Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.6 Johannesburg Jun. 2013

Incident reconstruction simulations-potential impact on the prevention of future mine incidents

R.C.W. Webber-YoungmanI; E.A. van WykII

IUniversity of Pretoria

IITshwane University of Technology

SYNOPSIS

The mining industry in South Africa faces real challenges with regard to the reduction of safety-related incidents. The purpose of this paper is to highlight the need for alternative interventions in addition to other safety improvement strategies already employed on mines. It furthermore supports an existing paradigm: incident investigations. An investigation into fatalities in the South African mining industry shows that although great progress has been achieved through the reduction in fatalities in all sectors of the industry over the last few years, more can and should be done to achieve status of 'zero harm'. Fatalities and lost time injuries on mines result not only in large financial losses, but also in disruptions of mining operations in general through Section 54 stoppages to resolve the situation. The approach of the paper is therefore not to try and prove whether there is high fatality rate and/or lost time injuries, but in what way incident reconstruction simulations (IRS) can have an impact in the future prevention of such incidents. The challenge therefore lies in the utilization of pro-active systems that would show employees the possible outcomes of being exposed to certain hazards. In real life, these incidents cannot be re-enacted and in most cases we can only learn through the previous mistakes of others. A virtual reality (VR) education and training system will enable employees to be 'exposed' to different hazards in a safe environment, and simulation, in a 'forgiving' environment, of the possible consequences of unsafe acts. According to the Occupational Safety and Health Act (OSHA), unsafe acts and unsafe conditions are indirect causes of safety-related incidents, but there are also direct causes; for example, unplanned release of energy and/or hazardous material, and basic causes, for example, management safety policies, personal factors, and environmental factors. The administrative workload associated with any incident investigation places a large burden on the investigation team, and in most cases other employees are informed through vague administrative processes what the 'real cause' for the incident/accident was. New preventative strategies are often put in place without showing the employees what the real causes of the incident/accident were. This can be mitigated through the use of interactive VR simulations/animations of the hazards that they are exposed to and how to deal with them. If VR interventions are not used as proposed by this paper, the real causes and consequences of almost all fatalities and lost time injuries may never be fully understood. This paper also emphasizes what potential impact IRS could have on the prevention of future mine incidents as part and parcel of a pro-active risk prevention strategy. The intention is therefore not to replace any other risk prevention strategies, but to visually enhance the reality of the incident.

Keywords: virtual reality, risk management, incident reconstruction simulations, interactive safety training, usability context analysis, mine safety.

Background

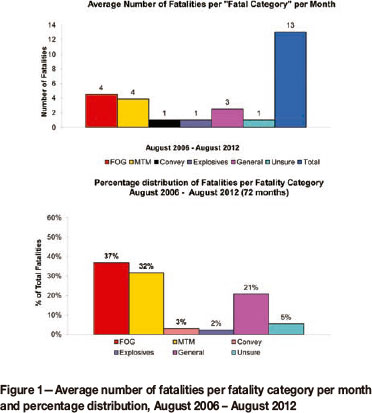

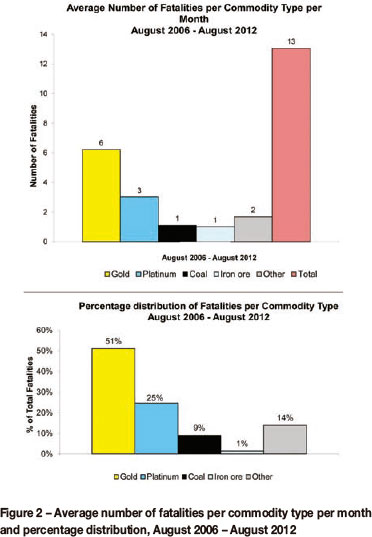

The South African mining industry places great emphasis on creating a safe, healthy, and productive working environment. Figures 1 and 2 show fatality numbers and other details reported from August 2006 to August 2012. (Department of Mineral Resources). Fatalities have a major influence on the perception of mining as a career, as well as a negative impact on the perception of mining as a good and safe working environment. This negative impression has been exploited extensively by the media over the past few years. This paper highlights the fact that mining engineering and related technical disciplines play a very important role in promoting a safe, healthy, and productive working environment for the mining industry.

Figures 1 and 2 show the breakdown of fatalities over the period August 2006 to August 2012 (72 months). The data is presented in terms of total number and percentage distribution of fatalities in each fatality category (cause of death) and commodity type respectively. It is quite clear that the gold mining industry still has the highest fatality rate compared with other commodities mined. Figure 2 shows that almost 80% of our fatalities come from the hard rock industry (gold and platinum). Figure 1 shows that approximately 13 people are killed each month on South African mines (864 for the period August 2006 until August 2012 for all commodities). Figure 2 also shows that falls of ground still remains the biggest killer on our mines (4 per month on average, or 37% of the total), while machinery/ transport and mining-related fatalities are the second highest risk. This indicates the rise of a new danger, which relates to increasing trackless/mechanized mining activities, with specific reference to the platinum industry as well as the coal mining industry. Both extensively make extensive use of heavy machinery such as continuous miners and haulers for coal.

