the surface. This displaced ore is drawn up and out of the system for storage. The velocity of rock that has been forced into motion by drilling or breakage is unknown, but some consideration would have to be given to high-speed projectiles when designing a mining cover. A typical diagram of this technique can be seen in Figure 3.

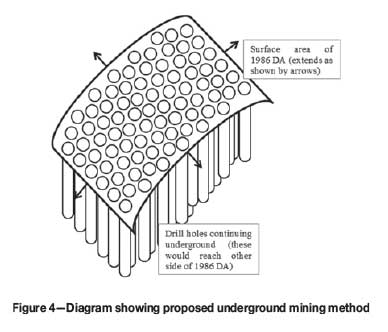

The underground mining method involves drilling large holes from one side of the asteroid through the centre to the other side using some form of tunnel boring machine (TBM), in a similar way to auger mining in terrestrial operations, as shown in Figure 4. This will allow an adequate production rate for the 1986 DA operation. The machinery is held in place by pressure against the walls of the drill-holes, thus eliminating the problem of very low gravity. Ore could be directed up the existing hole with ease due to the low gravity and collected at the top.

The most suitable mining method is to develop a strip mining system that incorporates anchorage to hold the equipment to the surface, as well as a mining cover to contain disturbed metal for storage.

It has been assumed that the entire asteroid will be mined eventually; however, the envisaged operation will exploit only one-tenth of the possible resource. In this respect, the final pit layout must not impede further mining operations. Another factor that should contribute to the design of the final pit layout is the effect that extraction could have on 1986 DA's orbit around the Sun. Removing an isolated section of the asteroid could change the rotation of 1986 DA and propel it into an altered and potentially dangerous orbit.

It is most appropriate to perform mining operations in such a way that the final pit layout consists of strips that encircle the asteroid to maintain its trajectory and minimise change in rotational kinetic energy.

All infrastructures would need to be adequately lightweight to minimize transport costs. Apart from this consideration and the additional stability measures required in a minimal gravity situation, infrastructure would generally be similar to equivalent terrestrial operations.

The smelting apparatus could be a stand-alone unit that uses the Sun's radiant energy. The smelter would be mobile, using low-powered thrusters to move around the asteroid, so as to always be on the side facing the Sun. This movement would depend on the current task of the smelter. Metal could then be fashioned into blocks ready for transport or moulded directly into shapes for building material. Because of the low gravity, soft metal could possibly be shaped in a similar way to glass-making, by pulling and shaping the metal as it solidifies (Roesler, 2013).

An economic evaluation of the 1986 DA operation, based on a typical NPV analysis, was performed to determine the financial and technical feasibility of an off-Earth mining project.

The design assumes that mining would be fully automated and that the relevant robotic technologies are available. Investigating the feasibility of a robotic operation is relatively simple; there are no provisions made for sustaining life. There would need to be a crew on Earth or in a spacecraft or station in orbit to monitor the operation to maximize productivity and utilization of the equipment fleet. In other words, full automation is not assumed.

Equipment selection and infrastructure

The main equipment components are machines for rock breakage and drilling, handling broken ore, and support. The latter include fuel replenishing machines, robotic service machinery (mobile or fixed), mobile anchorage systems, and mining cover to collect perturbed ore.

There would also need to be other on-site components that are separate from the task of mining, but are included in the equipment costs, such as the smelting apparatus and storage system (if payload is transported only when 1986 DA is a short distance from Earth).

On-site infrastructure includes components that are either fixed or mobile but are not directly involved in the mining operation. The other infrastructure components are the storage systems for both mined 'run-of-mine' ore and for the smelted metal. These have to be lightweight holding containers that are kept in position near the asteroid through the use of very low-power thrusters.

Economic analysis

The main part of the economic analysis involved a year-by-year cash flow analysis, and therefore a detailed financial and technical model was developed. The model included transport costs, mining/smelting equipment, mining costs, saleable material, and operating margin.

For capital cost analysis, it was considered unnecessary to specify the number of spacecraft required to transport payloads of metal from 1986 DA to Earth orbit. Instead, the cost per ton of payload was used. A spacecraft configuration rule of thumb (Turner, 2010) is that the payload weight averages about one-third of a spacecraft's dry weight. Owing to the long transit time, it is assumed that each spacecraft will make one return trip per year. Because of this, the total weight of the spacecraft is comparable to the annual production of the operation. At 20 Mt per year, the total weight of the payload-bearing spacecraft would be 66.6 Mt.

