Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.114 n.7 Johannesburg Jul. 2014

PHYSICAL BENEFICIATION

Production of pelletizing concentrates from Zandrivierspoort magnetite/haematite ore by magnetic separation

P. Muthaphuli

Anglo American Mining and Technology, Technical Solutions Research

SYNOPSIS

Kumba Iron Ore's Zandrivierspoort (ZRP) magnetite-haematite project aims to mine and beneficiate a magnetite resource with low contaminant levels to produce from 1 Mt/a to 2.5 Mt/a product, which will be either a concentrate, micro-pellets for direct reduction, or blast furnace pellets. Anglo American Technical Solutions Research conducted a number of piloting campaigns to validate the process design flow sheet, demonstrate process performance, and to generate data for use as a design basis. Secondary to this, the pilot plant was to produce approximately 7 t of magnetite-haematite concentrate with low enough SiO2 to be used as feedstock for pelletizing studies.

The pilot plant achieved 34.2% mass yield, at 69.0% Fe, 2.2% SiO2, from an IsaMill grind of 80% -45 µm. This product quality will compare favourably to other leading direct reduction (DR) pelletizing concentrates. However, two-stage comminution to 80% -75 µm and beneficiation of ZRP ore will produce a blast furnace (BF) quality pelletizing concentrate, indicative quality being 67.6% Fe and 4% SiO2, at higher mass yields. An economic evaluation between producing a DR and a BF pelletizing concentrate will have to be conducted prior to finalizing the concentrate production flow sheet..

Keywords: Magnetic separation, iron ore, magnetite, haematite.

Introduction

Kumba Iron Ore is looking to grow its production from the current 44 M/ta to 70 M/ta by 2019. Of this planned growth, approximately 6 Mt/a is scheduled to come from projects in South Africa's Limpopo Province. The Zandrivierspoort (ZRP) project aims to mine and beneficiate a magnetite resource with low contaminant levels to produce from 1 Mt/a up to 2.5 Mt/a product in the form of either a concentrate, micro-pellets for direct reduction, or blast furnace pellets. Anglo American Technical Solutions Research conducted piloting campaigns with a bulk sample obtained from the ZRP site. Kumba Iron Ore is currently designing a plant that will process the ZRP magnetite-haematite ore- body. Anglo American Technical Solutions Research conducted these piloting campaigns to validate the process design flow sheet, demonstrate process performance, and to generate data for use as design basis. Secondary to this, the pilot plant was to produce approximately 7 t of magnetite- haematite concentrate with low enough SiO2 to be used as feedstock for pelletizing studies at Kumba's Value in Use Laboratory and elsewhere. The piloting campaign entailed crushing the run-of-mine to -1 mm prior to low-intensity magnetic separation (LIMS) and rare earth drum separation (REDS) for haematite scavenging, ball milling in closed circuit with a vibrating screen, cleaning of the ball mill circuit product through three stages of LIMS, IsaMilling the ball mill LIMS concentrate, and further re-cleaning of the IsaMill product through three LIMS stages. A combination of LIMS and REDS in different parts of the circuit was chosen to recover magnetite and liberated haematite respectively. Magnetite is ferromagnetic, thus it can be effectively recovered using LIMS (800-2000 G) while haematite is paramagnetic, thus requires high magnetic field intensities (>6000 G) (Wills and Napier Munn, 2006). This paper presents interpretations of the feed sample characterization, pilot plant mass balance results, and the implications for the proposed ZRP plant flow sheet.

Background

ZRP geological outline

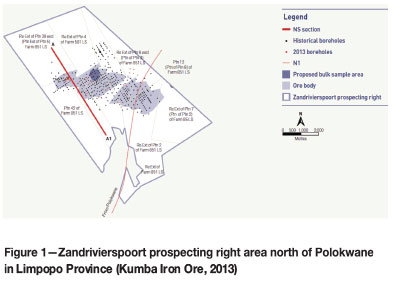

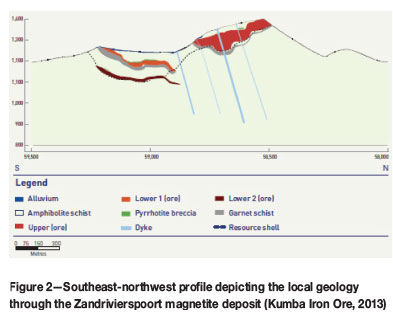

The Zandrivierspoort prospecting right is located approximately 25 km northeast of Polokwane on the farm Zandrivierspoort 851 LS, in South Africa's Limpopo Province, as shown in Figure 1 (Kumba Iron Ore, 2013). The low-grade magnetite project mineral resource base is estimated at 476.1 Mt with 34.5% Fe (Kumba Iron Ore, 2013). Zandrivierspoort is a banded iron formation (BIF) magnetite deposit in the palaeoproterozoic Rhenosterkoppies greenstone belt or Rhenosterkoppies fragment, which occurs to the northwest of the main, northeast-trending Pietersburg greenstone belt. Figure 2 represents a vertical profile (slice) intersecting the three- dimensional model of the Zandrivierspoort deposit (A-A1 red line in Figure 1), demonstrating the company's interpretation of the relationship between the orebodies, waste material, and local geology (Kumba Iron Ore, 2013).

