Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.114 n.12 Johannesburg Dec. 2014

A SOUTHERN AFRICAN SILVER ANNIVERSARY MEETING, 2014 SOMP

Mine disaster and mine rescue training courses in modern academic mining engineering programmes

H. Mischo; J. F. Brune; J. Weyer; N. Henderson

Technical University Bergakademie Freiberg, Freiberg, Germany

SYNOPSIS

The mining industry worldwide is currently facing a significant restructuring process. In most underground mines, widespread mechanization of the mining processes increases production while reducing staff numbers. At the same time, mining depths as well as the lateral spread of the mine workings are increasing. This ever-changing mining environment requires sophisticated solutions for the design and operation of underground mines. In fact, a reduced number of mining engineers is taking responsibility for ever-increasing mine operations. This applies not only to the excavation of the minerals, but also to all other aspects of the mining operation, including health and safety, disaster management, and mine rescue organization.

Most mining engineering graduates entering the industry lack experience in mine emergency management. Young engineer trainees must learn mine emergency management and rescue work in addition to their normal training experience on the job. Often, and unfortunately, emergency and rescue training at different mining companies is not carried out to the highest level and standard and with the best possible training outcomes. The tasks and challenges a young engineer faces while being trained in a new position do not leave much room for additional training in mine rescue and emergency management. At the same time, experienced, 'old hands' are retiring and cannot easily be replaced due to limited graduation numbers.

Strategies are being developed at mining universities worldwide to train mining engineering students in handling mine emergency situations and to provide hands-on experience for managing potential accident and disaster scenarios underground. Two of these strategies, from the USA and from Central Europe, are presented in this paper. These specific strategies have to be seen under special consideration of the local and regional boundary conditions, but might serve as case studies for mining schools and universities in other countries.

Keywords: mine disaster and emergency management, education and training, mine rescue training, underground education and training, student education and training, internationalization.

University mine rescue training courses at Colorado School of Mines

Industrial background

The mining industry in the USA is still a major contributor to the primary sector of the economy. In 2010, there were a total of 819 underground mines actively operating in the USA (CDC-NIOSH, 2010).

Well-established mine regulations at the federal and state levels and specialized enforcement authorities provide a high-quality legislative and organizational environment for the implementation and organization of mine rescue and emergency management. Federal regulations require each underground mine to have two mine rescue teams available while miners work underground. Small and isolated mines may share rescue teams by entering into agreements with neighbouring mines or the States. These primary rescue teams must be available on-site within 'reasonable time' following notification (US Code of Federal Regulations. 2014.

The mine rescue training programme at Colorado School of Mines

In the early 1980s, Missouri University of Science and Technology (MST) was the first to institute a university mine rescue team to prepare mining engineering students to handle mine emergency response and rescue situations. In 2009, the Colorado School of Mines (CSM) followed with its own programme. Currently (2014), eight North American mining universities operate mine rescue programmes fielding one or more mine rescue teams.

CSM currently trains three student mine rescue teams: an experienced men's team, an experienced women's team, and a co-ed team made up of first- and second-year students to allow new members to gain exposure and to be trained for the experienced teams. The first CSM team was formed in 2009, the second in 2010, and the third team in 2011. Membership in the CSM mine rescue programme is voluntary and open to students of all majors at CSM. The programme is organized and run by students, and the participating students do not receive school credit for their participation. Currently, the teams are made up of engineering students from nearly all major engineering courses at CSM. The only condition of membership is that the students are able to meet basic physical requirements in order to ensure the personal health and safety of the team members and of the entire team during programme activities. The student team captains design training plans together with the faculty programme coordinator. The programme's faculty advisor assists with the logistics of the trainings and helps organize practices, practice sites, equipment, tools, and supplies. Mine rescue specialists from the mining industry are often called in to help at these practices and to teach specific subjects ranging from equipment maintenance to mine ventilation, first aid, communication, and map work. The teams are organized in the same way as professional North American mine rescue teams, with each team composed of a minimum of seven members: five members in the underground team and two at the fresh air base. All team members must be trained to wear breathing apparatus and in first aid, and many members are trained as emergency medical technicians. Generally, two or more members of each team are designated technicians with expertise in equipment maintenance, while at least three members specialize in first aid. Teams are also trained in the operation of an incident command centre.

