Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.10 Johannesburg Jan. 2013

CONFERENCE PAPERS

Integrated optimization of underground mine design and scheduling

J. LittleI; P. KnightsI; E. TopalII

ISchool of Mechanical and Mining Engineering, University of Queensland

IIWA School of Mines, Curtin University, Australia

ABSTRACT

It is common practice for underground mine plans to be created sequentially, where results from one planning process form the input data for another. While this is practical for manual methods, computerized optimization techniques should consider an integrated approach to creating the global mine plan. This is because optimizing an individual mine planning process, such as stope layouts, introduces a likelihood of increasing costs or decreasing revenues associated with other areas, such as production scheduling, as harmful decisions must be balanced. Considering the interaction and influence that individual underground mine planning processes have on each other during optimization will provide more profitable results than if these are ignored.

Optimization techniques for stope layouts and production scheduling are reviewed. An integer programming model is proposed that allows for either integrated or isolated optimization. Both approaches are separately applied to a block model. The results demonstrate the model's ability to produce optimal long-term sublevel stoping mine plans and the benefits of using an integrated approach.

Keywords: underground mine optimization, stope layouts, underground production scheduling, integer programming, mathematical programming application.

Introduction

It is well recognized that software tools for strategic underground mine planning are lacking, and that the demand for these tools will increase as deeper deposits amenable to underground mining continue to grow in value. While a number of optimization techniques have been developed for stope layout design and progress continues to be made in the area of production scheduling, both of these mine planning areas are amenable to improvement in terms of guaranteeing optimal results. Firstly, stope layout methods struggle to produce truly optimal results and scheduling is hindered by excessive solution times. Secondly, as stated by Chadwick (2009), optimization has the ability to add significant value to a mining operation, but only if the whole process is considered simultaneously, not in isolation as it presently the case.

Currently it is common practice for mining engineers to plan each area separately, where the results from one area forms the input data for another. Once planning for each area has been completed, all areas are then combined to form an overall mine plan. To ensure maximum value is obtained from a deposit, however, the three key areas of mine planning - that is stope layouts, development, and production scheduling - must be optimized simultaneously due to the close interaction and influence each area has on the other. This is because improvements made in individual areas do not always translate into total system improvement, as revenues can be reduced or costs transferred elsewhere in the mine plan. Thus, when generating a mine plan, the simultaneous consideration of key individual mine planning areas will yield the best results for any operation (Morin, 2002).

This paper reviews some mathematical programming tools that have been developed for optimizing stope layouts and long-term production schedules for underground metalliferous mines. It also highlights studies that have discussed the benefits of using an integrated approach for mine planning. An integer programming (IP) model is presented to optimize stope layout designs and production schedules, which allows for either an integrated or isolated approach to be used. Using both optimization approaches, this model is applied to a gold deposit and the results are discussed comparing the value of the competing approaches.

Previous optimization studies

Stope layout optimization

There are a variety of optimization techniques that have been developed to generate optimal stope layouts. While these techniques use the term optimization to describe their approach, all fail to truly generate optimal results in three dimensions.

Alford (1995) developed the Floating Stope Algorithm. Initially a cut-off grade is specified to separate ore and waste blocks. Subsequently, a rectangular block representing the minimum stope size is floated through the block model to identify the stope position of highest grade. Two envelopes are used. The inner envelope contains all blocks above the cut-off that can be mined and is the union of all the best grade stope shapes. The outer envelope is the union of all possible stope positions for each block above the cut-off that can be mined. The final stope layout relies on input from the mining engineer but should be as close as practical to the inner envelope and lie within the outer envelope. The Multiple Pass Floating Stope Process is an extension to this process, as it allows more envelopes to be generated and provides extra information to the mining engineer when selecting the best stope design (Cawrse, 2001). The main problem with this approach is that it cannot guarantee optimal results as it only suggests stope designs within a range, which in some instances overlap, and requires the final decision to be made by the engineer. The Australian Minerals Industry Research Association (AMIRA) P884 research project, PRIMO (Planning & Rapid Integrated Mine Optimisation) recently developed the Vulcan Stope Optimiser (Maptek, 2011), which appears to enhance aspects of the Floating Stope Algorithm. For instance, it is now able to specify mineable shapes as opposed to suggesting general areas. It does this for a range of cut-off grades, mining dimensions, mining orientations, and mining methods.

The Stope Sizer algorithm, used internally by Snowden Consultants, creates a series of mining envelopes for a range of cut-off grades in three dimensions (Snowden, n.d.). Each envelope consists of a series of selective mining blocks (SMBs), which represents the minimum allowable mining width and dip angle in each dimension. Stope Sizer begins by identifying the highest grade SMB and continues until there are no more SMBs in the block model. The SMBs may share blocks with previously selected SMBs but they are not allowed to share the value of those common blocks. This is done to ensure the partial SMBs satisfy the cut-off grade. Once an envelope is determined for the first cut-off grade, the process is repeated for the next cut-off grade until all cut-off grades have been considered. This results in a series of mining envelopes at a range of cut-off grades. As no economic evaluation is completed during this stage, these results are transferred into Snowden's Evaluator where a production schedule, development schedule and projected cash flows are generated. A fundamental flaw of this approach is that the location and size of final stope layouts are not clearly outlined, and as such an engineer is required to guide the final design.

