Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 no.10 Johannesburg Jan. 2013

CONFERENCE PAPERS

Yield improvement at a mid-sized coal mine in the Witbank coalfields

J.O. Claassen

University of the Free State

ABSTRACT

A study was initiated and solutions implemented to address the root causes of a 30°/o^J0°/o lower than predicted product yield achieved at a Mpumalanga coal mine. A holistic MRTM approach, which focused on improving exploration, geological sampling and analysis, geological modelling, planning, mining, and beneficiation practices, was used. The study indicated that deviations in the planned versus actual yields at the DMS plant were caused mainly by incorrect geological yield predictions, high and variable levels of dilution, and near-dense material, as well as the textural properties of the ore.

Keywords: MRTM, mining value chain improvement, Witbank coalfields, complex geology.

Introduction

It is a well-known fact that ore grades in most commodities are declining at a concerning rate. This situation is further complicated by an increase in the variability of ore (textural variances, complex mineral associations, presence of weathered material and competing species, etc.), and orebody morphology (increased variances in dip, seam thickness, floor conditions, etc.). The outer perimeter of the Witbank coalfields (WCF) is a case in point.

Variable geological environment

The WCF have for many decades supported the production of high-quality coal from the inner basin. A higher demand for coal in recent years and many mines in the region nearing the end of their economic life moved the attention of miners to pockets of coal situated in the outer perimeter of the basin. These pockets are typically found in interconnected troughs, ravines, and sinkhole- and small basin-like structures supported by an undulating glacial floor formed in the geological past between mountains and a subsiding Ecca sea, as shown in Figure 1. The deposition of peat on an irregular Ecca coastline was associated with major subsidence events with throws of between 20 m and 30 m, approximately 20 000 years apart. This resulted in an irregular distribution (spatially and morphologically) of some of the major coal seams found in the Mpumalanga region, as shown in Figure 2.

Apart from the geological complexities introduced merely as a result of the depositional environment, further complexity was introduced through subsequent dolerite intrusions in the WCF and surrounding areas. This resulted in devolatization and weathering of coal as well as seam misplacements along fault lines.

Stratigraphically, dull and massive coal seams interbedded with bright coal layers and shale and/or mudstone horizons of varying thickness found in these areas form part of the Vryheid Formation. The coal deposit is supported by a competent Dwyka tillite floor and capped by sandstone of the Volksrust Formation.

End-to-end mining approach

It should be clear from the previous section that a special effort is required to mine coal in the outer perimeter of the WCF in an effective, productive, and economic manner that keeps customers happy most of the time. More specifically, the impact of variable geological, mining, and processing conditions should be clearly understood and catered for throughout the mining value chain. Figure 3 shows the impact of variability in these environments on the profitability of a mining operation if these factors are not adequately considered.

Figure 3 also indicates how variability caused by complex geological environments (e.g. the outer perimeter of the WCF) contributes towards the inability to effectively manage mining operations, which includes development of realistic/executable mine plans. This, in turn, causes an unstable and unpredictable (difficult to plan and forecast) mining environment. Therefore, the exploitation of geologically complex environments is more often than not hampered by unstable and unpredictable mining operations. This is despite the fact that the alignment of ore and orebody characteristics with downstream processing (the geometallurgical approach) requirements (technology and processing thresholds) has in most cases been rigorously tested and incorporated in mine designs and plans.

It is believed that it is essential to also take a flow-based approach to day-to-day operations when mining in complex geological environments, i.e. identify and actively manage all factors that impact the rate at which product is produced (within specification). This approach includes not only a focus on the physical flow of material, but also the flow of product payability attributes through the mining value chain (Claassen, Laurens, and Van der Westhuizen, 2013a, 2013b). Product payability refers to the monetary value that can be generated from the product, and product payability attributes in this paper refers to all the factors in the ore and orebody, as well as mining practices, that can cause product payability attrition/loss. Stabilizing production, improving product yield, and ensuring consistent product quality will therefore increase product payability.

In the ensuing sections a case study is presented where a holistic mineral resource throughput management (MRTM) flow-based approach (including TOC principles) was used to stabilize production and to improve product yield at a midsized coal mine (MSCM) situated in the outer perimeter of the WCF.

