Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.11 Johannesburg Nov. 2013

Truck cycle and delay automated data collection system in surface coal mining

P.G. Terrazas PradoI; V. KecojevicI; D. BogunovicII; P. MongeonII

IDepartment of Mining Engineering, West Virginia University, Morgantown, WV, USA

IINorth American Coal Corporation, Ackerman, MS, USA

ABSTRACT

This paper presents the results of research on the development and application of a custom-made truck cycle and delay automated data collection system (TCD-ADCS) in a surface coal mining. Truck cycle and delay field data are locally stored in trucks and then synchronized and replicated through a wireless network into a centralized server containing an already-developed integrated production management system (IPMS). The system relies on motion sensing and distance travelled in order to automatically define the cycle starting/ending points, cycle time, position, and delay time. Connectivity and communication between loading equipment and trucks are also established. Communication between the equipment operators and TCD-ADCS system is via a user-friendly graphic interface. The hardware used for the development of this system consists of a rugged touch-screen personal computer, 2.4 GHz radio transmitter antenna, and a commercial GPS receiver. The system was developed, tested, and deployed at a surface coal mine in the USA.

Keywords: surface coal mining, truck and shovel, data collection, information systems.

Introduction

Data collection represents a significant endeavour in the mining industry. Many companies invest a considerable amount of time and money in order to obtain data from their operations. In the case of surface mining, operations need to collect different types of data, such as production rates, energy/fuel consumption, cycle times, delays, number of operating hours, etc. Raw data, or field data, needs to be mined and filtered prior to the generation of daily, weekly, monthly, and yearly reports.

There are different methods that can be used for data collection, including operator's daily production log, engineer's field time study, and an automated information system. In some surface mines, the equipment operator is required to write down the starting and ending times of every truck cycle. This is usually accomplished in an operator's journal, which can be very distracting and time- consuming to maintain. The second approach requires an engineer to constantly take time- measurements from several cycles in a single shift in order to generate reliable data. This task is also highly time-consuming. Finally, data can be collected and transferred directly from the mine site using an automated information system (AIS). Information technology (IT) provides the industry with hardware, software, and networking components, while the application of information systems (IS) enables mining operations to manage hardware and software to collect and process data. Both IT and IS help the industry retrieve field data in real time, and thereby eliminate paper-based reports. The development and implementation of IS and IT have made it possible to apply computerized systems capable of recording data directly from the equipment.

The Australian company APS has developed a series of sophisticated ITs capable of tracking and recording truck data such as GPS locations, production cycle time, idle time, delay times, and production records (APS, 2011). This system's infrastructure consists of touch-screen displays, GPS antennae, radio communication, and multiple sensors located within the structure of the equipment. The entire system is capable of reporting to a centralized server in real time (APS, 2011). Although this tool is highly sophisticated and useful, a significant amount of employee training may be required before it can be used, and it can constitute a large capital investment for smaller operations. Another automated information system has been developed by Wenco International Mining Systems, who provide a FleetControl system that is capable of collecting activity, location, time, and production data directly from the field (Wenco, 2012a). It controls several mining activities, and connects directly to an on-site and off-site WencoDB system (Wenco, 2012b), which is a tool operated with a MS SQL server database. Like the APS system, this monitoring system is well-suited for larger surface mines, and it also may require significant employee training. Hawkes et al. (1995) suggest using various IS such as AMSKAN, DISPATCH, and PMCS 3000, which are all available on the market. Systems like VIMS (Vital Information Management System) by Caterpillar (2012) and Komtrax Plus (formerly VHMS) by Komatsu (2012) are also used for equipment data management. In addition to the abovemen-tioned systems, there are several other commercially available systems developed to collect, analyse, and report mine production data. However, the application of available systems restricts the client to using the data analysis and reporting features provided, restricting the opportunity to apply the IT that best fits the mine's needs.

Development and integration of a custom-made AIS for field data collection may prove to be more efficient than using available systems on the market. It allows the mine to make changes and adjustments that best fit the company's business model to generate more effective results. The current commercially available systems may be too comprehensive for the needs of the mine, particularly smaller operations. Furthermore, a custom-made system may not only entail lower capital and maintenance costs, but could also be more user-friendly.