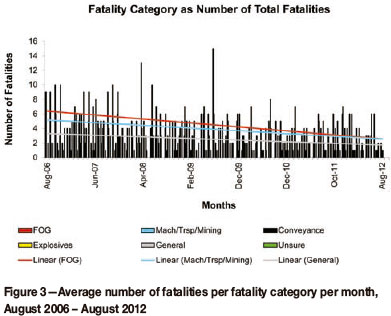

The significance of these statistics is that over a period of 72 months there has been a steady decrease in fatalities through sustained efforts by mining companies (Figure 3). However, fatalities are still unacceptably high, and more emphasis should be placed on strategies to achieve the 'zero harm' goal embraced by all South African mines. All mining companies have embarked on focused risk management programmes. Experience has proved that fatalities are 'cyclical' in nature. Periods of high fatality rates are often followed by periods of lower rates, owing to intense attention to improve adherence to safety standards. However, the aim is to minimize this cyclicity so as to institute a meaningful drive towards zero harm. Lack of knowledge (through a lack of education and training) plays a definite role in increasing the fatality rate. Various approaches should therefore be employed to make workers aware of the consequences of unsafe acts; and here, VR reconstructions of incidents have an important role to play in reinforcing awareness of these consequences.

In South Africa, the Mine Health and Safety Act (1996) has identified the need to establish a culture of health and safety as one of its key objectives. This objective is supported by a number of statutory provisions that require employee participation, instruction and training, risk management, disclosure of information to employees, and the employee's right to leave a workplace that poses a serious danger to health and safety. The Act further requires the employer to consider, as far as reasonably practical, an employee's training and capabilities in respect of safety and health before assigning a task to that employee. The employer is also required to provide employees, as far as practicable, with any information, instruction, training, or supervision that is necessary to enable them to perform their work safely and without risk to health (Le Roux, 2005).

In this regard a very important responsibility lies with the employer - that of being aware of the progress and competency levels of each of its employees. Unless a very structured support programme is in place, this will be very difficult to monitor and keep current. It is also important that the necessary facilities to support this programme must be in place, and that a very quick way of ascertaining employees' levels of knowledge needs to be available.

From the data presented earlier, it is obvious that there has been a steady improvement in the reduction of fatalities on South African mines, but that there are still too many fatalities. Taking into consideration the costs pertaining to each incident, it makes sense to invest into practices that will help to reduce the fatality and injury rate on mines. Virtual reality simulations have been identified as a very powerful tool for assisting in the quest for zero harm, and their ability to actively support other prevention strategies will be highlighted in this paper.

Virtual reality education and training simulations

Virtual reality, popularly referred to as VR, is a rapidly growing technology that utilizes the ever-increasing power of computing to simulate real-world and imaginary environments and situations with a high degree of realism and interactiveness. However, instead of looking at a flat screen or a piece of paper, the person who experiences VR is surrounded by a three-dimensional computer-generated representation and is able to move around in the virtual world and see it from a different perspective (Kizil et al., 2007). VR simulation/animation products have been on the market for the past few years, and have undergone several improvements in terms of quality and speed, including sound effects, so that they can be readily applied to simulate any mine hazard and constitute an interactive approach to the education and training of new workers in the mining industry. VR can fulfil several functions, such as visualizing data, incident reconstruction, simulation applications, risk analysis, hazard awareness applications, and many more.

VR has the ability to provide the best tools for incident reconstruction, and also has a real contribution to make in terms of training and hazard identification without exposing the employee directly to hazardous situations. Kizil and Joy (2007) highlighted the fact that high-quality three-dimensional graphics, sound, and dynamic simulation combine to form a uniquely engaging experience.

VR-based training and education models will not only reduce injury and fatality numbers, but also reduce the associated costs. VR multimedia training can dramatically reduce the cost of delivering the training by decreasing learning time for trainees and instructors, the need for expensive and dedicated training equipment, and also travelling expenses. Figure 4 highlights the major benefits of using VR for training.

The main difference between conventional and VR training lies in the fact that VR has the potential to immerse trainees in realistic functional simulations of workplaces and equipment, and trainees can demonstrate mastery of skills by performing tasks in multiple scenarios.

The Research Training Institute emphasized the fact that VR applications can reduce the duration of training by more than six times (RTI, 2001). This provides an opportunity to expose many more employees to a training system and in thus improve their overall knowledge and awareness of hazards. The fact that VR can be used interactively at strategic points throughout the mine enhances the awareness factor even more, and adds value in terms of exposing employees to the dangers of hazards without them having to experience the real thing. In most cases it is quite common to say that workers 'don't always know what they don't know', and VR has a great role to play in this regard.

Rheingold (1991) pointed out that in future people might find it quite hard to think that they previously had to deal with education and training needs without VR. Nowadays, students and learners all over the world are more visually inclined, and lecture material and other education tools have to include audio and visual elements. Students want to see and hear, in addition to reading, and this factor will have to be included in all long-term strategies for education and training models. In the South African mining environment this becomes even more crucial due to the fact that we have 11 official languages, which also complicates knowledge transfer. VR technology has the ability to build choice of language into the system, which will improve comprehension and also the potential to retain the knowledge gained for a much longer period (if not permanently). VR simulations have already become important in terms of transferring knowledge to students in the mining industry.

It is therefore also quite obvious that VR has a great potential to increase productivity, better utilization of time and, most importantly, improve health and safety awareness, and in this way reduce incidents. VR technology can, and in some cases has already, contributed to the improvement of the mining industry's safety record and to saving lives (Kizil and Joy, 2007).

Various VR prototype systems are installed at some South African mines and smelting plants. These have been well received and have provided an interesting and engaging alternative to conventional training programmes. It has also been indicated (Van Wyk and De Villiers, 2008) that VR improved the safety culture on mines.