Applying MRTM principles in a complex mining operation

Root-cause analysis

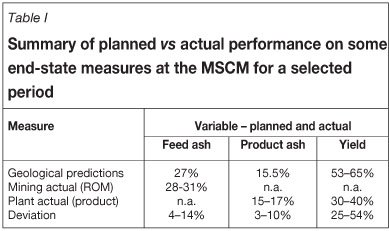

In mining a rule of thumb exists that if the deviation of planned versus actual performance of end-state measures is equal to or greater than 10%, then the operation is deemed to be unstable. The planned versus actual values of some endstate performance variables at the MSCM were determined and are included in Table I.

From Table I it is evident that there was reason to believe that the MSCM investigated was running an unstable and unpredictable operation. An end-to-end mining value chain improvement approach (MRTM) was employed to address the causes of these deviations. A high-level diagram and several detail cause-and-effect diagrams that considered all mining steps were therefore compiled to assist with finding the root cause(s) of these deviations. Special attention was given to the factors (product payability attributes) that impacted beneficiation plant yield. Some of the root causes of poor plant yield identified during this process are listed in Table II.

Resolving causes of lower than expected plant yield

A simple algorithm that calculates the impact of product payability factors on the overall yield possible at the MSCM for the area under investigation is shown in Equation [1].

where:

Theoretical yield = yield determined under ideal conditions in a laboratory through sink-float analyses

In the ensuing sections the contribution of these factors to the lower-than-expected yields at the MSCM at the time of the study and ways to mitigate their impact are discussed in detail.

Theoretical yield

The theoretical yield determined through washability tests on prepared core samples is probably one of the most important measures of a coal mining operation in any phase of the project. It directly impacts the feasibility of a mining venture in the initial phases of the project and the stability of a running operation, as shown previously.

Great care is therefore taken to ensure that drilling, core logging, and sampling and analysis of core material are done correctly and according to prescribed codes (Claassen, Laurens, and Van der Westhuizen, 2013a). Despite all the effort that goes into this part of the project, a yield 'fudge factor' is still commonly employed in industry to correct theoretical values to give more realistic yield predictions. This fudge factor is generally based on experience and/or actual results obtained from a running operation. It more often than not does not reflect the true complexity/variability of a specific ore and orebody with respect to the behaviour of ore through the different phases of the mining value chain. Furthermore, to base the yield correction factor on the actual performance of an unstable and unpredictable operation only makes matters worse.

Therefore, instead of building the exploration, sampling, analysis, and modelling programme of a coal reserve on generalized norms/codes/practices that use average standards, an attempt was made at the MSCM to rather develop a fit-for-use programme that takes the variability in the geological environment and the behaviour of the material (flow focus) in downstream processes into account. This was achieved by aligning the exploration drill grid size and sampling frequencies with the complexity of the ore and orebody in a scientific manner, among other things, as discussed later.

In order to improve the accuracy of theoretical yield predictions, it was decided to first of all perform a geostatistical study (non-spacial and spacial) on the data gathered from the area under investigation. Geostatistical tools were employed to determine whether different populations are present in the analytical data, the optimal exploration grid size as indicated earlier, and the extent of the nugget effect.

a) Presence of multi-populations in data-The presence of different populations in the data or a multi-population data-set can typically be caused by the following:

- Sampling across boundaries/contacts

- Areas of complex geological structure

- Inclusion of waste lenses

- Different stages of sampling and sampling techniques

- Changes in the laboratory used for analyses

- Changes in people used

- Changes in relevant policies or procedures

- Cost-cutting exercises

- Different drilling campaigns

- Different types of host rocks

- Contamination in sampling equipment/poor sampling.

A probability plot can be used to indicate the presence of one or more populations in a data-set if a random sample is taken. One plot done at the MSCM in a portion of the area under investigation is included (Figure 4).

The 'kink' in the graph indicates the presence of at least two populations in the data-set. Since drilling, sampling, and analysis had been performed by the same individuals and companies for many years at the time of the study, there was little reason to belief that a change in practices and human behaviour contributed towards the multi-dimensional dataset. Instead, it was found that sampling practices carried over from previously mined (less complex) areas resulted in sampling practices across coal horizons that were not compatible in the area under investigation. More cores were drilled adjacent to existing ones and the sample frequency was increased to reflect the complexity of the ore and orebody in an attempt to shed more light on this matter. The results obtained from this intensive sampling campaign are discussed later.

