Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.12 Johannesburg Jan. 2013

GENERAL PAPERS

Particle collision during the tribo-electrostatic beneficiation of fly ash based on infrared thermography

H.S. Li; Y.H. Chen; K.B. Wu; X.X. Zhang

School of Chemical Engineering and Technology, China University of Mining and Technology, Xuzhou, People's Republic of China

SYNOPSIS

Tribo-electrostatic beneficiation is effective for separating unburned carbon from fly ash. During the process, the fly ash particles become charged owing to friction and collision inside a tribo device. The intensity of friction and collision between particles can be deduced from the tribo device temperature field, obtained by infrared thermography. The purpose of this research was to establish whether an appropriate configuration of tribo device models can be obtained from particle collision experiments using infrared thermography. An experimental set-up was configured to study tribo devices with different arrangements and spacing of the friction rods, and the effect that this has on interparticle collision and the tribo-electrostatic beneficiation process. The experimental material was fly ash particles with a size range from 38 µm to 74 µm and loss on ignition (LOI) 12.65%. The operating conditions were electric field voltage 40 kV and the air flux ranged from 12 to 24 m3/h. The results show that the temperature inside the tribo devices is directly proportional to air flux and particle collision rate. The arrangement and spacing of the friction rods has an important effect on the temperature field distribution. An equilateral triangular arrangement with 20 mm spacing significantly increases the temperature value and collision probability. The optimum operating parameters were established through tribo-electrostatic beneficiation experiments on the fly ash, and the results (LOI of the product at the two electrodes and rate of removal of unburned carbon at the negative plate) were consistent with those of the infrared thermography experiments. A tribo device with friction rods configured in an equilateral triangle arrangement and with 20 mm spacing again yielded the best results. This approach constitutes a new technique for the optimization of tribo device design.

Keyword: fly ash, tribo-electrostatic beneficiation, tribo device, infrared thermography.

Introduction

Coal is the primary energy source in China, contributing more than 50% of the country's energy supply. In 2009, about three billion tons of coal was consumed, with the power industry accounting for 50% or more of consumption. Fly ash is a solid waste produced and discharged by coal-fired power plants. The fly ash yield is about 1/3 to 1/4 of the coal consumption (Gao et al., 2003). According to statistical analysis, the accumulation of fly ash in China has reached over 12 billion tons and is increasing by 0.16 billion tons annually. In 2009, fly ash production was about 375 Mt, over twice the total volume of city household garbage. The fly ash causes serious problems such as water pollution, air pollution, land pollution, health effects, etc. (Baltrus et al., 2002). However, fly ash is also a useful resource (Ying et al., 2003), and its utilization helps to protect the environment and conserve resources. Consequently, the government has increased its efforts to promote the utilization of fly ash resources.

The fly ash produced by coal-fired power plants contains a certain range of carbon content because of incomplete combustion. It is necessary to separate unburned carbon from fly ash prior to utilization (Vimal et al., 2009). The separation not only recovers the unburned carbon for recycling, thus saving energy, but also improves the fly ash product quality (Hwang et al., 2002).

Tribo-electrostatic beneficiation is widely recognized as an appropriate method for fly ash separation. Research has shown that two processes are pivotal for the tribo-electrostatic beneficiation of fly ash (Kelly et al., 2010). One is the process of particle charging inside the tribo device, the other is efficient separation in an electric field. The particle charging process depends mainly on the action of contact, friction, and collision. These processes generate heat, with the quantity of heat depending on the frictional and collisional action of particles.

The temperature of the particles can therefore be used as an indirect measure of the friction and collision intensity. The distribution and spacing of friction rods has an effect on the motion of the particles. The temperature field of a tribo device was measured using infrared thermography in order to evaluate the efficiency of interparticle friction and collision indirectly, and the results were verified by fly ash tribo-electrostatic beneficiation experiments.