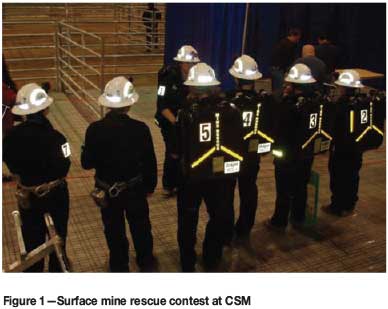

Training objectives are established at the beginning of each academic year. Practices may include full mine rescue problems, post-disaster exploration exercises in artificial smoke, technical rescue training, and specialty practices. In total, at CSM the teams practice more than 2000 man-hours per year. The overarching goal is that each rescue team and every team member can demonstrate proficiency and understand mine rescue procedures, regulations, and mine rescue rules. Training is often carried out in a two-stage approach. In the first stage, rescue teams practice in simulated mine environments installed at a surface facility. Training objectives are to execute mine rescue tasks in a simplified mine layout on surface without the obstacles and environmental conditions that rescuers would face in real underground emergencies. The surface facilities are open so that teams can see each other and instructors can observe each team member individually. Mine rescue contests (Figure 1) have been established in many locations and at various levels of competence as a way to train teams to think through specific situations and to prepare for real underground exploration exercises.

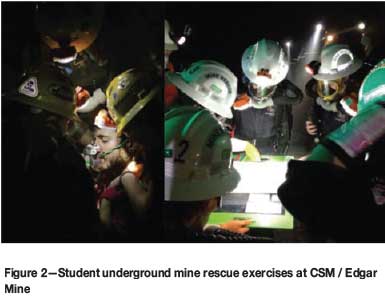

In the second stage, CSM mine rescue teams train in a real underground mine environment. These underground exercises allow teams to develop advanced team communication skills and to practice realistic mine rescue scenarios. These exercises are held at the Edgar Experimental Mine, which is operated by CSM in Idaho Springs, Colorado (Figures 2 and 3). A typical example of such underground exercise is an exploration-focused practice such as a scavenger hunt in a smoke-filled section of the mine. With limited visibility created by theatre smoke, the teams work under breathing apparatus to find and map a specified number of objects and report their exact location to the fresh air base (FAB). Teams also record air quality and damage to ventilation control equipment, roof falls, and other evidence of a fire or explosion. Team members stationed at the FAB record all observations and report them to the incident command centre (ICC). Such exercises not only test the team's ability to move and co-operate in smoke, but they are also a great tool to practice communication between the map man, the co-captain, and the FAB. Other types of mine rescue practices may include high- and low-angle technical rope rescue, confined space training, and firefighting both underground and at surface locations. The Edgar Mine is equipped with a confined space maze that is currently being upgraded to provide a realistic experience for navigating complex, tight spaces in smoke and for carrying out rescue missions where an injured person must be extracted. The CSM teams are also given access to a large variety of additional firefighting and medical rescue training courses held at the Edgar Experimental Mine for professional firefighters and emergency management teams from nearby cities and towns. CSM mine rescue teams also develop valuable skills in special interest areas that include first aid, mine ventilation management, and rescue equipment maintenance.

Each year, all three CSM mine rescue teams compete in professional mine rescue contests. These contests are a great opportunity for the student teams to test their skills against professional mine rescue teams and to expand their network. The contests evaluate the competitors on their knowledge of mine rescue rules and regulations, their ability to work as a team, technical understanding of their equipment, and first aid abilities. The contests are split into four sections: written test, field competition, technician competition, and first aid competition. Each section challenges a different aspect of the team's mine rescue knowledge and enables judges and trainers to easily identify areas needing improvement. All CSM teams compete in state-wide and regional mine rescue contests, and often attain top placements in competitions with professional mine rescue teams.

Every other year, the CSM mine rescue programme hosts the Biennial Intercollegiate Mine Emergency Response Development Exercise (MERD) at the Edgar Mine in Idaho Springs, Colorado (Figure 4). This competition is for student mine rescue teams only. At the most recent MERD in the spring of 2013, five rescue teams participated; three from CSM, one from the University of British Columbia in Vancouver, Canada, and one from the Missouri University of Science and Technology at Rolla, Missouri (Figure 5).

