Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.114 no.7 Johannesburg Jul. 2014

PHYSICAL BENEFICIATION

The Lamella High Shear Rate REFLUX™ Classifier

T. Orupold; D. Starr; T. Kenefick

FLSmidth Pty Limited (Australia)

SYNOPSIS

This paper covers the commercial development of gravity separation of fine particles using a Lamella High Shear Rate REFLUX™ Classifier (REFLUX™ Classifier), focusing primarily on coal applications. The REFLUX™ Classifier is a fluidized bed device that incorporates a system of closely spaced parallel inclined channels located above the fluidized bed. These channels make it possible to achieve a significant suppression of the effects of particle size, resulting in a highly effective separation on the basis of density. The improved gravity separation performance is shown to be remarkably high, with a significant reduction in the variation of separation density with particle size, and a significant reduction in the change in Ecart probable error (Ep) with size.

The first full commercial-sized units of the REFLUX™ Classifier were field-tested in late 2009 in coal applications. More recently, the technology has been applied in fine particle separation in minerals applications and there are a number of full-sized units operating in chrome applications in South Africa. Initially, pilot-scaled units (typically the RC™300) were trialled in iron ore, mineral sands, and manganese plants amongst other minerals, typically after other technologies failed to achieve the desired results. Currently a number of laboratories globally are carrying out more testing in minerals applications.

More than 50 RC™ units are now operating in coal and minerals applications. This paper introduces the REFLUX™ Classifier technology, identifies commercial applications, and gives some commercial results.

Keywords: gravity separation, classification, fluidized bed.

Introduction

In coal and mineral processing, gravity separation of fine particles (generally less than 2 mm in size) is normally carried out in water through the application of various gravity separation devices, including spirals and variations of upstream classifiers. The objective is to produce a separation on the basis of particle density, ideally with particles lower than the target density reporting as one flow stream and those higher in density reporting as a second flow stream. In practice, as the particle size range of the feed increases the overall separation efficiency declines significantly. When targeting a given product grade, this loss of efficiency leads directly to lower recovery of the valuable component. The efficient separation of a broad size range of particles on the basis of particle density in a low-density fluid such as water remains a considerable challenge.

There is a growing trend to replace existing technologies for beneficiating fine minerals and coal, nominally less than a few millimetres in size, with technologies based on fluidized beds. Generally, fluidized beds tend to be hydraulically limited and are constrained by feed conditions, and hence the feed needs to be as concentrated as possible to maximize throughput. However, the FLSmidth REFLUX™ Classifier achieves a much higher hydraulic capacity through the incorporation of parallel inclined plates in the fluidized bed housing, and therefore this unit requires a much smaller footprint within the plant.

The REFLUX™ Classifier (RC™) is an innovative device offering advantages in both gravity separation and particle size classification. The device combines a conventional fluidized bed with sets of parallel inclined plates, as shown in Figure 1. Feed slurry enters below the plates while fluidization water is introduced through a distribution plate in the base. The slurry feed moves downwards into the vessel, forming a bed of particles that is fluidized from below. High-density particles settle into the lower portion of the bed, and light and fine particles are transported upward, with the majority flow towards the lamellae. The high hydraulic load carries the suspension up into the parallel inclined lamella plates. Here slower settling particles, which are unable to settle against the fluidization water, emerge through the plates and report to the overflow. Faster settling particles drop out of suspension and onto the plates before sliding back to the zone below.

At high bed concentrations in the reflux zone, this reject suspension provides an autogenous dense medium, allowing the separation to proceed largely on the basis of density. When the density of the fluidized bed exceeds the set-point value, a valve opens near the base of the unit and discharges some of the denser particles as an underflow stream.

The inclined channels, the geometry of which is defined by the plate length, L, perpendicular channel spacing, z, and angle of inclination with the horizontal, h (Figure 2), provide a significant hydraulic advantage over conventional fluidized beds, consistent with the well-known 'Boycott Effect' (Boycott, 1920; Ponder, 1925; Nakamura and Kuroda, 1937; Zhou et al.; 2006) showed that over the range h = 60-80 degrees the performance was optimal, hence all of the work since then has been based on an angle of inclination of 70 degrees.

Development of the REFLUX™ Classifier

As the fundamental research was funded by the Australian coal industry, all the initial testing and subsequent pilot and full-scale work were performed using Australian coals. Mineral testing started in South Africa many years after development of the first commercial units. All the development details in this paper are therefore based on work with Australian coals.

