Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.114 n.12 Johannesburg Dec. 2014

A SOUTHERN AFRICAN SILVER ANNIVERSARY MEETING, 2014 SOMP

New systems for geological modelling-black box or best practice?

C. Birch

School of Mining Engineering, University of the Witwatersrand

SYNOPSIS

A 'geologically constrained' orebody model has long been hailed as vital for a Mineral Resource statement that is compliant with the South African Code for Reporting of Exploration Results, Mineral Resources and Mineral Reserves (SAMREC Code). In this paper, the requirements for geological modelling as contained in the outline for the SAMREC Code are considered, and whether the new modelling software available on the market is a 'black box' or is better for modelling than traditional methods of wireframe creation.

Implicit geological modelling is a technique that uses a radial basis function to establish and update geological models relatively quickly and efficiently from borehole data, outcrop data, manually interpreted vertical or horizontal sections, and structural data. Assays and any coded drill-hole data, such as lithology and alteration, can be interpolated.

Leapfrog Geo software is an example of this new approach to geological modelling. A case study of a short training course in geological modelling for non-geologists at the University of Witwatersrand, as part of the Higher Certificate in Mineral Resource Management, is presented. The benefits of this type of geological modelling software are considered for this type of assignment as well as for mining industry applications.

The use of geological models in mine planning is reviewed and a case study is presented comparing the variations in mine plan design and financial output of 13 final-year Mine Design projects from the University of the Witwatersrand School of Mining Engineering. These designs were all based on the same geological model created in the traditional way, and yet the resultant mine designs were significantly different, with very different resulting financial outlooks for the project. This raises questions as to how significant a very detailed model in the pre-feasibility and feasibility phases of projects really is, considering the huge costs involved in gathering the required data to build a SAMREC-compliant geological model.

Keywords: implicit geological modelling, mine design, software.

Introduction

This paper examines geological modelling from the perspective of a lecturer from the School of Mining Engineering with a background in Resource Geology as well as Mineral Resource Management. The questions that are raised look primarily at how geological modelling has changed recently and whether the new methods are acceptable for creating resource statements that comply with the South African Code for Reporting of Exploration Results, Mineral Resources and Mineral Reserves (SAMREC Code) or other international reporting codes.

The ease with which a student can be taught to do geological modelling is considered, as well as how the models that are created using implicit geological modelling software compare to those created in traditional ways. This is to answer the broad question whether the new modelling methods are just 'black boxes' or if they should be considered to be the best practice.

The paper then continues to look at mine designs and their production schedule-based discounted cash flows with the resultant net present value (NPV) and internal rate of returns (IRR). These two figures are often the numbers on which the investment decision is based, or by which projects are ranked in times of limited capital. This portion of the study was also conducted in the academic environment but was based on a real-world mine. The question was to consider how important the geological model is in the mine design, because so many other factors can also influence the final investment decision.

The School of Mining Engineering, at the University of the Witwatersrand in Johannesburg, South Africa is recognized as one of the top mining engineering schools and departments throughout the world. Mining engineers play a key role in the planning and exploitation of mineral resources. The School's programme is designed to provide the graduate with the engineering expertise that he or she will require as a mining engineer. The 4-year BSc Mining Engineering programme is the school's flagship programme and includes individual and group project work. The final project is a mine design project completed during the final months of the students' undergraduate year (University of the Witwatersrand, 2013). The School also has postgraduate programmes (MSc and PhD), as well as certificate programmes in Mine Planning and Mineral Resource Management for people currently in the mining industry. This study has been conducted considering students in both their final year of the BSc Mining Engineering programme as well as students on the Mineral Resource Management Certificate programme.

Geological modelling

Geological modelling is a computerized representation of lithological, structural, geochemical, geophysical, and diamond drill-hole data on and below the Earth's surface (Fallara, et al., 2006).

Geological models are based on limited data for subsurface interpretation. They simplify the complexity found in nature. Traditionally, accuracy of the resultant models depended on the experience and training of the modeller. In mining, geological models are used to predict the presence of economic quantities of minerals, and then quantify the amount of material available. Models are nowadays a fundamental part of mine planning. Prediction has an extrapolative rather than interpolative character, and thus involves risk and leads to decision-making (Hodkiewicz, 2013).

