Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.114 n.11 Johannesburg Nov. 2014

GENERAL PAPERS

Characterization and flocculation studies of fine coal tailings

S. Kumar; S. Bhattacharya; N.R. Mandre

Department of Fuel and Mineral Engineering, Indian School of Mines, Dhanbad, India

SYNOPSIS

The re-use of waste water from coal preparation plant tailings is always desirable, but is generally problematic in terms of solid-liquid separation. Dewatering and disposal of coal slurry at a high percentage of moisture poses a major technological and environmental challenge to mining and mineral processing industries world-wide. Characterization and floccu-lation of these coal tailings reveals that the separation of fine coal tailings depends on factors such as size distribution, slurry viscosity, zeta potential, pulp density, circuit design, plant operating parameters, and the behaviour of solid particles in an aqueous medium. The present study was carried out on -600 mm coal tailings collected from a coking coal preparation plant of Jharia Coalfield, India, using anionic flocculent. Characterization studies revealed that the zeta potential was highest (-44 mV) at a pH of 9.0, the size range of the particles was 1.1-700 μτη, and the average ash content was 62.57%. Flocculation studies were performed at different solid concentrations, pH values, and polymer dosages. The results indicated an efficient settling rate of 178.15 mm/min at 8% solid (w/w) at a flocculent dosage of 32.50 g/t solid. The turbidity of the clear liquid obtained was 7.42 NTU.

Keywords: flocculation, coal fines, settling, dewatering.

Introduction

Coal mining has essentially become a set of mechanized operations. Mining and subsequent processing generate considerable amounts of fine tailings. About 20% of the product from a typical coal preparation plant (CPP) is less than 500 μΐη in size (Parekh, 2009). Generally this fine fraction is discarded due to the high cost of processing it. The fine solid particles in CPP tailings also present many environmental and economic challenges to society and industry. Discard of fines also disturbs the overall water balance of the circuit by increasing make-up water requirements to the plant. Therefore dewatering of such coal tailings is fast emerging as one of the priorities for CPPs around the world.

With the development of advanced coal cleaning technologies such as flotation, the Jameson Cell, Pneufloats, etc., cleaning of fine size coal to low ash and low sulphur contents is feasible nowadays. However, the commercialization of these technologies is hindered, partly due to the poor efficiency of dewatering circuits for fine coal slurry, which may be attributed to the presence of coal particles of different sizes, shapes, surface area, and specific gravities, and their unique behaviour in the aqueous environment. Furthermore, industrial waste slurries containing colloidal particulate matter, in particular coal and mineral processing plant tailings with a high proportion of clay materials, pose significant challenge in dewatering (Philip et al., 2011).

Therefore, to significantly improve the dewatering performance, it is important to understand the characteristics of coal, the chemistry of the carrier liquid, the impurities present, and their influences on the solids content. Industrial fine coal dewatering circuits contain thickeners, cyclones, screens, filters, centrifuges etc., either in combination or individually. However, most of these dewatering options, which reduce the moisture level to 20-30%, entail high capital and operating costs and hence conventionally are used for dewatering of clean coal and not for coal tailings.

Most CPP tailings are settled in tailing ponds, usually at high water content, 65-75% (w/w), causing continuous loss of water. Therefore, it is essential to model a suitable low-cost dewatering method, usually by sedimentation in a thickener, to make it possible to recycle a large volume of clean water in CPPs (Sabah et al., 2004). Thickeners are the most commonly used equipment for dewatering of slurry; the design considerations are based on the settling rates of the slowest settling particles and conditions for minimum disturbance of the medium (water) through which the solid particles are allowed to settle (Gupta et al., 2006). From the literature it may be seen that waste slurries produced from CPPs contain high percentages of ultrafine particles and inorganic impurities, which are composed of clay minerals such as kaolinite and illite, muscovite, quartz, and coal particles (Das et al., 2006). The natural sedimentation rate of these particles in colloidal and finely divided suspended form is very low. Flocculation technology is applied in most CPPs to enhance the settling rate of solids and to recover water from the tailings.

Flocculation is a complex process and its effectiveness depends not only on the use of appropriate chemical reagents (coagulants, flocculants etc.) and their method of addition, but also on the mineral composition (Sabah et al., 2004). Accurate determination of the physical, chemical, and electrokinetic properties of solid matters in pulp, especially when using flocculants, plays a key role in the success of destabilizing fine-particle suspensions.

