Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.10 Johannesburg Jan. 2013

CONFERENCE PAPERS

A framework to simplify the management of throughput and constraints

A. Cambitsis

Cyest Corporation

ABSTRACT

We show that the prioritization of business improvement and performance management decisions may be significantly improved by taking into account the systemic effects of changes made in a single process area. To do so we build a model of a mining value chain, taking into account consequential downtime that arises from downstream and upstream starvation and choking effects of each activity. Introducing the concept of internal capacity, this approach yields insight into the relative importance of key metrics such as loading and hauling rates. We suggest that a holistic view of this type should be a core component of business improvement and performance management decisions.

Keywords: value driver trees, production constraints, throughput analysis, capacity analysis, TOC (Theory of Constraints), activity interdependencies, unit cost reduction.

Introduction

Companies in the resources space increasingly need to find ways to squeeze more out of their assets, as driven by global competitive pressures for capital and the risk of commodity price downturns. Most resource companies have now established continuous improvement programmes and corresponding organizational structures that are focused on driving initiatives to maximize value within the current asset base.

In this context, while cost management and improvement are crucial to running an effective and profitable organization, the greatest gains can generally be obtained by increasing production volumes or throughput. The sensitivity analysis shown in Figure 1, which is for a relatively high-margin mine, shows the impact on profit of a 10 per cent change in costs versus a 10 per cent change in production volume (taking variable costs into consideration).

As can be seen, an improvement in production volume has a significantly higher impact on the bottom line than the same percentage improvement in cost. In fact, the higher the margin of the mine, the more pronounced the impact of volume relative to cost. This also holds true for lower margin operations, but here the difference is not as pronounced.

Moreover, not only is production volume a more impactful lever, but there are often greater opportunities to realize gains in this area. The volume of ore produced and sold by a mining operation is the result of a set of activities operating in sequence to extract the ore, transport it, and beneficiate it. The rate (and often the quality) at which this is achieved is influenced by various interdependences between the activities in this value chain. Therefore to maximize throughput one needs to manage across the whole value chain, and understand the impact of these interde-pendencies clearly. Attempting to manage activities in isolation of the upstream and downstream dynamics, as we will show, is not a very effective way of maximizing throughput. Because organizations tend to assign responsibilities and manage in silos (i.e. per activity), in practice this leads to a sub-optimal system and a reduced potential to increase throughput on most operations.

Of course this concept is not new. Theory of constraints (TOC) and lean manufacturing address the issue of system throughput. In this paper, however, what we will show is that by building a model of the value chain, and using visually intuitive value driver trees, one can introduce a series of metrics whereby it is possible through the course of normal operational reporting to manage constraints and throughput. In other words, the lean and TOC techniques alluded to can be packaged into a system for managing the operations.

What is a value driver tree?

A value driver tree is a way of visualizing a model of a business in a way that links the value metric (what management or stakeholders care about) to the operational drivers (the things that can be influenced to change the value metric). In this respect a value driver tree is the visual representation of a mathematical model of a business (or a portion thereof). Most of us are familiar with spreadsheet-based models of a business, often used for planning or budgeting processes. In essence all these models are nothing more than a series of mathematical relationships relating input variables to output variables. The complexity often comes in the number of the variables and relationships, how they are organized, and how transparently these are represented.

In our case we use the Carbon Modelling platform, an object-orientated modelling software technology that allows us to build complex models of a business, but still visualize the model or aspects of it in a visually accessible and intuitive value driver tree, as shown in the example in Figure 2 for a hauling activity.

The value driver tree is useful because:

1. It is visually appealing and engaging

2. It shows how different areas of responsibility (e.g. engineering and operations) link together and affect the value metric (in the case above the tons hauled).

Modelling an activity using a value driver tree model

We start off by modelling a basic unit of production. This could be a piece of equipment such as a truck or milling line, or an activity as a whole such as drilling or crushing. In either case the output is the quantity of product (be it metres drilled or tons crushed), and this is a direct function of the amount of time the activity or equipment is operating and the rate at which it operates. This is a reasonably universal way of describing any production activity and in fact can even be applied to service activities.

The following basic equation determines the quantity produced:

Quantity produced = production rate χ net production time

Figure 3 shows this in a value driver tree format with the production output being at the apex and the drivers being beneath it. The sensitivity analysis on the right of the diagram shows the impact that a 10 per cent change on each driver individually has on the quantity produced. Because of the multiplicative relationship, a 10 per cent change on either driver has the same result.

We now take this a step further, and expand the net production time into available time and operational delays. Simply put, the generally accepted definition of available time is the time in which the equipment is available to work. Due to operational reasons (such as no operator, shift changes, upstream activities being down, etc.) the equipment or activity does not necessarily operate the full amount of the available time. These delays are accounted for in the operational delays variable shown in Figure 4.