Resource geologists traditionally favoured the use of sectionally hand-digitized wireframe models for resource estimation (e.g. those created with Datamine, Gemcom, or other mining software packages). Automated methods were generally not considered appropriate by those traditionally doing modelling for estimation purposes. They were looked on as 'black boxes' that allowed the computer to do the interpretation, rather than the geologist. Advances in the software available for the automatic creation of geological models (implicit geological modelling) have led to the challenging of the traditional methods. This paper considers the advantages of these new methods, and asks if they are not actually the best practice.

The modelling challenge

Traditionally, 3D models are built from isolated borehole intersections as well as other sources of information (sections, surface mapping etc.). Interpretation is required to fill in the gaps between the areas of certainty. The models often simplify real-world complexity due to the lack of information. Owing to the degree of interpretation required, the model builder's skill, training, as well as personality all affect the resultant model, making verification of the model very difficult. Auditing the results presented in a resource statement could thus be exceedingly difficult as the model can never be replicated exactly. The production of these models is very time-consuming, as well as costly, considering the labour costs of a skilled geologist required for this task.

The challenges in geological modelling are thus to reduce the time it takes to build these models, to represent real-world complexity, and have models that anyone can replicate forauditing purposes. As new information becomes available, the models should be easily updated to reflect the new data accurately.

The benefits to the individual scientist of improving the method of building geological models are that the hours spent doing the boring wireframing are reduced. Due to the repetitive nature of this task it is often left to junior staff. There is then more time to verify the models and interpret specific aspects which the model has not represented adequately. The throughput of models increases and thus there is more job satisfaction for staff, more publications, and increased promotional opportunities. Updating models with new information can be done as soon as it becomes available, as the model can be linked to the database and thus automatically updated as the database is amended.

The benefits to the 'client' organizations are that the models are more consistent. There is less variation between their own in-house models and those created by independent consultants. This will allow models to be easily audited for inconsistencies and errors and thus give credibility to the resource statements published. The models are created efficiently and thus are easily updated as the new data is loaded without requiring expensive and time-consuming editing of the current model. This will aid decision-making as all the data available is utilized and the model uses the latest data.

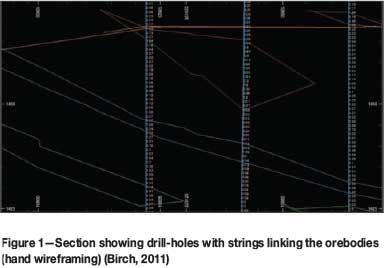

Traditional wireframing

Traditional models are created using wireframes based on geological logging of boreholes. This type of modelling is time-consuming and a good understanding of the geology is needed to make it effective. To create this type of model, the orebody is sliced into sections and the orebody intersections of the boreholes are linked by strings (Figure 1).

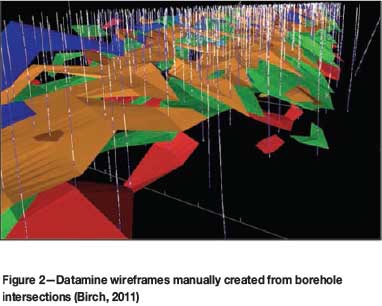

The method is time-consuming, and very repetitive, and relies on a fair amount of interpretation by the modeller while linking the strings. After the entire orebody has been interpreted, the strings are linked together to form the wireframes. This process must then be carefully checked to ensure there are no cross-over strings or openings as this will prevent the modelling software (e.g. Datamine) from filling the wireframe volumes with blocks that are needed for the evaluation, as shown in Figure 2.

If the initial borehole logging was done by inexperienced geologists who interpret the geology incorrectly, the computer modelling and orebody evaluation will not be effective.

Implicit geological modelling

Implicit geological modelling is a technique that uses a radial basis function to establish and update geological models relatively quickly and efficiently from borehole data, outcrop data, manually interpreted vertical or horizontal sections, and structural data.

The radial basis function allows scattered 3D data points to be described by a single mathematical function. Models can be isotropic, meaning without any trends or directional bias, or anisotropic, based on planar, linear, or more complex structural trends. Assays and any coded drill-hole data, such as lithology and alteration, can be interpolated (Hodkiewicz, 2013).

A commonly used software package for implicit geological modelling is Leapfrog Geo (Leapfrog, 2010).

Benefits of implicit geological modelling over traditional wireframing

A comparison of implicit geological modelling and the traditional method of hand digitization is shown in Table I.