The Fimiston gold mine in Western Australia has developed and used its own surface mining reporting system (Karunaratna and Mattiske, 2002). It consists of a combination of data collection tools that have been adapted to multiple development stages of the mine.

The Integrated Production Management System (IPMS) developed by Bogunovic (2008) was implemented for a specific coal mining operation in the USA. The system includes production, energy consumption, and CO2 emission data from multiple items of equipment in the mine. Data from various sources such as spreadsheets and paper-based forms is integrated into the IPMS and near real-time reports are generated. The mine recognized a need to develop customized technologies that will facilitate automated data collection and transfer directly from the field to the IPMS. Therefore, the main goal of this research study was to develop and implement an automated information system that is able to collect field data from dump trucks, and to transfer such data in real time through a wireless network (WLAN) to an IPMS located in an office environment. The specific research objectives were to:

(i) Establish communication between trucks, loaders, and a remote server, using a wireless network

(ii) Build a software application to collect truck cycle records such as loading time, dumping time, haul time, haul distance, load location, and dump location

(iii) Create a software application for delay time and delay category recognition during regular operating hours

(iv) Generate a user-friendly front-end interface for truck and loader operators

(v) Select and integrate computer hardware such as touch-screen displays, portable computers, GPS antennae, wireless modem PC-cards, and appropriate radio antennae (all hardware must be mounted in a secure form on trucks and loaders)

(vi) Establish communication between an automated data collection system (ADCS) and the existing IPMS (the developed automated information systems must be able to synchronize data in real time).

The system, called the Truck Cycle and Delay Automated Data Collection System (TCD-ADCS), was specifically developed for a coal company that owns a mine in the southern part of the USA.

Methodology

The TCD-ADCS is a custom-made system that fulfills the company's business model. Data flow, naming conventions, a variety of codes, and many other details used for day-to-day process are integrated in this system. In addition, the system was built within the company, and all maintenance and upgrades are provided by the mine's IT personnel. Since the TCD-ADCS was designed around the company's business model, it can be applied to other mines within the same company.

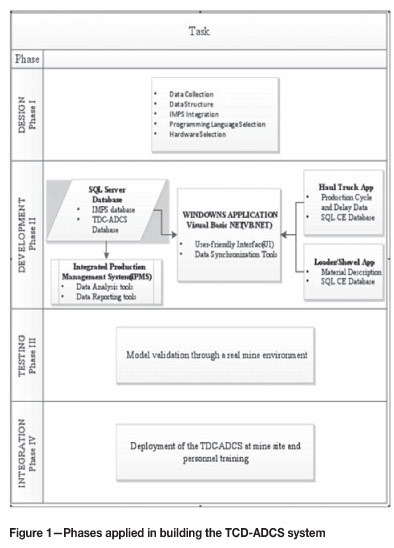

There were four major phases (Figure 1) in building the TCD-ADCS system: design, development, testing, and integration.

The design phase required detailed knowledge of both the field data structure and the data management. In other words, there was a need to define what data to collect and how to collect it from the field. The database file provided by mine management consisted of over 70 tables and corresponds to the IPMS database structure. These tables contained employee data, crew definition, scheduling, and field equipment.

It was required that the new TCD-ADCS be compatible with the existing IPMS system in order to maintain an identical data structure and establish interaction between the two systems. Tables of interest were separated as incoming data tables, and certain rules were set to maintain the data integrity of the existing database. Under no circumstances can employee identification numbers, employees' full names, equipment serial numbers, equipment categories, equipment fleet, crew codes, etc. be altered in the equipment. Mechanisms that allowed interaction between the data coming from the field and the office database were established.

Also, the TCD-ADCS structure provides communication between loading equipment and haul trucks. This technique consists of using the available wireless ad-hoc network and data synchronization methods instead of implementing hardware expansion for peer-to-peer communication. For the TCD-ADCS, loaders play an important role as primary equipment for the generation of cycle records. The loading equipment operator is in charge of pre-selecting and defining specific material description and dumping location values during truck cycle runs. Dump location and material description data is transferred in the form of a message broadcast, which is the synchronization of data created by the loader and retrieved by trucks from a centralized server.

