Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.11 Johannesburg Nov. 2013

Effect of microemulsified collector on froth flotation of coal

L. Li; X. Lu; J. Qiu; D. Liu

Chemical and Environmental Engineering College, Shandong University of Science and Technology, Qingdao, P.R. China

ABSTRACT

The performance of microemulsified diesel and conventional diesel collectors in coal flotation was compared by flotation indicators, including combustible recovery, ash content of the clean coal, and the flotation index. An efficient separation with lower dosage was obtained using the microemulsified diesel collector. Under optimum separation conditions, the microemulsion consumption was 100 g/t less compared with diesel. The saving in diesel consumption using the microemulsion reached about 70%, disregarding the consumption of the surfactant and cosurfactant. Frothing tests showed that the frother dosage was decreased by using the microemulsion collector, because of the surfactant and cosurfactant added during preparation. The microemulsified diesel collector is superior to the conventional diesel collector in terms of diesel consumption and separation efficiency, but the selectivity requires further improvement.

Keywords: froth flotation, microemulsified collector, coal.

Introduction

The modernization of mining methods and cleaning processes has increased the quantity of raw fine coal particles produced (Cebeci, 2002; Kim et al., 1991; Pawlak et al., 1985). Coal preparation or cleaning is the removal of non-combustible minerals from run-of-mine coal (Capes and Germain, 1982; Erol et al., 2003; Mehrotra et al, 1983). Conventional coal beneficiation techniques are inefficient for fine coal processing (Kim et al., 1991; Mehrotra et al., 1983). Froth flotation is a fine particle separation process, based on the difference in surface hydrophobicity of different components. It is often very effective for coal cleaning, since coal is naturally hydrophobic and minerals are generally hydrophilic. Because of coal's hydrophobicity, froth flotation has employed mostly non-polar oil collectors such as kerosene, crude petroleum, fuel oil. and certain coal-tar distillates (Wójcik et al., 1990; Solov'eva and Muklakova, 1995; Petukhov, 1995). The collector disperses into droplets in the pulp, and these droplets collide with, adhere to, and coat the coal particles, thus increasing their hydrophobicity (Polat et al., 2003). Dispersing- these non-polar oils is often difficult, and the size of the oil droplets is often large. This results in high collector consumption and poor flotation performance. Investigating means of decreasing the collector dosage and cost are therefore of interest.

Non-polar oils can be dispersed into smaller droplets by emulsification (Duong et al, 2000; El-Shall et al., 2000; Laskowski, 1992; Laskowski and Wang, 1997; Song et al, 1999). Emulsions are mixtures in which small droplets of one phase are dispersed in another. They are thermodynamically unstable, so emulsified collectors are also unstable, and demulsification can occur during storage. Demulsification of collectors significantly reduces their separation efficiency. A special emulsification device with a complex structure and high energy consumption has been reported to mix and prepare unstable emulsified collectors; however, its application in the coal froth flotation industry is impractical (Jones et al., 1978).

Microemulsions are transparent and thermodynamically stable. Similar to emulsions, they consist of a surfactant (or surfactant and cosurfactant), oil, and water. The cosurfactant is usually a short-chain alcohol with two (ethanol) to four (butanol) C atoms. The average droplet size of microemulsions is 5-100 nm, compared with hundreds of micrometres for emulsions (Huibers, 1996). Microemulsions are kinetically and thermodynamically stable, and thus can be formed spontaneously (Vollmer and Vollmer, 2001). Oils can be dispersed into smaller droplets by microemulsification. The spontaneous formation of microemulsions reduces the difficulty and energy consumption associated with preparation.

There are no reports on the use of microemulsions in coal flotation. The current study investigates the application of microemulsions for coal flotation. Preliminary research of the formula of the microemulsified collector has been investigated, and the optimal formula is used in this study.

Material and methods

Sample

The coal sample was obtained from the Pangta coal washing plant in Shanxi, P. R. China. The proximate analysis results of the sample are shown in Table I.