These student MERDs are a great opportunity for mining engineering students to network and learn from each other, while also obtaining advice from professional mine safety and rescue specialists. Each team is assigned a mentor, an expert in the mine rescue field, who follows the team throughout the competition and provides advice, allowing the students to learn as much from the competition as possible. Professional mine rescuers bring a wealth of helpful suggestions and advice for the student teams, teaching from their real-life experiences. There are also several professional mine rescue trainers, with years of experience in the field of mine safety, who attend the student practices and competitions, mentor students, and teach classes in their areas of specialty. These experts serve as role models for the students and are a great resource throughout their collegiate career and often into their professional lives as well.

Mine rescue and mine disaster management training at the Technical University Bergakademie Freiberg

Industrial background

Due to the ongoing restructuring and simultaneous decline of the number of large underground mining operations, the mining industry in Central Europe is experiencing a steady reduction of staff numbers in the remaining mines. It is feared that the well-established, centralized mine rescue organizations may collapse within the next decade. With this, a large number of small mines and underground operations may face a lack of skilled and capable mine rescue support. New strategies and organizational efforts for sustainable mine rescue operations in Germany are currently being discussed. German federal mining law requires companies to provide suitable mine rescue coverage for their underground operations. Mines must either establish their own rescue teams or join and support centralized mine rescue organizations or rescue teams. Based on the size and number of the active underground mining operations in Germany, five central main mine rescue centres are maintained nationwide. Two of these centres are operated by the German hard coal mining industry, while the other three centres are run by the BG RCI, the employers' workman's compensation insurance association for the minerals and chemical industries. These central mine rescue centres are responsible for the education and certification of mine rescue team members and the ongoing education and training of teams and team leaders. The rescue centres are equipped with sophisticated testing equipment for maintaining and calibrating mine rescue equipment. The centres also establish guidelines and recommendations for the use of the personal protection and rescue equipment, as well as for the execution and coordination of rescue operations, and set the standards and write content for mine rescue training courses.

In Germany, every active member of a mine rescue team must be a minimum of 18 years old and should not be older than 40. All members are volunteers, and individuals may serve as a team member, a team captain, or a chief. All members must be fully cross-trained, experienced miners who are familiar with a variety of situations underground. All rescue team members must have medical clearance under German medical standard G26/3, a specially designed, extensive medical examination under physical stress for people working under breathing apparatus. This clearance must be obtained before a rescue team member may be permitted to wear a breathing apparatus in a mine rescue operation. This thorough medical examination must be passed every second year and must also be renewed after recovering from illness or accident. The content and duration of the training for rescue team members, team captains, chiefs of rescue teams, and equipment attendants (bench technicians) are prescribed in the guidelines of the central mine rescue stations. These guidelines also govern education and training for mine rescue teams, organization and preparation of rescue operations, the minimum number of rescue teams that must be present on site before a rescue operation can commence, and a list of equipment required in order to start the rescue operation. An apprentice may become a mine rescue team member after attending a one-week basic training course and passing additional theoretical and practical examinations.

Due to the ongoing restructuring in the mining industry, some changes in the basic structures of mine rescue operations must be implemented. Generally, a minimum of three fully operational mine rescue teams must be on site to start a mine rescue operation in a non-coal mine, while ten teams must be present at a hard coal mine. Under the new structure, smaller, three-man teams maybe formed under certain circumstances at small mines to enter the mine for life-saving operations only, with a second team on standby. The new regulations, together with other restructuring elements, adapted laws, as well as modified operating schemes have been presented to the public and are expected to be implemented during the year 2014. The mining engineering department of the Technische Universitat Bergakademie Freiberg (TU BAF) has been part of the restructuring programme for several years and has hosted a number of scientific conferences and workshops on the reorganization and restructuring of the mine rescue scheme in central Germany.

Mine rescue and disaster management courses at Technische Universitat Bergakademie Freiberg

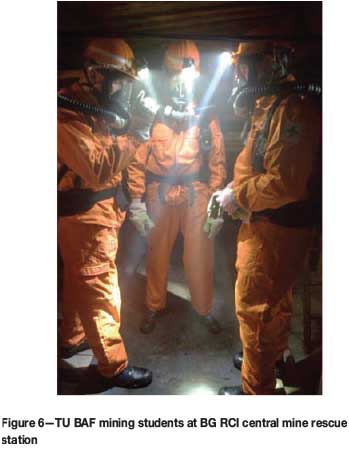

Occupational health and safety is a core competence for mining engineering graduates. This led to the incorporation of related course content into the mining engineering curriculum almost a century ago. Today, a specific course covers the subject not only for mining engineering students, but also for all other raw-material majors. For several decades, mining engineering students have been trained in a supplementary course in mine rescue provided by the central mine rescue station of BG RCI in Leipzig (Figure 6). During this block course, students are introduced to the structure, tasks, and responsibilities of mine rescue as well as the organization of a mine rescue operation.