Van Wyk and De Villiers, as well as other authors, highlighted the following potential benefits of VR training:

It is a low-cost alternative to creating full-scale real-life training scenarios

Systems can be designed to be multilingual and trainees can be taught in their mother tongue

VR is a very flexible configuration and is open to ongoing modification and customization

It offers an opportunity to create a wide variety of scenarios, including those rarely or never experienced in real life

It also exposes users to simulated situations that would have been dangerous to encounter in real life

This virtual 'time on task' experience helps to enforce the learning that took place during the conventional classroom instruction

The VR training system provides appropriate levels of trainee interaction

Trainers can review trainees' records from an extensive database, compare results, and generate graphs of performance of individuals or groups

Trainee problem areas are easily identified.

Usability context analysis (UCA) for VR training

Before VR education and training methods/tools are used it is very important that certain technical aspects should be considered. The usability of any tool or system has to be viewed in terms of the context in which it is used and its appropriateness to that context. Usability is a general quality of the appropriateness to a purpose of an artefact (Brooke, 1998). The International Organization for Standardization (ISO) defines usability as the extent to which a product can be used by specific users to achieve specified goals with effectiveness, efficiency, and satisfaction in a specified context of use (ISO, 1997). The context of use includes the users, tasks, equipment (hardware, software, and materials), and the physical and social environments in which the product is used. Context analysis provides a framework to ensure that all factors that may affect the usability of a product are considered (Van Wyk and DeVilliers, 2008).

UCA is therefore a structured method for eliciting detailed information about a product, how it will be used, and for deriving a plan for a user-based evaluation of a product. For this method, stakeholders meet to detail the actual circumstances (or intended use) of a product (Bevan, 1997). The significance of this is that it is important to establish in detail in what context VR will be used. Several aspects such as language, academic level, type of tasks, different types of equipment, as well as how appropriate VR will be for that specific target population, need to be considered before a final decision can be made for a specific VR application.

Education/training challenges in the South African mining industry

Promoting a strong safety culture requires that the significance of unsafe acts be emphasized. In the context of the South African mining industry with its diverse workforce it becomes a very serious challenge to ensure that every person that is exposed to risks understands the consequences of unsafe acts. In the South African mining context, we have multi-cultural and multi-lingual environments where the language per se is a risk as well, as the meaning of different risks and the prevention and or dealing with them can be interpreted differently by different language groups. This in itself is a major risk, as one can never be sure that the same message was heard by all as it was intended.

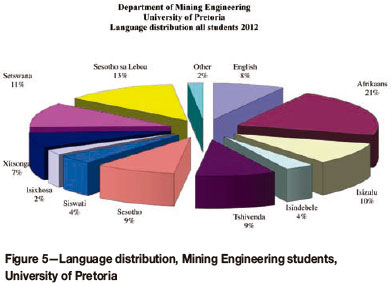

The Department of Mining Engineering at the University of Pretoria conducted an investigation into the different languages spoken by students in the department, and a very interesting aspect was identified. Figure 5 shows clearly the challenge in terms of the transfer of knowledge which educators at the university face.

Only 8% of the students have English as their first language, with Afrikaans at 21% and Sesotho Leboa at 13%, and other language distributions following. The significance of this is that for 92% of all the students English, which is the medium of instruction, is not their mother tongue. There is therefore the real potential that the message delivered might be received very differently among different language groups. The way in which this message is interpreted becomes evident only once the students have been tested on it, and it may be found that some of them did not get the message at all. In most cases this will be too late, and a group of students will fail, not because they did not care, but because they did not understand. It is also known that approximately 10% of South Africans have English as first language, which compares well with the 8% for the students. Therefore 90% of all South Africans get educated and trained in a language other than their mother tongue. From a risk perspective, the danger lies in that information given may be misinterpreted or misunderstood

Obviously the language spoken will differ from area to area in South Africa, and herein also lie some challenges, as some areas in terms of demographics are better schooled than others, and this can lead to potentially misunderstanding.

These factors led to a strategy of changing the approach to teaching and learning at the Department of Mining Engineering at the University of Pretoria, by changing the way in which the information was made available to the students. Learners in the 21st century are all visually oriented rather than verbally oriented. Thus education and training methods need to be adapted to include more visual material. This led to a new education model, based on a technology-enhanced flexible learning paradigm, which was established at the University of Pretoria in 1997. The aim was to improve the students' abilities to acquire and apply the knowledge gained. There was also an additional need to ensure that every student (based on the challenges with regard to the multilingual environment) received the same 'message' and information to be applied.

Prior to this intervention, lecture notes were paper-based only (one-dimensional and very difficult to comprehend unless well explained). With large groups and also a multi-language student environment this became more and more difficult to achieve. The idea behind changing the way the information was transferred to the students was to ensure that everybody had an equal chance of understanding what was offered to them.

The result of this intervention was that electronic, interactive course notes were developed, which included videos, animations, photos, mouse-overs (moving the mouse over specific drawings chosen, made it more clear through descriptions highlighted in the drawing). Another feature that added a lot of value was cross-links (links between the different document chapters).

The process that is followed is according to the ADDIE Instructional Design model, and it is explained as follows:

Analysis-read through the notes

Design-identify the media elements (lecturers must source the media elements, which forms a very important part of the whole process, especially where very vague technical content is concerned)

Development-lecturers approve the suggested media elements, which are then built into an MS Word document before it is converted into a PDF document

Implementation--links are built in PDF documents

Evaluation-lecturers work through the documents to verify that all the included elements are correct. An external user also tests each and every link to ensure that all is working as intended.