Available time is often expressed as a percentage of calendar time and is thus known as availability, and the net operating hours as a percentage of the available hours is known as use of availability (UoA) - i.e. the percentage of available time that translates into operating hours. These definitions typically form part of what is known as a 'time model'. Most mining and production organizations have their version of the time model, and while these may vary somewhat from each other, the core principles shown here are reflected in each of them.

Available time can be decomposed as the total calendar time available, less the time in which the equipment is not available: we broadly refer to these lost hours as maintenance downtime (Figure 5). Maintenance downtime itself can be of the planned or unplanned variety, the difference being that the latter occurs at a measurable statistical rate but is uncertain in timing.

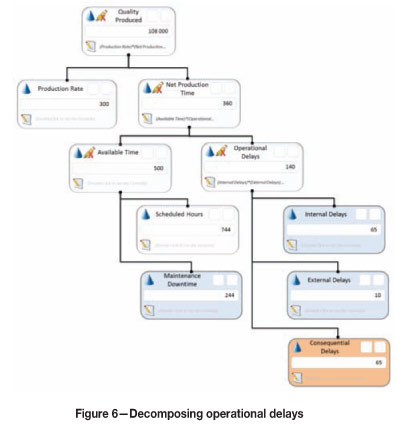

We further expand operational delays into three categories (Figure 6):

1. Internal delays - delays, such as a shortage of operators, that arise within the process or activity and can be influenced by management within the relevant silo

2. External delays - delays arising from external considerations such as bad weather, which directly affect the process but cannot usually be directly managed

3. Consequential delays - delays caused by a knock-on from upstream or downstream activities, in the form of 'choking' or 'starvation'. Choking refers to the activities' inability to push more product downstream because of a full stockpile or the next activity being unable to take the product. Starvation refers to the activity having no feed from the upstream activity.

The concept of internal capacity

With the above as a basis, we can now define the concept of internal capacity for an activity. Internal capacity is defined as the quantity that the activity would produce if it were not starved or choked. In other words, if the process were able to operate in isolation, without any consequential delays, then based on figures achieved for all other internal variables this is the production that the activity would have achieved (Figure 7).

Note that reaching this level of production does not necessitate any improvements in the activity per se; it simply requires better coordination, or isolation of the impact of upstream and downstream downtimes. The difference between the internal capacity and what was actually achieved is a crucial concept.

Key drivers of an activity in the context of a value chain

But what happens if we look at this activity in the context of a value chain? Our model helps us establish this by analysing the activity with the consequential downtime factored in. We see that in fact the loading rate (not hauling) is the factor with the biggest influence on hauling production (Figure 8). Hauling rate in fact has declined in importance to the point where it is negligible. What this indicates is that there is no point in improving the hauling process until it is de-bottle-necked by improving loading throughout.

This is the power of modelling the complete system holistically: considerations that may appear important within each silo in fact may not be significant at all in the big picture. More importantly from a management perspective, the KPIs of an individual silo owner may not have any relationship to the performance of the whole business, and in fact it may be counterproductive to spend money fine-tuning one area of the business when it is not involved in the systemic constraints.

Conclusion

Focusing on increasing throughput of a mining company is usually a very effective way of increasing value because:

1. A certain percentage change in volumes (throughput) drives more value than the same percentage change in costs

2. There is generally unrealized throughput potential in the existing asset base due to the interdependent nature of ore flow through a value chain.

By building a model of the value chain using visual value driver tree principles, and paying respect to the interdepen-dencies between activities, we can demonstrate how managing an activity in isolation (and incentivizing management as such) does not help increase overall system throughput.

The model, however, allows us to understand which activity is constraining throughput, and how system throughput is further diminished by starving or choking the constrained activity. A model of this nature contains metrics that can assist management to understand the true potential of the value chain, and which areas to focus on in order to maximize flow through it. Such models can be built for mining operations and introduced into daily performance management activities, helping management realize maximum value from the installed asset base.

Acknowledgements

The author would like to thank his team members and clients who have over the years developed models of increasing sophistication that led to the insights reflected in this paper, and for their commitment to finding ways of improving how businesses can be run using more scientific decision-making tools.

Bibliography

Cambitsis, A. 2012. Using equation based modelling to model value chain throughput. Internal White Paper, Cyest Corporation. [ Links ]

Goldratt, E. 1992.The Goal: A Process of Ongoing Improvement. 2nd rev. edn. North River Press, Great Barrington MA. [ Links ]

Sye, G.L. 2009. Process Mastery with Lean Six Sigma. A Pactitioners Guide to the Utilisation of Modern Day Lean Six Sigma Methodology. Soarent Vision, Brisbane, Australia. [ Links ]