Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 no.11 Johannesburg nov. 2013

The effect of substituting fractions of imported coking coals with coke oven tar on coal blend, carbonization, and coke properties

S.S. Makgato; R.M.S. Falcon

School of Chemical and Metallurgical Engineering, University of Witwatersrand, Johannesburg, South Africa

ABSTRACT

In this study, coke oven tar additions over a range of 0-8 wt.% were evaluated as a possible substitute for imported coal fractions. The coke oven tar used was collected from tar decanters in the byproducts section of the coking plant. The moisture content in the tar varied depending on the residence time and water carryover from the coke oven tar separators to the storage tanks. Moisture contents of 1 wt.%, 3 wt.%, and 6 wt.% were investigated in order to evaluate the effect on coal blend, carbonization, and coke properties. At 6 wt.% moisture content with 6 wt.% coke oven tar, although the coke quality improved the yield showed a 4% decrease. On the other hand, 1 wt.% moisture content with coke oven tar of 6 wt.%, increased the yield by 1% and the coke quality improved. However, the latter process was characterized by an excessive increase in wall pressure and pushing energy, both of which are detrimental to the oven walls. The optimum moisture content in coke oven tar was found to be 3 wt.% with a coke oven tar addition of 6 wt.% in the coal blend. With these conditions, the coke properties improved and wall pressure and pushing energy were acceptable. However, a decrease in coke yield of up to 2% was observed. Despite this, coke oven tar addition is considered to be a viable option based upon economic factors of a reduction in the quantity and cost of imported coking coals that is required to achieve the same optimum final coke product.

Keywords: coal substitution, coke oven tar, tar moisture, coal blend, coke, coke quality.

Introduction

The development of the iron and steel industry has changed the international coking coal market considerably over the years, resulting in a prominent increase in coal prices and making it more difficult to obtain coals that were readily available on the market previously (Ruiz et al., 1990; Fernández et al., 2012). As a result of economic considerations, coke producers have opted to reduce the percentage of these expensive coking coals in their blends. South Africa has limited supplies of prime coking coals, which are produced mainly from Tshikondeni Mine in Limpopo Province with very small quantities from KwaZulu-Natal (Jeffrey, 2005). Blend coking coals (or semi-soft coking coals) with less than 10 wt.% ash content are mined at Grootegeluk- in the Waterberg (Jeffrey, 2005). In order to produce coke of sufficient strength and quality, the South African iron and steel industries import coking coals from countries such as the USA, New Zealand, and Australia, to mention just a few. The properties of these imported coals are shown in Tables I to IV.

Table I shows the origin and properties of the coking coals, and Table II shows their corresponding ultimate analysis and sulphur.

Table III shows that poor-coking high- and low- volatile coals have low fluidity and a narrow plastic range. The thermoplastic properties of coals depend on their rank, but the degree of coalification (rank) is not the only factor that influences the thermoplasticity of a given coal (Díaz-Faes et al., 2007). Other factors, including the proportion of macerals (vitrinite in particular) and their associated microlithotypes, also play a major role. Vitrinite is the predominant maceral in coking coal and the main contributor to coke quality. The reflectance of vitrinite indicates the rank or the degree of coalification of coal which, in turn, controls the coking capacity in the vitrinite macerals in the coal (i.e. the properties of swell, plasticity, and fusion). Generally, coal rank is directly proportional to volatile matter and carbon content in European and US coals, but due to the heterogeneous nature of South African coals, rank is more reliably determined by vitrinite reflectance (see Table IV for vitrinite reflectance distribution and mean values).

From Table IV, it will be noted that coal A is a non-coking Bituminous C coal (RoVr% = 0.712). Coals B and D fall in the mid-Bituminous prime coking range of rank, i.e. Bituminous B (RoVr% = 1.1-1.3), and coal C falls border line between Bituminous B and C (RoVr% = 0.9), i.e. just below and marginal to the prime coking category.

The imported coals constitute up to 65 wt.% of metallurgical coal blends. Factors such as increased coal consumption, the high price of imported coals, the reduction in existing coking coal reserves globally, reduction in both qualities and quantities of available blend coking coals,- fragile environments and poor roof conditions due to the depth and complex geology of remaining reserves, as well as insufficiently developed infrastructure to transport coking coals are concerns that the iron and steel industry must overcome in order to remain competitive well into the 21st century. The latter factor is supported by Eberhard (2011), who emphasized that a major current constraint in moving coal to the end user is South Africa's aging and inefficient rail infrastructure.