The size distribution and ash yield of the size fractions are shown in Table II.

Reagents

Reagents were nonylphenol ethoxylated 10/NP-10 (Laurenthall Enterprises, AR grade), pentanol (Merk, AR grade), MIBC (Merk, AR grade), and diesel oil. Diesel oil was obtained commercially, and had a density of 0.83 g/cm3, API grade of 38.8, and viscosity of 4.5 cp. Double-distilled deionized water was used in the experiments.

Microemulsified collector preparation

The microemulsified collector was prepared by phase inversion emulsification. NP-10 (surfactant) and pentanol (cosurfactant) were mixed at a mass ratio of 3:2 to form the surfactant phase (SA). SA, diesel, and water were mixed at a mass ratio of 3:5:6 with a magnetic stirrer for 3 minutes at 25°C. The microemulsified collector was determined to be an O/W (oil in water) microemulsion by staining. The size of the dispersed diesel droplets was measured with a Malvern Zetasizer. Figure 1 shows the droplet size distribution. The average size was about 31 nm.

Denver cell flotation

Flotation tests were carried out using a Denver laboratory flotation machine. The cell had a capacity of approximately 1.5 dm3, and 90 g samples were used. The stirring speed and air flow rate into the cell were 1250 r/min and 6 L/min, respectively. In each test, the slurry mixture was first agitated in the flotation cell for 3 minutes, after which the collector was added and the suspension was conditioned for 3 minutes (collector stirring time). The frothing agent (MIBC) was added, and the pulp was conditioned for 3 minutes. After collecting the flotation product for 3 minutes, the froth concentrates were dried, weighed, and the ash content measured (wt.% on dry basis). The combustible recovery and flotation index were calculated from Equations [1] and [2], respectively.

Combustible recovery (CR):

Flotation index (Fl):

where Ac is the ash content of clean coal, Af the ash content of the feed, Mc the mass of clean coal, and Mf the mass of feed.

Results and discussion

Collector dosage

This study aimed to evaluate the collector performance of microemulsified and conventional diesel. The collector/frothing agent ratio was held constant at 7.

Figure 2 shows that combustible recovery increased with increasing collector dosage. As the microemulsion dosage increased from 400 g/t to 1000 g/t, the combustible recovery increased from 76.21% to 97.29%. For the diesel fuel, the combustible recovery increased from 62.30% to 92.18% as the oil dosage increased from 400 g/t to 1000 g/t. The combustible recovery curves for the microemulsion and diesel showed similar trends. A low collector dosage was insufficient to adsorb on all coal particles, thus competition between particles with different surface properties took place. Only strongly hydrophobic particles were floated, and a lower combustible recovery was obtained. The number of droplets available for adsorption increased with increasing collector amount, and the combustible recovery increased. A lower amount of microemulsion collector achieved a similar combustible recovery to diesel, probably because of the nanometre-sized oil droplets. After microemulsification, the amount of collector adsorbed on the surface of coal particles decreased, on the basis of similar coverage area.

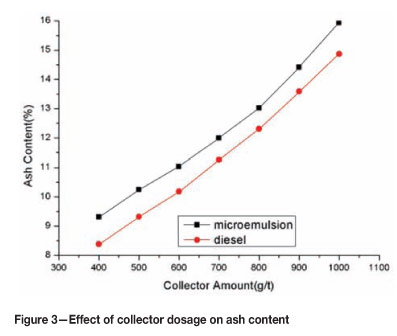

Figure 3 shows that ash content increased with increasing collector dosage. As the microemulsion dosage increased from 400 g/t to 1000 g/t, the ash content increased from 9.31% to 15.94%. For diesel, as the oil dosage increased from 400 g/t to 1000 g/t, the ash content increased from 8.38% to 14.87%. The ash content in the product obtained from the microemulsion collector was higher than from the diesel collector, which may be related to the surfactant in the microemulsion. The higher amount of surfactant adsorbed on the particles surface may have reduced the selectivity of the flotation process (Aktas and Woodburn, 1995; Asplin et al., 1998). Although surfactant addition affected the ash content, the observed changes were minor.