Capital costs of all spacecraft were based on the Russianbased Angara A3 space vehicle, currently in development by Khrunichev State Research and Production Space Centre (Khrunichev State Research and Production Space Centre, 2013). The mass of this vehicle will be 14.6 t and the total development cost is US$70 million. In this respect, the cost per ton of spacecraft needed is about US$19.4 million.

Capital costs are made up of both the transport equipment and the mining equipment, which includes the costs of the smelting, anchorage, and extraction equipment. The transport capital was benchmarked at US$19 million per ton of machinery. Due to the limited level of knowledge about mining equipment costs, the assumed value for this element was also assumed to be US$19 million per ton. The total capital expenditure for the 1986 DA operation would be $1.31 x 1015.

Operating costs include the fuel costs for operation of all equipment (mining equipment and transportation equipment) as well as consumables for the mining operation. The amount of fuel needed for the transportation between Earth orbit and 1986 DA was calculated by using the Tsiolkovsky rocket equation (Equation [1]) (Braeunig, 2012):

This formula uses the 66.6 Mt for vehicles calculated previously, but this value is varied on each leg of the journey depending on whether the spacecraft would be empty, carrying payloads, or transporting mining equipment. The delta-V is the change in velocity necessary to reach 1986 DA and is known to be 7.195 km/s (Benner, 2013). Cost of fuel was assumed to be US$10 000 per ton, a relatively high cost due to the remote location of the operation. Consumables were assumed to be US$5 000 per ton of ore mined. The total operating costs associated with the 1986 DA mining operation equal just less than US$140 x1012 in present value. This value assumes that a low-cost technology option would be available in the orbit. Fuel costs comprise a major part of the total project costs, and will most likely be the parameter that has the greatest effect on the feasibility of the 1986 DA mining operation. Table II summarizes the assumptions for economic analysis.

Assuming that all of the mined material is sold, 20 Mt of stainless steel will be sold per annum, at a price of $8 million per ton. This provides a yearly income of just above US$160 x 1012, starting in the second year and continuing until the 101st year, when the final shipment arrives at the market. The total revenue for steel sales throughout the life of the mine (LOM) would be just over $1.45 x 1015 in present value, before costs.

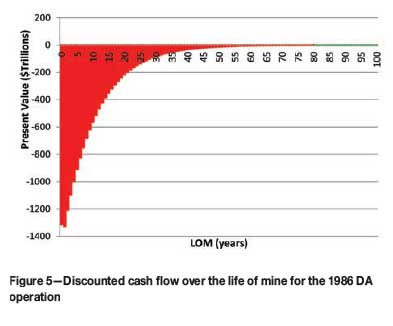

The NPV of the 1986 DA operation for a 100 year LOM is calculated as just over US$658 billion. For the scale and the length of life of the operation, this NPV cannot be considered feasible, even with an extremely high profit, since this operation has a payback period of 80 years (Figure 5). The profit made over the LOM is minimal compared to the initial capital investment. This evaluation has assumed 100% equity finance; however, the results indicate that the large capital investment (Table II) will be only marginally repaid. The project would therefore not be attractive because of the relatively small profit expected over 100 years in relation to the large capital investment.

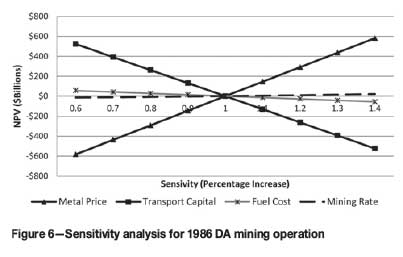

A sensitivity analysis was undertaken to indicate the effects of different variables on the project NPV. This is an important aspect of any financial evaluation, and even more so for an off-Earth operation because of the relative uncertainty of the NPV. The results of the sensitivity analysis can be seen in Figure 6, which indicates that a number of parameters strongly impact the NPV of the operation. This analysis indicates the most important areas where further research and technology advances are required in order to make asteroid mining and other forms of off-Earth mining operations viable.