Ataee-Pour (2004) introduces the concept of a Maximum Value Neighbourhood Algorithm. This method identifies the best combination of blocks, known as a neighbourhood, by evaluating all possible neighbourhoods around each block. Each block is assigned a value representing the profit or loss made if mined. The neighbourhood sizes are constrained by mine geometry requirements. The neighbourhood that provides the maximum net value is included in the final stope. This technique has three main shortcomings that limit its ability to produce optimal results. Firstly, altering the starting location of evaluation alters the set of stope layouts generated from the same orebody. Secondly, blocks that are examined earlier in the process are given preferential selection. Finally, costs based on the size of the stope, or neighbourhood, are not examined; rather only costs relating to individual blocks are taken into account.

Sens and Topal (2008) develop an algorithm to produce stope boundaries in three dimensions for profit maximization based on the selection of stopes in order of the user's specified preference criteria. After converting all blocks to a regular size, the program selects the highest valued stope and then eliminates all other stopes sharing common cells. The process continues until no stopes remain to be examined. The limitation of this original approach is that it cannot consider all combinations of stopes layouts because stopes are chosen in order of the user's preference, such as selecting stopes in order of highest profit per cubic meter. Further study has been completed to address this issue by developing envelopes around stopes and then considering their average value when individual stopes are selected (Topal and Sens, 2010).

Alford and Hall (2009) propose a method to produce a set of stope shapes in three dimensions for a range of cut-off grades. This method uses nested stopes, which is the underground mining equivalent of nested pits used for open cut mining. It is able to determine the best set of stope heights and extraction levels. Stope optimization can be run on a sequence of cut-off grades to produce a series of nested stopes. Due to the specification of a cut-off grade in the design process, however, optimality is automatically violated. Work completed by Smith and O'Rourke (2005) concluded that using cut-off grades to drive mine design and planning is unnecessary as the optimization process will mine the portion of the deposit that is most economical within the limits of the operation.

Grieco and Dimitrakopoulos (2007) use mixed-integer programming (MIP) techniques to determine stope and pillar designs based on grade uncertainty and pre-defined levels of acceptable risk. This approach is applied to Kidd Creek Mine in Canada. The model determines how many rings a stope will contain based on a minimum and maximum allowable stope size. A ring is represented by a binary decision variable indicating whether it is part of a stope or not. While this approach can incorporate risk into the design, it is able to analyse only rings that have been pre-defined in terms of location and size to determine the most profitable stopes. The Kidd Creek example assumed these rings to be of large volume and in certain positions. This does not allow a more thorough and thus accurate examination of the orebody over smaller areas and of stopes in different locations. This in turn prevents the model from being able to generate truly optimal stope designs. Furthermore, as each ring is represented as a binary variable this encourages a very long solution time. It should be noted that the solution time of an MIP model increases exponentially as the number of integer variables present in the model increases. As such, this can severely limit the practical use of this model in industry applications.

Production scheduling optimization

In addition to being employed in an application for stope layout optimization, MIP is a common mathematical programming tool used for underground mine production scheduling as it has the ability to handle multi-constrained problems while providing a multi-period production schedule that satisfies a required objective. While progress has been made in the area of long-term production scheduling for underground metalliferous mining operations, no approaches are currently available commercially, and the few that have been applied in industry are generally minesite-specific. Consequently, underground mine scheduling is primarily carried out manually. Manual techniques cannot guarantee optimality due to it being almost impossible to satisfy the compounding complexities of all scheduling rules when combined with several competing objectives.

Trout (1995) uses MIP to develop an optimal production schedule with the aim of maximizing the net present value (NPV) for a sublevel stoping copper ore operation located in Mt Isa, Australia. The model was applied to a representative data-set containing 55 stopes and extended over a two-year period. It was written using C++ code and solved in CPLEX on a dual 75 MHz processor Sun SparcStation 10/512 with 128 MB RAM. An integer solution was obtained after 1.6 hours; however, the solution was interrupted prior to proof of optimality due to a 50 MB RAM limit imposed on the computer. Under the same operational conditions, a manually generated schedule produced a before-tax NPV of $273 million while the MIP-generated schedule produced a before-tax NPV of $337 million, providing an improvement of 23 per cent, thus indicating the relative merit of employing MIP techniques over manual techniques for production scheduling.

Nehring and Topal (2007) improve Trout's (1995) work by creating a new constraint to limit multiple fillmass exposures that performs its task without breaking other operation constraints. Furthermore, Little (2007) successfully reduced the solution time of this MIP model. This was achieved by reducing the five sets of binary decision variables to one set. The reasoning for this reduction was based on two theories developed relating to natural sequence and natural commencement that allowed various production phases to be defined as a function of the first extraction commencement variable, applicable to the sublevel stoping mining method (Nehring et al., 2009). When applied to a conceptual nine stope example with the objective function to maximize the NPV, both original and revised models generated the same production schedule and NPV but required significantly different solution times. Overall, the number of binary variables in the original model was reduced by 80 per cent in the new model and there was a 92 per cent improvement in required solution time (Little et al., 2008).