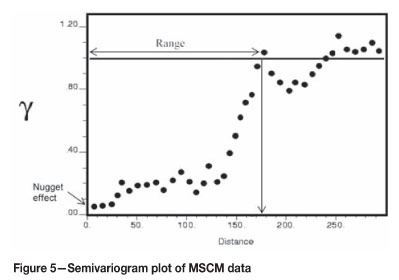

b) Optimal exploration grid size- Semivariogram plots were used to determine the optimal exploration grid size based on the variance in yield in the area under investigation. One of the plots obtained during the study is shown in Figure 5. The semivariogram plot in Figure 5 suggests that an optimal/maximum grid size (range value) of about 175 m for the yield variance in the area under investigation should be used. At the time of the study, greenfield exploration work was done on a 250 m grid, compared to the recommended 350 m for a Measured Reserve stipulated in the SAMREC Code (SAMREC, 2009) (Figure 6).

From the study it was concluded that the level of information gathered on a 250 m exploration grid did not adequately reflect the variability/complexity in the yield (this can be done for other variables as well) in the area under investigation. The exploration grid size was subsequently reduced to ensure a higher level of confidence in the exploration data. An infill drilling programme was also initiated in more problematic areas.

c) The nugget effect-Figure 5 shows very little yield variation at small lag distances. This finding, combined with an audit performed on sampling, preparation, and analytical practices, confirmed a notion that the contribution of these practices to notable planned versus actual yield differences can be ignored.

The geostatistical study performed at the MSCM clearly indicated a higher level of geological complexity in the area under investigation compared to previously mined areas. This change in complexity had a detrimental impact on the accuracy of the theoretical yield predictions. Geostatistical tools were successfully used to align the yield variance in the orebody with the optimal exploration grid size and core sample frequency in a manner that reflect the complexity of the ore and orebody.

The exact contribution of incorrect yield predictions (specifically the influence of grid size) to the deviation in planned versus actual yields achieved in the DMS plant was not calculated. The impact of the other yield attrition factors was quantified in order to replace the average yield fudge factor in use for the specific area under investigation. This exercise resulted in the development of area-specific yield values, in MRTM referred to as condition-driven standards (CDS).

Coal compatibility

When a flow view is taken of the mining value chain, the compatibility of different material entities in the ROM needs to be considered. Incompatible material (ore or ore-waste combinations) behaves differently in downstream processes (from drilling to product stockpiling) and typically results in lower throughput rates and higher product payability attrition.

In the previous paragraph a decision taken to drill extra holes and increase sample frequency on these drill cores was mentioned. The results obtained from one such test borehole, where 30 cm composite samples were taken, are shown in Table III.

Table III clearly shows the presence of different strata in the 3 m coal seam. Since the DMS plant equipment can be set at only one specific density set-point at a time, material is inevitably lost when bulk mining combines these sub-seams in the plant feed. At the MSCM the total coal seam was mined in more or less two halves at the time of the study. In order to show the impact of this non-compatibility of the different sub-seams on yield, the CPU simulation package developed by the CSIR was used. In all simulation runs the yields obtained from the traditional bulk mining approach were compared with results generated from selective mining of the sub-seams. Tables IV and V indicate the cut-point densities typically required to produce a 15% ash product and the estimation of yield differences between bulk and selective mining, respectively.

The output from all simulations performed (6.1% yield difference obtained in the example in Table V) suggested that the bulk treatment of non-compatible material has an estimated 5% impact on the theoretical yield value determined for the area under investigation. This also implies that the average cut densities and yields obtained from washability tests performed on composite samples collected in a manner that simulate the mining method employed (bulk mining) do not adequately reflect the complexity of the coal. The actual plant yields achieved were therefore always lower than predicted.

A re-classification of coal seams based on the impact of material compatibility on flow and product payability was performed. The associated changes to the geological and planning models assisted the MSCM to minimize the detrimental effects of treating material with poor compatibility.