Experimental system

Technical analysis

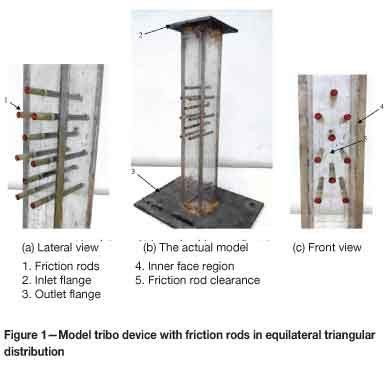

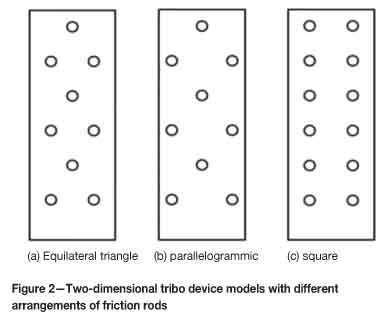

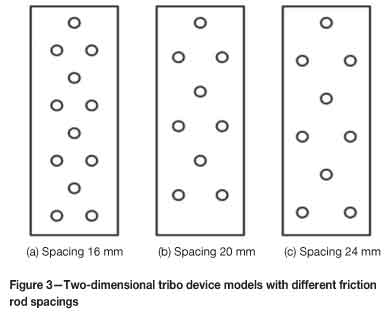

The obverse section plane of the tribo device is a rectangle with length 115 mm and width 40 mm, and its cross section is a square with width 40 mm. The friction rods, which are 5 mm in diameter, may be arranged in an equilateral triangle, parallelogram, or square, with spacings of 16 mm, 20 mm, or 22 mm. The friction rods are run through the tribo device completely. The tribo device and friction rods are made of white organic glass with thickness 5 mm and celandine green fibre respectively. As an example, the actual model with friction rods in equilateral trianglular distribution is shown in Figure 1. The two-dimensional tribo device models are shown in Figures 2 and 3.

The temperature can be measured by either contact or non-contact methods. In contact methods, the measurement components are in direct contact with the measured object. The temperature of the sensing elements is equal to that of the measured object after thermal equilibrium has been achieved. The sensing methods generally used are the thermocouple and thermal resistance. The method is intuitive and reliable, but the temperature sensing elements affect the temperature field and cannot reflect the temperature distribution of the whole area reliably during the measurement process. In non-contact thermometry, heat is exchanged by radiation. The measurement process has no effect on the measured object, and it is easy measure the temperature at multiple points simultaneously. It needs the higher requirements for the object and environment. In this project, therefore, the temperature fields of the visualization tribo devices with different structures were measured by infrared thermal imaging using a FLUKE Ti10 thermal imaging camera.

Experimental system

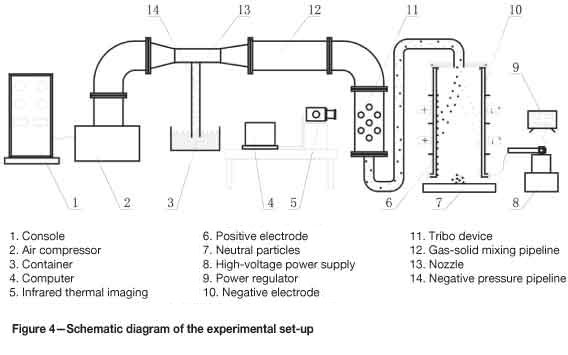

The experiment set-up is shown in Figure 4. The fluidized bed boiler fly ash used in this study was obtained from a thermal power station of the Fujian province in China. The particle size was 38-74 µm, and the average loss on ignition (LOI) 12.65%. The feed mass of fly ash was 20 g for each experiment. All experiments were conducted at an ambient temperature of 23.5°C.

The experimental method is described as follow. The air compressor is controlled by a console in order to obtain an air flux ranging from 12 m3/h to 24 m3/h. At the nozzle, the gas velocity inside the pipe increases rapidly due to the decrease in cross-sectional area. The pipe length is as short as possible to reduce the friction between the gas-solid mixture and the inner surfaces of the pipe. The particles are sucked into the pipeline from the container due to the negative pressure inside the elongated pipeline. The gas and solid phases are mixed fully in the pipeline and injected into the tribo device, where the temperature of the particles increases owing to friction and collision. The infrared thermal imaging device installed on the experimental platform can detect the temperature field distribution. The temperature distribution of the inner surfaces of the tribo device was measured at ambient temperature before each experiment. SmartView software was used for data analysis and processing.

Figure 4 also outlines the fly ash tribo-electrostatic beneficiation process. When unburned carbon and fly ash particles pass across the tribo device, the particles collide with each other and move along with wall friction. The polarity of unburned carbon is opposite to that of the fly ash particles. The charge on the unburned carbon particles was negative during this research. The charged particles are carried into the high-voltage static field by airflow. The unburned carbon and fly ash particles move with different trajectories under the combined forces of gravity force and the electric field. Most of the unburned carbon particles were absorbed on the positive plate because of their negative charge. The fly ash, which collects on the negative plate, has a low carbon content. The neutral particles are collected by a container at the bottom of the electric field.