Following the laboratory and theoretical development (Galvin and Nguyentranlam, 2002; Galvin et al., 2002a, b) of the REFLUX™ classifier technology, the next step was to conduct performance testing of commercial-sized units.

In 2005 the performance of the first-generation full-scale REFLUX™ Classifier (RC™ 1800), supplied by Ludowici Australia, was evaluated using a coal and mineral matter feed nominally less than 2 mm in size. The unit was installed, commissioned, and studied at a Lower Hunter Valley coal preparation plant. The plates were inclined at an angle of 60 degrees to the horizontal and were spaced at 120 mm intervals.

In late 2008, further research conducted by Galvin (Galvin et al., 2010) established that the efficiency could be significantly increased by reducing the lamella channel spacing. Based on this result, Ludowici redesigned the REFLUX™ Classifier, with the RC™2020 being the first of new design units.

In late 2009 the performance of a full-scale RC™2020, supplied by Ludowici Australia, was evaluated at a Central Queensland coal preparation plant. The inclined plates were inclined at an angle of 70 degrees to the horizontal and spaced at 6 mm intervals for this installation.

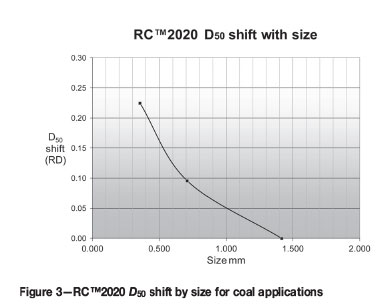

The results of the 2005 and 2009 tests were reported by Orupold et al. (2013). The RC™2020 exhibited significantly lower Ep values and a reduced D50 shift by size. The RC™2020 results are represented in Figure 3 and Figure 4.

Figure 3 shows a relatively moderate D50 shift with change in particle size when compared to other echnologies.

Figure 4 shows that Ep values are still very low even at fine particle sizes.

The RC™2020 then became the mainstay unit, with over 40 units sold globally in three years. The RC™2020 design has now been replaced by the RC™2000 (Figure 5).

The operational process capabilities of the RC™2020 and RC™2000 are generally equivalent. Based on site feedback from global locations, the RC™2020 was re-designed as the RC™2000 to incorporate various enhancements for improved internal feed preparation and distribution, and others for lamella channel protection, including internal oversize protection and de-aeration. The latter are additional safety features and do not preclude in-plant installation of oversize protection and de-aeration of the feed. The RC™2000 body is fully fabricated from 304 stainless steel with wear-resistant lining and parts in the higher wear sections.

Further enhancements to the channel design will allow the RC™2000 a throughput advantage of 15% over the similar sized RC™2020. FLSmidth, which acquired Ludowici Australia (Pty) Ltd in 2012, now produces commercial sized units from RC™850 to RC™3000, all based on the RC™2000 design. Also available for in-plant testing is the RC™300 pilot-scale unit, which is a pilot-scale unit designed to take the equivalent of one spiral start. It is 1/36th the size of a RC™2000 full-scale commercial unit, although it is roughly the same height. Many features are shared with the commercial units, including the lamella plates, pressure probes, and fluidizing nozzles. A number of underflow valve configurations are available to cater for various applications. Currently, more than 24 RC™300 units are in use in coal and minerals applications in six countries around the world. The RC™300 is shown in Figure7.

Coal applications

The FLSmidth® RC™300 REFLUX™ Classifiers have been used extensively for onsite pilot-scale test work. RC™2020 and, more recently, RC™2000 units have been installed in greenfield and brownfield applications in Australia, New Zealand, China, India, the USA, and Mozambique. Larger RC™2350 units were commissioned in August 2013 in Australia, and RC™3000 classifiers are expected to be commissioned in Mozambique in 2014. A number of plants have in excess of six units.

Most applications are as primary separation devices, although a number have been installed as scavenger units to recover lost coal from other processes.

The REFLUX™ Classifier is targeted at the treatment of -2.00 mm coal and is effective down to 0.125 mm. However, as noted by Galvin et al. (2010), the REFLUX™ Classifier, in common with other gravity separation devices, can show a shift in cut-point by size. This effect is pronounced with the finer sizes. Therefore the generally targeted size fraction has a top-to-bottom size ratio of 8:1. In Australia this is generally -2.0 mm +0.250 mm. In the USA the units operate treating finer material (-1.00 mm +0.150 mm) (Ghosh et al., 2012).