Dilution/contamination

Dilution or contamination also has a significant impact on material flow and product payability (yield and product quality) in a mining value chain. It is therefore essential to identify areas where a higher potential for dilution exists(undulating floor conditions, faults, increased dip angles, etc.) and put the necessary steps in place to mitigate its impact on production. At the MRTM this situation is effectively dealt with by classifying the orebody according to flow and product payability needs and scheduling according to the condition-driven standards associated with the identified areas, as shown in Figure 7.

This approach enables the exploitation of even difficult-to-mine areas, but under very specific conditions, e.g. mining at a specific time of the day/production cycle (e.g. daytime or just before/after plant maintenance), at a specific rate (not an average rate), at predetermined plant settings (batch operations), etc. A buffer strategy that supports mining from difficult areas is also put in place in a manner that does not compromise flow and product payability.

Ash dilution from difficult-to-mine areas at the MSCM was a major concern at the time of the study. The dilution correction of the theoretical yield was traditionally performed using an average factor determined for the mine as a whole. Yield predictions were found to be too optimistic for the difficult-to-mine areas as a result of this. A yield correction factor of about 4% was calculated for ash dilution for the area under investigation.

Ultra-fines

The MSCM needs to deal with severe weathering within coal seams as a result of dolerite intrusion in the geological past, as alluded to earlier. Added to this challenge was the rapid degradation of shale and shaly coal when exposed to water and air in the area under investigation. The combined effect of these two ore and orebody characteristics had a detrimental impact on the flow of material through downstream processes and the yield at the time of the study.

To counter the almost 9% yield impact of ultra-fines losses experienced and overloading of the slimes handling section in the plant caused by a high fraction of ultra-fines in the plant feed, particular attention was given to the cleaning of benches (housekeeping focus), blasting practices, and changing the buffer strategy to limit the degradation of run-of-mine material.

Coal liberation

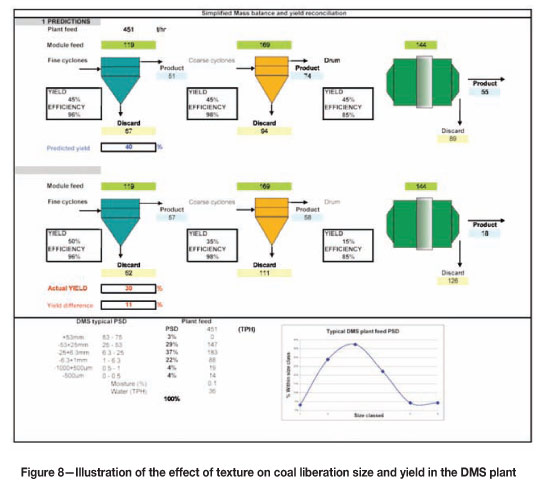

Meso-textural variations are fairly common in stratiform deposits. Interlayered dull and bright coal of variable thicknesses found abundantly in the outer perimeter of the WCF is a case in point. The liberation size and associated yield of coal can be related directly to the meso-texture of the ore. In many instances, fractional washability of coal is performed in order to capture this characteristic of the ore. If this is not done, e.g. all core is crushed to <12.5 mm prior to sink-float analyses, the yield will generally be overestimated, as was the case at the MSCM at the time of the study. Events were noted where yields of approximately 50%, 35%, and 15% were recorded for the fine, medium, and coarse coal fractions in the DMS plant, respectively. The combined yield of the three streams gave a much lower overall plant yield than the yield predicted by the geological model, as illustrated in Figure 8.

Figure 8 indicates the significant impact that texture and liberation size have on overall plant yield. Apart from the yield impact, the qualities of the different products were also affected, with most of the vitrinitic/bright coal reporting in the fine cyclone feed. Since the different fractions are sold into different markets, densities had to be reduced for the coarser fractions to reach the product specification, with a resulting decrease in the yields achieved.

More work was undertaken to refine the 11% yield correction factor obtained from this part of the study. Core crushing methods that simulate the natural breakage properties of the coal and fractional sink-float tests were introduced at the laboratory handling the geological samples in an attempt to generate more accurate yield predictions.