In order to meet the escalating worldwide requirements for metallurgical coke with a concern for preserving the base of raw materials, the limited reserves of prime coking coals, semi-soft coking coal, and non-coking coal, and in an environmentally friendly manner, increasing efforts have been made over the years to find new ways of improving coke quality while conserving the range of cokeable coals. A variety of technologies such as coal pre-treatment, stamped charging, briquetting charging and formed coke, addition of petroleum coke to coal blends, and chemical additives such as oil, diesel and tar to coal blends, or substitution of coking coals by non-coking coals have been reported by various researchers (Jackman and Helfinstine, 1979; Kestner et al., (1981); Chatterjee and Prasad, 1982; Leibrock and Petak, 1983; Gonzalez - Cimas et al., 1986; Lin and Hong, 1986; Taylor and Coban, 1987; Alvarez et al., 1989; Das et al., 2002; Plancher et al., 2002; Shevkoplyas, 2002; Benk, 2010; Saxena et al., 2010; Benk and Coban, 2011; Melendi et al., 2011; Díez et al., 2012).

In the current study, coke oven tar addition was chosen as it is a readily available material, relatively inexpensive, and was previously reported to give a good performance as a modifier. However, tar addition entails some challenges, such as facilities for adequate proportioning of the tar mix with coal, proper mixing of coal and tars, and deposition of tar on belt conveyors and return idlers (Chatterjee and Prasad, 1982). Despite these reported issues, the use of coke oven tar is still the objective of this study. The intention is to investigate the effect of substituting various fractions of imported coking coals with coke oven tar and to confirm whether those challenges encountered by other authors (Chatterjee and Prasad, 1982) could be resolved and whether coke quality could be maintained or possibly optimized.

Materials and methods

Experimental procedure

The four bituminous coals used to make the blend in this study were supplied by members in the South African steel industry, as these coals are frequently included in the industrial blends used to to produce metallurgical coke. The coals tested cover a wide range in volatile matter content, thermoplastic properties, and geographical origin. The blending was conducted by mixing the four coals in specific proportions similar to those used in commercial blending procedures. This blend was then divided into representative parcels for testing with coke oven tar.

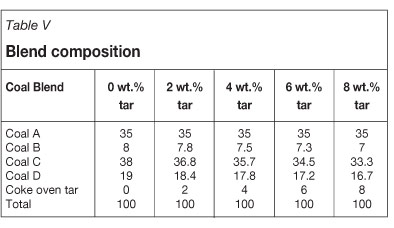

The coke oven tar, produced from an industrial coal blend similar to the base coal blend used in the study, at 55 ±2°C was collected from tar decanters in the by-products coking plant. The tar was mixed with the coal blend as shown in Table V, using an RV11 mixer that was optimized to run for 30 seconds in order to obtain a uniform mixture. From 2 - 8 wt.% of coke oven tar, with moisture contents of 1%, 3%, and 6% was used. The moisture content was measured using the Karl Fischer titration method. The study did not include coke oven tar additions of 10 wt.% or higher due to operational problems when working with such large volumes.

Coal moisture measurements (air dry base)

Inherent moisture in individual coals and the coal blend was measured according to the ISO 331:1983 standard procedure.

Bulk density measurement

The bulk density of the prepared blend was determined as per ASTM: D291-60. An adequate quantity of representative samples of the blend was taken for various laboratory tests before charging the blend into the oven.

Pilot plant oven

Carbonization tests were carried out in a pilot plant oven of approximately 350 kg capacity. The dimensions of the oven are 915 mm length x 455 mm width x 1015 mm height, with a usable volume of 0.35 m3. The distance between thermocouples was approximately 60 mm between middle and top, 60 mm between top and wall, and 140 mm between middle and wall. A programmable controller was used to control the oven temperature. The temperature at the centre of the coal charge was monitored by means of a thermocouple connected to a computer. The coal was gravity-charged into the oven when the oven reached 1200°C. The temperature of the wall was kept constant throughout the test. The coking time was fixed at approximately 19 hours throughout all the tests.

Coke moisture measurement

Moisture content was determined by establishing the mass loss of a sample after drying it in an oven with set temperature of 150 ± 5°C and forced air circulation.

Coke Irsid indices measurement

Coke Irsid indices were measured according to the ISO 556 standard procedure.