The course ends with a 'hot' emergency practice under breathing apparatus in the BG RCI exercise and training centre, which resembles the confined spaces and obstacles of an underground mine (Figure 7). Like every other mine rescue team member, the students also must obtain the medical certificate G26/3 before being admitted to this course. The course was formerly a mandatory part of mining engineering education, but owing to the constraints of the European harmonization in engineering education, the legal situation now is that it can be offered on a voluntary basis only. Nevertheless, the vast majority of students participate in the training.

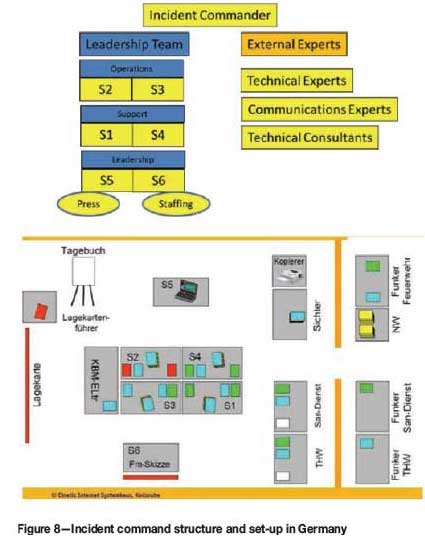

During a mine emergency, mining engineers often play a leading role in the organization and the technical management of the disaster instead of going underground with the mine rescue teams. To prepare engineering students for this role, a new course on incident control and management was added at TU BAF in 2012. This course is taught primarily by guest lecturers, who are also working as expert consultants in mine emergency management for the German mining industry. The course content includes incident command structures (adapted from military command structures - Figure 8), incident management, use of control and software tools, communication, organization of incident control, as well as public relations in cases with serious and fatal injuries. Students perform several practical exercises where they assume different roles managing an emergency. The role-playing exercises are designed following real incidents and include the necessary internal and external communication as well as public relations management, including press releases and press conferences. This course is mandatory for all mining engineering majors.

In 2013, staff of the mining engineering department of TU BAF had the chance to participate in the second MERD at the Colorado School of Mines as external observers. Following this exercise and close interaction and discussions with their American colleagues, a similar student mine rescue team structure has been implemented at TU BAF, making use of the 'FLB Reiche Zeche' research and experimental mine on campus (Figure 9). A member of the CSM student mine rescue team was invited to Germany and worked on an implementation project at TU BAF in the summer of 2013. The Freiberg student mine rescue team will be trained like all other professional mine rescue teams in the region and will also be outfitted with the standardized breathing and technical rescue equipment. The goal is to not only operate this mine rescue team for the training of the students, but also to support the existing mine rescue structure of the FLB experimental mine with additional forces. An extensive training space at the FLB is being modified to be used as an underground mine rescue training centre not only for mine rescuers, but also for underground and confined space training for firefighters, the federal agency for technical relief (THW), and other special rescue teams. Currently, the legal requirements for the large scale integration of a student mine rescue team into the safety and rescue structure of the mine as well as into the overall disaster control structures of the region are being discussed with the local mining authorities.

Support and equipment for mine rescue teams

The CSM mine rescue programme receives technical and financial support from many corporate sponsors in the mining industry. Companies support the collegiate mine rescue system by providing funding for travel, donating equipment, and volunteering their time as experts and trainers. CSM mine rescue teams also frequently borrow equipment from Freeport-McMoRan's Henderson Mine Rescue Team and from the State of Colorado Front Range Mine Rescue Team. From the inception of the CSM mine rescue programme, these two organizations have provided strong support by permitting the students to use their equipment. The CSM teams are working toward acquiring all necessary gear to become independent and fully equipped mine rescue teams. During the 2012-2013 school year, the programme was successful in expanding its equipment inventory, with the donation of five new Sentinel BG-4 rebreathing apparatus sets from Drager and a Mine ARC permanent mine refuge chamber installed in the Edgar Mine. Currently, CSM is rebuilding and expanding the training maze with a section of belt conveyor, a sound system to produce realistic sounds of equipment starting up, and sensors to monitor the rescue team operation in thick smoke.