Reliable wireless data transfer is essential, since this will avoid field data corruption. It is important to realize that instability of data routes can result in data loss. Equipment must be able to communicate to a centralized server regardless of its location in the mine site. Unfortunately, network administrators do not have complete control over possible events that may disrupt the on-site network components. In a surface mine, wireless network components can be easily affected by weather conditions, power supply failure, or hardware damage. In the case of such events, the TCD-ADCS is able to invoke a local data storing feature.

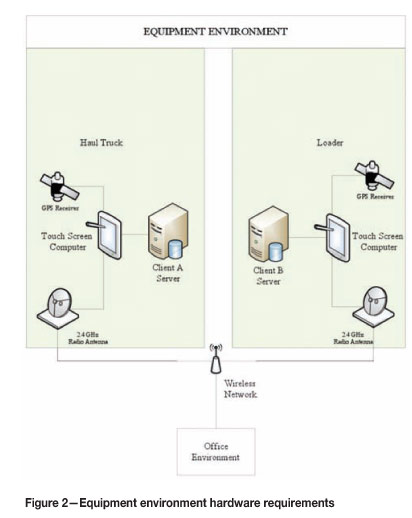

The required hardware for the TCD-ADCS system was selected and divided into two categories: equipment hardware and non-equipment hardware. Non-equipment hardware refers to ITs that establish the local area network (LAN), wireless network (WLAN), servers, modems, routers, and other passive and active network components. Most network components are located in an office environment. Some of them, like wide-range wireless receivers and repeaters, are located throughout the mine site. Equipment hardware refers to the combination of passive and active computer components added to the mining equipment (e.g. trucks and loaders). This cluster of components is similar to that of an office environment (e.g. computers, modems, and receivers). The design and development phases of this research project required installation of hardware for wireless communication, GPS signal reading, data storage, and ultimate user interaction (Figure 2). As a result, the following hardware additions for field equipment were selected: a Panasonic portable touch-screen computer (also as remote server), a Garmin GPS 18 USB receiver, a PCTEL 2.4 GHz radio transmitter antenna, a Motorola Mesh WLAN PC modem, and miscellaneous passive computer components.

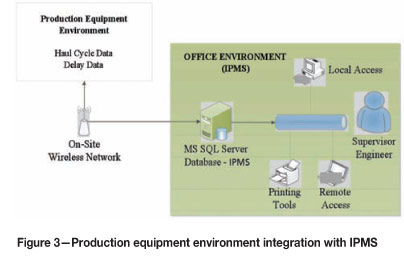

The second phase of this research included the development of the following components in the TCD-ADCS: loading system application (LSA), truck system application (TSA), and synchronization agents. The combination of these three components led to the development of a production equipment environment (PEE) information system remotely integrated with an office environment (Figure 3).

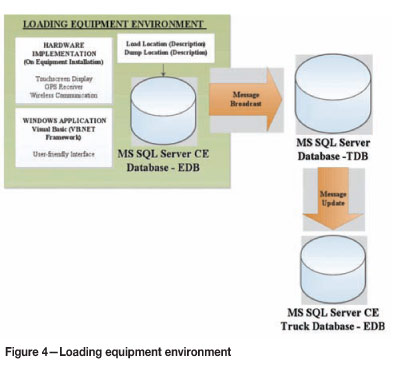

A loading system application (LSA) is a collection of hardware, software, and a unique SQL server environment (Figure 4). This equipment environment is capable of transmitting a loader message to the truck fleet through a wireless network. The structure of a loading equipment environment includes an end-user interface developed for MS WindowsTM applications, a database engine for equipment application (EDB), data synchronization features, and hardware implementations.

The functionality of this system application was reduced only to the pre-selection of a horizon and dump location for truck production cycle data generation. Along with hardware and physical database implementations, the LSA is presented through a graphical user interface (GUI). The GUI, in direct interaction with the loader operator, is limited to a few available options (menus and buttons) in order to decrease complexity and potential sources of distraction. The goal of the loader's GUI is to allow a brief user-friendly interaction between the hardware (PC) and the operator while accomplishing the LSA objective.

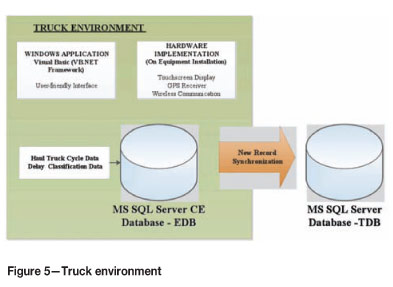

A dump truck environment was introduced as the major data collection feature in the TCD-ADCS. The truck environment includes computer hardware, truck system application (TSA), and a physical local database engine. The physical development was accomplished using similar techniques to those of the development of the loading equipment environment. Integrating a MS SQL server CE database enabled the real-time data synchronization to the remotely located temporary database TDB (Figure 5).