Topal (2003) uses MIP to develop an optimal production schedule that seeks to minimize deviation from specified production targets of three types of ore products for Kiruna Mine in Sweden, a large-scale iron ore sublevel caving operation. The use of defining 'machine placements' instead of individual production blocks and developing algorithms relating to early and late start times reduced the number of variables in the model. When applying these theories, an optimal solution is obtained in under 100 seconds when implemented over a 36-monthly time period on a Sun Ultra 10 machine with 256 MB RAM. The deviation from target was reduced from the manual's schedule of 10-20 per cent to 6 per cent with no constraint violation. The model also allows for the generation of a long-term schedule for 60 time periods in five minutes. The model was ultimately implemented as part of the mine's production scheduling process (Topal, 2008).

Nehring et al. (2010) explore the benefits of generating short- and long-term production schedules simultaneously. The short-term objective of minimizing deviation to targeted mill feed grades is combined with the long-term objective of maximizing the NPV into the one MIP model. A case study reflecting a marginal sublevel stoping copper operation is provided to show the value of using an integrated optimization approach instead of optimizing the short- and long-term schedules separately. The operation consists of 14 stopes, 11 of which are yet to begin production. Various resource, timing, and geotechnical constraints are applied. Long-term scheduling is conducted over a 12-month time frame, while short-term scheduling is spread across the initial two months of the schedule, where each month is divided into five equal time horizons of approximately six days. Results show that ultimately a better NPV is achieved when using the integrated approach. Interestingly, prior to applying grade deviation penalties, the segregated and integrated NPVs are $719 821 million and $719 722 million respectively. After the application of grade deviation penalties, however, these NPVs are $705 521 million and $708 222 million respectively. The value of the integrated approach is evident.

Value of using an integrated optimization approach

It is clear that underground mine planning optimization work completed to date has been focused solving an individual mine planning area with little consideration for its flow-on effects to other planning areas. It has been generally accepted that the 'optimized' solution for the first problem forms the input for the following problem, and so on until a mine plan has been completed. The acknowledgement of the importance of an integrated approach towards optimization is, however, growing. It is being recognized that decisions made in individual planning areas naturally influence the overall outcome, and focusing on local sub-objectives can be counterproductive to the overall objective.

Poniewierski, MacSporran, and Sheppard (2003) and Smith and O'Rourke (2005) investigate the complex interaction between stope layouts, production scheduling and cut-off grade optimization. Poniewierski, MacSporran, and Sheppard examine two main orebodies at Mt Isa's Enterprise Mine. Over 200 schedules are generated for thirteen stoping layouts. Each case is examined using mining, concentrating, and smelting net cash flows, and the NPV. A cut-off grade for each orebody is selected based on that which achieves the maximum NPV while allowing for an appropriate production rate. While this example does not consider all possible designs and schedules together due to software limitations, it illustrates the connection and complex interaction between stope design and production scheduling and demonstrates the need to consider these areas simultaneously if globally optimal results are to be achieved.

Whittle (2009) also acknowledges the need for a holistic approach towards planning decisions. This is based on his experiences over the past six years with optimization studies that have been undertaken for more than 15 different mining and mineral processing companies. A hypothetical nickel operation is used to illustrate the consequences of using four objectives commonly applied as decision criteria in mine planning. These are (1) maximizing the size of the deposit, (2) minimizing mining costs, (3) maximizing mine life, and (4) maximizing recovery. While these individual objectives are commonly considered to create value for an overall project, on further investigation it is revealed they can actually be harmful. For instance, in regards to minimizing mining costs, it is highlighted that using larger equipment with lower operating costs per ton or bank cubic metre (BCM) can reduce mining selectivity and increase dilution. Therefore, this well-intentioned goal reduces the value of the operation. While this paper focuses on higher level mine planning processes involving geology, mining, processing, and marketing interfaces, the principles remain applicable to stope layout design and production scheduling optimization.

Finally, Whittle (2010) discusses Enterprise Optimization, a methodology proposed for increasing the economic value of mining and mineral processing operations through better long-term planning decisions. The fundamental concept of this approach is to optimize the whole operation simultaneously. Specifically, it involves optimizing (1) ten key steps in the value chain together (such as pit design, scheduling, cut-off grades, processing plant specifications, and logistics), (2) all assets together, and (3) all periods together. Its advantages are illustrated by providing an open-cut copper-gold operation case study where the effect one decision has on another is explained and Gemcom's Whittle software and Whittle Consulting's Prober software are used. Application of this methodology improves the NPV from $1 598 million (derived from the manually generated plan) to $2 775 million, which is an increase of 73.7 per cent. While the optimized plan is relatively more complicated, it is justified by the increase in NPV. Some key differences between the two plans are an increase in plant throughput during the early years of production and an approximate doubling of early feed grades to the plant. Additionally, and quite importantly, it is noted that counter-intuitive outcomes results from employing simultaneous optimization, such as a reduction in pit size (and hence reserves), an increase in operating and capital costs, and a decrease in plant recovery. The value of this simultaneous optimization approach comes from understanding how different steps in the value chain affect one another and can work together. This example shows that decisions that are traditionally fixed and made early and in isolation in the planning process, such as plant configuration or production rate, should be dynamic and decided in tandem with other key decisions if maximum value of the operation is to be realized.