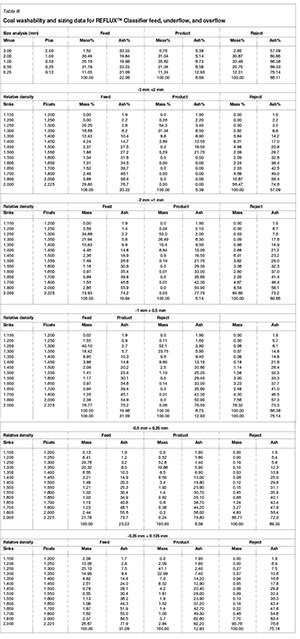

The first RC™2020 unit was installed as a trial in a Central Queensland coking coal plant in 2010. The results from the 8-hour acceptance run sampling are given in the Appendix. The cut-point for the targeted -2.0 mm +0.0250 mm fraction was RD 1.60 with an Ep of 0.07.

In 2008 the Australia Coal Association Research Program (ACARP) published a report into extending the size fractions that the REFLUX™ Classifier could treat. The pilot RC600 used for this research successfully extended the top size to 8 mm. In 2014, a follow-up ACARP-funded project will look at extending the REFLUX™ Classifier range to a top size of 4 mm in a full-scale demonstration plant in the Hunter Valley, NSW, Australia. This research is independent of FLSmidth.

Minerals applications

The FLSmidth® RC™300 and RC™850 REFLUX™ Classifiers have been used extensively for onsite pilot-scale test work. A wide range of mineral applications have been tested, including iron ore, chromite, manganese, and mineral sands. The vast majority of the test data discussed in the following sections was obtained using the Lamella High Shear Rate REFLUX™ Classifier technology, utilizing 6 mm spacing between lamella channels.

Iron ore - Australia

A Western Australian iron ore bulk sample (nominally -1 mm +0.106 mm) was tested using an RC™300 REFLUX™ Classifier (RC™300). The material was a sample of a resource that contained a significant amount of naturally occurring (liberated) fine iron ore (-1 mm particles). The resource owners considered the finer fractions to be unrecoverable, as no other technology was successful in reducing the silicates and aluminates to a commercially viable level.

Heavy liquid separation (HLS) analysis of the sample had shown a separation at a specific gravity (SG) of 3.8 could achieve a yield of around 40%. The corresponding iron recovery would be around 60% and the combined silicates/aluminates would be less than 10%. This separation would produce a commercially viable concentrate.

As the resource owner was unable to perform an onsite test, a representative bulk sample was collected. A RC™300 pilot-scale unit was used in a simulated REFLUX™ Classifier circuit. The feed material was prepared to match the roposed feed circuit. However, due to the nature of the simulated circuit set-up and limited sample size, the test work conditions were not fully optimized and only several short 'sighter' tests and a single longer run were conducted.

During the test work the RC™300 was fed with 30-35% (w/w) slurry of the bulk ore sample and water at a flow rate of 4.5-5 m3/h. Several relative density (RD) set-points were investigated during the test work, while the fluidizing water flow rate was kept constant at 4.85 m3/h. The best separation produced an underflow stream consisting of 60% iron and less than 10% combined silicates/aluminates. Figure 8 shows the comparison of the HLS and RC™300 test data.

Although the yield was only around 19%, the product from the REFLUX™ Classifier would equate to a significant financial benefit to the resource owner. The additional iron recovery would be achieved without increased mining or liberation expenses. Also, a reduction in the size of downstream processing units handling the disposal of the -1 mm discard stream would be possible.

Commercial RC™2000 units will enter into production in Western Australia in the later part of 2014.

Iron ore - South Africa

In 2014 a full-scale RC™2020 unit was installed as a trial in a large South African iron ore beneficiation plant, replacing other gravity and magnetic devices. The unit was commissioned late March 2014, and from April it commenced operation as a commercial unit. Initially, the unit is to upgrade -1.00 mm +0.200 mm material to required specification. Results to April/May 2014 have indicated haematite recoveries in the order of 84%.