Addition of flocculents (long-chain polymers) in a dilute stable suspension bridges particles together, leading to the formation of highly porous and irregularly shaped flocs that have complex shapes, and possess rapid initial settling velocity, trapping some liquid in their structures (Parsapour et al., 2014). The nature of flocs depends on factors such as the physical properties of the solids (surface chemistry, size, size distribution, shape, density), the nature of the liquid (viscosity, dielectric constant), the nature of the suspension (electric charge, pH, ionic strength, temperature), and the nature of the flocculent (chemical properties of the main part and chains, molecular weight, molecular weight distribution, electric charge, charge density). Also, the properties of flocs, such as flocs size, density, structure, and strength significantly influence the settling rate and hence the performance of solid-liquid separation.

Furthermore, an understanding of the interaction mechanism between polymeric flocculent and solid particles in a slurry and the associated flocculation mechanism is of great practical and fundamental importance in mineral processing and interface science (Yaguan Ji et al., 2013). For effective flocculation, synthetic or natural polymeric reagents are generally used as flocculating agents in most CPPs. However, the optimization of process parameters such as suspension pH, polymer type, and dosage are also important to achieve the desired settling rate and the water clarity values (Das et al., 2006). This paper presents the results of a study of the physical and electrochemical characteristics of coal tailings and the flocculation process, using a synthetic polymer at various pulp densities and slurry pH values.

Experimental

Materials

The coal sample used in the experiments was collected from Jharia Coalfield, India. The capacity of the plant (plant feed) was 200 t/h (ROM coal), of which 25-30 t/h reports as plant tailings. A high molecular weight polyacrylamide-based anionic polymer, Magnafloc1011 (M1011) supplied by BASF India, was used in the flocculation tests, having a bulk density of 0.7 g/cm2, size 98% <1000 μm, and viscosity varying from 300 cP at 0.1% concentration to 1997 cP at 1% concentration.

Prior to the flocculation tests, a homogeneous stock solution (0.25% w/w) of polymer was prepared using distilled water. The stock solution was further diluted to 0.02% (w/w) concentration for the flocculation tests. Slurry pH was adjusted by addition of either HCl or lime solution prior to adding the flocculants.

Methods

Characterization studies

Size analysis of a representative sample was done at sieve sizes of 600, 425, 300, 211, 152, 104, 75, and 53 μηι. Sub-sieve analysis of the -53 μm size sample was carried out using a Warman Cyclosizer. A Nano-S90 zeta sizer was used to analyse smallest size particles.

For zeta potential measurement, a suspension containing 0.05-0.1 wt% coal was prepared, the pH value of which was adjusted using either HCl or NaOH. After being left to settle for 6 hours, the upper portion of the diluted fine suspension was extracted for zeta potential measurement using a Zeta-Meter 4.0, which is equipped with a microprocessor unit capable of directly measuring the average zeta potential and its standard deviation. The zeta potential was measured at different level of pH from 2-12.

Flocculation studies

The coal sample was subjected to flocculation tests using a 1000 ml graduated cylinder. For this purpose the desired amount of coal was mixed in water to the desired pulp density and the pH of the slurry was adjusted by using dilute HC1 and NaOH. The water used for the slurry preparation was collected from the tailing thickener overflow in order retain the properties of slurry at actual site conditions. The desired amount of polymer solution was then added into the coal slurry and thoroughly mixed by inverting the cylinder 10-12 times (Mandre and Panigrahi, 1997). After a mixing, the cylinder was allowed to stand undisturbed. The height of the slurry and water interface was recorded as a function of time to calculate the settling rate of the flocculated suspension. Typically, the profiles were characterized by fast initial settling rates followed by an intermediate region of reduced settling rate and then a period of consolidation of the sediment. After 15 minutes' settling time, the clear water was sampled for turbidity measurement using a turbidimeter.

Results and discussion

Characterization of fine coal tailings

Characterization studies of the coal sample indicated a particle size ranging from 1.1 μηι to 700 μηι as shown in Table I. The ash content of the sample was found to be 62.57% and the solid specific gravity measured was 1.712.

Particle size analysis

The particle size analysis of the sample (Figure 1) indicated that about 7-8% of the sample was larger than 600 μm in size, and about 50% finer than 150 μm. According to the Wentworth classification, about 14% of the sample was in the clay fraction (< 4 μm), 26% was in the in the fraction (4-63 μm) (Sabah et al., 2004); and 60% in the sand fraction (> 63 μm) attributed to the presence of carbonaceous and ash- forming materials as reported in the literature.