Optimization model formulation

The proposed mathematical model uses IP techniques to generate long-term mine plans that focus on optimizing stope layouts and production schedules for sublevel stoping operations. IP techniques are used as it has been shown that they can successfully handle multi-constrained problems while providing a multi-period production schedule that satisfies a required objective.

The model is defined in the following paragraphs.

Subscript notation

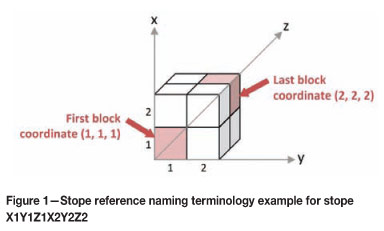

i stope reference name: i = X1Y1Z1X2Y2Z2, X2Y2Z2X3Y3Z3.....I.

The naming terminology for each stope is defined by the location of the first and last blocks within the stope. An 'X' 'Y', or 'Z' is placed before each location number to inform the user as to which axis it is referring to. For instance, assuming the 2 x 2 x 2 block sized stope presented in Figure 1 has its starting block location at 1, 1, 1, and its last block location at 2, 2, 2, its reference name would be X1Y1Z1X2Y2Z2.

m metal type: m = a, b, c, ... M

z backfill type: z = a, b, c, B

t schedule time period: t = 1, 2, 3, T

Sets

bi set of all stopes that share common blocks with stope i

ji set of all stopes that are adjacent to stope i oi set of all stopes which must be offset from stope i ei set of all stopes which do not share common extraction levels with stope i pt set of time periods that comprise all time periods up to and including the current period i.

Parameters

EQi extraction tonnage for stope i

Gim ore grade (%) of metal type m for stope i

BQi backfill volume for stope i

OHt ore handling tonnage limit for time period t

UMmt maximum contained metal tonnage target for metal

m in time period t

LMmt minimum contained metal tonnage target for metal

m in time period t

BSzt backfill supply limit of backfill component z in time period t

Wmt metallurgical recovery (%) of metal type m in time period t

CFi partially discounted cash flow generated by stope i

PVt present value discount factor applied to time period t.

Decision variables

ait 1 if production of stope i is to commence in time period t,

0 otherwise.

Objective function

Maximize:

Constraints

Equation [1], the objective function, maximizes the cash flow of the operation by determining the best stope size(s) to use while generating a corresponding production schedule. Equation [2] ensures only one stope from all stopes that share at least one block is allowed to be produced. It also ensures all selected stopes are produced only once. Equations [3] and [4] ensure the contained metal tonnage lies between an upper and lower limit in any time period a stope is in extraction. These constraints reduce grade fluctuations received by the plant and thus help allow for its efficient operation. Equation [5] restricts extraction capacities from exceeding the shaft/LHD/truck fleet capabilities. Equation [6] limits the amount of backfill used in each period from exceeding the mine's supply. Equation [7] horizontally offsets stopes of the same size that lie directly above another. This prevents all vertical boundaries between backfilled stopes, which could be considered vertical planes of weakness, transversing across multiple extraction levels. If allowed to exist, they could encourage failure of backfill material. Equation [8] ensures that simultaneous production of two adjacent stopes does not occur. This prevents the formation of excessively large voids, which improves geotechnical stability of the surrounding area. Equation [9] limits production of stopes around a backfilled stope to one adjacent stope over all time periods. Corner stopes are excluded from this rule. The exposure of only one side of a fillmass ensures stresses are effectively managed by avoiding excessive stress around that fillmass. Equation [10] ensures practical drawpoint levels are established by prohibiting the selection of stopes adjacent to each other but not sharing common drawpoints levels. Equation [11] enforces the use of integer values for the decision variable.

Excessive solution times, which are a function of the number of integer variables present, can be a common characteristic of IP problems, and this can often result in no optimal solution being obtained. Thus, while effective programming of a model is crucial to its performance, integer variable reduction work completed by Topal (2008) illustrates that data management is also an effective way to assist the performance of an IP problem. For this study, some data is pre-processed prior to running the IP model. This data is pre-processed by running an application developed for this study (herein referred to as the Data Application) that uses Visual Basic language and Structured Query Language. Based on a series of user inputs it determines:

> All possible stopes that lie within the block model bounds (which is based on minimum and maximum allowable stope sizes)

> Corresponding weight-averaged grades and extraction tonnages and backfill volumes for each stope

> A partially discounted cash flow (profit) generated from the extraction of each stope (which is calculated from revenue, fixed and variable costs, and a discount rate)

> All geotechnical information required by the MIP model for each stope (which refers to Equations [7] to [10]).