The metal price was based on the cost of purchasing and launching material from Earth to the asteroid's orbit (NEA). As the NPV is very sensitive to this parameter, it is recommended that further analysis is done on the expected value of materials in space. This value would change constantly, as it does on Earth, and hence establishing a correct estimate for metal price would involve cross-disciplinary work beyond the scope of this project. This parameter cannot be changed by altering the project scope -the metal price is the cost of sourcing the material on the Earth and launching it into space. The value would increase as Earth's reserves of iron ore are diminished, but would decrease as space launches become more economical. Whatever the case, the results indicate that this parameter strongly affects the NPV of the 1986 DA mining operation.

The NPV is equally sensitive to the percentage of mined metal that the operation manages to sell. It is assumed that 20 Mt will be mined per annum; the market needs to be large enough to absorb this amount for the project to succeed at current figures. Mining in excess of the demand would be detrimental to the operation. This parameter would only negatively impact the NPV, as it is not possible to sell more product than the operation produces.

Another very critical parameter identified is the transport capital. Due to the long travel time between 1986 DA and Earth, it is assumed that enough payload shuttles to transport a year's worth of material are available. Costs for transport could be reduced by building faster shuttles, so as to reduce the total number needed, or by using lightweight materials to transport run-of-mine more efficiently.

The NPV of the operation is relatively insensitive to the the fuel cost and the amount of fuel needed for transportation, although it is still influenced by these parameters. As for metal, it is hard to assume a value for fuel in space, but fuel costs could be reduced by establishing an in-space fuel industry. More fuel-efficient equipment and vehicles would also reduce the amount of fuel needed for the project. Further research should be undertaken in this direction.

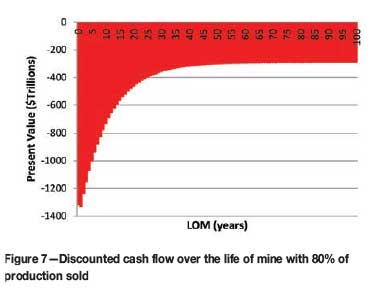

To further analyse the monetary value of the parameters that have the greatest effect on the NPV, a number of alternative case studies were developed from the base case. The first alternative assumes that the same mining rate, but only 80% of the ore transported back to Earth orbit is sold each year. This situation would have dramatic financial consequences for the 1986 DA operation. The operation would not make a profit, as shown in Figure 7.

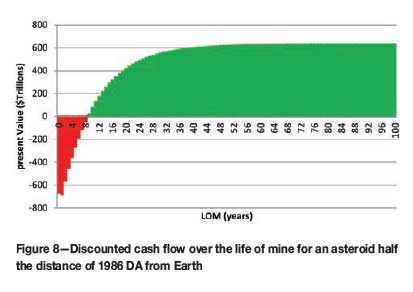

The second alternative case study assumes that there is an equivalent asteroid that is half as distant from the Earth as 1986 DA. This would halve the transport capital as two trips could be made per year, utilizing the payload-bearing shuttles more productively. The payback period of this alternative is 8.5 years and the NPV for this scenario is just over US$630 x 1012, which is much higher than for the base case (Figure 8). As can be seen, the capital investment is also great deal lower than that of the base case. This allows for a quicker payback and higher profit margin. This alternative is therefore much more feasible as a mining operation than the base case operation.

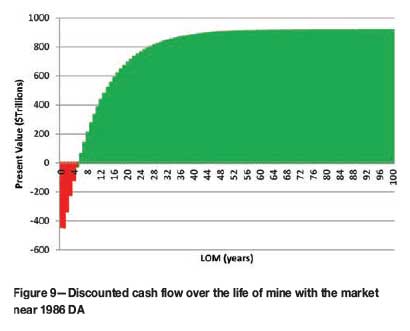

The final alternative study assumes that the market consumers for the stainless steel product are either mobile or located relatively close to the mine site, so that no transportation of the refined material is necessary. The only need for shuttles would be for yearly consumables and the initial transportation of mining equipment. Because of this smaller ongoing payload, it is important to spread the weight of the mining equipment transported to site across a number of years. The first three years will thus involve the transport of increasing amounts of mining equipment to 1986 DA, with production rates ramping up to the base case amount. In the first year, half of the mining equipment will be taken to 1986 DA, along with necessary fuel and consumables; in the second year other necessary equipment would be brought, with the remainder in the third year. This alternative yields a much higher return than the base case situation. The payback period would be 5.5 years and the NPV for this scenario would be almost US$916 x 1012 (Figure 9). As can be seen, this scenario is a much more attractive investment than the base case, due to the short payback period and the much higher NPV.