The significance of the above is that since the system was introduced some three years ago in the Department of Mining Engineering at the University of Pretoria, the pass rate applicable to mining courses has improved significantly. In some cases there was a 100% improvement compared to previous year's results. The question to answer is, therefore, 'What does this have to do with the prevention of incidents or ensuring that unwanted events be avoided?' to say the least, everything? This aspect will be dealt with in detail in the rest of this paper.

VR incident reconstructions - their significance

When an accident/incident occurs on a mine it is followed by a series of investigations as prescribed by the Mine Health and Safety Act (MHSA). In the context of the South African mining industry, this usually starts with a Section 54 served on the mine (immediate stoppage of all mining-related activities until such time that the deficiency has been dealt with satisfactorily).

Incidents in many cases are referred to as near-misses where no losses were experienced, but where any losses occurred such incidents are thoroughly investigated and this leads to some preventative actions being put in place (also applicable to near misses where necessary, depending on the reasons for the near miss). In most cases these actions are reactive, and incidents could have been prevented through a thorough risk management process to identify the major risks and preventative measures to avoid them. Education and vocational training play a very important role in the promotion of incident prevention cultures. During education and training periods, individuals learn not only the skills and knowledge of a particular sector or profession, but also values and business cultures, including safety and health cultures.

Agioutantis et al. (2003) noted that continuous employee education and training as a means of establishing a strong safety culture in the mining industry is a major factor in preventing fatal and non-fatal incidents. The important aspect to consider here is to what extent employees are educated and trained on a continuous basis and the frequency of these training sessions. It is important to note that the more a message is repeated in different ways the more it will be ingrained in the minds of the people exposed to it. The role of VR techniques through computer software should not be underestimated in terms of the transfer of this knowledge.

Tracy (1992) defines training 'as any learning experience provided to employees to bring about changes that promote the attainment of the goals and objectives of the organization.' More practically stated, training can be defined as any programme consisting of the presentation of information followed by an assessment of the trainee's retention of such information. At this point it is also important to note that there is a real difference between education and training. It can be simply stated that education is the stage where the knowledge is presented to the learner (find out what you don't know) and training the stage where this actual knowledge is now used (applying the knowledge that you were not aware of).

There are various ways of educating people, and the use of the ADDIE process mentioned earlier is one of the better ways of getting knowledge transferred to learners (education). There are also several ways of delivering training, and they are (Weisiger et al., 2001):

The traditional method of classroom and lecturer ('chalk and talk'), nowadays the most inefficient

The traditional methods enhanced by various visual aids (that is Powerpoint presentations, video projections, etc.), in-class exercises, and problem-solving activities, which aim to stimulate learners in a lecture environment

Skills training by an apprenticeship-type programme delivered outside the confines of the classroom

Computer-based training (CBT), which can be broadly categorized as follows:

- Simple presentation-type systems

- Interactive systems

- Easy-to-use VR systems

- Web-based training

A combination of the above methods.

In the context of the South African mining industry and the challenges it faces, it makes sense that combinations of the abovementioned methods can and will add a lot of value considering our diverse culture working environment. Weisiger et al. (2001) also noted that CBT showed great promise in all situations where training is needed. This way of training can be very beneficial, especially where repetition is needed. The flexibility and power offered by computers nowadays allow for the integration of various types of media elements and should be incorporated as such.

It is also important to note that a multimedia training application can be developed at a significantly lower cost than a VR environment. Such a system can be created to address most, if not all, of the various learning styles of employees, through the use of videos, animations, and audio files to meet the needs of both visual and verbal learners. VR training applications, on the other hand, can vary from simple animations to fully immersive environments with true navigation capabilities (for example, flight simulators, drill rig operation simulators etc.). It is, however, important to note that users should be able to control the pace of the training order to match their individual learning rates (Weisiger et al., 2001).

The need for incident reconstructions

People in many cases have no experience or clue of what the consequences of their actions may be. Take for example the evaluation of professional sports events. These events are recorded on video with the idea of evaluating them afterwards to identify flaws or improvements in form. Such recordings are important to the athlete because they not only show flaws in performance, but also the resulting consequences. These concepts are also used in mine training videos, but unfortunately are very limited in their capacity to show the full consequences of unsafe acts (Capelle, 1999). Incident reconstruction as a means of incident prevention has a major role to play in terms of recreating the incident realistically. A very important part of using this type of intervention is to not only re-create the incident through VR, but to also create a prevention VR example. In this way the consequences of unsafe acts can be realistically shown, as well as how these unwanted events could have been avoided.

It is important to note that incident recreation starts with the incident investigation. The purpose of any incident investigation is to find the root cause of the incident. This can be a very challenging procedure, and may comprise the following sequence of events (Capelle, 1999):

As much information as possible pertaining to the incident must be gathered

Investigators must observe and note all conditions, locations, and equipment involved in the incident

Photographs and/or video footage of the incident scene will be very helpful in both the incident investigation and the incident recreation

A plan of the incident scene should be developed to describe the circumstances relating to the incident

The physical evidence of what may have caused the incident should be documented

All the physical evidence and information gathered should be given to incident experts

These experts can analyse the information using a variety of tools. (Needless to say, incident investigations are usually handled by experienced personnel).