Implementation of the proposed model

The IP model described in this paper allows for two types of optimization approaches to be employed. The first is an integrated approach where stope layouts and a production schedule are optimized simultaneously by applying all constraints in the model to the data-set. The second follows the more traditional mine planning approach, an isolated approach, where by activating the constraints described by Equations [2], [5], and [7], optimal stope layouts are first determined and then, by activating all constraints, a production schedule is generated for these pre-selected stope layouts. Using the same IP model and input data, these two optimization methods are employed to compare the value of using each approach.

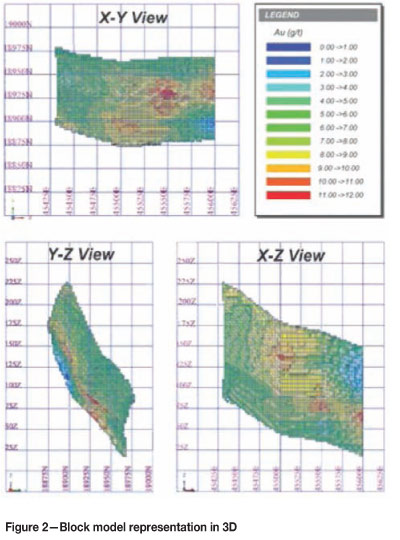

The IP model is applied to part of a hypothetical gold deposit containing 64 443 blocks, of which 8 515 are ore blocks, as shown in Figure 2. The blocks differ in size with dimensions varying from 2.5 m to 10 m in the x, y, and z directions. The section of the deposit considered for this study consists of a quartz carbonate vein containing gold that strikes in the east-west direction at approximately 60 degrees. It lies approximately 350 m below surface. The resource estimate for this deposit is approximately 503 000 t at 7.33 g/t Au.

All blocks are firstly converted to a regular 2.5 x 2.5 x 2.5 m block size for ease of processing data. This increases the number of ore blocks to 12 134. For this example two stope sizes are considered - 20 m x 20 m x 20 m and 30 m x 30 m x 30 m - however, more can be examined. Based on these two possible sizes 2 006 stopes exist within the block model bounds, as calculated by the Data Application. For this study, the application creates stopes at every 10 m interval in the x, y, and z directions.

It is specified that production must be completed in 23 time periods. Each stope's production profile follows one period of preparation (which includes development and drilling), two periods of extraction, one period of void, and one period of backfilling. These activities must follow each other consecutively in order without interruption. Note that internal development included during the period of preparation refers to development required to prepare a single stope for production. Development that benefits more than one stope is assumed completed. Also, while it is recognized that internal development activities result in the production of some ore, it is assumed that for this example none is produced during this activity.

This operation's extraction capacity is 40 000 tonnes of ore per period, which is based on loader, truck, and shaft capacities. The mill feed head grade requirement must not exceed plant specifications of 120 000 g per period, but must also achieve at least 60 000 g per period. Backfill availability is 60 000 m3 per period. Density assumptions for ore, waste, and backfill material are 2.65 nWt, 2.85 m3/t, and 2.05 m3/t respectively.

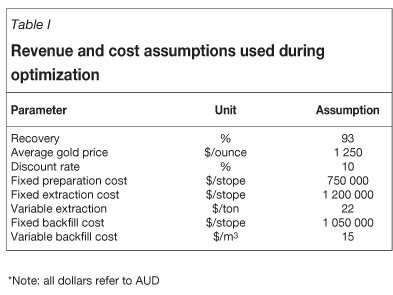

Assumptions for the revenue and cost calculations are provided in Table I. Variable costs are incurred throughout the duration of each activity and are based on the stope's size, while fixed costs are incurred once at the start of each activity irrespective of the stope's size. All costs are not based on any past or existing operation. For scheduling purposes a 10 per cent per annum discount rate is applied.

Based on these assumptions, 289 stopes are identified as profitable by the Data Manager.

Finally, stope data referring to geotechnical considerations, such as determining adjacent stopes, offset stopes, and extraction level stopes is generated using the Data Application.

Integrated optimization

As the integrated optimization approach entails optimizing stope layouts and production schedules simultaneously, all ten constraints in the IP model were applied at once.

The IP model was written using a mathematical programming language (AMPL) code and solved using the solver package CPLEX 10.3 (ILOGTM) on a standard office computer. The run time required to obtain an optimal solution was approximately 31 hours.

The NPV obtained for this example was A$22.7 million. All stopes selected for production were of the 30 x 30 x 30 m size. No 20 x 20 x 20 m sized stopes were chosen.

Results showing those stopes selected (represented by coloured boxes) are presented in Figure 3 and Figure 4 in plan and section view respectively. The number printed within each stope specifies the time period production begins for that stope.

Isolated optimization

The isolated optimization approach first determines stope layouts and then schedules those selected layouts. Therefore the constraints described by Equations [2], [5], and [7] were applied to generate the stope layouts. The extraction capacity for Equation [5] was left unlimited so that the best possible layouts were chosen. Equation [7] was applied to ensure that stope layouts selected were offset from each other for geotechnical stability. Once stope layouts were selected during this optimization phase, all constraints in the model were applied to schedule when stopes should be produced within the specified time period. Equation [5] had its ore handling limit reduced back to 40 000 tonnes per period. Also, Equation [7] did not need to be re-applied as it was used during the stope layout optimization process.