Full results cannot be released at this time, but the user will publish the results at future SAIMM conferences. The user also is conducting research at other sites with RC™100 and RC™300 laboratory and pilot units.

Mintek also has a RC™100 laboratory-scale unit available for independent research and materials testing purposes.

Iron ore - Canada

Amariei et al. (2013) reported an investigation into spiral feed and spiral reject retreatment of Canadian iron ore using a Ludowici® RC™300. The pilot-scale tests were compared with sink-float (HLS) tests for two samples - Sample1, a spirals feed sample screened to -0.106 mm, and Sample2, a spirals reject stream 'as received', containing coarse silica (+0.106 mm).

Both samples were analysed using sink-float tests to establish a means of comparison for the streams produced from the RC™300.

The RC™300 was fed at approximately 40% of the maximum feed capacity. Several relative density (RD) set-points were investigated during the test work for both samples. The effect of fluidizing water rate was also investigated during the test work, although only on Sample1.

RC™300 processing of Sample1 produced an underflow stream consisting of 69.8% iron and 1.13% combined silica. This is an impressive result considering the feed stream contained 42.6% Fe and 30.7% SiO2. The weight yield corresponded to 54.8%.

RC™300 processing of Sample2 produced an underflow stream consisting of 67.1% iron and 3.00% combined silica. Considering the sample originated from a waste stream containing 30.0% Fe and 55.6% SiO2, this recovery is an encouraging result for the REFLUX™ Classifier technology. The weight yield corresponded to 39.5%.

Of particular interest is the comparison that Amariei et al. (2013) investigated between the RC™300 results and the sink-float tests for each feed stream. The RC™ performed very close to the accepted maximum achievable results.

Iron ore - other

The RC™300 has been (or is being) tested for beneficiation of fine iron ore at a number of other locations globally. The minerals being tested include haematite, goethite, and magnetite.

Mineral sands

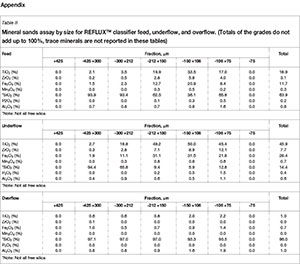

The RC™300 has been utilized for pilot-scale test work on mineral sand deposits in South Africa, India, and Australia. Laboratory-scale test work has also been conducted in Australia. The majority of the tests have shown upgrades in heavy mineral content. Unfortunately, the data from the test work is usually 'commercial in confidence.' Table II shows results from mineral sand tests for two different head grades of heavy minerals (HM). The test work was performed at a feed rate of 30 t/m2/h, which would equate to 100 t/h of dry solids through a full-scale RC™2000 unit.

The test data for the results shown in Table I are summarized in the Appendix.

Although the test work conditions were not optimized, the recoveries of HM as shown in Table I represent good upgrading of the HM content in the concentrate or underflow stream. In the case of the low head grade material, the upgrade ratio was over 7 times.

The test work completed using the RC™300 strongly indicates that HM can be upgraded using a reduced number of units compared to competing technologies.

A commercial unit is now operating in a mineral sands application.

Chromite - South Africa

Onsite pilot-scale tests were successfully conducted in South Africa for an existing chromite operation in 2009 using an RC™600. The test work resulted in the resource owner installing six full-scale production RC™2020 REFLUX™ Classifiers for continuous commercial operation across four sites in South Africa. The resource owner has requested that plant performance data is not is not publicized.

Manganese

Onsite test work using the REFLUX™ Classifier technology has been undertaken on manganese, following on from laboratory and offsite pilot-scale test work. Due to the throughput requirements of the test work (production of a 5000 t sample for market testing), a small commercial RC™850 was used for this trial. The grade/yield characteristics for the RC™ product exceeded those of competing technologies. As with other results, the end user does not wish to be identified and publication of any results is not permitted.

Currently, the design of a full-scale plant with a number of RC™2000 units is being finalized and, subject to market conditions, a project go-ahead is expected in 2014.

Other minerals

The REFLUX™ Classifier technology has been tested using both laboratory and pilot-scale units on various minerals and in industrial applications. Unfortunately due to commercial sensitivities, details and data are not available for publication at this stage.

Conclusions

The RC™ is usually used to process -2 mm feeds where there is a difference in particle density between the valuable mineral and gangue.