Size distribution of ash

The distribution of ash-forming materials in different size ranges was investigated. Figure 2 shows that the ash content decreases with decreasing size fraction, except for the -53 μm size fraction. The higher ash content in the -53 μm size fraction could be attributed to the presence of higher amount of clay and slits in this fraction, while the increase in ash content with increasing size fraction may be due to the presence of non-combustible materials such as quartz and other silicate minerals, as reported by Sabah et al. (2004).

Lower rank coals are weakly hydrophobic; hydrophobicity increases with an increase in rank, reaches a maximum for medium-volatile and low-volatile bituminous coals, and decreases for anthracite.

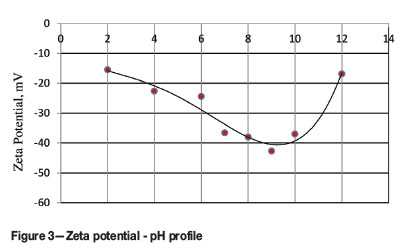

Zeta potential

Zeta potential studies were carried out at different pH values. The results (Figure 3) revealed that the tailings exhibit negative charge at all pH values. The negative value of the charge increases with increasing pH up to 9. Increases in pH above 9 results in decreasing negative zeta potentials, with a value of -16 mV at pH 12. This phenomenon may be attributed to the presence of alumina and silicate particles, which result in lower negative zeta potential values. Furthermore, the varying zeta potential in the acidic medium may be attributed to the change in surface pH, while that in the alkaline region may be ascribed to the binding of more cations.

A moderate zeta potential value of -38 mV was observed at pH of 8, which was the natural pH of the slurry. According to the ASTMD-4187 standard test method, if the zeta potential of colloids in water or waste slurry is above -60 mV, the stability of the system is classified as 'perfect' (Sabah and Erkan, 2006). As the zeta potential of the tailing slurry in the

present case was -38 mV at the natural pH of 8 (Figure 3) of the slurry in the plant, it may be classified as highly stable, thus the settling characteristics could be enhanced using flocculation.

Flocculation studies

Effect of solids concentration and slurry pH

Preliminary flocculation studies were carried out to examine the effect of pulp density and slurry pH on the settling rate of particles. Experiments were carried out at solid concentrations of 4, 6, 8, 10, and 12% (w/w) at a fixed polymer dosage of 6.5 g/t solid. Since the suspension pH plays a significant role in polymer adsorption at the particle/water interface and can determine the flocs sizing and the settling rate of solids (Sabah et al., 2004), the slurry pH was also varied, with values of 4, 6, 8, 10, and 12.

As shown in Figure 4, at low pH values, a remarkable decrease in the settling rates were observed at all solid concentrations. Here it may be observed that, at 8% solid concentration with slurry pH of 8, the settling rate is as high as 54.26 mm/min. However, with further increase in pH above 8, a decrease in settling rates were observed. This may be attributed to the fact that the suspension pH changes the charge characteristics of polymer chain and their conformation in solution, which directly affects the flocculating power of the polymer and hence results in a change in settling rate of particles (Foshee and Swan, 1982).

Also, at low pH the flocculation power of anionic polymers by the bridging mechanism decreases as the polymer molecules are in a random coil configuration in solution, whereas at relatively high pH configuration of the polymer extends due to electrostatic repulsion between the charged groups on the polymer chain (Taylor and Morris, 2002).

Furthermore, the relatively low settling rate at low pH could be due to the weakened electrostatic attraction of the negative particle surface, since the zeta potential of the original sample was about -16 mV at pH 2, whereas at the natural pH of 8 the zeta potential was about -38 mV. Also, the covalent bond and/or electrostatic bond formation between the (=C-O-) groups of anionic polymers and metal cations on the external surfaces of mineral particles may be inhibited at low pH values (Sabah et al., 2004).

In order to support above findings, some experiments were carried out to study the settling rate of particles without flocculent. These experiments were carried out at 8% solid concentration (w/w) and at pH values of 4, 6, 8, 9, 10, and 12 as previously. The results shown in Figure 5 indicated that, at a slurry pH of 9 where the zeta potential was about -44 mV, the settling rate was as low as 4.13 mm/min. At the natural pH of 8, the settling rate was 5.27 mm/min. Further decreases in pH resulted in a marginal improvement in the settling rate, which reached a maximum value of 6.20 mm/min at a slurry pH of 4. However, the improvement in settling rate with increasing pH was more marked in the basic region. These findings support the supposition that the polymer is definitely disturbing the stability of the suspension, as the settling rate obtained using flocculent (Figure 4) is nearly 10 times higher than that obtained without using flocculent (Figure 5).