Coke Micum indices measurement

Coke Micum indices were measured as per the ISO 1881 standard procedure.

Determination of CRI and CSR

The coke samples produced were prepared and tested for CSR and CRI measurement as per specification in the ASTM D5341-99 standards.

Stability and hardness factor determination

For stability and hardness determinations, each sample of dry coke of designated size (-75 +50 mm) was weighed to the nearest 0.025 kg. A 10 ± 0.25 kg sample was tumbled in a rotating drum for a total of 1400 revolutions. Two indexes of strength, the stability factor and the hardness factor, were determined by sieve analysis of the coke after treatment. All of the coke were removed from the drum and sieved using a 25 mm square mesh sieve and a 6.3 mm square-mesh sieve. The coke remaining on each of the sieves and the coke that passes through the 6.3 mm sieve were weighed.

Results and discussion

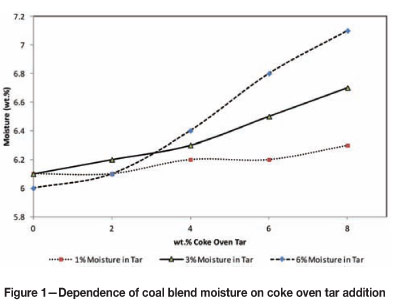

Effect of coke oven tar addition on coal blend total moisture

Figure 1 depicts the relationship between coal blend moisture and coke oven tar addition. As the tar addition increased, the coal blend total moisture increased correspondingly, due to the moisture content in the coke oven tar. The addition of coke oven tar with a range of moisture contents changes the heat transfer through the coal mass significantly. According to Krebs et al. (1996), two effects could be responsible for these modifications. The first is a physical effect in which coke oven tar acts as a vehicle for the volatiles by penetrating the porous structure of the coal and accelerating the desorption of low-molecular-weight compounds trapped within the macromolecular network. The second effect is a chemical one, the coke oven tar partially depolymerizing the coal network to release low-molecular-weight components with similar sizes but different compositions. High moisture content is less desirable in a coal blend because it translates to high energy consumption due to the additional energy required to drive off the moisture in the coal blend. In addition, studies of the effect of water on carbon formation have shown that water (as moisture) in the coal charge can inhibit the formation of carbon deposits during the carbonization process (Krebs et al., 1996).

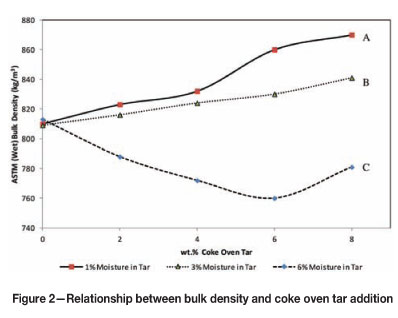

Effect of coke oven tar addition on bulk density

The bulk density was determined by measuring the height of the sample charged in a cold steel box having the same size as the movable wall oven. Figure 2 depicts the correlation between bulk density of coal blend and coke oven tar addition. As shown, over the 0-8 wt.% addition range, the bulk density increased from 810 to 870 kg/m3 using tar with 1% moisture, and from 810 to 835 kg/m3 with 3% moisture content. In contrast, the bulk density decreased from 813 to 760 kg/m3 over the 0-6 wt.% tar addition range, then started to increase at 8 wt.% addition when using coke oven tar with 6% moisture content.

The decrease in bulk density is attributed to agglomeration occuring when liquid-like coke oven tar is added to a coal blend charge. Bulk density is the parameter usually used to describe coal compactness. Therefore, if coal is compacted, the bulk density increases. On the other hand, the increase in bulk density can also be attributed to an increase in moisture content of the coal charge. The relationship between bulk density and moisture content may be governed by a number of factors such as particle size distribution, interparticle friction, and particle deformation under given agglomeration and packing conditions. Various authors have shown that bulk density is influenced by the moisture content of the coal and the use of additives such as oil (Chatterjee, and Prasad, 1982; Standish et al., 1991; Yu et al, 1995). Yu et al. (1995)- considered intraporosity and intraporosity. These also contribute to agglomeration as the major influence on the overall bulk density of a coal packing system.

The results in this study are in good agreement with the findings of Chatterjee and Prasad (1982), who reported a bulk density improvement from 768 to 803 kg/m3 with tar addition. Chatterjee and Prasad (1982) also added 0.2% of light diesel oil (LDO) to a coal blend with an equally beneficial effect on bulk density. However, although those authors emphasized that the addition of 0.2% LDO or 0.4% furnace oil to the coal charge did not affect coke quality at levels of 5-6% moisture content, the cost of LDO would be a drawback and this cannot be underestimated.