In terms of general incident recreation a sketch of the area may be all that is required. This sketch must also include the types of cameras and the locations from which any photographs or videos were taken. Dimensions, topography, and distances that may clarify the events before, during, and after the incident must be included. All measurements should be recorded as accurately as possible, although it might not be necessary for these to be exact. In many instances, general incident recreation procedures involve static pictures and graphics that are not realized as training material, but as an investigation tool. With little extra effort, however much of this material can be utilized for recreating the incident in a VR environment (Capelle, 1999).

To prevent repeat incidents it is obvious that every employee on a mine can and should be offered the chance to be able to understand whatever happened regarding a specific incident. It is also not always possible to transfer the knowledge through a formal education/training process, and it is here where VR techniques can be utilized to construct a very clear recreation of the incident.

Interestingly enough, in the USA, admissibility of VR recreations in court has been denied for several basic reasons (Joseph, 1996). VR is considered a computer simulation that is supposed to be programmed to reflect reality. Because of this, concerns about factuality and scientific foundations used as part of the recreation are raised. Because the facts presented are based solely on the data that is entered into the recreation, a VR recreation is considered by the courts as a form of hearsay, and therefore, is possibly inaccurate. The four main issues identified are as follows:

The underlying scientific theory

The computer simulation program used

The accuracy of the data used

The incorporation of all data used.

Later it was found that courts in other countries, such as the UK, allowed VR creations (Schofield et al., 2002). Nevertheless, some simpler uses of VR are generally admissible in court. Environmental visualizations are amongst the most common of these. An important point to mention is that a VR creation for use in mine training environments need not meet the requirements established by the judicial systems of different countries. Therefore the recreation of an unsafe act that has been proven to result in injury need only be a generic case, rather than a specific, historically accurate case. This generic case should, however, be based on the actual conditions and their actual results (in other words as realistic as possible). It is therefore obvious that low-cost VR reconstruction of incidents is a valuable training tool in the same way that many professional sports use video recordings of performances for evaluation purposes.

Case studies pertaining to IRS

In order to show the effectiveness in bringing the consequences of unsafe acts across to a mining community, several basic incident descriptions that led to one or more fatalities were obtained from different mines. The purpose of this is to show how confusing words could be, and also how difficult it was not only to 'picture' the incident, but also to visualize preventative measures. The main purpose of employing VR is not as a scare tactic, but rather to emphasize the safe actions that could have prevented the incident. In this way the focus is on the positive message that we want to convey, rather than the negative message of fatality. The seriousness of the unsafe act is not underplayed (it did lead to a fatality), but more emphasis is placed on what could have been done to avoid the incident. VR plays a very important role because in the training process a dangerous situation can be repeated several times for the learner to eventually comprehend, without the risk of any damage. The learner therefore experiences the real-time conditions without being exposed to them directly. The repetitive nature of the training in 'real-time' reconstructed simulations and animations make the learner confident to deal with real situations underground. People trained on simulators such as aircraft or drill rigs for that matter, when put onto the real thing find it much less daunting and challenging and adapt to it much quicker.

Some examples of incident descriptions

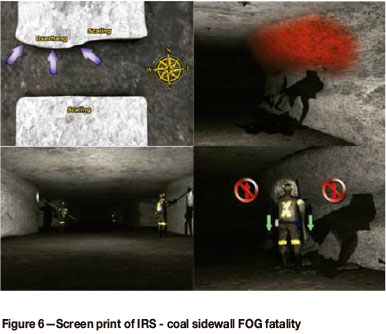

Coal sidewall FOG fatality (description as per actual incident report shown below, names marked* are fictitious)

Statement by Peter*; I Peter* am employed as a general worker. On the morning of 06 December 2010, I together with John* was barring in the main travel road. I was on the left hand side of the road and my colleague was on the right hand side. We progressed in a western direction from the main shaft. At about 10:20 I heard a loud noise and I then ran away. After the dust had subsided, Alfons* and I walked back to the area where John and I had been working. John was covered by a large piece of coal. We moved the pieces that had been cracked by hand and a LDV arrived and the driver assisted us to remove the co-worker from the fall. Another LDV arrived and was dispatched to summon the ambulance. When the ambulance arrived we had already removed John from the coal. I have been trained to bar at the training center and on the job. I do not have a competency B qualification. We did a mini risk assessment this morning before starting work. The topics discussed were lock out of machinery and barring. The control measures for barring was to use a sounding stick and to suspense reflective sticks where we were working. Only Afons, John and I did the mini risk assessmentfor barring.

Statement by Afons*; I am employed as a roof-bolt operator but was recently deployed to assist with the barring of tractor roads. On the morning of 6 November 2010, I together with Peter and John were in the process of barring the traveling road from the main shaft to 3E shaft at around 10:20. I was ahead of John and Peter when I heard a loud noise and a cloud of dust enveloped me. Peter and I ran away. When the dust cleared, we noticed that John was not with us. We went back to where John had been barring and found him covered by a large piece of coal. We had to lift up the large piece of coal in order to remove him from thefall of coal which came from the sidewall. Johan arrived on the scene shortly after thefall. He helped us remove the coal before somebody else arrived and went off to summons an ambulance. The ambulance arrived at about 10:45. The ambulance driver and Johan applied first aid. At that stage John was still alive but he did not respond when we talked to him. I examined the area where the fall occurred before the accident but did not see any cracks. There was an overhang but it was not very big. I did not see any other person examine the area before the accident. I have been trained to examine an area and to carry out barring operations both at the training centre and on the job. I have had competency training, A or B but am not sure which one.