In contrast to the loading equipment's role in the TCD-ADCS, haul trucks employ a system application designed to generate production cycle and delay data in real time directly from the mine site. The truck environment's responsibility is to store and report loading, dumping, hauling, returning, and delay times, along with GPS data. Also, the structure design includes features that log operating hours and GPS tracking.

The objective of the TSA is to introduce an end-user interface while minimizing the interaction between the system application and the truck driver. Enabling the system application to insert most of the field data into the equipment database reduces the potential for human error. For example, to avoid creating false field data, the TSA's GUI does not include a feature to manually submit completed truck cycle runs into the equipment database. Instead, the system application follows a logical sequence of cycle stages before inserting new records into corresponding field tables. In this way the integrity of every truck cycle includes loading, haulage, dumping, return, and variable delays.

The testing phase began after the development of the TCD-ADCS, and included GUIs for the LSA and TSA. During testing, the programming code was debugged and elements on the GUIs were rearranged. Equipment operators on the mine suggested several aesthetic modifications for the LSA- and TSA. Initially, the testing phase took place in a closed environment where multiple mine personnel had the opportunity to interact with the TCD-ADCS. Through this process, fictional data was generated for data synchronization testing purposes. Subsequently, the testing phase continued when the TCD-ADCS was introduced to a real mine environment.

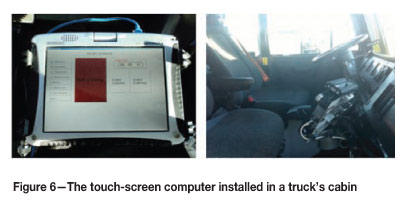

The final phase in the process was the deployment of the TCD-ADCS in a surface coal mine. The deployment phase included merging databases, hardware installation, and employee training. In this stage all excess components used in the development phase were eliminated and only essential parts required for synchronization with the IPMS database were deployed. The hardware installation on the field equipment was accomplished with the help of the IT and maintenance departments at the mine site. Figure 6 shows the touch-screen computer installed in a truck's cabin.

During the deployment phase, equipment operators were exposed to office training sessions before using the TCD-ADCS. They found the simple GUI interaction with the system was quick and user-friendly. Prior to ultimate application and integration in multiple trucks, the TCD-ADCS was tested over a six-month period to resolve unexpected issues and make operators comfortable using the system.

Results and discussion

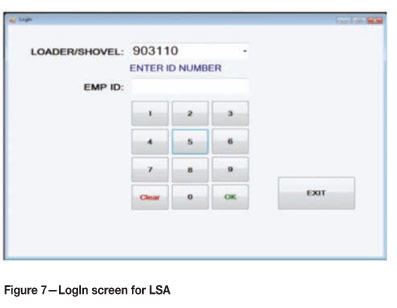

The loader system application (LSA) was not designed for equipment production or delay time data gathering. Its primary objective is to provide a GUI to select material descriptions and dump locations. The LSA uses the TDB as mediator in order to establish equipment communication. Built with two WindowsTM screens, the GUI for the LSA includes LogIn and Main modes.

Beginning with the LogIn screen, the LSA offers a physical platform for the registration of the loader's operator (Figure 7). In this manner, production records will be assigned to both truck and loader operator during IPMS reporting.

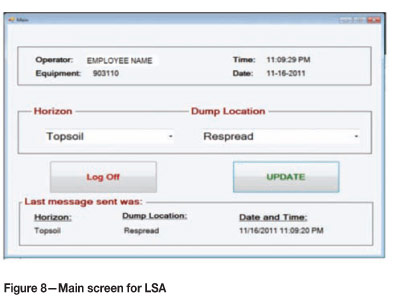

The second and most important form in this GUI is the Main screen (Figure 8). The default screen has been highly simplified to produce an effective interaction with the operator. The Main screen is organized in three sections, including basic user information, horizon and dump location selection, and selection history. At the top of this screen, the operator finds information introduced and selected while at the LogIn mode. This upper section also includes time and date stamps. Within the second section, the selection of horizon and dump location is made through combo boxes or dropdown lists. Ideally, the loader operator will manually select items that best fit the material handling. This data is reported as a message broadcast into the TDB. Later, this data is synchronized back to trucks for accurate production data generation. Finally, the last section in the Main screen is a visual reference of the latest broadcast. The operator may refer to this section for up-to-date decision-making.