The current study reveals that the moisture content of coke oven tar does influence bulk density. Chatterjee and Prasad (1982) did not highlight this aspect in their findings. However, this is clearly confirmed in the current study. Furthermore, Chatterjee and Prasad used prime and medium coking coal constituents in the blend, as opposed to the large proportion of soft coking coal used in the current study.

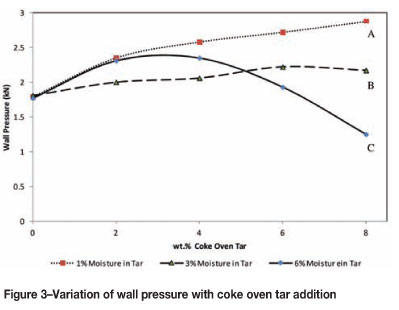

Effect of coke oven tar addition on coking pressure

Generally, coking pressure is defined as the force per unit wall area. Melendi et al. (2011) defined coking pressure as the force generated by the charge on the oven walls during the transformation of coal to coke. This force has a major impact on the life of the conventional slot coke oven. Fernández et al. (2012) mentioned that the most important variables that affect the generation of coking pressure are the characteristics of the coal blend and bulk density. According to Nomura and Thomas (1996), the origin of wall pressure during carbonization is the gas pressure developed in the plastic layer.

In order to investigate the effect of coke oven tar addition on coking pressure during carbonization, the charged coal was carbonized in the pilot plant oven and the changes in the coking pressure during carbonization were monitored. Figure 3 depicts the variation in coking pressure over 0-8 wt.% coke oven tar addition. With 1% moisture content in coke oven tar, coking pressure increased from 1.75 to 2.88 kN, mainly due to an increase in bulk density. At 6% moisture content, the coking pressure remained constant at additions of 2 and 4 wt.%, and then decreased to 1.25 kN with 8 wt% addition, resulting in a noticeable decrease in bulk density. Finally, with 3% moisture content in coke oven tar, the coking pressure increased from 2.0 to 2.17 kN and then remained relatively constant between 2 wt.% and 8 wt.% coke oven tar addition. The high coking pressures generated by coal blends with 2-4 wt.% coke oven tar addition containing 1% and 6% moisture contents are likely to shorten the life of the coke oven, with operational problems such as stickers and heavy pushes causing deterioration of the bricks in the oven walls. This view is supported by Fernández et al. (2012), who stated that the most important variables that affect the coking pressure are the characteristics of the coal blend and bulk density.

The pressure developed in a coke oven depends on the bulk density of the coal in the oven and additional parameters such as the permeability of plastic layers (Jackman and Helfinstine, 1979). These authors have shown that the permeability of plastic layers increases with increasing coke oven tar addition. According to Jackman and Helfinstine (1979), loosely packed coal tends to develop low pressure during carbonization. These findings are supported by a further case reported by Melendi et al. (2011), who mentioned that coal-tar mixtures increased coking pressure.

Coke shrinkage needs to be considered as a further factor that may affect wall pressure. Shrinkage is sometimes related to the volatile matter content of the coal. However, despite significant differences in volatile matter content in the current suite of coals (see Table I), the shrinkage characteristics of the coals (Table III) and their blends were very similar, indicating that this was not a factor contributing to the differences in wall pressure observed for the coal blend studied.

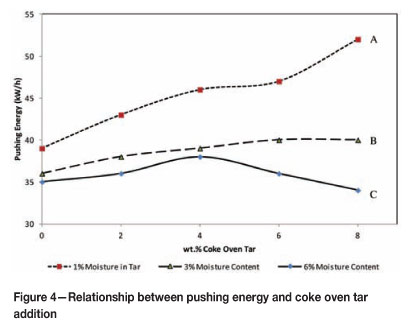

Effect of coke oven tar addition on pushing energy

The effect of coke oven tar addition on the pushing energy of the coal blend was studied. The results (Figure 4) indicate that 1% moisture content in coke oven tar, pushing energy increases strongly (39 to 53 kW/h) over entire range of increasing addition. An excessive increase in pushing energy is less desired as it is detrimental to the oven walls. At 3% moisture content, pushing energy increases moderately (36 to 39 kW/h) over entire range of increasing addition. At 6% moisture content, the pushing energy increases slightly and then decreases with tar addition above 4 wt.%.