Equipment efficiency

The single biggest variable that impacts plant beneficiation equipment efficiency (normally in the region of 98% for cyclones and 86% for the drum) at the MSCM is the amount of near-gravity material (NGM) present in the area under investigation. The treatment of coal with high levels of NGM results in the so-called cut-point shift, which causes the production of high-ash products. This cut-point shift has been recorded to be as high as 0.25 RD units, i.e. instead of cutting at a RD of 1.40 (medium density), the material is actually separated at a RD of 1.65. When material with high NGM levels is treated, the medium RD set-point is reduced to counter the high ash values in the products, which causes lower yields. An attempt was made to predict the yield loss as a result of misplacement caused by the presence of NGM, as shown in Figure 9.

For a typical 40% NGM coal, a yield loss of about 6.2% (9.4%-3.2%) can be estimated using Figure 9. Material with NGM levels as high as 80% was recorded at the MSCM. More work in this area is required to refine the model.

The impact of high levels of NGM on the performance of the DMS plant was mitigated through the implementation of a number of projects that focused on the ability of the dense medium cyclones to handle higher levels of NGM and scheduling batches (from classification of the orebody) of compatible coal to the plant. Operating the DMS plant at lower tempos also proved to assist with the management of product quality.

Plant operations

When a typical DMS plant is started up after extended stoppages and maintenance interventions, the dense medium circuit can take a couple of hours to stabilize and to reach the required set-point values (depending on how well it was shut down). During this period, instantaneous yield losses in the order of 10% are experienced. It was estimated that an overall yield loss of about 0.5% can be expected as a result of operating the plant at lower densities than required.

Other factors

The influence of other factors such as spillage, moisture in plant feed and product, and precision errors on weightometers was also evaluated and found to have an insignificant impact on the overall yields achieved at the MSCM.

In summary, if the factors determined above (prior to improvements implemented) are substituted in Equation [1] and a theoretical yield of 60% is used, an overall yield nearly 50% of the theoretical yield is obtained as shown in Equation [2]:

Yield correction factors of about 10% have been traditionally used at the MSCM. The geological model therefore, without exception, over-estimated the plant yield for coal delivered from the area under investigation. This in turn destabilized the operations as the different departments introduced more variability to the system in an attempt to improve performance, as discussed earlier. However, the identification and quantification of the impact of some critical factors influencing product payability (and material flow) and the solutions subsequently implemented not only ensured more accurate theoretical yield predictions, but also significantly improved the DMS plant yield and system throughput as it stabilized the overall mining value chain.

Conclusions

Some factors that influence the accuracy of theoretical yield values determined for a mid-sized coal mine situated in a complex geological environment, such as the outer perimeter of the Witbank coalfields, were discussed. The importance of determining fit-for-use yield correction factors compared to using average norms and standards was also highlighted. Furthermore, it was suggested that ore and orebody characteristics must be aligned with downstream processes and equipment from a physical material flow and product payability point of view in day-to-day operations to ensure optimal mine performance in complex geological environments.

References

Falcon, R.M.S. 1986. A brief review of the origin, formation and distribution of coal in southern Africa. Mineral Deposits of Southern Africa. vol. ii. Annhauser, C.R. and Maske, S. (eds.). Geological Society of South Africa. pp. 1879-1898. [ Links ]

Fabianska, M.J. and Kruszewska, K.K.J. Relationship between petrographic and geochemical characteristics of selected South African coals. International Journal of Coal Geology, vol. 54, no. 1-2. pp. 95-114. [ Links ]

Claassen, J.O., Laurens, P.G., and W.A. Van der Westhuizen. 2013a. Improvement and optimisation methodologies in the South African mining industry. Journal of the Southern African Institute of Mining and Metallurgy. In review. [ Links ]

Claassen, J.O., Laurens, P.G. and Van der Westhuizen, W.A. 2013b. Operating and improvement methodology effectiveness in mining. Journal of the Southern African Institute of Mining and Metallurgy. In review. [ Links ]

SAMREC (South African Mineral Resource Committee). 2009. The South African Code for Reporting of Exploration Results, Mineral Resources and Mineral Reserves (the SAMREC Code). 2007 Edition as amended July 2009. http://www.samcode.co.za/downloads/SAMREC2009.pdf [Accessed 31 August 2012]. [ Links ]