As per safety requirements, the truck operator is responsible for completing a pre-shift equipment inspection, which usually takes fifteen minutes and is conducted prior to boarding the truck. After this step, the PC installed in the equipment's cabin (integration phase) initializes the TSA.

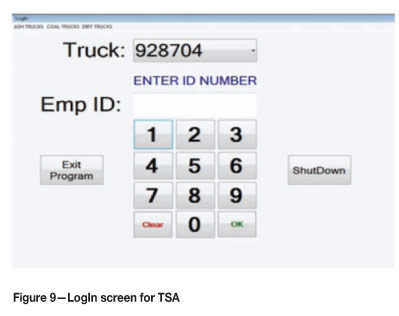

The GUI for trucks includes the following screens: LogIn, Default, Delay, and Setup.

Similar to the LSA, the TSA begins by showing an initial LogIn screen (Figure 9). The operator is required to insert and select basic personal and equipment information. Both of these entries are used throughout the field data generation process.

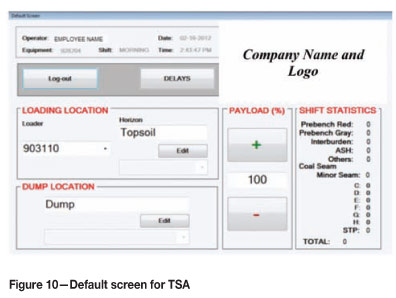

After the login process, the operator can see the TSA's default screen (Figure 10). At this point, the system application is ready to start collecting field data. One of the main purposes of the GUI is to provide the driver with visual information during each cycle run. The top of the default screen displays selected items during the login process (i.e., employee name and equipment number). This particular mine operates under two 12-hour shifts (morning and night). The system application recognizes the shift description based on a login time stamp. Also, using a date stamp, the TSA assigns a crew ID code that corresponds to the scheduled crew.

A secondary purpose of the default mode is to collect items from the screen and use them as components of the production cycle records. For instance, the truck operator is responsible for choosing the loading equipment number with which he or she is working. Once a selection is made, the subsequent production records carry both loader and truck equipment numbers. This way, the IPMS can generate production reports based on trucks or loaders separately.

When a loader number is selected, the horizon and the dump location items are automatically updated. Therefore, the truck driver is excused from specifying the horizon and the dump location. However, the GUI provides the truck operator with features that allow a manual change of both objects. This process is done by using the edit keys. A manual change may occur during a loss of network connectivity or if a verbal request is made by the supervisor.

Shifts statistics are also viewed at the Default screen. Prior to the implementation of the TCD-ADCS, the truck cycle number was the only data available for drivers. Now, the operator can have a visual reference of how many cycles have been completed, as well as the material cycle category. In most cases, drivers often kept a written production log with the total number of cycles. Some operators even used thumb counting-clickers to keep track of cycles. The production logs were collected at the end of every shift by supervisors, who were responsible for manually introducing the total cycle count for every truck into the IPMS. However, since the implementation of the TSA, each production cycle is reported into the database in real time. With every cycle completion, each production record includes data that describes the characteristic of the truck cycle, including date and time, shift, crew, equipment number, employee number, loader ID, loader employee number, horizon, dump location, average payload, and material description.

Finally, while in the default mode, GPS sentences are constantly received by the Garmin GPS 18 USB receiver. The TSA uses GPS data efficiently, since it can be overwhelming to the EDB. A new record on the GPS stable is inserted after the equipment reaches a certain distance from the most recent recording. Through this process, the distance travelled during haulage and return stages on each truck cycle is measured.