The increase in pushing energy on wall pressure would therefore appear to be attributed to the combined effects of coke oven tar addition and moisture content. Namely, higher pressures occur with the addition of 2-4 wt%, coke oven tar with 1% and 6% moisture contents. Lower pressures occur with the addition of coke oven tar at any proportion up to 6-8 wt%, but where coke oven tar has moisture contents of less than 6%.

Another factor affecting pushing energy is bulk density. A decrease in bulk density results in less coke throughput, which means less pushing energy is required. Possibly as the bulk density decreases, the tunnel head space increases, resulting in carbon deposition which could lead to an increase pushing energy. The difference in energy needed to push the coke oven tar with lower moisture content as opposed to higher moisture content can be explained in terms of the extra mass of coal loaded into the ovens. However, an increase in pushing force is less desirable since it leads to the physical deterioration of the coke oven batteries. This is a definite risk that may lead to premature capital expenditure in the mid- to longer term.

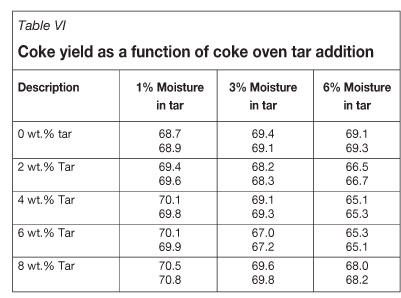

Effect of coke oven tar addition on coal-to-coke yield

The yield of coke produced from carbonization of the coal blend with coke oven tar additions is given in Table VI.

Considering the optimum condition of 6 wt.% tar addition at 1% moisture content, coke yield increased by 1%. At 3% moisture content, coke yield decreased by 2%, and decreased even further up to 4% at 6% moisture content.

The transformation of coal to coke is known to be influenced by coal moisture, coal grind, oven charging, oven charge density, and oven filling levels. All these factors affect the quantity of coal in an oven. Although the 3% moisture in coke oven tar resulted in a bulk density increase, coke yield decreased, confirming that bulk density is not the primary factor involved. Other factors to be considered are the effective heating rate of the coal charge, the rate of contraction, the final temperature gradient, and the finishing temperature, as these also play significant roles in coke yield. In the current case, it would appear that the decrease in coke throughput is a result of a deteriorating heat transfer mechanism due to lower packing density. This means that the lower homogeneity of coal blend density over the height of the oven and oven length brings about a further decrease in oven productivity. In addition, it is generally expected that as the surface moisture of the coal increases, throughput decreases.

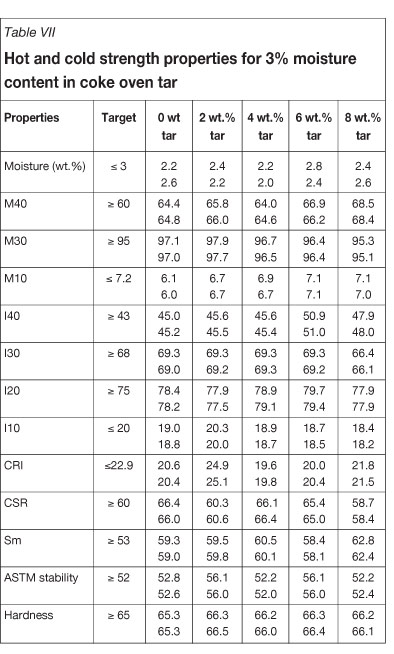

Effect of coke oven tar addition on coke properties

Table VII presents a summary of the coke properties as a function of coke oven tar addition.

Only coke properties for the optimum condition (3% moisture content in the tar) are presented. Coke oven tar addition reduced the abrasion resistance and M10. I10 increased at 2 wt.% addition and decreased at 4-8 wt.% to an average of 18.5 against a target I10 of < 20. In terms of coke fragmentation, M40 increased with increased coke oven tar addition. The I40 also increased with increasing coke oven tar addition. The highest I40 of 50.9 was achieved at 6 wt.% coke oven tar addition.

These results are supported by studies reported by Collin and Bujnowaska (1994), who confirmed that coke properties improved with coke oven tar addition. The results are also in good agreement with the results reported by Chatterjee and Prasad (1982), who stated that the improvement in coke strength is due to the fact that coke oven tar increases the amount of liquid phase, which is essential for the formation of an adequately bonded structure during carbonization. It is this material that provides the 'glue' and thereby improves coke strength.