The purpose of coal flotation is to minimize the ash content with the highest possible combustible recovery. In practice, a lower ash content is obtained at the expense of combustible recovery. Thus, it is reasonable to consider both combustible recovery and ash content when evaluating the efficiency of the flotation process. The flotation index (FI) was used to evaluate flotation of the same coal under different separation conditions, and to characterize the flotation. FI can be used to determine the quality of the process. The relationship between FI and collector (microemulsion and diesel) dosage is shown in Figure 4.

Figure 4 shows that FI increased with increasing collector dosage. The FI reached a maximum of 54.5% at a dosage of 600 g/l when using microemulsified collector, and 48.8% at 700 g/t using conventional diesel. The better separation efficiency at lower collector dosage achieved with microemul-sified diesel is attributed to the nanometre-sized droplets being better dispersed, which increases the probability of collision between coal and collector particles, and shortens the attachment period (Rubio et al., 2007). Under optimum flotation conditions (maximum FI), the microemulsion consumption was 100 g/t less than with diesel. The microemulsion preparation formula showed that the diesel accounted for approximately 35% of the microemulsion. Thus, the diesel consumption decreased by approximately 70% for the microemulsion, without considering the consumption of surfactant and cosurfactant.

Collector/frother radio

The effect of frother dosage was investigated at the optimum microemulsion and diesel contents of 600 g/t and 700 g/t, respectively, as determined above.

Figure 5 shows FI curves using the microemulsion and diesel collectors at various collector/frother ratios. Increasing the frother amount caused the FI to increase to a maximum, before decreasing. A maximum FI of 61.5% and 58.0% was achieved with microemulsified and conventional diesel, respectively, at collector/frother ratios of 8 and 7, respectively. The lower frother dosage for microemulsified diesel may be related to the surfactant and cosurfactant.

Conclusions

The microemulsified collector containing nanometer-sized oil droplets was superior to the conventional diesel collector in terms of both diesel consumption and separation efficiency. Under optimum separation conditions, the consumption of microemulsified collector was 100 g/t less than that of standard diesel. Diesel consumption using the microemulsion decreased by about 70%, disregarding the consumption of the surfactant and cosurfactant. Microemulsified diesel also resulted in better separation efficiency at lower dosage. The frother dosage was lowered by using the microemulsion, because of the surfactant and cosurfactant added during preparation. However, the selectivity of the microemulsified collector requires further improvement.

Acknowledgements

Financial support from the Young Scientists Fund of the National Natural Science Foundation of China (No. 51104095) and the China Postdoctoral Science Foundation (No. 2012M511534) is gratefully acknowledged.

References

Aktas, Z. and Woodburn, E. 1995. The effect of non-ionic reagent adsorption on the froth structure and flotation performance of two low rank British coals. Powder Technology, vol. 83 pp. 149-158. [ Links ]

Asplin, R., Sadr-Kazemi, N., and Cilliers, J. 1998. The effect of surfactant concentration on batch flotation mineral flux and froth structure. Minerals Engineering, vol. 11. pp. 257-269. [ Links ]

Capes, C. and Germain, R. 1982. Selective oil agglomeration in fine coal beneficiation. Marcel Dekker, New York. [ Links ]

Cebeci, Y. 2002. The investigation of the floatability improvement of Yozgat Ayridam lignite using various collectors. Fuel, vol. 81. pp. 281-289. [ Links ]

Duong, C., Choung, J., Xu, Z., and Szymanski, J. 2000. A novel process for recovering clean coal and water from coal tailings. Minerals Engineering, vol. 13. pp. 173-181. [ Links ]

El-Shall, H., Abdel-Khalek, N., and Svoronos, S. 2000. Collector-frother interaction in column flotation of Florida phosphate. International Journal of Mineral Processing, vol. 58. pp. 187-199. [ Links ]