The efficiency of the tribo devices was evaluated from the LOI of the fly ash and removal of unburned carbon rate (RCR). The RCR is described as follows:

where LOIs is defined as the LOI of fly ash samples before the experiment, and LOI- the LOI of fly ash after removing unburned carbon. The value can be obtained from the fly ash recovered on the negative plate.

Results and discussion

The temperature field was measured at air flow rates of 18 m3/h and 24 m3/h. The distributions of temperature and isothermal points were analysed according to a single experimental result. The temperature distribution of the inner surfaces and friction rods clearance are discussed for tribo devices with different arrangements and spacings.

Arrangement of friction rods

Temperature field measurements

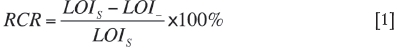

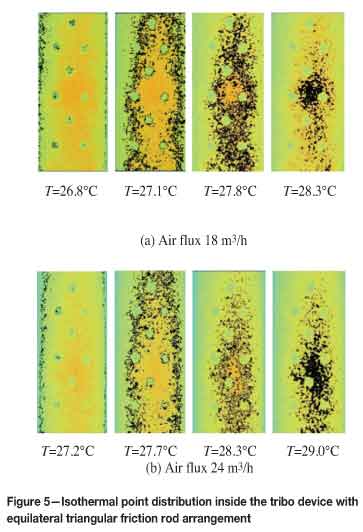

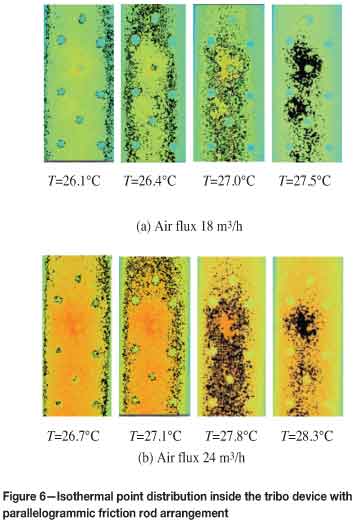

The isothermal point distributions of different tribo devices are shown in Figures 5 to 7. The colour diversity indicates the temperature difference. The black points are the isothermal points. The temperature of the isothermal points is noted under each figure. The figures show that the isothermal point distribution of the inner surface is zonal along direction of motion of the particles.

For the tribo device with the friction rods in equilateral triangular arrangement, the inner surface temperature is 26.8°C (air flux 18 m3/h) and 27.2°C (air flux 24 m3/h) - 0.7°C and 0.5°C higher than those for the parallelogrammic arrangement, and 1.4°C higher than for the square arrangement. For the equilateral triangular arrangement, the middle clearance temperature between the friction rods is the highest among three tribo devices. The temperature of the third to fifth row of friction rods temperature is a maximum for the equilateral triangular arrangement at an air flux of 18 m3/h. The area of maximal temperature moved downwards gradually as the air flux was increased to 24 m3/h. The area of influence of the maximum temperature zone is reduced to the fourth to sixth row of friction rods for the square distribution.

Therefore, the tribo device with equilateral triangular arrangement of the friction rods has an advantage in terms of the action of friction and interparticle collision, and therefore a higher efficiency according to the temperature distribution.

Beneficiation experiments

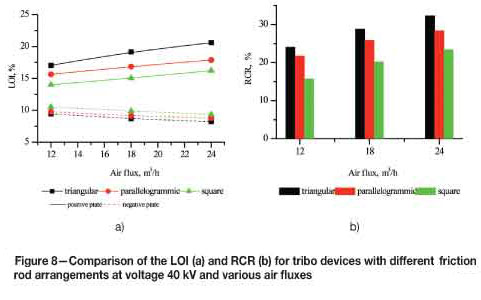

The fly ash tribo-electrostatic beneficiation experiments were conducted in order to evaluate the efficiency of the tribo devices. The electric field voltage was 40 kV and the air flux ranged from 12 m3/h to 24 m3/h. Figure 8 plots the comparison of the LOI and RCR for the tribo devices with different arrangements of the friction rods.