Bulk sample preparation and characteristics

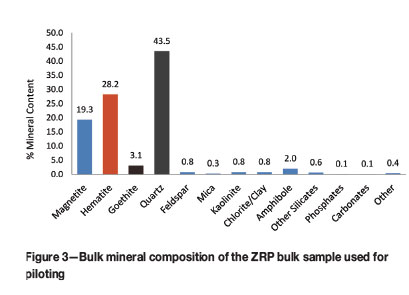

Kumba Iron Ore delivered approximately 38 t of run-of-mine (ROM) bulk sample at a 150 mm top size. This was reduced using a jaw crusher to 100% passing 70 mm. The jaw crusher product was further crushed to 100% passing 40 mm prior to comminution by high-pressure grinding roll (HPGR). The HPGR crushing was conducted at Mintek using a Koppern HPGR unit to produce 100% passing 1 mm product, which yields more than 60% liberation of the magnetite and haematite combined. On average, the bulk sample received contained 35.7% Fe with a 40:60 magnetite to haematite ratio. Figure 3 shows the bulk mineralogical composition of the bulk sample processed through the pilot plant.

Previous company internal data indicated that the average ZRP orebody contains approximately 40.8% magnetite with a 70:30 magnetite to haematite ratio (Kumba Iron Ore, 2013). The implications of the lower magnetite to haematite ratio of this bulk sample on the pilot plant mass yield will be highlighted and discussed under the mass balance results.

The Bond Ball Mill Work Index (BWI) was determined at a limiting screen of 75 µm. The BWI test was carried out in accordance with the modified Warren Spring Laboratory method. The BWI of this ZRP ore was measured at 17.6 kWh/t, which is in line with previous values obtained from other hardness testing carried out on ZRP drill cores at Anglo Research (van Drunick, 2007). A grind of 80% passing (P80) 75 µm was chosen targeting a blast furnace pelletizing concentrate with 67% Fe and less than 5% SiO2, while a 45 µm grind was targeting a direct reduction pelletizing concentrate with a much cleaner product containing 69% Fe and less than 2% SiO2. Batch grinding and Davis tube tests at 1000 G (Murariu and Svoboda, 2003) had shown that these qualities were achievable at P80 of 75 µm and 45 µm.

Piloted flow sheets

High-SiO2 concentrate production (blast furnace pelletizing concentrate)

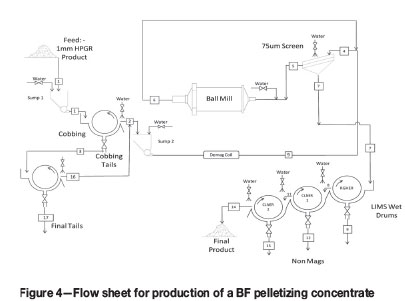

Figure 4 illustrates the first phase of the piloting campaign, in which the circuit was operated with a cobbing and a REDS scavenger magnetic separator, the ball mill in closed circuit with a 75 µm screen, and the product of the ball mill circuit reporting to three stages of LIMS cleaning. The ZRP ore consists of magnetite and haematite, a significant amount of which has been shown to be intimately associated with the magnetite. The product of the REDS scavenger was combined with the cobbing product to feed the ball mill circuit.

The addition of a REDS scavenger improves yield due to the recovery of additional mass of fully liberated haematite which is not recovered across the cobbing LIMS because of its lower magnetic susceptibility.

L0W-SÍO2 concentrate production (direct reduction pelletizing concentrate)

The blast furnace pelletizing concentrate was sent to the Anglo American Platinum Division Metallurgical Laboratory (DML) for IsaMilling using a 100 litre (M100 IsaMill) pilot plant unit with 75 kW installed power. Davis tube test work data showed that it was possible to reduce the SiO2 content in the concentrate to around 2% from a grind of 80% -45 µm.