The professional mine rescue teams from local Colorado mining companies and local fire departments are also major supporters of the CSM mine rescue programme. They volunteer their time to assist with practices and help advance the students' learning.

At TU BAF, the established annual mine rescue block course at the central mine rescue station in Leipzig is sponsored by the BGRCI. The incident management course is run by lecturers from CKK Company and sponsored by the RWE Group. The on-site mine rescue training is executed by the foremen of the Wismut GmbH mine rescue station, which still represents the core of the new Saxonian mine rescue structure. Training is supervised by their chief advisors and the CEO of the Leipzig Mine rescue station.

For mine rescue education at TU BAF and for the training of the new student mine rescue team, the Dragerwerk AG & Co. KGaA has donated a number of brand-new Drager PSS® BG4 Plus breathing apparatus sets as well as latest-generation gas detection devices. The MSA Auer GmbH, a subsidiary of the MSA group, has donated several latest-generation gas detection devices as well as two sets of AirElite 4h breathing apparatus. These AirElite 4h units provide the same standard as all the other regional mine rescue units in Saxony, thus allowing the student mine rescue teams to be trained together with the professional mine rescue teams (Figure 10).

Conclusions

Student mine rescue and emergency training is a unique way to emphasize the importance of mine safety and mine emergency management to young engineers. It allows students to enter the industry with valuable skills, including recognition of safety and health hazards in mining, while providing an opportunity for professional networking. Participation in student mine rescue also benefits students from majors other than mining engineering by developing skills that lead to responsible performance under pressure, while emphasizing the importance of working as a team in the challenging environment of an underground mine rescue. Different legal and industry standards and boundary conditions in different mining regions may require specialized curricula for student mine rescue training courses.

References

Bezirksregierung Arnsberg. 2001. Bergverordnung fur die Steinkohlenbergwerke (BVOSt) (Mine Regulations for Hard Coal Mines). 10. January 2000, updated 1 June 2001. [ Links ]

EN-ISO 50303. 2000. Normen fur den Explosionsschutz im Bergbau - Gruppe 1, Kategorie-M1-Gerate fur den Einsatz in Atmospharen, die durch Grubengas und/oder brennbare Staube gefahrdet sind; Deutsche Fassung (Standards for Explosion Prevention and Protection in Mining Operations - Group 1, category M1 equipment intended to remain functional in atmospheres endangered by firedamp and/or coal dust). [ Links ]

Henderson, N., Mischo, H., and Brune, J. 2014. Students mine rescue in today's mining engineering curriculum. Mining Engineering, vol. 66, no. 2. pp. 33-37. [ Links ]

Hermülheim, W., Bresser, G., Fuchs, E., Langer, G., Ollesch, E., and Junker, M. 2007. Handbuch fur das Grubenrettungswesen im Steinkohlenbergbau (Mine Rescue Compendium for Hard Coal Mining). VGE Verlag, Essen. ISBN 9783-7739-1365-4. [ Links ]

Junghans, R.1969. Lehrbuch der Sicherheitstechnik. Band 1 Grubensicherheit (Textbook of Safety Technology, Part 1 Mine Safety). Deutscher Verlag fur Grundstoffindustrie VEB, ASIN B002PPZRMO. [ Links ]

Mischo, H. (ed.). 2013. Zukunftige Organisation des Grubenrettungswesens in Sachsen (Future Mine Rescue Organisation in Saxony). Medienzentrum der Bergakademie Freiberg. ISBN 978-3-86012-465-9. 182 pp. [ Links ]

Mischo, H. and Weyer, J. 2014. Reorganisation of mine rescue services scheme in Central Europe. SME Annual Meeting, Salt Lake City, UT, 23-26 February 2014. Preprint 14-064. [ Links ]

Us Department of Health and Human Services. CDC-Niosh 2010. http://www.cdc.gov/niosh/mining/statistics/allmining.html [Accessed 12 April 2014]. [ Links ]

US Code of Federal Regulations. 2014. Title 30, Part 49, Mine Rescue Teams. [ Links ]

Westfälische Berggewerkschaftskasse Bochum. 1985. Grundriss der Bergtechnik (Basics of Mining Technology). VGE Verlag, Essen. ISBN 9783-7739-0443-6. [ Links ]

† Colorado School of Mines.