Statement by Johan*; I am the Shift Boss, I reported on duty on the 6th November 2010 at about 06H00. I went underground at 10:05, to inspect west 323. I got to the LDV and we drove towards west 323. We drove from main shaft towards 3e shaft along West 1.I saw dust, a reflective hard hat and a headlamp on the floor. We stopped the LDV and with further investigation we found that the sidewall has collapsed. I saw a person lying underneath the pile of coal and we started to remove the coal pieces from the person. While we were busy removing the coal pieces I instructed Bertus*, to call control room to summon the ambulance. The other members of the barring team helped us to remove the big coal pieces from the person. When we removed most of the coal I felt for a pulse, but could not find anything and also saw the injured did not breathe and did not respond to us. Bertus returned and said that he informed the control room about the accident. I drove to the shaft to fetch the ambulance to speed up the process. Pieter* drove the ambulance. The person was removed and taken to surface. I went underground together with the investigation team for the in-loco. I have nothing further to declare.

Sequence of events / Story line

Description

- 07:00 - The barring team consisting of 7 people went underground.

- 07:10 - They all arrived at the green area,

- 07:15 - The miner (Hans*) got a call from his wife and left the mine to attend to personal matters.

- 07:20 - The miner informed the shift boss that he had to leave and was excused

- The team started with the safety talk about barring roof and sides

- The shift boss joined the team at the green area and continued with the safety talk about the lock out procedures

- 08:00 - The team loaded the material onto the LDV and were transported to their place of work

- 08:05 - They arrived and did a risk assessment after which they started with the work and continued with the barring work until the accident happened

- 10:20 - The accident happened

- After the dust to cleared the witnesses started to recover the injured from the coal

- Shift boss Hannes* (conveyor belts) arrived soon afterwards, checked for life essentials, assisted to remove the injured and summoned an ambulance

- 10:45 - The ambulance arrived at the scene of the accident, loaded the injured and left for surface with the two witnesses

- + 11:05 After arriving on surface Danie* drove to the first aid room where he found the surface ambulance waiting

- The paramedics took over from Danie* , examined him and then removed him from the ambulance to the first aid room

- + 11:25 The doctor confirmed that the injured passed away.

Figure 6 is a screen print from the actual VR incident reconstruction of the abovementioned incident.

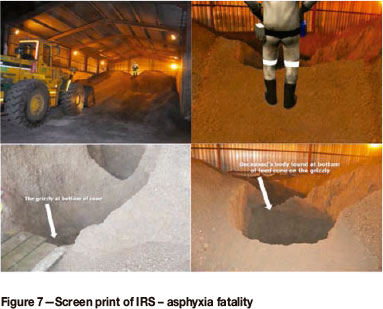

Asphyxia fatality (description as per actual incident report)

Joseph* a front end loader operator was working night shift on 14 August 2010. At approximately 5:00 on the morning of the 15th the Raw Material Operator, Sipo* instructed him to push up the Attaclay (similar to Bentonite) material in the bunker. Attaclay is stored in a shed and reclaimedfrom the bottom through a vibratingfeeder and conveyor system. At approximately 5:10 a bypassing dumper driver (Joseph*) saw the deceased standing on top of the pushed up Attaclay material. When Joseph* returned after approximately 3 minutes, he noticed the deceased was not there and that his hard hat was lying on the Attaclay heap. He immediately stopped and inspected, but could not locate him. Joseph then reported the incident to the Local Control Room Operator. The deceasedfell around 4m onto the feeding grizzly at the shed and was found with his face down and covered to some extent with Atta Clay. The Post Mortemfindings indicate fractured ribs on the right side and congested internal organs. The cause of death was reported as Asphyxia.

Figure 7 is a screen print from the actual VR incident reconstruction of the abovementioned incident.

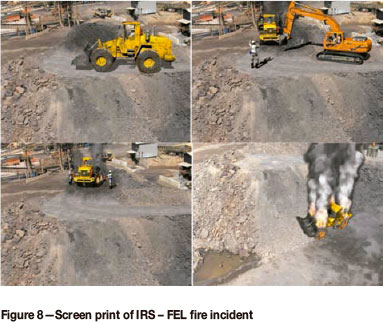

Front end loader (FEL) high wall incident (description as per actual incident report)

On Thursday, 25 March 2010, Front End Loader (FEL) operator, Peter* was busy leveling dumper loads of untreated slag at the Furnace 3&4 slag dump. During the leveling process the high wall at the rear left side of the FEL collapsed while the loader movedforward. The driver stopped the loader a distance away from the collapsed high wall and got out of the loader to callfor assistance. On return it was found that allfour tyres were burning. Attempts to extinguish the fire did not succeed. An excavator was brought in to pull the FEL away. While pulling the FEL, the left rear wheel cleared the area that collapsed. The FEL jack knifed to the right and the left front wheel went over the edge. The FEL started sliding down the slope, toppled over and landed back on its wheels at ground level.

Statement

At around 04H35 on 25March 2010Joseph* called me from furnace 6 to come to furnace 3 slag dump. When I arrived at the scene I saw FEL L220-8 at the edge of the slag dump busy burning all tyres. I then gathered fire extinguishers to try and curb the fire, but we couldn't bring it to abrupt stop, because the loader was standing on a hot surface. We use the Excavator to pull the loader away from where he stands. Before we pull we dig the hole on the right hand side trying to make it easy when we start to pull the right wheels must fall into hole and is going to be easy to take it out. Unfortunately when we start to pull the structure off, the loader slid towards left and it overturned and landed on the wheels on the bottom of the slag dump. We use all the fire extinguishers we have try to control the fire but unfortunately the fire destroy the life of the loader.