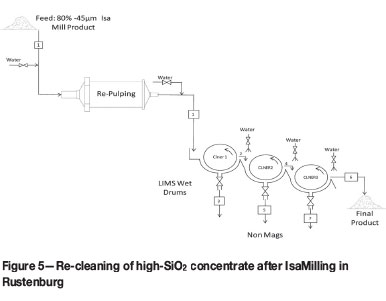

The IsaMill product was re-pulped using a ball mill to break lumps and allow for dilution prior to the three LIMS cleaning stages as illustrated in Figure 5. This circuit was run at very low feed densities as its primary objective was to produce a high-quality concentrate that is low in SiO2. Thus it was critical to avoid SiO2 entrainment, which would have been worsened by high feed densities.

Equipment specification

Ball mill and screen

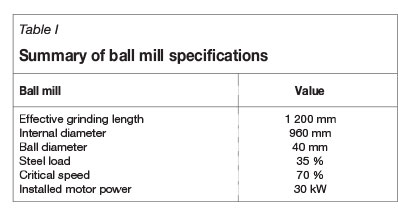

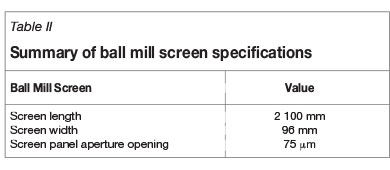

Table I and Table II summarize the ball mill and screen specifications respectively. The ball mill had rubber liners. The screen was a retro-fit of a linear screen that was modified and fitted with a 75 µm woven wire cloth due to the lack of pilot Derrick screens in the country at the time of the test work. The screen deck was re-designed and fitted in- house.

Magnetic separator specifications

The four LIMS units were salvaged from an old magnetic separation plant and refurbished in-house with assistance from Eriez Magnetics. The REDS was hired from Multotec. Table III summarizes the magnetic separator specifications and operational settings employed. All the LIMS had a concurrent tank configuration, while the REDS had a counter-rotation configuration.

The drum-tank clearance for both the LIMS and REDS was as narrow as mechanically possible to ensure high magnetite and haematite recovery (Dworzanowski, 2010). For the REDS, the drop in magnetic field strength away from the drum surface is very significant, thus a need for very narrow drum-tank clearance.

Mass balance results and discussion

High-SiO2 concentrate production

Primary LIMS cobbing

Blast furnace (high-SiO2) concentrate production involved running the circuit as illustrated in Figure 4. The plant was fed at 714.5 kg/h at a head grade of 35.7% Fe. The average plant feed magnetite to haematite ratio was 1:1.5 (or 40.1% to 59.9%). Table IV summarizes the overall circuit mass balance. Mass balancing was conducted using the least-square error technique adapted from JKSimMet and JKSimFloat (JKTech, 2001). Mass balance adjusted flow rates and assays compared well with measured data from the piloting work, with standard deviations less than 5% (Table IV).

The LIMS cobbing stage operated at 4.03 m3/h per metre drum length. This stage achieved a mass yield of 57.5% with 1.47 times Fe upgrading. Overall mass rejection was 42.5%, which was expected given the significant liberation at a 1 mm top size. Even though the cobbing stage rejected 42.5% of the mass in the feed, the magnetite recovery across this stage was 98.4%, while the haematite recovery was 74.6%. Again, the high haematite losses confirm a need for haematite scavenging at a higher magnetic field strength from the cobbing tails.

Cobbing scavenger (REDS)

The cobbing tails were re-treated in the cobbing scavenger. Mass balance showed that this drum received 42.5% of the mass that was fed to the plant at 14.3% solids and slurry feed rate of 4.26 m3/h per metre drum length. The cobbing scavenger recovered 3.5% mass relative to plant feed while recovering 38.4% of the magnetite and 23.8% of the haematite in the cobbing tails. The concentrate from this scavenger contained 38.6% Fe with 44.7% SiO2. Overall, the scavenger improved the haematite recovery from 74.6% to 80.6% before ball milling. Mineralogical analysis of the cobbing scavenger feed showed that only 4.2% of the haematite in this stream was fully liberated, with approximately 44.8% occurring with 80-95% liberation by surface area. The poor haematite liberation explains the low haematite recoveries across the cobbing scavenger.