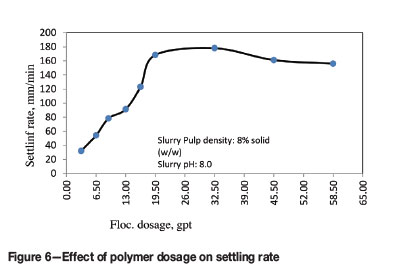

Effect of polymer dosage on settling rate

Studies were further extended to investige the effect of polymer dosage on the flocculation of CPP tailings. The studies were carried out at 8% solid concentration with the polymer dosage varying from 3.25 g/t solid to 58.5 g/t solid.

All tests were carried out at pH of 8, which is the natural pH of the tailing slurry and also provides good settling conditions, as shown in Figure 4. The 8% solids concentration was chosen as it resulted in a better settling rate than other concentrations (Figures 4 and 5). The results (Figure 6) show clearly that the settling rate increases with increasing polymer dosage, reaching a maximum at a dosage of 32.50 g/t solid.

At low polymer dosages, the floc size is very small due to insufficient polymer adsorption on the particles, which results in poor settling rate. With increasing flocculent dosage, the amount of adsorbed polymer increases, resulting in the incorporation of more suspended particles in the flocs and enlargement of the floc size, leading to the enhanced settling rate. From Figure 6, it may also be noted that the optimum settling rate of 178.15 mm/min was achieved at 32.50 g/t solid. The decrease in settling rate with increase in flocculent dosage beyond this point may be attributed to the formation of large size but less compact flocs (Tao and Groppo, 2000).

Studies on pulp density of settled slurry and clear liquid

Apart from obtaining a good settling rate, it is also imperative to analyse the compaction behaviour of settled slurry, as this is a controlling parameter for the determining the concentration of underflow slurry from sedimentation-based equipment such as thickeners. The turbidity of the overflow liquid is also an important parameter, as the liquid is recycled back to the plant as make-up water. Therefore, the studies were further extended to observe the effect of polymer dosage on the concentration of settled slurry and turbidity of the supernatant water. Test work was conducted at a slurry density of 8% solid concentration (w/w) and pH 8 with different flocculent dosages. The height of the mudline was measured after 15 minutes of settling time and the pulp density was calculated.

Figure 7 shows that with increasing flocculant dosage, the pulp density of the settled slurry increases to a maximum of 1.212 at a dosage of 32.50 g/t solid, and then decreases significantly with further increases in dosage. The pulp density at flocculent dosage of 19.50 g/t solid was only slightly lower than the maximum 1.205 compared with 1.212. This may be attributed to the formation of larger size and less compact flocs (Tao and Groppo, 2000).

Figure 7 also shows that the turbidity of the supernatant liquid (measured after 15 minutes of settling time) decreases rapidly with increasing flocculent dosage up to 19.5 g/t solid, and thereafter shows only a minor decrease with further flocculent additions up to 58.5 g/t solid. At the optimum settling conditions of 32.5 g/t solid and pH 8 (Figures 4 and 6), the turbidity was 7.42 NTU.

Furthermore, the addition of flocculent at an optimum dosage of 32.50 g/t solid improved the settling rate by about 34 times compared with than that obtained without flocculent (Figures 5 and 6). Also, the turbidity of the supernatant liquid was decreased to about 25% of that without flocculent (Figure 7). It may also be noted that the lowest turbidity values were obtained with very a high dosage of polymer (58.5 g/t solid), as shown in Figure 7. However, at this dosage, the settling rate is below the maximum (Figure 6).

Conclusions

Characterization studies of the sample indicated a particle size ranging from 1.1 to 700 μm, with about 50% of material in the -50 μm size fraction; an ash content of 62.57%, fixed carbon 15.16%, and volatile matter 20.79%. The zeta potential was -38 mV at the natural slurry pH of 8 and no isoelectric point occurred between pH values of 2 to 12, hence according to the ASTMD-4187 standard test method, the stability of the suspension may be disturbed by using polymers to enhance settling.