This simple comparison of the two methods illustrates that there is no basis to the claim that traditional digitization is superior to implicit geological modelling for the generation of geological models. Table II shows that implicit geological modelling methods are in fact superior to hand digitization.

In modelling of true 3D objects, such as orebodies, interpolation methods in implicit geological modelling do not rely on sectional information to produce a 3D model. This is one of the major weaknesses of traditional modelling where the 3D model is built up from a series of sectional interpretations (Cowan, 2010).

International reporting codes

Investors have become far more circumspect in investing in mineral projects following scandals like Bre-X (Cawood, 2004). This has led to the introduction of various reporting codes, which are essentially aimed at protecting investors and holding professionals responsible for the figures that they release in the public domain. Compliance with these codes is considered a prerequisite for public listing on various international stock markets like Toronto (TSX), Australia (ASX), and the Johannesburg Securities Exchange (JSE). Codes, as opposed to laws, allow for professional judgment, and a good guide as to what is acceptable is doing what a reasonable person would do. To ensure compliance with this principle, mineral resource practitioners try to follow best-practice principles as far as practically possible, because this makes it easier to justify the decisions to professional peers if called upon to do so.

There are several classification schemes worldwide, including:

> Canadian CIM classification (NI 43-101)

> Australasian Joint Ore Reserves Committee Code (JORC Code)

> South African Code for the Reporting of Mineral Resources and Mineral Reserves (SAMREC Code).

In this paper, the SAMREC Code has been used for illustration purposes, but the other codes share the same definitions and broadly follow the same requirements for compliance. Figure 3 shows the relationship between mineral occurrences, Inferred, Indicated, and Measured resources, as well as the modifying factors required to convert Resources into Reserves.

Compliance with the SAMREC Code regarding the declaration of resources and reserves requires various aspects to be recorded and documented in a series of tables. Figure 4 is an extract from SAMREC Code Table 4, which deals with interpretation/modelling and thus is relevant for this discussion on geological modelling techniques.

Before implicit geological modelling can be accepted as a viable technique and be considered compliant with the SAMREC Code, the issue whether an automated modelling method can be considered to comply with the provisions laid out for modelling techniques as described in the SAMREC Code needs to be determined.

Table 4 in the SAMREC Code does not prescribe what modelling technique must be used. The Code does not specify what specific methods should be used for resource estimation process, provided that the geological assumptions are clearly stated and that these assumptions are reasonably consistent with the data. It is therefore inappropriate to suggest that a certain method (e. g. sectional digitization) is more suitable than other methods of modelling (Cowan, 2010).

Modelling summary

It is felt that the benefits of implicit geological modelling include faster modelling results, allowing for quicker response to new information becoming available. This will allow the exploration team to change their exploration strategy faster and focus exploration efforts on the areas with the highest possible returns. Furthermore, compliance with SAMREC has been demonstrated using the implicit geological modelling method. Focused exploration will have an upside in the tonnage available for mining, which will benefit the client when it comes to finding investors to progress the project.

Leapfrog Geo (a well-known example of implicit geological modelling software) is, however, considered with suspicion by traditional resource geologists, who still feel more comfortable with creating wireframes manually. A method that models the orebody automatically is perceived as a 'black box', and errors in data capturing and input will not be picked up. It is felt, however, that similar input errors can compromise the current method also, especially where the person doing the initial core logging is not skilled. Ultimately, any method must be checked, double-checked, and then independently verified.

Case study - can a non-geologist produce a valid geological model?

The School of Mining Engineering at the University of the Witwatersrand offers a Certificate in Mineral Resource Management (MRM). The MRM programme is a 2-year modular programme that was developed in close collaboration with industry and is aimed at filling a competency gap in the field of MRM. Delegates who successfully complete the programme obtain a certificate of competency in Mineral Resource Management. The programme is also a stepping stone to a postgraduate qualification at the School of Mining Engineering. Delegates may also register for specific individual modules and receive a certificate of competence in the module (University of the Witwatersrand, 2013). Not all the delegates on the programme are from a mining technical background.