With increasing air flux, the LOI at the positive electrode plate increases gradually. The difference between the three tribo devices is obvious. The triangular friction rod arrangement has the highest positive plate LOI (20.6%), and the square arrangement the lowest (16.23%) at a voltage of 40 kV and air flux of 24 m3/h. For the negative plate, the LOI is inversely proportional to the air flux. The LOI for the square arrangement is higher than for the other tribo devices.

The tribo device with a triangular arrangement is the most efficient, since it shows the largest difference between the LOI of the two plates LOI and the largest RCR for the negative plate. The parallelogrammic arrangement is the second most efficient, and the square arrangement the least efficient.

Spacing of friction rods

Temperature field

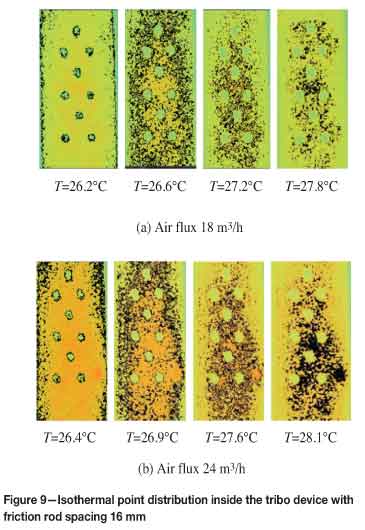

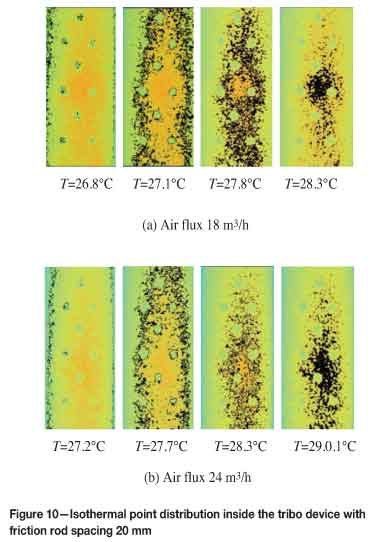

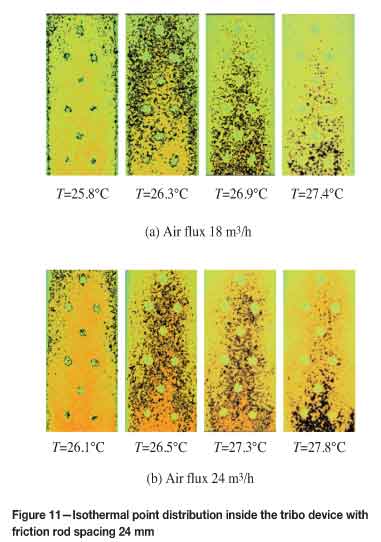

The isothermal point distributions for tribo devices with different friction rod spacings are shown in Figure 9 to 11. The ambient temperature of the friction rods is higher than that of other points. The inner surface temperature of the tribo device with spacing 20 mm is the highest among the three tribo devices. With a spacing of 16 mm, the probabililty of inter-particle collision near the inner surface is very low. The iosothermal point distribution on the inner surface is therefore even and the temperature is low. The inner surface temperature for a spacing of 24 mm is 25.8°C at an air flux of 18 m3/h, and 26.1°C at 24 m3/h.

The friction rods clearance temperature is highest at a spacing of 20 mm. The isothermal points are distributed uniformly from the third to the sixth row of friction rods for spacing 16 mm at an air flux of 18 m3/h. The distribution for a spacing of 24 mm is more sparse from the first to the third row of friction rods. The distribution of clearance temperature changes as the air flux increases, .

The value and distribution of maximum temperature are different for the three types of tribo device. The maximum temperature for spacing 16 mm is 27.8°C at air flux 18 m3/h.

With the air flux increased to 24 m3/h, the maximum temperature rises to 28.1°C and its range of influence increases gradually. The maximal temperature at spacing 20 mm is 28.3°C at an air flux of 18 m3/h and it is located from the third to the fifth row of friction rods. As the air flux rises to 24 m3/h, the temperature maximum increases to 29.0°C and its position extends to the sixth row of friction rods. The maximum temperature for spacing 24 mm is 27.4°C (air flux 18 m3/h) and 27.8°C (air flux 24 m3/h). The temperature for the tribo device with spacing 20 mm is higher than that of the other spacings, therefore the inter-particle friction and collision efficiency will be the greatest.