Erol, M., Colduroglu, C., and Aktas, Z. 2003. The effect of reagents and reagent mixtures on froth flotation of coal fines. International Journal of Mineral Processing, vol. 71. pp. 131-145. [ Links ]

Huibers, P.D. 1996. Surfactant self-assembly, kinetics and thermodynamics of micellar and microemulsion systems. University of Florida. [ Links ]

Jones, T., Neustadter, E., and Whittingham, K. 1978. Water-in-crude oil emulsion stability and emulsion destabilization by chemical demulsifiers. Journal of Canadian Petroleum Technology, vol. 17, no. 2. pp. 100-108. [ Links ]

Kim, S., Morsi, B., Araujo, G., Chiang, S.-H., Blachere, J., and Sharkey, A. 1991. Effect of grinding conditions on the performance of a selective agglomeration process for physical coal cleaning. Coal Preparation, vol. 9. pp. 141-153. [ Links ]

Laskowski, J. 1992. Oil assisted fine particle processing. Developments in Mineral Processing, vol. 12. pp. 361-394. [ Links ]

Laskowski, J. and Wang, Q. 1997. Amine-containing oils as extenders in the flotation of sylvinite ores. Proceedings of the XX International Mineral Processing Congress, Aachen, Germany. Hoberg, H. and Von Blottnitz, H. (eds.). GMDB, Gesellschaft für Bergbau, Metallurgie, Rohstoff- und Umwelttechnik, Clausthal-Zellerfeld, Germany. pp. 605-616. [ Links ]

Mehrotra, V., Sastry, K., and Morey, B. 1983. Review of oil agglomeration techniques for processing of fine coals. International Journal of Mineral Processing, vol. 11. pp. 175-201. [ Links ]

Pawlak, W., Turak, A., and Ignasiak, B. 1985. Selective agglomeration of low rank bituminous and sub-bituminous cretaceous coals. Proceedings of the Fourth International Symposium on Agglomeration. Toronto, 2-5 June. Capes, C.E. (ed.). L.G. Kuhn, Toronto, Ontario. [ Links ]

Petukhov, V. 1995. Conditioning of coal for froth flotation with kerosine collector. Fuel and Energy Abstracts, vol. 36, no. 4. pp. 245-245. [ Links ]

Polat, M., Polat, H., and Chander, S. 2003. Physical and chemical interactions in coal flotation. International Journal of Mineral Processing, vol. 72. pp. 199-213. [ Links ]

Rubio, J., Capponi, F., Rodrigues, R.T., and Matiolo, E. 2007. Enhanced flotation of sulfide fines using the emulsified oil extender technique. International Journal of Mineral Processing, vol. 84. pp. 41-50. [ Links ]

Solo'eva, T. and Muklakova, A. 1995. Method for determination of flotation activity of apolar reagents during flotation of coals. Fuel and Energy Abstracts, vol. 36, no. 4. pp. 246-246. [ Links ]

Song, S., Lopez-Valdivieso, A., and Ding, Y. 1999. Effects of nonpolar oil on hydrophobic flocculation of hematite and rhodochrosite fines. Powder Technology, vol. 101. pp. 73-80. [ Links ]

Vollmer, D. and Vollmer, J. 2001. Bending free energy and spontaneous curvature for micelles and microemulsions with weak and strong surfactants. European Physical Journal E, vol. 4. pp. 153-159. [ Links ]

Wjcik, W, Jańczuk, B., and Bialopiotrowicz, T. 1990. The influence of an apolar collector on the contact angle, detachment force and work of adhesion to the coal surface in agglomeration flotation of a low rank coal. Fuel, vol. 69. pp. 207-210. [ Links ] ♦

Paper received Aug. 2013

Revised paper received Sep. 2013.

© The Southern African Institute of Mining and Metallurgy, 2013. ISSN 2225-6253.