Geological modelling module

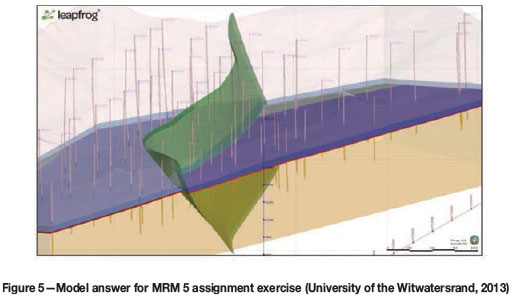

The MRM 5 module is an introduction to geological modelling and students are evaluated via examination and a practical assignment using Leapfrog Geo software. The practical assignment was based on a borehole data-set from the Merensky Reef supplied by Leapfrog South Africa. Leapfrog South Africa personnel modified the data-set to include some obvious and not-so-obvious errors. The students had to validate the data and produce a geological model. They were given strict instructions regarding the colour coding and how the output was to be presented. This module was presented in September 2013 by the author.

The focus of the assessment was ascertaining that the data errors were all identified and rectified. A detailed report on these errors was required. The model also had to be compliant to the 'client' requirements regarding colours and the format of the final output files. The models created by the students were furthermore compared to the model created by the author for accuracy. Figure 5 shows the author's model.

Figure 6 shows one of the models created by a student on the MRM 5 programme. This student had no previous geological modelling experience prior to attending MRM 5, and is an employee in the legal department one of the large mining companies.

As can be observed, all the major data errors were identified and rectified and the resultant model is visually similar to the model created by the module presenter. This type of deposit is traditionally difficult to model using traditional wireframe methods due to the very thin nature of the economic horizon. Leapfrog Geo allows the modeller to identify the age relationships between the various lithologies, and then creates the stratigraphic sequence automatically from the borehole intersections. The fault is digitized from the surface mapping and when activated, the displacement is automatically determined.

For an experienced modeller, this assignment could be completed in a very short period of time. The process followed for an entire deposit, would be the same as for this assignment, but just on a larger scale. As new data is loaded into the database, the model would be updated automatically. The most important component of the modelling process is data verification and ensuring the database is accurate. Most errors are easily identified in the model and thus the ability to quickly create a model goes a long way towards ensuring that the final model is accurate.

How important is the geological model in the mine design?

The international reporting codes require extensive documentation and compliance regarding the quality of the sample data and how it is collected, stored, and processed. This leads into the modelling and evaluation techniques used until the output of the classified resource statement is obtained. The SAMREC Code in South Africa is the guide to what is an acceptable level of detail for this statement (SAMREC, 2009). For the conversion of Mineral Resources to Mineral Reserves, the modifying factors must be stated and justified. These include the following:

> Mining methods

> Minimum mining dimensions

> Mining dilution mining method

> Mine design criteria

> Infrastructure

> Capacities

> Production schedule

> Mining efficiencies

> Grade control

> Geotechnical and hydrological considerations

> Closure plans

> Personnel requirements.

The whole scheduling aspect of a mine design is critical in converting the Mineral Resource into a monetary value due to the considerations of the time value of money (and resultant net present value, NPV, and internal rate of return, IRR).

This paper considers how assumptions made during the mine design and scheduling process can affect the financial outlook of a project at the pre-feasibility study (PFS) stage, using the School of Mining Engineering Final Mine Design Project as a case study. Thirteen groups of students were given the same geological model as a starting point for their mine designs. This model can be considered a perfect representation of the orebody for the purposes of this project, as they were not required to recreate or verify this model as part of their project. In reality, when a group of consultants do pre-feasibility studies on an orebody, each consultant would create their own geological model, which adds a whole layer of variation when comparing the results. The mine design exercise presents a fairly unique opportunity to compare 13 interpretations of the same geological model taken to PFS level. In the corporate world, due to the costs involved, a company would never commission 13 different mine designs.

Final Mine Design Project

Seventy final-year students were split into 13 groups with 5 or 6 members in each group. According to the brief given at the start of the project, the students had to carry out a mine design exercise to the level of a PFS based on the mineral deposit block model supplied to them. They were to utilize the knowledge gained over their previous coursework, as well as experience gained during vacation work, to complete the project. They then had to make a substantiated recommendation regarding the viability of mining the deposit. The financial aspects of the project were thus critical, as well as the technical aspects. For 2013, the final mine design project was the Lily Gold Mine, close to Barberton in the eastern part of South Africa.