The risk of this project is that there would need to be a sufficient market close to 1986 DA, or that customers would have to collect the product from site themselves. This has the potential to decrease the value of the product from the current assumption of US$8 million per ton. As can be seen from the sensitivity analysis (Figure 6) and in Figure 5, the sales percentage is a very sensitive parameter and if this scenario cannot sustain a market of 20 Mt/a, the NPV of the project will suffer dramatically.

Conclusions

The time is approaching when an industrial market will be developed in orbit around the Earth. Owing to the Earth's finite resources and the high costs of launching materials from the Earth's surface, this market may need an off-Earth minerals industry to supply it with essential raw materials, most importantly water. Before the industrial demand reaches an unmanageable level, relevant research needs to be conducted such that off-Earth mining is an attractive investment for mining companies.

The increased resources could push the terrestrial minerals market into a surplus, damaging mining companies' terrestrial operations and depressing mineral prices. There is, however, a huge opportunity for mining companies to utilize off-Earth deposits to support space exploration and development. The mining industry has valuable experience in developing and applying technologies for discovering, extracting, and processing natural resources. This experience will allow the space industry to create a permanent and self-sustaining presence in space. The space industry, conversely, can benefit the mining industry through the advancement of technologies that will allow mineral extraction in not only off-Earth situations, but also in hostile terrestrial environments such as deep oceans. A strategic partnership between mining, space, and research organizations and industries will be needed to achieve such a goal.

The asteroid chosen to assess the feasibility of off-Earth mining in this study is a large metallic NEA approximately 0.5 AU (half the distance between Earth and the Sun) from Earth. The asteroid has a uniform composition that is essentially naturally-occurring stainless steel. This material could be used as a construction material for future satellites and spacecraft.

A theoretical assessment of 1986 DA as a suitable mining location was conducted and, using certain assumptions, of an economic model developed to determine the financial value of a mining operation on the asteroid.

1986 DA has a total reserve of 20 x 109 t of raw stainless steel which could be mined using an open cut strip-mining method or an underground drilling method. The operation would produce 20 Mt of stainless steel per year over a mine life of more than 100 years. This steel will be smelted and transported by shuttle to an Earth orbit and marketed for off-Earth construction.

The results of the financial and technical model indicate that the project would have a very high NPV of just over US$658 x 109. However, due to the relatively large initial cost of US$1.3 x 1015, the project cannot be considered a worthwhile operation.

A number of alternative case studies were investigated, with the highest NPV attributed to a scenario in which the mined ore would be utilized near the mining operation and would not need to be transported to an Earth orbit. It was concluded that at current prices and with current technology, even with a number of assumptions such as a pre-existing fuel industry, the risk is too great for an asteroid mining operation to succeed. The alternative case studies may be economically viable, but in reality the likely market for the products of a space mining operation will be developed in orbit around the Earth, as in the original case.

The NPV of the 1986 DA operation was found to be most sensitive to the metal price, capital cost of transport, cost of fuel, and the amount of fuel required. It is recommended that these parameters be further assessed.

It is recommended that similar analyses should be performed for other known M-type NEAs. A comparison of different case studies would illustrate the benefits of targeting nearby asteroids compared with asteroids with a relatively low delta-V or those with a valuable orebody, as is the case with 1986 DA.

It is obvious that there is a severe lack of knowledge about specific NEAs (in terms of their compositions and surface properties). It is hence recommended that before any mining company commits to a full-scale operation, physical exploration be undertaken. This involves flybys and sample returns from the asteroids. Although the full-scale extraction of off-Earth minerals is not currently feasible, it is recommended that further research by the mining industry be undertaken, as space mining will eventually be inevitable as the pace of space exploration and development activity increases.

Acknowledgements

The authors would like to acknowledge Dr Gordon Roesler for his support and guidance during the research.