Results of the beneficiation experiments

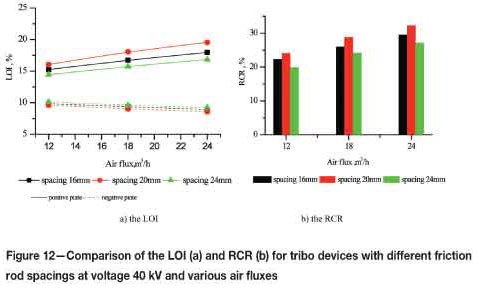

The results of the tribo-electrostatic beneficiation experiments using devices with different spacings are illustrated in Figure 12. The operational conditions were the same as those for the previous experiment.

At a voltage of 40 kV and air flux of 24 m3/h, the positive plate LOI for spacing 20 mm is the maximum at 19.56% and that for spacing 24 mm is the minimum at 16.84%. As the air flux increases from 12 m3/h to 24 m3/h, the negative plate LOI for spacing 20 mm decreases to 8.56%. The negative plate RCR for spacing 20 mm is higher than that of other spacings under all operating conditions. The negative plate RCR for 20 mm spacing increases from 24.05% to 32.29% as the air flux increases from 12 m3/h to 24 m3/h. The LOI difference between the two plates and the negative plate RCR for spacing 20 mm are higher than those for other spacings. The optimal spacing is therefore 20 mm.

Conclusions

An experimental study of particle collision and fly ash benefi-ciation was conducted for different kinds of tribo-electrostatic devices. The results show that:

1. The distribution of the temperature field is regular and symmetrical. The temperature is a function of the air flux and particle collision rate. The isothermal point distribution depends on the distribution and spacing of the friction rods. The temperature of the friction rods clearance is higher than that of the inner surface, and this represents the region where particle collision is most intense.

2. The temperature field inside the tribo device is an indirect indication of the efficiency of inter-particle friction and collision. The difference in temperature and isothermal point distribution is obvious for different kinds of tribo devices. According to the temperature distribution, the tribo device with friction rods in an equilateral triangular arrangement and spacing 20 mm is a reasonable choice to obtain the maximum temperature and the best collision efficiency.

3. The infrared thermography results were verified by the fly ash tribo-electrostatic beneficiation experiments. The results obtained from the two methods are consistent with each other. From the LOI difference at the two electrodes and negative plate RCR, it can be concluded that the tribo device with an equilateral triangular distribution of friction rods at a spacing of 20 mm is the best choice for industrial application.

Acknowledgements

The financial support provided by the National Natural Science Foundation of China (Project 51105362) for this work is gratefully acknowledged.

References

1. Gao, M.H., Zhang, X.X., and Chen, Q.R. 2003. De-ashing of fine-coal using triboelectrostatic beneficiation technology. Journal of China University of Mining and Technology, vol. 32, no. 6. pp. 674-677. [ Links ]

2. Baltrus, J.P., Diehl, J.R., Soong, Y., and Sands, W. 2002. Triboelectrostatic separation of fly ash and charge reversal. Fuel, vol. 81, no. 6. pp.757-762. [ Links ]

3. Ying, H., Masaki, T., and Nobuo, T. 2003. Removal of unburned carbon from municipal solid waste fly ash by column flotation. Waste Management, vol. 23, no. 4. pp. 307-313. [ Links ]

4. Pandev, V.C., Abhilash, P.C., Upadhyay RN, and Tewari, D.D. 2009. Application of fly ash on the growth performance and translocation of toxic heavy metals within Cajanus cajan L.: implication for safe utilization of fly ash for agricultural production. Journal of Hazardous Materials, vol. 166, no. 1. pp. 255-259. [ Links ]

5. Hwang, J. Y., Sun, X., and Li, Z. 2002. Unburned carbon from fly ash for mercury adsorption: i. Separation and characterization of unburned carbon. Journal of Minerals and Materials Characterization and Engineering, vol. 1, no. 1. pp. 39-60. [ Links ]

6. Kelly, E.G. and Spottiswood, D.J. 1989. The theory of electrostatic separation: a review. Part II: particle charging. Minerals Engineering, vol. 2, no. 2. pp. 200-202. [ Links ]

Paper received Oct. 2012

Revised paper received Sep. 2013

© The Southern African Institute of Mining and Metallurgy, 2013. ISSN 2225-6253.