Ball mill circuit

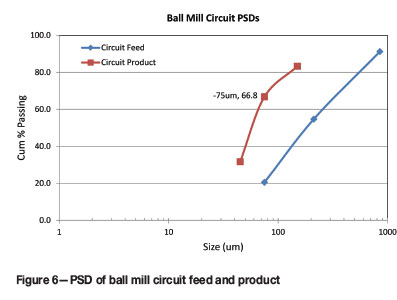

The LIMS cobbing stage and the cobbing REDS scavenger stage concentrates, together with the ball mill discharge, were fed to the screen. The combined stream feeding the screen represented 114.8% of the plant feed. Around 53.1% of the screen feed went to the screen undersize. The screen oversize/ball mill feed was measured at 384.4 kg/h. On average, the ball mill power draw was 7.55 kW, which translates to a 19.6 kWh/t power consumption. Figure 6 summarizes the particle size distribution (PSD) around the ball mill circuit, which was operated at 76.9% solids by mass discharge and 70% critical speed.

Due to the inefficiencies of an in-house built screen, the ball mill circuit product was much coarser at 66.8% passing 75 µm compared to the targeted 80% passing 75 µm. This poor grind resulted in poor liberation of magnetite from silica, which had an impact on the concentrate grade as will be discussed in the next section. However, the product from this campaign was scheduled for IsaMilling to 80% -45 µmprior to secondary cleaning.

Primary LIMS cleaning stage

The primary LIMS cleaning stage consisted of three drums in series; which were rougher, cleaner, and re-cleaner as shown on the flows sheet in Figure 4. This stage was fed by the ball mill screen undersize at 436.1 kg/h, representing 61.0% of the mass of the plant feed, with a 49.7% Fe grade.

The rougher LIMS was operated at 7.64 m3/h per metre drum length at 8.7% solids by mass. Overall, the rougher LIMS stage rejected 19.3% mass out of the 61.0% that was in the feed, while achieving a 1.24 times Fe upgrading ratio. The rougher concentrate contained 63.8% Fe with 9.0% SiO2. This stage achieved a 98.1% magnetite recovery and a 73.6% haematite recovery. Thus, relative to the plant feed, 1.9% magnetite and 21.3% haematite was lost from the rougher LIMS stage.

The primary cleaner LIMS received feed from the rougher LIMS. This drum rejected only 1.2% out of the 41.8% mass that constituted the feed, achieving 1.01 times Fe upgrading ratio. The SiO2 grade across this stage dropped from 9.0% to 8.3%. This primary cleaner LIMS stage achieved 99.8% magnetite recovery and 95.8% haematite recovery. The high haematite recovery shows a strong mineral association between magnetite and haematite.

The primary recleaner LIMS treated the concentrate from the cleaner LIMS. This last stage upgraded the Fe content from 64.4% to 64.9% while rejecting 1.18% mass out of the 40.5% that fed the stage. This recleaner LIMS stage achieved 99.7% magnetite recovery and 95.5% haematite recovery. Based on these results, it is clear that LIMS scavenging will be required only on the rougher tails, which contains 1.9% of the ROM magnetite. Overall this campaign achieved a 39.3% mass yield at an Fe grade of 64.9%, with 7.7% SiO2 and 0.10% Al2O3. The low Fe grade and high SiO2 can be attributed to poor liberation as a result of a coarser grind. The final concentrate contained 49.5% magnetite and 41.6% haematite.

Low-SiO2 concentrate production

IsaMilling of the high-SiO2 concentrate

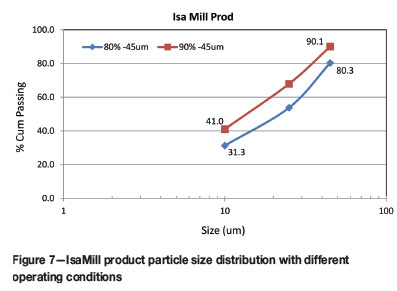

Part of the concentrate (approximately 10%) from campaign 1 was milled to 90% passing 45 µm. The M100 IsaMill was operated at 80% mill filling, 1.34 t/h throughput, and a feed SG of 1.40. Under these conditions the IsaMill specific energy was 22.6 kWh/t. The rest of the campaign 1 concentrate was milled at a reduced mill filling of 60%, operating at 1.82 t/h throughput with a feed SG of 1.46. With these conditions, the IsaMill specific energy was 13.6 kWh/t. The IsaMill achieved a grind of 80% -45 µm. Figure 7 shows the difference in grind under the two operating conditions.

Cleaning of the 80% -45 µm IsaMill product

This run involved cleaning of campaign 1 concentrate after IsaMilling. This circuit consisted of three stages of LIMS.

Mineralogical analysis was conducted prior to this campaign to ascertain the degree of liberation and feasibility of producing a concentrate suitable for direct reduction quality pellets. Table V summarizes the mineralogical results with respect to mineral association by size on the IsaMill product.

Mass balance results as summarized in Table VI show that the three stages achieved 90.2% mass yield (34.2% relative to ROM) and reduced the SiO2 content from 6.56% to 2.25%. The 9.8% mass rejection is in line with the indications from the mineral association information in Table V.