Similar to the integrated approach, the IP model was written using AMPL code and solved using CPLEX 10.3 (ILOGTM) on a standard office computer. The run times to obtain an optimal solution for both stope layouts and a production schedule were instantaneous.

Stope layout results

During the stope layout optimization phase, 18 stope layouts were identified as optimal. All stope layouts selected were 30 x 30 x 30 m in size. No 20 x 20 x 20 m sized stopes were chosen.

Production scheduling results

A data file was created around these 18 stopes and was used by the IP model to schedule as many stope layouts as possible within the 23 time periods.

During the first optimization run when all constraints were applied, the model was unable to obtain a result without breaking at least one constraint. This was because the pre-optimized stope layouts limited the scope in which scheduling could occur. Consequently, the time frame over which the operation was scheduled was reduced to 21 time periods as this allowed for a feasible result to be obtained.

The NPV achieved for this isolated approach was A$16.6 million. Figure 5 and Figure 6 show those stopes selected for production, in plan and section view respectively, with their respective production start times.

Discussion

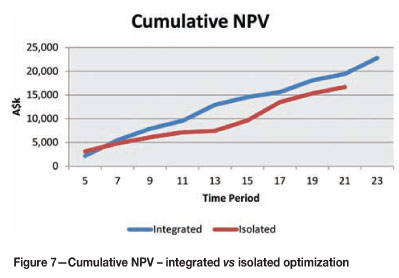

While the goal of optimizing a mine plan is unlikely to be disputed, it is critical to determine the comparative value of competing optimization approaches. Results generated by employing these two approaches show that the integrated optimization method provides a better NPV. Figure 7 presents the cumulated NPV results over the scheduled periods for these two approaches. Note that the mine life for the integrated approach is 23 periods, as per the specified scheduling requirements; however, the mine life for the isolated approach is 21 periods due to the need to reduce the scheduling time periods to ensure a result that satisfied all operational constraints could be obtained.

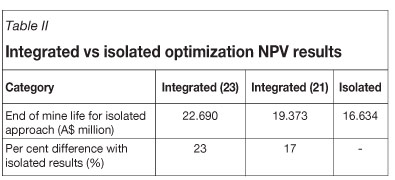

Figure 7 shows that during the production of the first stope the isolated method produced a better NPV; however, after that its cumulative NPV was lower for all remaining time periods. At the end of 21 periods, the end of the mine life for the isolated approach, the integrated approach produced an NPV that was 17 per cent higher. At the end of the mine life for the two scenarios, that is 21 periods for the isolated approach and 23 periods for the integrated approach, the integrated approach produced an NPV that was 36 per cent higher. Table II presents the cumulated NPVs for the two approaches at the end of 21 periods and also at the end of their respective mine lives.

This NPV difference can be attributed to one main reason. That is the integrated optimization approach allowed for the interaction and influence of stope layouts and production schedules on one another to be assessed. This, therefore, allowed the model to foresee and manage issues between the two mine planning areas, which meant (1) the model could rectify the mine plan to provide a better NPV, and (2) all specified constraints were satisfied. It is important to note that this ability incorporates other important but less obvious advantages, such as the identification of risks and opportunities in the mine plan as well as the potential to utilize time spent on the overall planning process more effectively and strategically. Each of these benefits is discussed.

Holistic outlook

Table III details those stopes chosen by each optimization approach. The numbers in brackets beside the stope names indicates their profitability ranking - the lower the number, the more profitable the stope. Note that the stopes shown under the Production Scheduling column for the isolated optimization approach are those included in the final mine plan.

As can be seen in Table III, the highest valued stopes selected by the integrated and isolated approaches are ranked 13 and 5 respectively and their NPVs are A$3 391 000 and A$3 893 000 respectively. Despite the initial selection of a better valued stope by the isolated approach, a better NPV was not obtained by the end of the mine life. This was because decisions made during the optimization of stope layouts, which essentially meant employing a short-term or narrow outlook as planning was focused solely on stope layouts, which limited production scheduling opportunities. This illustrates that the influence one planning area has on another can be significant. If these influences are ignored, then the risk of increasing costs or reducing revenues downstream in the planning process is introduced, as harmful decisions made during an earlier optimization process are balanced.

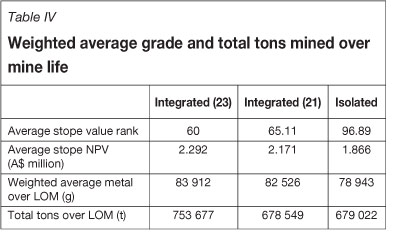

The integrated approach, however, was able to consider producing different sets of stopes in different configurations at different time periods. This allowed the model to consider the interaction between the two planning areas and thus select more profitable stopes overall, which produced a higher NPV. Table IV presents the average stope value rank, the average NPV for all stopes selected, the weighted average metal production over the life of mine, and the total tonnage mined for the two optimization methods. As can be seen, the integrated approach selected more profitable stopes overall, which resulted in mining more tons at a higher grade over the mine's life. Even if the mined metal content or NPV was considered over 21 periods, the number of periods the isolated approach was scheduled over, the integrated approach still produced a better result.