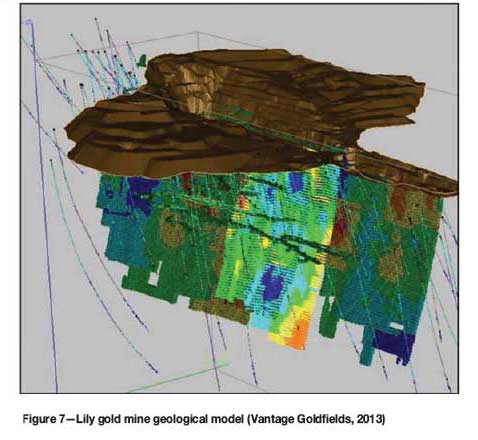

The students were supplied with a high-quality geological block model of the deposit created by the mine geological team (Figure 7). For purposes of this study, this block model can be considered to be perfect, as they all were given the same model and accepted it as a true representation of the deposit.

Lily Gold Mine

The Lily Mine began as an open pit operation in 2000. The open pit closed down in 2008 after producing more than 100 000 ounces of gold. The orebody extends for at least 2000 m along strike and has been drilled to a depth of approximately 700 m. A detailed geological model was created by the mine and was presented to the students for their mine plan (Figure 7). The current underground mine design has been constrained due to available capital, and the students were expected to take this into account and thus come up with designs significantly different due to the removal of this constraint.

Mine Design report

The students were instructed to start their designs at the stage where the mine began underground operations and the plant had a maximum capacity of 37 000 t/month. If they wished to increase the plant capacity, they would have to budget for this increase in their mine design. The students were given the geological model as generated prior to the underground development; based on the sampling in the pit as well as the surface diamond drill-holes (Figure 7). The final report presented to the School of Mining was to cover all the aspects of a mine design and was expected to be at a level of detail that would be acceptable as a PFS. Most of the staff in the School were allocated specific chapters in the report and mentored the students as to what was expected to complete their chapters. They then graded those chapters as part of the final mark. The students also presented their final designs to a panel of staff members, as well as external examiners from industry. In 2013, the external examiners were staff from Lily Gold Mine.

Mine financial valuation

For this study, the variations between the mine designs and their impact on the financial valuation chapter of the report were considered. For this chapter, the students had to determine the construction/establishment times and costs, as well as operating costs for the life-of-mine. They had to determine appropriate levels and methods of beneficiation and apply the correct royalty and income tax rates. They then had to do a full cost-benefit assessment of the project, including a discounted cash flow (DCF) analysis and calculate the resultant net present value (NPV) and internal rate of return (IRR). Based on these figures, they had to make appropriate recommendations regarding investment in the project.

Results

The final financial results from the groups were very different. Only two of the groups chose to increase their planned tonnages from the mine above the current plant's maximum of 37 000 t/month. With these two groups, the capital costs for construction of the mine varied primarily with the plant costs and building extra mining capacity. The lower resultant mining costs allowed for lower cut-off grades and higher extraction rates. Some of the groups were very conservative as to how much of the measured reserve they putt into their life-of-mine plan, and all the groups restricted their designs to only the Measured portion of the Mineral Resource statement.

The mining profiles (production ramp-up and grade) were very different between the groups. The capital spending scheduling was also very different. The relationship between higher initial capital spend and a lower mining cost would be expected, but this is not always apparent when looking at the relationship between capital and working costs in these designs.

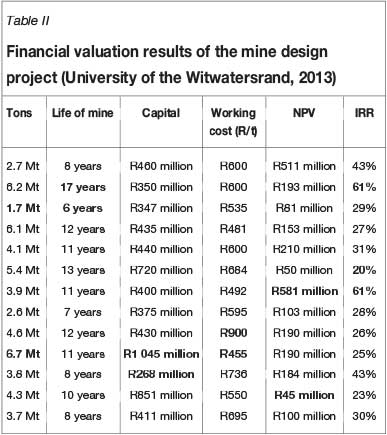

The tons mined, life-of-mine, capital costs, working costs, NPV, and IRR are shown in Table II.

The life-of-mine tonnage profiles vary from 1.7 Mt to 6.7 Mt. The life-of-mine varies from 6 to 17 years. The capital costs vary from R286 million to R1 045 million. The working costs vary from R455 to R900 per ton. The resultant NPVs range from R45 million to R581 million, and the IRR varies from 20% to 61%.

There is thus a three-fold increase from the lowest IRR to the highest, and an order of magnitude difference between the lowest and highest NPV.