As per Table V, most of the haematite that was recovered from campaign 1 (up to primary LIMS at -75 µm) was still associated with the magnetite even after IsaMilling to 45 µm. This is further confirmed by the high haematite recovery of 89.2% as indicated in Table VI. Given the high recoveries of magnetite and haematite, undertaking a test work campaign for the scavenging of the secondary LIMS tailings after IsaMilling was not considered worthwhile.

The ZRP concentrate at 80% -45 µm compares well with other DR pellet concentrates due to its low impurities levels, as summarized in Table VII.

Conclusions

► The pilot plant achieved 34.2% mass yield, at 69.0% Fe, 2.25% SiO2 from a grind of 80% -45 µm. The lower overall mass yield of 34.2% compared to the expected 40% is a result of the low magnetite and high haematite content in the bulk sample

► The ZRP concentrate is very low in impurities, containing 2.25% SiO2, 0.07% Al2O3, 0.01% K2O, 0.01% P, 0.13% Mn, and virtually no TiO2 and V2O5

► The primary LIMS product could be sold as a blast furnace pelletizing concentrate or could be processed further. If so, the secondary LIMS product after IsaMilling could be sold as a direct reduction pelletizing concentrate

►The cobbing stage achieved a mass yield of 57.5% with a 1.41 times Fe upgrading ratio. The ROM mass rejection was high (42.5%), but this was due mainly to the high haematite content of the bulk sample

► Even though the cobbing stage rejected 42.5% of the mass fed, the magnetite recovery across this stage was very good at 98.4%, while the haematite recovery was low at 74.6%. These results suggest a need for haematite scavenging from the cobbing tails at a higher magnetic field strength

► The primary LIMS (rougher, cleaner, and re-cleaner) performance, with over 98% magnetite recovery, shows that a LIMS scavenger will be required only for rougher tails, which accounts for about 1.9% loss of the ROM magnetite and most of the lost haematite

► The REDS scavenger on cobbing tails recovered 38.4% magnetite and 23.8% haematite from the cobbing tails. Overall, the REDS scavenger improved the haematite recovery from 74.6% to 80.6% before ball milling

► Most of the haematite that was recovered after milling to 75 µm was found to be associated with magnetite, even after IsaMilling to P80 45 µmThis was further confirmed by the high haematite recovery of 89.2% achieved during re-cleaning of IsaMilled concentrate

► The piloting work shows the full-scale plant should not differ significantly from the piloted flow sheet.

Recommendations

► The pilot plant LIMS, cobbing, and rougher, were not optimal but still produced good results in terms of magnetite recovery. The full-scale plant should use countercurrent units, not concurrent, and with higher drum surface magnetic field strength, 2000 G not 1500G.

► A trade-off study should be conducted to evaluate the economic feasibility of using wet high-intensity magnetic separation (WHIMS) or spirals for haematite recovery compared with REDS scavenger on cobbing tails.

Acknowledgements

The author would like to thank Anglo American Mining & Technology and Kumba Iron Ore for permission to publish this paper. To the staff at Anglo American Mining & Technology, Technical Solutions Research, who assisted during these pilot plant test work campaigns, thank you for your diligent and hard work.

References

Dworzanowski, M. 2010. Optimizing the performance of wet drum magnetic separators. Physical Beneficiation 2010 Conference, CSIR, Pretoria, 4-6 May 2010, Symposium Series S61. Southern African Institute of Mining and Metallurgy, Johannesburg. pp. 11-12. [ Links ]

JKTech. 2001. JKSimMet Steady State Mineral Processing Simulator Manual. Chapter 6. Indooroopilly, Queensland, Australia. [ Links ]

Kumba Iron Ore Limited. 2013. Integrated Report 2013. http://www.kumba.co.za/reports/kumba_ar2013/integrated/pdf/ mineral_reserves_2013.pdf [Accessed 5 June 2014]. [ Links ]

Murariu, V. and Svoboda, J. 2003. The applicability of Davis Tube tests to ore separation by drum magnetic separators. Physical Separation in Science and Engineering, vol. 12, no. 1. pp. 1-11. [ Links ]

Wills, B.A. and Napier Munn, T. 2006. Wills' Mineral Processing Technology. 7th edn. Butterworth-Heinemann, Oxford. pp. 354-359. [ Links ]

Van Drunick, W. 2007. Zandrivierspoort iron ore metallurgical characteri sation. Kumba Iron Ore. Unpublished Internal Report. pp. 3-4. [ Links ]