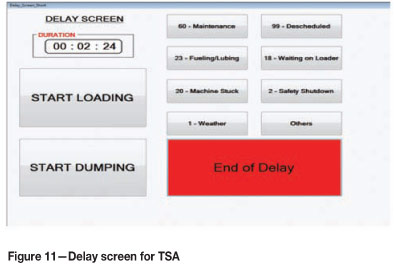

A major feature of the TCD-ADCS is the delay recognition and delay data collection capability. The TSA's GUI includes a delay mode that provides easy access for manual delay code selections. The Default screen includes a delay key to activate this mode. This key does not necessarily need to be selected manually. The system application frequently uses the GPS integration to take measurements of the truck's ground speed. Therefore, it is possible for the system application to be aware when the equipment stops. It is not adequate to assume that all stopping events are considered delays, since some truck cycle stages require the equipment to reach stopping points. While in the delay mode, loading and dumping events are treated differently from variable delays. On the delay screen (Figure 11), the equipment operator finds a list of options containing most common variable delays. Also, loading and dumping notifications are accepted on this screen.

When a truck cycle run is interrupted by a delay event, it is the operator's responsibility to immediately identify the reason for stopping. This is done by clicking on one of the delay options. Once a delay code selection is made, the TSA waits for an end-of-delay acknowledgement. However, the system application is programmed with a default delay code in case no delay selection is made. Just like with the delay recognition logic, the GUI is able to automatically click the End of Delay key by measuring the ground speed. All truck delay events generated from the field are labelled with equipment number, employee number, date, shift, crew, delay code and category, duration, and start and end time.

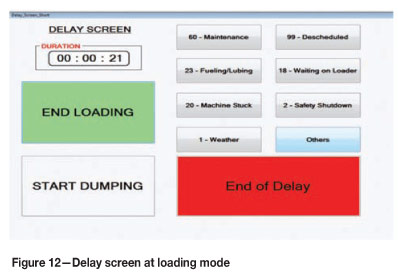

Since the TSA has no interaction with the truck's onboard controls, the recognition of loading and dumping events can be difficult. As a solution, the system application contains a loading and a dumping key within the delay mode. While the truck is loading, the driver must indicate by clicking on the Start Loading button, upon which the GUI immediately changes the functionality of this key to an End Loading key (Figure 12). Again, using the GPS ground speed measurement, the TSA automatically concludes the loading recording when truck movement is detected.

The Start Dumping key follows the same procedures as the Start Loading key, except it is used for dumping events only. Additionally, this key includes a synchronization call at the end of every dumping event. In this way, the TSA maintains the TDB with the most recent truck cycle data available.

Finally, a Setup screen (Figure 13) is incorporated into the GUI for definition of variables. This screen can be accessed only by the supervisor or the mine engineer. In this screen, the authorized personnel are able to change specific parameters used throughout the process of truck cycle and delay data collection.

After the integration of the TCD-ADCS, paper-based cards were eliminated and replaced with the data synchronization features included in the system application. Data transfer is automatically completed in real time, allowing for the latest data generated in the field to appear in the IPMS soon after collection. Field tables within the IPMS are constantly being populated by TSAs. Therefore, paper-based cards are used only as a backup in case the TCD-ADCS is temporarily unavailable.

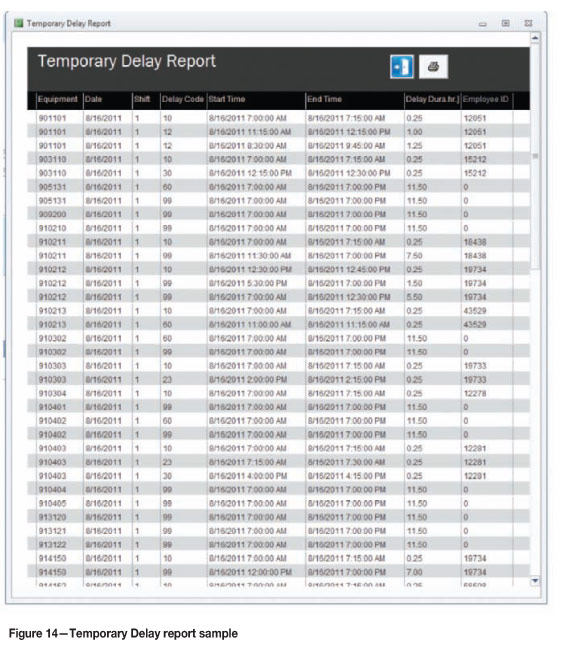

Figure 14 shows customized report samples for truck delays generated by the IPMS. These reports contain useful information about the equipment for the management personnel to use and improve their decision-making. The compatibility of the TCD-ADCS and the IPMS provides an accurate and efficient custom-made truck production monitoring system for the surface coal mine.