It is well known that coke size depends on fissures occurring in coke, and that coke oven flue temperatures and the addition of inert substances are further factors controlling coke size (Nomura and Arima, 2013). However, as the latter factors were not considered in the current tests, the results relate more to the impact of coke oven tar addition and moisture content. The results for coke mean size (Sm), measured as the +35 mm fraction are significant and positive. The Sm also considerably improved with coke oven tar addition.

Other coke properties such as stability and hardness were also studied as a function of coke oven tar addition. The hardness factor indicates the tendency of the coke to abrade into fines during handling, and the stability factor indicates the tendency of the coke to break upon on impact (Gray et al., 1978). As shown in Table VII, hardness was not affected by coke oven tar addition (it remained constant through all levels of addition) and stability increased with tar additions of 2 wt.% and 6 wt.% . The results are in good agreement with Du Broff et al. (1985), who mentioned that a stability index of between 50 and 60 is preferred for an acceptable strength metallurgical coke. The stability results of 52 to 56 in the current set of tests, using a 3% moisture content coke tar addition, fall well within the range for this prime metallurgical coke category.

Conclusions

The results of this study indicate that coke oven tar can be used as a partial substitute for imported prime coking coals, and tar addition leads to maintained or improved metallurgical coke qualities.

The specific conclusions are summarized as follows:

- Moisture content in coke oven tar was found to influence coke qualities

- Moisture content in coke oven tar attributed to the effects of coke oven tar addition on bulk density, wall pressure and pushing energy

- The optimum moisture content in coke oven tar was found to be 3% with a 6 wt.% tar addition

- Up to 2% decrease in coke yield was observed at 6 wt.% tar addition, without any deterioration in coke quality

- Despite this 2% decrease in coke yield, coke oven tar addition is still a viable option based upon the economic factors of reduced quantity and cost of imported coking coal while achieving a similar or better final coke product

- Coke producers could benefit from the adoption of coke oven tar additions for production of metallurgical coke, especially in countries where large proportions of import coking coals are used in the blend

- The results from this study are a first step in the development of improved coke quality through coke oven tar additions for metallurgical industries where prime coking coal availability and costs are of great concern.

Finally, it must be stated that although all the objectives in this study were accomplished, further work needs to be undertaken to scale up this process for commercial purposes. It is the intention of the authors to conduct further investigations in this regard.

References

Alvarez, R., Menendez, R., Marsh, H., Miyar, E.A., and Canga, C.S. 1989. Improving coke strength by co-carbonization of aluminium with high volatile Spanish coal. Fuel, vol.68. pp. 1325-1329. [ Links ]

Benk, A. 2010. Utilisation of the binders prepared from coal tar pitch and phenolic resins for the production of metallurgical quality briquettes from coke breeze and the study of their high temperature carbonization behaviour. Fuel Processing Technology, vol. 91. pp. 1152-1161. [ Links ]

Benk, A. and Coban, A. 2011. Molasses and air blown coal tar pitch binders for the production of metallurgical quality formed coke from anthracite fines or coke breeze. Fuel Processing Technology, vol. 92. pp. 1078-1086. [ Links ]

Chatterjee, A. and Prasad, H.N. 1982. Possibilities of tar addition to coal as a method of improving coke strength. Fuel, vol. 62. pp 591-600. [ Links ]

Collin, G. and Bujnowaska, B. 1994. Co-carbonization of pitches with coal mixtures for the production of metallurgical cokes. Carbon, vol. 32, no. 4. pp. 547-552. [ Links ]

Días, S., Sharma, S., and Choudhury, R. 2002. Non-coking coal to coke: use of biomass based blending material. Energy, vol. 27. pp. 405-414. [ Links ]

Díaz-Faes, E., Barriocanal, C., Díez, M.A., and Alvarez, R. 2007. Applying TGA parameters in coke quality prediction models. Journal of Analytical Applied Pyrolysis, vol. 79. pp. 154-160. [ Links ]

Díez, M.A., Alvarez. R., and Cimadevilla, J.L.G. 2012. Briquetting of carbon-containing waste from steelmaking for metallurgical coke production. Fuel, vol. 114, in Press. pp. 1-8. [ Links ]