References

Balla, V.K., Roberson, L.B., O'Connor, G.W., Trigwell, S., Bose, S., and Bandyopadhyay, A. 2012. First demonstration on direct laser fabrication of lunar regolith parts. Rapid Prototyping Journal, vol. 18, no. 6. pp. 451-457. [ Links ]

Belfiore, M. 2013. Deep space industries, a new asteroid-mining hopeful. www.popularmechanics.com/science/space [Accessed 19 May 2013]. [ Links ]

Benner, L.A.M. 2013. Near Earth asteroid delta-V for spacecraft rendezvous. echo.jpl.nasa.gov/~lance/delta_v/delta_v.rendezvous.h.html Accessed 8 September 2013]. [ Links ]

Bernold, L.E. 2013. An Australian lunar soil simulant to study lunar mining and construction. Off Earth Mining Forum, University of New South Wales, Sydney Australia, 19-21 February 2013. www.youtube.com/watch?v=yvBVuewGuxs [Accessed 17 May 2013]. [ Links ]

Blair, B., Diaz, J., Duke, M., Lamassoure, E., Easter, R., Oderman, M., and Vaucher, M. 2002. Space resource economic analysis toolkit: the case for commercial lunar ice mining. www.isdc2007.org [Accessed 19 May 2013]. [ Links ]

Braeunig, R.A. 2012. Rocket propulsion. www.braeunig.us/space/propuls.htm [Accessed 12 September 2013]. [ Links ]

Buet, M., Pearson, J., Bennett, D.S., and Komerath, N. 2013. 'Cornucopia Mission' robotic mining system for rapid earth orbit capture of asteroid resources. http://www.csc.caltech.edu/stuff/VoyagerFinalReport.pdf [Accessed 17 Nov 2013]. [ Links ]

Creagh, S. 2013. Moon mining a step closer with new lunar soil simulant. The Conversation. theconversalion.com/moon-mining-a-step-closer-with-new-lunar-soil-simulant-12310 [Accessed 16 May 2013]. [ Links ]

Duke, M.B., Gustafson, R.J., and Rice, E.E. 1997. Mining lunar polar ice. American Institute of Aeronautics and Astronautics, Inc. (AIAA). AIAA- 98-1069. pp. 1-10. [ Links ]

Erickson, K.R. 2006. Optimal architecture for an asteroid mining mission: equipment details and integration. Proceedings of Space 2006, San Jose, California, 19-21 September 2006. pp. 1-16. [ Links ]

Gertsch, L.S. and Gertsch, R.E. 2003. Surface mine design and planning for lunar regolith production. Space Technology and Applications International Forum- STAIF2003: Conference on Thermophysics in Microgravity; Commercial/Civil Next Generation Space Transportation- Human Space Exploration. AIP Conference Proceedings, vol. 654. pp. 1108-1115. [ Links ]

Ingebretsen, M. 2001. Mining asteroids. IEEE Spectrum, vol. 38, no. 8. pp. 34-39. [ Links ]

Karr, L.J., Paley, M.S., Marone, M.J., Kaukler, W.F., and Curreri, P.A. 2012. Metals and oxygen mining from meteorites, asteroids and planets using reusable ionic liquids. 2012 PISCES Conference, Pioneering Planetary Surface Systems Technologies and Capabilities, Waikoloa, Hawaii, 11-15 November 2012. www.ntrs.nasa.gov/search.jsp?R=20130001749 [Accessed 17 May 2013]. [ Links ]

Kowal, C. 1988. Asteroids: their nature and utilization. Space Science Telescope Institute, Maryland, USA. p. 151. [ Links ]

Khrunichev State Research and Production Space Centre. 2013. Angara launch vehicles family. http://www.khrunichev.ru/main.php?id=44 [Accessed 12 September 2013]. [ Links ]

Lucas, M.T. and Hagan, P.C. 2014. Comparison of two excavation systems for the mining of lunar regolith. Mining Education Australia Journal of Research Projects Review, vol. 3, no 1. Hagan, P. (ed.). Australasian Institute of Mining and Metallurgy, Carlton, Victoria, Australia. pp. 39-44. [ Links ]