Flocculation studies carried out at pulp pH values from 4 to 12 and densities from 4 to 12% solids (w/w) showed an increase in settling rate up to a pH of 8, followed by a decrease with further increases in pH at all solids concentrations. Studies with varying flocculent dosage at 8% solids concentration (w/w) and pulp pH of 8 (the optimum settling conditions) showed the highest settling rate of 178.15 mm/min at dosage of 32 g/t solid, with a decrease in settling rate at higher dosages.

Turbidity values showed a continuous decrease with increasing flocculent dosage, although the effect was minimal at dosages higher than 32.50 g/t solid. The turbidity was 7.42 NTU under the best settling condition of 8% solid concentration (w/w) and pH 8. Thus flocculation improved the settling rate by about 34 times, and the turbidity of the clear liquid was decreased to about 25% of the original turbidity of the clear liquid obtained without using flocculent.

Under the optimum settling conditions, the pulp density was increased from 1.128 g/cm2 (the pulp density of tailing slurry discharged from the plant, 27.24% solid, w/w) to 1.212 g/cm2 (42% solid, w/w). Considering small variations in the actual plant performance, it is estimated that the moisture content of the fine coal tailing can be reduced by around 10-12% from the level currently discharged with the plant final tailing from the thickener underflow. This would significantly reduce the plant operating costs by reducing the fresh make-up water requirement, and also the inventory cost by enabling the use of a lower capacity tailing discharge pump and related pipe, fittings, valves etc.

Acknowledgement

The authors wish to express their gratitude to BASF India for supplying flocculent and to Tata Steel India for supplying the coal samples for carrying out the tests.

References

Das, B., Prakash, S., Biswal, S.K., and Reddy, P.S.R. 2006. Settling characteristics of coal washery tailings using synthetic polyelectrolytes with fine magnetite. Journal of the Southern African Institute of Mining and Metallurgy, vol. 106. pp. 707-712. [ Links ]

Foshee, W.C., Swan, M.J., and Klimpel, R.R. 1982. Improvement in coal preparation. Water classification through polymer flocculation. Minerals Engineering, March. pp. 293-297. [ Links ]

Gupta, A. and Yan, D.S. 2006. Introduction to Mineral Processing Design and Operation, First Edition. Elsevier, Amsterdam. [ Links ]

Mandre, N.R. and Panigrahi, D. 1997. Studies on selective flocculation of complex sulphides using cellulose xanthate. International Journal of Minerals Processing, vol. 50. pp. 177-186. [ Links ]

Parekh, B.K. 2009. Dewatering of fine coal and refuse slurries problems and possibilities. Procedia Earth and Planetary Science, vol. 1. pp. 621-626. [ Links ]

Parsapour, Gh.A., Hossininasab, M., Yahyaei, M., and Banisi, S. 2014. Effect of settling test procedure on sizing thickeners. Separation and Purification Technology, vol. 122. pp. 87-95. [ Links ]

Ofori, P., Nguyen, A.V., Firth, B., McNally, C., and Ozdemir, O. 2011. Shear-induced floc structure changes for enhanced dewatering of coal preparation plant tailings. Chemical Engineering Journal, vol. 172. pp. 914-923. [ Links ]

Sabah, E. and Cengiz, I. 2004. An evaluation procedure for flocculation of coal preparation plant tailings. Water Research, vol. 38. pp. 1542-1549. [ Links ]

Sabah, E. and Erkan, Z.E. 2006. Interaction mechanism of flocculants with coal waste slurry. Fuel, vol. 85. pp. 350-359. [ Links ]

Tao, D., Groppo, J.G., and Parekh, B.K. 2000. Enhanced ultrafine coal dewatering using flocculation filtration processes. Minerals Engineering, vol. 13, no. 2. pp. 163-171. [ Links ]

Taylor, M.L., Morris, G.E., Self, P.G., and Smart, R.C. 2002. Kinetics of adsorption of high molecular weight anionic polyacrylamide onto kaolinite. The flocculation process. Journal of Colloids and Interface Science, vol. 250. pp. 28-36. [ Links ]

Ji, Y., Lu, Q., Liu, Q., and Zeng, H. 2013. Effect of solution salinity on settling of mineral tailings by polymer flocculent. Colloids and Surfaces A: Physicochemical and Engineering Aspects, vol. 430. pp. 29-38. [ Links ] ♦

© The Southern African Institute f Mining and Metallurgy, 2014. ISSN2225-6253. Paper received Jun. 2014; revised paper received Sep. 2014.