DuBroff, W., Kaegi, D.D., Knoerzer, J.J., and Spearin, E.Y. 1985. Solvent pretreatment of coal to improve coke strength. US Pat. 4528069. [ Links ]

Eberhard, A. 2011. The future of South African coal: market, investment and policy challenges. Working Paper 100. Program on Energy and Sustainable Development, Stanford University. pp. 1-44. [ Links ]

Fernández, A.M, Barriocanal, C., and Alvarez, R. 2012. The effect of additives on coking pressure and coke quality. Fuel, vol. 95. pp. 642-647. [ Links ]

Gonzalez-Cimas, M.J., Patrick, J.W., and Walker, A. 1986. Influence of pitch additions on coal carbonization. Fuel, vol. 66. pp. 1019-1023. [ Links ]

Gray, R.J., Goscinski, J.S., and Shoenberger, R.W. 1978. Selection of coals for coke making. Joint Conference of the Iron and Steel Society of AIME and Society of Mining Engineers (SME) of AIME. Pittsburgh, PA, 3 October 1978. [ Links ]

Jackman, H.W. and Helfinstine, R.J. 1979. Preheating coal blends as a means of increasing coke strength. Circular 453, illinois State Geological Survey. pp. 1-15. [ Links ]

Jeffrey, L.S. 2005. Characterization of the coal resources of South Africa. Journal of the South African Institute of Mining and Metallurgy, vol. 105, no. 2. pp. 95-102. [ Links ]

Kestner, M.O., Gilewicz, S.E, and Aktuna, M.E. 1981. Method of improving the bulk density and the throughput characteristics of coking coal. US Pat. 4304636. [ Links ]

Krebs, V., Furdin, G., and Mareche, J.F. 1996. Effects of coal moisture content on carbon deposition in coke ovens. Fuel, vol. 75, no, 8. pp. 979-986. [ Links ]

Leibrock, K. and Petak, H. 1983. Coke production from low-coking blends by densification. Fuel Processing Technology, vol. 7. pp. 91-107. [ Links ]

Lin, M-F. and Hong, M-T. 1986. The effect of coal blend fluidity on the properties of coke. Fuel, vol. 65. pp. 307-311. [ Links ]

Melendi S., Díez, M.A., Alvarez R., and Barriocanal, C. 2011. Plastic wastes, lube oils and carbochemical products as secondary feedstocks for blast -furnace coke production. Fuel Processing Technology, vol. 92. pp. 471-478. [ Links ]

Nomura, S. and Arima, T. 2013. Effect of coke contraction on mean coke size. Fuel, vol. 105. pp. 176-183. [ Links ]

Nomura, S. and Thomas, k.M. 1996. Some aspects of the generation of coking pressure during coal carbonization. Fuel, vol. 75, no. 7. pp. 801-808. [ Links ]

Plancher, H., Agarwal, P. K., and Severns, R. 2002. Improving form coke briquette strength. Fuel Process Technology, vol 79. pp. 83-92. [ Links ]

Ruiz, O., Romero-Palazon, E., Díez, M.A., and Harry, M. 1990. Co-carbonization of green petroleum cokes with Cortnwood coal: influence on structure, reactivity and microstrength of resultant cokes. Fuel, vol. 69. pp. 456-459. [ Links ]

Saxena, V.K., Varma, A.K., and Kumar, G. 2010. Effect of stamping and binder on coke quality for LVMC coal. Proceedings of the XI International Seminar on Mineral Processing Technology (MPT-201o), Jamshedpur, India, December 2010. pp. 489-497. [ Links ]

Shevkoplyas, V.N. 2002. Coal carbonization with addition of hydrochloric acid as a way of improving coke quality. Fuel, vol. 81. pp. 947-950. [ Links ]

Standish, N., Yu, A.B., and Zou, R.P. 1991. Optimization of coal grind for maximum bulk density. Powder Technology, vol. 68. pp. 175-186. [ Links ]

Taylor, J.W. and Coban, A. 1987. Factors affecting the tensile strength of formed coke made from lignite char. Fuel, vol. 66. pp. 1274-1280. [ Links ]

Yu, A.B., Standish, N., and Lu, L. 1995. Coal agglomeration and its effect on bulk density. Powder Technology, vol. 82. pp. 177-189. [ Links ] ♦

Paper received Aug. 2013

Revised paper received Oct. 2013

© The Southern African Institute of Mining and Metallurgy, 2013. ISSN 2225-6253.