Figure 8 is a screen print from the actual VR incident reconstruction of the abovementioned incident.

Significance of incident descriptions and VR application

From the foregoing incident descriptions and statements it is clear that there is detailed information that in some cases is also very confusing. From statements made a vague understanding of what happened is possible, but it is quite clear that a VR incident reconstruction simulation will be able to amplify the understanding. What is more important, however, is that once VR reconstructions of the abovemen-tioned incidents have been done, then VR reconstruction simulations of the preventative procedures/controls should be included as well. In this way not only consequences, but also the correct procedure by which the incident could have been avoided, can be shown. In this way corrective actions are preempted and the learner exposed to the danger and taught how to deal with it, without any potential loss. The actual VR reconstructions of the abovementioned incidents and other detail pertaining to them showed that the understanding of the incidents was enhanced significantly.

Methodology for IRS

An investigation methodology should identify not only how an incident occurred, but also why it occurred. By augmenting the investigation methodology with the use of incident reconstruction simulations the circumstances relating to the serious accidents described previously can be simulated to prevent recurrences. This can be achieved by illustrating the corrective actions and key learning point that arose from the investigation. According to De Landre et al. (2006) the 'effectiveness of corrective actions and key learning in reducing error is clearly an area which needs to be improved upon, evidenced by repeat incidents seen throughout many industries.'

An IRS provides the opportunity to apply information extracted from the incident investigation into an effective learning tool. This includes information relating to the physical evidence and conditions that existed at an incident site, the actions of employees, procedures that failed to prevent or mitigate the incident, and the pertinent organizational factors. The focus should be on making the work environment safer. This can be achieved through utilizing incident reconstruction simulations in a number of ways:

To increase hazard awareness orientation

To prevent repeat occurrences of similar incidents

As a training tool around corrective measures put in place following the incident

As a visual explanation of the incident to assist with incident comprehension and analysis.

An animated incident reconstruction simulation typically consists of the following components:

A virtual environment with animated scenes showing what happened.

Scenes indicating the cause/s of the incident by highlighting the erroneous actions undertaken.

Scenes indicating the correct procedures dealing with such circumstances.

The methodology used in the development of an IRS usually depends on the purpose of the IRS. Should the IRS be required as a visual tool to assist comprehension and analysis of the incident, such simulations would have to be developed rapidly in order to be available to aid in the investigation process. In this case the focus will be on an exact reconstruction of the events that led up to the incident, the actual incident itself, and the immediate consequences. The corrective measures will not necessarily be finalized at this stage, but many of the causes of the incident may be known and can be included in the simulation.

In the case of developing an IRS to be used as a training intervention to improve hazard awareness and to prevent recurrences, then the IRS should include lessons learned and corrective actions taken to address such hazards.

A typical development methodology for an IRS includes the following five steps:

- Understand what happened. In order to be able to recreate the events, the developers of the simulation need to gain a thorough understanding of what exactly transpired. The first step in obtaining such knowledge is usually to study the investigation report, if it is available

- Conduct a site visit. The developers need to visit the site of the incident, so that video footage and photos can be taken of the actual environment where the incident occurred, as well as other areas that may be required for the simulation. This will empower the developers with sufficient material to be able to create the virtual environment for the simulation. During the site visit, any questions the developers may have regarding their understanding of the incident can be cleared up by informed staff members

- Develop a storyboard for the simulation. The storyboard provides rough sketches and a script, indicating the visuals that will be shown as well as the accompanying text and narration. The storyboard is sent to the client for approval, and modifications are made where required

- Build the visual simulation. Appropriate software is used for the development of a three-dimensional virtual environment of the location, and then objects are modelled and animated in this environment in order to reconstruct the incident, indicate the causes, and show the correct procedures

- Add text and narration. Appropriate text is added to the simulation where descriptions may be required or to emphasize important points pertaining to the incident and corrective measures. Narration in the required language is then added to the visuals.

In a training environment the completed IRS can be used in a number of ways:

As a training video that can be played at training venues, change houses, access points to workplaces, etc.

In a facilitated group training session where the facilitator can highlight deviations from procedures, possible contributing factors, lessons learned, corrective actions taken, as well as possible new procedures implemented

As in interactive computer-based training system, where trainees can be shown the hazardous environment prior to the incident and then need to identify the hazard correctly, select possible risks associated with such a hazard, and indicate measures to prevent incidents. The incident can then be shown as a possible consequence of not addressing the hazard correctly.