Adherence to constraints

Another shortcoming of the isolated approach is that due to its inability to foresee issues generated by stope layout optimization decisions on production scheduling optimization, the model was unable to conduct scheduling over the specified 23 time periods. Scheduling, instead, needed to be reduced to 21 periods for the IP model to produce a result. This again illustrates the dangers of isolated planning, where initially generating part of a mine plan with one goal in mind, such as to solely optimize stope layouts, may mean that not all constraints can be satisfied when planning another area, such as production scheduling.

The ability of the integrated approach to foresee planning issues, however, ensures constraints can be adhered to, such as scheduling over the required time periods. As the consequences of certain decisions made during the optimization of both layouts and schedules were analysed, this meant all constraints could be satisfied and the mine life adhered to. This highlights the significance and importance of using an integrated optimization approach to generate a sound mine plan.

Risk and opportunity identification

While there are clear NPV and adherence to constraint advantages when using an integrated optimization approach, it is important to note other related benefits of this approach as well.

Firstly, in failing to address all constraints in a coherent manner, the isolated approach may not only produce a sub-optimal result but it also exposes the operation to substantial risk. It does this by leaving it vulnerable to a restriction that has not been adequately anticipated or a relationship between two planning areas not fairly represented, and these could obstruct further progress. Due to the need to identify a larger range of operating conditions and constraints upfront and the fact that the integrated approach takes a holistic view when undertaking optimization, potential risks to the success and progress of the operation as a whole can be identified earlier, and this means the dangers and costs inherent in these risks can be addressed earlier too.

Secondly, while both methods provide operations with a better mine planning process that is less reliant on manual techniques and more on reliable, automated, mathematical techniques, the integrated approach also provides the opportunity to make more realistic comparisons between different investment options and/or projects. The provision of more comprehensive and holistic estimates on NPV early in the process facilitates informed financial decisions about the allocation of limited resources and the avoidance of mistaken commitments to less than optimal operations.

Mine planning time

A final key difference between the two approaches was the solution time. Based on the time required purely for optimization, it seems that the integrated approach is more time-consuming when compared to the isolated approach (31 hours versus instantaneous). When, however, both approaches are assessed over the full life time of the project it is likely that the integrated approach will prove more time-efficient because it enables the engineer to organize the whole project in a structured manner from the beginning and avoid continual repeated piecemeal assessments as the project progresses. Additionally, in relation to the isolated approach, if risks are identified after the optimization of the initial mine planning area, this means re-work of previous planning areas for the engineer to address these risks. Thus the integrated approach facilitates a more efficient use of time because all necessary planning work is done at the beginning in a coherent manner.

Conclusions

The focus of underground mine planning optimization work completed to date has been directed towards solving a single mine planning area. This approach means a mine plan is formed by using the 'optimized' solution for the first problem as the input for the following problem, and so on until a whole mine plan has been formed. There is, however, a growing consensus around the benefits of integrating the mine planning of these separate areas into one optimization process. This paper, in addition to presenting a model that can generate optimal stope layout designs and long-term production schedules for SLS operations, has demonstrated the benefits of using an integrated optimization approach for mine planning instead of the traditional step-by-step approach. While optimization of part of a mine plan will generally tend to yield better results than manual planning methods, the integrated optimization approach provides even better operational and financial advantages due to its ability to assess the interaction and influence between planning areas.

The key conclusions drawn from testing these two mine planning optimization approaches are:

1. The isolated approach has a short-term, or narrow, outlook due to its initial sole focus on selecting stope layouts without consideration for the impacts on production scheduling. This in turn limits the scope in which production scheduling optimization can work due to the various constraints specified, and this ultimately harms the NPV because costs are either transferred or revenues reduced elsewhere in the mine plan

2. The integrated approach, in contrast, takes a holistic view of the operation which allows it to foresee and, therefore, manage issues between the mine planning areas and accommodate all constraints upfront. This ensures a more considered and comprehensive mine plan is generated, which means a better NPV is achieved. Additionally, this approach allows for risks and opportunities to be identified more readily, which means risks can be reduced or opportunities capitalized on more easily in the planning process. Using this approach also means it is more realistic to expect a sound comparative evaluation of projects within reasonable time frames, and this facilitates better informed operational and financial decisions.

Future work

This work provides a foundation on which future advances can be developed. The most notable is incorporating development optimization into the model. While the IP model has taken into account one development consideration, that is the location of extraction levels, it does not assess if other development requirements, such as shaft or decline construction time or their placement underground, can satisfy the proposed production schedule, or if the proposed stope layouts and schedule work well with development requirements both technically and financially. Optimizing development along with stope layouts and the production schedule will provided a globally optimal strategic mine plan.