Muff, T., Johnson, L., King, R., and Duke, M.B. 2004. A prototype bucket wheel excavator for the moon, mars and Phobos. Proceedings of the2004 Space Technology and Applications International Forum (STAIF-004), Albuquerque, New Mexico, 8-11 February 2004. [ Links ]

O'Leary, B. 1988. Asteroid mining and the moons of Mars. Acta Astronautica, vol. 17, no. 4. pp. 457-462. [ Links ]

Ostro, S.J., Campbell, D.B., Chandler, J.F., Hine, A.A., Hudson, R.S., Rosema, K.D., and Shapiro, I.I. 1991. Asteroid 1986 DA: radar evidence for a metallic composition. Science, vol. 252. pp. 1399-1404. www.echo.jpl.nasa.gov/asteroids/ostro+1991_1986DA_science.pdf [Accessed 12 September 2013]. [ Links ]

Pelech, T.M. 2013. Technical and economical evaluation of mining comets and the moon for an off-earth water market. B. Eng. thesis, UNSW Australia, Sydney Australia. [ Links ]

Prado, M.E. 2013. Asteroid mining. Projects to employ resources of the Moon and asteroids near Earth in the near term. www.permanent.com/asteroid-geologies.html [Accessed 10 May 2013]. [ Links ]

Price, S.D. 2004. The surface properties of asteroids. Advances in Space Research, vol. 33, no. 9. pp. 1548-1557. [ Links ]

Raymond, C.A., Jaumann, R., Nathues, A., Sierks, H., Roatsch, T., Preusker, F., Scholten, F., Gaskell, R.W., Jorda, L., Keller, H.U., Zuber, M.T., Smith, D.E., Mastrodemos, N., and Mottola, S. 2012. The Dawn topography investigation. Space Science Review, vol. 163. pp. 487-510. [ Links ]

Roesler, G. 2013. Australian Centre for Space Engineering Research, UNSW Australia. Personal communication. [ Links ]

Ross, S.D. 2001. Near-earth asteroid mining. www2.esm.vt.edu/~sdross/ papers/ross-asteroid-mining-2001.pdf [Accessed 16 May 2013]. [ Links ]

Schmitt, H.H., Farrelly, C.T., and Franklin, D.C. 2008. Mining and the future of space exploration. Proceedings of the First International Future Mining Conference and Exhibition 2008, Sydney. Saydam, S. (ed.). Australasian Institute of Mining and Metallurgy, Melbourne. pp. 91-97. [ Links ]

Slezak, M. 2013. Space miners hope to build first off-Earth economy. New Scientist, vol. 217, no. 2906. pp. 8-10. [ Links ]

Sonter, M.J. 1997. The technical and economical feasibility of mining the near-earth asteroids. Acta Astronautica, vol. 41, no. 4-10. pp. 637-647. [ Links ]

Sonter, M. 2001. Near earth objects as resources for space industrialization. Solar System Development Journal, vol. 1, no. 1. pp. 1-31. [ Links ]

Sonter, M. 2013. Project concepts for near-term commercial asteroid mining. Off Earth Mining Forum, University of New South Wales, Sydney Australia, 19-21 February 2013. www.youtube.com/watch?v=yvBVuewGuxs [Accessed 17 May 2013]. [ Links ]

Turner, M. 2010. Space design 101. Integrated Product Teams Lecture, University of Alabama, Huntsville, 18 January. matthewwturner.com/uah/ IPT2010_spring/lectures_videos [Accessed 12 September 2013]. [ Links ]

Yeomans, D.K., Ostro, S.J., and Chodas, P.W. 1987. Radar astronomy of near-Earth asteroids. The Astronomical Journal, vol. 94, no. 1. pp. 189-200. [ Links ]

Yoshikawa, M., Fujiwara, A., and Kawaguchi, J. 2007. The nature of asteroid Itokawa revealed by Hayabusa. Proceedings of the International Astronomical Union, vol.2, Symposium S236. pp. 401-416. [ Links ]

Zacharias, M., Gertsch, L., Abbud-Madrid, A., Blair, B., and Zacny, K. 2011. Real-world mining feasibility studies applied to asteroids, the Moon and Mars. AIAA SPACE 2011 Conference & Exposition, Long Beach, California, 27-29 September 2011. [ Links ]