Benefits of using VR incident reconstruction and training

From the abovementioned facts it is obvious that VR reconstructions have the ability to improve the understanding and basic causes of incidents. The consequences of unsafe acts can also be simulated in detail (with whatever outcome needed) without any harm caused. The use of sound and 3D interaction make the experience even more realistic, adding to the real-time experience. For VR interactive education and training systems the added benefits can be stated as follows:

The introduction of improved VR technology with the focus on safety improvement ensures that the workforce has a high level of competence before entering the real working environment

Incident and prevention reconstructions form very important parts of the overall risk management strategy to be employed on mines and have the real benefit that they can be done relatively cheaply compared to the costs associated with unwanted events

VR introduced the format of interactivity (participation) in learning material, which enhances the comprehension process

Deficiencies in training can be identified without risk, as high-risk scenarios are simulated in a safe and controlled environment. Working in such simulated environments increases the realism of the training experience, allows high-cost equipment to remain in production, and assists trainers in identifying unsafe practices performed by trainees

VR technology has shown a high level of usability, especially among the large number of mineworkers who have a low level of computer literacy

VR proved to be a successful bridge of the gap between illiteracy and higher levels of training with multimedia/visual conceptual learning

Literacy level is still a major problem, which is significantly addressed by 3D animated and multimedia effects, enabling the visualization of the actual problem described and enhancing understanding

With VR, sound can be introduced as well as different languages to describe the situation. It has been proved extensively through school systems that mother tongue education and training has the best chance of success compared with non-mother tongue training strategies

The reality of understanding complex scenarios and statements makes life much easier for learners.

Conclusions

From this paper the following can be concluded:

The mining industry in South Africa has always been under pressure to reduce fatality related incidents. A six-year analysis of fatalities on mines in South Africa showed that although there has been a steady reduction in fatalities over the last 6 years, fatalities still occur, with the majority in the hard rock mining environment, which led to several MHSA Section 54s to be served on the respective mines

There has been a downward trend in fatalities over the period August 2006 to August 2012

Falls of ground still remain the main reason for fatalities on South African mines. VR incident reconstruction simulations can and will add value to education and training with regard to identifying this risk and dealing with it

VR training initiatives have been identified as potentially major role players in creating training opportunities that will not only decrease the time spent on training people, but also in terms of creating a more extensive health and safety awareness programme on mines, which can be updated on an almost daily basis to serve the needs of the respective mines

Several education and training activities have been identified for VR training simulations and all have the potential to ensure that the success rate of training people on mines will continuously increase

VR interactive training simulations have been employed at Impala Platinum, Anglo American Platinum, Xstrata Alloys, and Samancor with great success and will in future be used in several more activities on other mines

It is therefore concluded that incident reconstruction simulations through the use of VR technologies can and will make a major contribution to the reduction of mine-related incidents, and should be considered for utilization as part of a risk management strategy towards the prevention of incidents.

Acknowledgements

The involvement and support of Simulated Training Solutions (Pty) Ltd and the Department of Mining Engineering at the University of Pretoria are hereby acknowledged.

References

Agioutantis, Z., Karmis, M., and Scharik, S.J. 2003. Methodology of incident recreation using Virtual Reality. SME Annual Meeting, Cincinnati, Ohio, 24-26 February 2003. pp. 1-5. [ Links ]

Bevan, N. 1997. Usability Context Analysis: A Practical Guide. NPL Usability Services, Teddington, UK. [ Links ]

Capelle, P. 1999, A Mind for Pool; How to Master the Mental Game. Billiards Press, Midway City, CA. [ Links ]

De Landre, J., Gibb, G., and Walters, N. 2006. Using incident investigation tools proactively for incident prevention. Australian & New Zealand Societies of Air Safety Investigators Conference 2006, Melbourne, Australia. [ Links ]

Department of Mineral Resources. http://www.dmr.gov.za/Mine_Safety/Accidents_Stats.html [ Links ]

Joseph, G.P. 1996. Virtual reality evidence. Boston University Journal of Science and technology Law, 2 May 1996. [ Links ]

Kizil, M.S. and Joy, J. 2007. What can Virtual Reality do for Safety. University of Queensland, St Lucia, Queensland. pp. 1-8. [ Links ]

Le Roux, A. 2005. Mine fatalities down, but still too high. Mining Weekly. http://www.miningweekly.co.za/min/features/health/?show=66581 [Accessed 12 June 2005] [ Links ].

Rheingold, H. 1991. Virtual Reality. Summit Books, New York. [ Links ]

Research Triangle Institute (RTI). 2001. http://www.rti.org/vr/w/results.html [ Links ]

Schofield, D., Noond, J., and Burton A. 2002. Reconstructing accidents: simulating accidents using virtual reality. Proceedings of the 30th International Symposium of Application of Computers and Operations Research in the Minerals Industry (APCOM), Phoenix, Arizona, 25-27 February. [ Links ]

Tracey, W.R. 1992. Designing Training Development Systems. American Management Association, New York, NY. [ Links ]

Van Wyk, E.A. and De Villiers, M.R. 2008. Usability context analysis for virtual reality training in South African mines. Proceedings of SAICSIT 2008 Annual Research Conference of the South African Institute of Computer Scientists and Information Technologists, Wilderness, South Africa, 6-8 October 2008 Cilliers, [ Links ] C., Barnard, L., and Botha, R. (eds.). ACM International Conference Proceedings Series. [ Links ]

Van Wyk, E.A. and De Villiers, M.R. 2009. Virtual reality training applications for the mining industry. Afrigraph, 6th International Conference on Virtual Reality, Computer Graphics, Visualisation and Interaction in Africa, Pretoria, South Africa, 4-6 February. [ Links ]

Weisiger, S., Karmis, M., and Agioutantis, Z. 2001. Multimedia training applications in the mining industry. Proceedings of the SME Annual Meeting, Denver, Colorado, February 2001. [ Links ]

Paper received Oct. 2011

Revised paper received Nov. 2012

© The Southern African Institute of Mining and Metallurgy, 2013. ISSN 2225-6253.