References

Alford, C. and Hall, B. 2009. Stope optimisation tools for selection of optimum cut-off grade in underground mine design. Proceedings of Project Evaluation 2009 Conference. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 137-144. [ Links ]

Alford, C. 1995. Optimisation in underground mine design. Proceedings of the 25th International APCOM Symposium, Brisbane, Australia, 9-14 July 1995. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 213-218. [ Links ]

Ataee-Pour, M. 2004. Optimisation of stope limits using a heuristic approach. Transactions of the Institute of Mining and Metallurgy A, vol. 113, no. 2. pp. A123-A128. [ Links ]

Carwse, I. 2001. Multiple pass floating stope process. Proceedings of the Fourth Biennial Conference: Strategic Mine Planning, Perth, WA, 26-28 March 2001. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 87-94. [ Links ]

Chadwick, J. 2009. Mine optimisation. International Mining Magazine, November. pp. 18-28. [ Links ]

Grieco, N. and Dimitrakopoulos, R. 2007. Managing grade risk in stope design optimisation: probabilistic mathematical programming model and application in sublevel stoping. Transactions of the Institute of Mining and Metallurgy A, vol. 116, no. 2. pp. A49-A57. [ Links ]

Little, J. 2007. A new approach to using mixed-integer programming for scheduling optimisation in sublevel stope mining. Bachelor thesis, University of Queensland, Brisbane. [ Links ]

Little, J. Nehring, M., and Topal, E. 2008. A new mixed-integer programming model for mine production scheduling in sublevel stope mining. Proceedings of the 2008 Australian Mining Technologies Conference, Twin Waters, Queensland, 16-18 September 2008. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 157-172. [ Links ]

Maptek. 2011, Vulcan 8.1 Stope Optimizer. http://www.maptek.com/pdf/vulcan/Vulcan_Q&A_optimizer_stope.pdf [Accessed 3 September 2011]. [ Links ]

Morin, M.A. 2002. Underground mine design and planning: complexity and interdependencies. Mineral Resources Engineering, vol. 11, no. 2. pp. 197-215. [ Links ]

Nehring, M. and Topal, E. 2007. Production schedule optimisation in underground hard rock mining using mixed integer programming. Proceedings of Project Evaluation 2007, Melbourne, Australia, 19-20 June 2007. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 169-175 [ Links ]

Nehring, M., Topal, E., and Little, J. 2009. A new mathematical programming model for production schedule optimisation in underground mining operations. Journal of the Southern African Institute of Mining and Metallurgy, vol. 110, no. 8. pp. 437-446. [ Links ]

Nehring, M., Topal, E., Kizil, M., and Knights, P. 2010. An investigation to integrate optimum long-term planning with short planning in underground mine production scheduling. Proceedings of the 19th International Symposium on Mine Planning and Equipment Selection (MPES 2010), Fremantle, WA, 1-3 December 2010. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 141-153. [ Links ]

Poniewierski, J., MacSporran, G., and Sheppard, I. 2003. Optimisation of cut-off grade at Mount Isa Mines Limited's Enterprise Mine. Proceedings of the Twelfth International Symposium on Mine Planning and Equipment Selection, Kalgoorlie, WA, 23-25 April 2003. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 531-538. [ Links ]

Sens, J. and Topal, E. 2008. A new algorithm for stope boundary optimisation. Proceedings of the The AusIMM New Leaders' Conference, Wollongong, NSW, 15-16 July 2008. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 44-47. [ Links ]

Smith, M.L. and O'Rourke, A. 2005. The connection between production schedule and cut-off optimization in underground mines. Proceedings of the 32nd International APCOM Symposium, Tucson, Arizona, 30 March-1 April 2005. A.A.Balkema, Leiden. pp. 643-654. [ Links ]

Snowden. n.d. Underground Optimisation. http://www.snowdenau.com/Admin/assets/microsoft%20word%20-%20090513%20stopesizor%20overview%20ab%20screen.pdf [Accessed 12 November 2010]. [ Links ]

Topal, E. and Sens, J. 2010. A new algorithm for stope boundary optimisation. Journal of Coal Science and Engineering, vol. 16, no. 2. pp. 113-119. [ Links ]

Topal, E. 2003. Advanced underground mine scheduling using mixed integer programming. PhD thesis, Colorado School of Mines, Colorado. [ Links ]

Topal, E. 2008. Early and late start algorithms to improve the solution time for long-term underground mine production scheduling. Journal of the Southern African Institute of Mining and Metallurgy, vol. 108, no. 2. pp. 101-107. [ Links ]

Trout, L.P. 1995. Underground mine production scheduling using mixed integer programming. Proceedings of the 25th International APCOM Symposium, Brisbane, Australia, 9-14 July 1995. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 395-400. [ Links ]

Whittle, G. 2009. Misguided objectives that destroy value. Proceedings of Orebody Modelling and Strategic Mine PlanningSymposium, Perth, WA, 16-18 March 2009. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 97-101. [ Links ]

Whittle, G. 2010. Enterprise optimisation. Proceedings of the 19th International Symposium on Mine Planning and Equipment Selection (MPES 2010), Fremantle, WA, 1-3 December 2010. Australasian Institute of Mining and Metallurgy, Melbourne. pp. 105-17. [ Links ]