The improvement in separation performance with the Laminar High Shear Rate REFLUX™ Classifier has been dramatic and has led to widespread adoption of the technology, which has been available commercially only since 2010, as the gravity separator of choice in coal applications, especially for cut-points below 1.80.

The REFLUX™ Classifier can treat coals at lower cut-points and at higher efficiencies, thereby allowing the production of lower ash products combined with improved yields.

The REFLUX™ Classifier has been installed in a number of minerals applications across the world. To date, all of the data is commercial in confidence; however, all the results show that the Lamella High Shear Rate REFLUX™ Classifier technology is well suited to minerals applications and in some instances can provide an excellent separation where other equipment struggles to meet grade and recovery targets.

FLSmidth is seeking to overcome the lack of publishable data by investing in laboratory and pilot-scale testing at its research facility in Salt Lake City, Utah. FLSmidth will also have the ability to test and recommend flow sheets for customer-specific applications.

The lack of specific data in this paper is to a large extent due to current global economic conditions, as all end users of this technology have embargoed publication of results and identification of installations as they try to achieve market advantage. The authors encourage potential end users to conduct their own test work on new minerals and industrial applications.

Acknowledgements

The authors gratefully acknowledge the financial support of ACARP forthese projects, and the work and support from Professor Kevin Galvin and his team at the University of Newcastle. We thank Sedgman for their investment in the full-scale RC™2020 trial in Central Queensland.

The authors also extend their appreciation to all the customers who have supported the development of this technology.

References

Amariei, D., Michaud, D., Paquet, G., and Lindsay, M. 2013. The use of a reflux classifier for iron ores: assessment of fine particles recovery at pilot scale. Proceedings of Physical Separation '13, Falmouth UK. Minerals Engineering International. [ Links ]

Galvin, K.P., Pratten, S.J., and Nicol, S.K. 1999. Dense medium separation using a teetered bed separator. Minerals Engineering, vol. 12, no. 9. pp.1059-1081. [ Links ]

Galvin, K.P. and Nguyentranlam, G. 2002. Influence of parallel inclined plates on a liquid fluidised bed system. Chemical Engineering Science, vol. 57. pp.1231-1234. [ Links ]

Galvin, K.P., Belcher, B.D., Callen, A.M., Lambert, N., Doroodchi, E., Nguyentranlam, G., and Pratten, S.J. 2002a. Gravity separation and hydrosizing using the Reflux Classifier. Proceedings of the Ninth Australian Coal Preparation Conference. Firth, B.A. (ed.). Paper G1. [ Links ]

Galvin, K.P., Doroodchi, E., Callen, A.M., Lambert, N., and Pratten, S.J. 2002b. Pilot plant trial of the Reflux Classifier. Minerals Engineering, vol. 15, no. 1. pp. 19-26. [ Links ]

Galvin, K.P., Callen, A.M., and Spear, S. 2008. ACARP Project C16040: Extending the Range of the REFLUX™ Classifier. Australian Coal Industry Research Program, Brisbane, Queensland. [ Links ]

Galvin, K.P., Callen, A., Zhou, J., and Doroodchi, E. 2004. Gravity separation using a full-scale Reflux Classifier. Proceedings of the 10th Australian Coal Preparation Conference and Exhibition, Polkolbin, New South Wales, 17-21 October 2004. Memnrey, W.B. (ed.). Paper H21. [ Links ]

Galvin, K.P., Zhou, J., and Walton, K. 2010. Application of closely spaced inclined channels in gravity separation of fine particles. Minerals Engineering, vol. 23, no. 4. pp. 326-338. [ Links ]

Ghosh, T., Patil, D., Honaker, R.Q., Damous, M., Boaten, F., Davis, V.L., and Stanley, F. 2012. Performance evaluation and optimization of a fullscale REFLUX Classifier. Journal of the Coal Preparation Society of America, vol. 11, no. 2. pp. 24-33. [ Links ]

Honaker, R Q. and Mondal, K. 1999. Dynamic modelling of fine particle separations in a hindered bed classifier. Society for Mining, Metallurgy, and Exploration, Denver, Colorado, March 1-3, 1999. [ Links ]

Orupold, T. and Starr, D. 2013. The development of the REFLUX® Classifier technology for coal applications. Proceedings of the International Conference and Expo on Coal Benefication 2013, New Delhi, India, 18-19 April 2013. [ Links ]

Appendix