Investors in mining projects often use the NPV and IRR as their primary decision-making tools. Based on the results of the exercise, potential investors would either reject this project as being too marginal (IRR of 20%) considering the current financial risks associated with mining gold in South Africa, or be very enthusiastic about the project and willing to invest (IRR greater than about 40%).

It must be noted that all the groups made errors in their projects, but they all produced designs of sufficiently high quality to pass the course. For the chapter on financial valuation, the lowest mark given was 50% and the highest was 90%. This chapter counted for 8% of the final Mine Design report mark.

Conclusions

New software is speeding up the geological modelling process and giving more consistent results. This allows more time to focus on interpretation and allows for faster revisions to the model. The learning curve is far quicker than for traditional modelling techniques and the skills set required to produce successful models is greatly reduced. This paper presents a case study demonstrating that a student with no previous geological experience can produce a simple model from a borehole data-set that broadly matches that produced by the lecturer, identifying a range of errors and correcting them. It has been shown that the SAMREC Code does not dictate the method that has to be used to create the model, being more focused on the correct recording and validation of the data used in the estimation of the mineral resource. It is thus felt that implicit geological modelling software like Leapfrog Geo is superior to traditional methods and should be considered best practice for geological modelling.

The SAMREC Code is very limited when it comes to specifying how the mine design is created and scheduled, which can have a major impact in the resultant NPV and IRR. All that the Code requires is that the modifying factors are documented and justified. Even a single geological model is open to huge variations in, and interpretations of, the mine design/scheduling phase, which can make or break the project's success. It has been shown that groups of student mining engineers, using the same geological model, can produce mine designs that result in significant variations in the financial outlook of the project.

Investors are often not experienced in mine design and scheduling. Even if they are satisfied with the capital and working cost stated in the design, the differences in when the capital is spent and the revenue obtained from the mining of the orebody are hard to verify. They are thus totally reliant on the experience of the mining engineer to optimize the design to ensure the highest return on the investment.

References

Birch, C. 2011. Mineral Resource Throughput Management Analysis of Otjikoto Gold Project, Situated near Otavi, Namibia. Masters dissertation, University of the Free State, Bloemfontein. [ Links ]

Cawood, F.T. 2004. Towards a mineral property valuation. Journal of the South African Institute of Mining and Metallurg, vol. 104, no. 1. pp. 35-43. [ Links ]

Cowan, E.J. 2010. Director: Prestologic. Personal communication. [ Links ]

Cowan, E.J., Beatson, R.K., Fright, W.R., McLennan, T.J., and Mitchell, T.J. 2002. Rapid geological modelling. Applied Structural Geology for Mineral Exploration and Mining, Kalgoorie, Western Australia, 23-25 September 2002. Abstract volume. Vearncombe, S. (ed.). Australian Institute of Geoscientists Bulletin, vol. 36, pp. 39-44. [ Links ]

Fallara, F., Legault, M., and Rabeau, O. 2006. 3-D Integrated geological modeling in the Abitibi Subprovince (Quebec, Canada): techniques and applications. Exploration and Mining Geology, vol. 15, no. 1-2. pp. 27-41. [ Links ]

Hodkiewicz, P. 2013. Leapfrog: new software for faster and better 3D geological modelling. http://www.srk.com.au [Accessed June 2013]. [ Links ]

Leapfrog. 2010. Leapfrog Geo. http://www.leapfrog3d.com/products/leapfroggeo [Accessed 2010]. [ Links ]

SAMREC. 2009. South African Mineral Resource Committee. The South African Code for Reporting of Exploration Results, Mineral Resources and Mineral Reserves (the SAMREC Code). 2007 Edition as amended July 2009. http://www.samcode.co.za/downloads/SAMREC2009.pdf [Accessed 10 April 2014]. [ Links ]

University of the Witwatersrand. 2013. School of Mining Engineering. http://www.wwits.ac.za/miningeng/4810/miningeng.html [Accessed December 2013]. [ Links ]

Vantage Goldfields. 2013a. Lily Mine. http://www.vantagegoldfields.com/index.php?option=com_content&view =article&id=73&Itemid=37 [Accessed December 2013]. [ Links ]

Vantage Goldfields. 2013b. Vantage Goldfields Project Locations. http://www.vantagegoldfields.com/index.php?option=com_content&view =article&id=76&Itemid=25 [Accessed December 2013]. [ Links ]