Conclusions

The surface mining industry is in constant need of more effective and efficient methods designed to take constant and accurate field measurements. More accurate data translates into better control of equipment and employee productivity. When field data is transformed into useful information, management decision-making is significantly improved.

This paper has focused on the development of a truck cycle and delay automated data collection system to be used in surface mining operations. The development of this custom-made system was inspired by the previous successful incorporation of the Integrated Production Management System (IPMS). The TCD-ADCS collects complete truck cycle data as well as fixed and variable delays in real time. The data collected includes loading and dumping times, haulage and return time and distance, average payload, load and dump locations, material description, operating hours, and delay code and duration. The system also includes a GPS tracker tool for the collection of coordinate locations of operational events. Field data analysis and reporting were not included in the scope of this paper. However, a complementary objective of this work included the creation of a system compatible with the IPMS for the analysis of data and reporting purposes.

The TCD-ADCS consists of two system applications developed for trucks and loaders. It offers user-friendly graphic interfaces for the operators, and provides data synchronization tools for real-time data transfer from the field to an office environment.

The results of the use of the TCD-ADCS and its outcomes can be summarized as follows:

- Successful data transfer from the field to an office environment using database synchronization

- Constant equipment communication through wireless network connectivity

- User-friendly GUIs for operator interaction with the TSA and the LSA

- Minimization of employee training

- Successful integration with the already existing IPMS

- Completion of paperless truck and shovel production monitoring system.

Using available technologies, it was possible to generate a field data recording system that best fits the mine's needs. The mine management team believes that the implementation of the new information systems and information technologies (i.e. the TCD-ADCS and the IPMS) has significantly changed the current production monitoring of the company. Interaction between the custom-made TCD-ADCS and the IPMS completes the data transformation cycle from raw field data to useful information, which can be used to make better management decisions.

List of acronyms

ADCS = Automated Data Collection System

AIS = Automated Information Systems

APS = Automated Positioning Systems

CE = Compact Edition

EDB = Database Engine for Equipment Application

GPS = Global Positioning System

GUI = Graphical User Interface

IPMS = Integrated Production Management System

IT = Information Technologies

IS = Information Systems

LAN = Local Area Network

LSA = Loading System Application

MS SQL = Microsoft Structured Query Language

PEE = Production Equipment Environment

TCD-ASCS = Truck Cycle and Delay Automated Data Collection System

TDB = Temporary Database

TSA = Truck System Application

VHMS = Vehicle Health Monitoring System

VIMS = Vital Information Management System

WLAN = Wireless Network

References

Automated Positioning Systems. 2011. Truck and Shovel. http://www.apsmining.com/Solutions/Truck%20and%20Shovel/default.aspx [ Links ]

Bogunovic, D. 2008. Integrated data environment for analysis and control of energy consumption (IDE-ACE) in surface coal mining. Doctoral dissertation, Pennsylvania State University. [ Links ]

Caterpillar. 2012. Vital information management system. http://www.cat.com/cda/layout?m=37498&x=7 [ Links ]

Hawkes, P.J., Spathis, A.T., and Sengstock, G.W. 1995. Monitoring equipment productivity improvements in coal mines. EXPLO 95 Conference, Brisbane, September 1995. Australasian Institute of Mining and Metallurgy. pp. 127-132. [ Links ]

Karunaratna, K. and Mattiske, T. 2002. Automated production data collection and reporting at a large open pit mine. CMMI Congress 2002, Cairns, QLD.. Australasian Institute of Mining and Metallurgy. pp. 141-149. [ Links ]

Komatsu. 2012. Komtrax-Plus. http://www.komatsuamerica.com/komtrax-plus [ Links ]

Wenco International Mining Systems Ltd. 2012a. Fleet Control. http://www.wencomine.com/products/ [ Links ]

Wenco International Mining Systems Ltd. 2012b. WencoDB. http://www.wencomine.com/products/ ♦ [ Links ]

Paper received Jan. 2013

Revised paper received Sep. 2013

© The Southern African Institute of Mining and Metallurgy, 2013. ISSN 2225-6253.