Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 no.4 Johannesburg Abr. 2013

PAPERS

Optimization of diesel usage at Uitvlugt Mine

O.G. Motlogelwa; R.C.A. Minnitt

School of Mining Engineering, University of the Witwatersrand

SYNOPSIS

Any company operating a fleet of trucks will be greatly advantaged if the associated fuel costs can be decreased. The optimal tonnage that trucks should be hauling to ensure minimum consumption of diesel fuel has been investigated. The fuel consumption in litres per ton for a fleet of trucks hauling different tonnages of iron ore was recorded in a time-motion study and the optimal tonnage was determined. The following points emerged as a result of the research:

► The diesel fuel consumption in litres per ton decreased with increasing tonnage, which means that in order to improve fuel efficiency, the trucks should carry 21 t

► As a result of queuing, Africa Truck Hire (one of the two equipment contractors) loses R282.57 per day to diesel that the trucks burn when they are left idling. It is thus advisable that the company adopt a policy of requiring the drivers to switch their engines off while queuing at the stockpile

► Filling up the trucks during each shift or rationing the quantity of diesel to 200 litres each shift has a negligible impact on the trucks' fuel efficiency

► For the company to spend 35% of their revenue on fuel, the diesel price would have to be between R8.14 and R8.78 per litre.

Keywords: optimal tonnage, idling, percentage of revenue, fuel.

Introduction

The mine

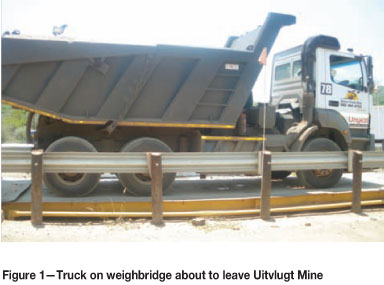

Uitvlugt is a surface iron ore mine in Limpopo Province. The operation is a joint venture between Basil Read Mining (BRM) and Blasting and Excavating (B&E). Once the ore has been fragmented by blasting it is hauled to the mine stockpiles. Two truck hire companies, Africa Truck Hire (ATH) and Richards Rentals, have been contracted to haul the iron ore from the Uitvlugt stockpile to the crushing plant at Mapochs Mine, approximately 30 km from Uitvlugt. The mine and the contractors operate five days a week on two shifts of ten hours each, beginning at 06:00 and ending at 16:00. At the time of this investigation, ATH operated 16 trucks and two excavators, with only one excavator in operation at any given time. Trucks are loaded with ore from the Uitvlugt mine stockpile and on departure they should be carrying between 18 t and 21 t. The mass of the trucks is checked at the weighbridge, as shown in Figure 1, and trucks that are too heavy or too light are sent back to the stockpile where ore is removed or added until they meet the specification.

The project

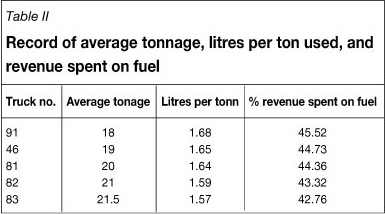

The cost of diesel fuel is for the account of the two truck hire companies, who are paid on the basis of total tonnage delivered to the Mapochs Mine crusher. According to the acting site manager of ATH on 1 December 2011, the company paid R10.02 per litre for diesel. Diesel cost is a significant expense to the truck hire companies, and any reduction in the fuel bill would be to their benefit. The percentage revenue spent on fuel was calculated from the fuel consumption and the tonnage delivered to Mapochs Mine crusher for the period 1 October to 8 December 2011 as shown in Table I. At the company's request, the revenue per ton of ore delivered to Mapochs, the total revenue, and any information deemed confidential but not compromising the report's integrity is not disclosed.

The values used to calculate the percentage of revenue spent on fuel which is shown on Table I may differ depending on the cost of fuel on a particular day, but are taken as good estimates for the purpose of this investigation. According to the site manager for ATH at Uitvlugt mine, the company should ideally spend 35% of its revenue on diesel, but this target is well below the current levels of expenditure.

Prior to November 2011 the company's policy was to allow the trucks one complete fill-up with diesel at any point during a shift, and as a consequence all trucks carried an unspecified amount of unused fuel in their tanks on the last day of the month when fuel- cost reconciliations are done. End-of-month fuel bills therefore reflect the unused diesel in the trucks. This means that the company has paid for diesel that was never used in production, resulting in a marginal increase in the monthly percentage of revenue spent on fuel. The unused fuel in trucks could also be considered as a buffer stock that marginally reduced the fuel costs for the following month.

However, in November 2012 company policy changed, allowing each truck to take on only 200 litres per shift, resulting in a 38.25% decrease in fuel costs for the November - December period (Table I). However, in November 2011 average percentage of revenue spent on fuel (42%) is still well above the required target of 35%, even though there was an improvement in December.

This project aimed at reducing the percentage of revenue spent on fuel. Mine management was of the opinion that increases in fuel costs with increasing tonnage hauled (litres per ton) was not entirely linear, but rather part of a typical cubic function cost curve. An experiment was devised to compare tonnages hauled against fuel consumption in order to identify the ideal tonnage that the contractors should haul. This would optimize the fuel bill without compromising production.

Literature review

Ideal tonnage

A study conducted by the South African Sugar Technologists' Association (Murray et al., 1980), entitled The effect of load and tractor size on tractor trailer fuel consumption, was aimed at determining the effect of increasing load sizes on fuel consumption. The report concluded that the fuel used decreased at a rate of 1.08 tit per 100 km for each ton increase in the load

The Department of Transport conducted a study entitled Effects of payload on the fuel consumption of trucks in 2007. The study looked at a range of load conditions and measured the fuel consumptions in order to show how fuel consumption varied with payload. In line with the work done by the Sugar Technologists's Association, this study also found that with increasing tonnage the fuel consumption per ton decreased (Coyle, 2007).

Both these studies provided indications that the relationship between optimal payloads and minimal fuel consumption can be determined experimentally.

Idling

In an article by the US Environmental Protection Agency (EPA), entitled What you should know about truck engine idling (EPA, 2002), three negative consequences of idling were identified. These included wastage of fuel and money, excessive engine wear, and the effects of pollution on the drivers' health. In the same article, it is generally accepted that the fuel consumed at start-up is equivalent to idling for 30 seconds, thus any idling of more than 30 seconds is a waste of fuel. It is also stated that idling for one hour can burn approximately one gallon of diesel (1 gallon = 3.79 litres). The California Energy Commission (2012) suggests that idling for 2 minutes is equivalent to driving for 1.6 km (one mile).

Full tank

Lewis (2012) suggests that not filling up to the brim with diesel can improve the efficiency by 1%. His logic is that the additional weight of a full tank of fuel reduces the power available for load hauling. Filling the tank to half or three-quarters full means the truck will drive more efficiently.

Methodology

The fuel consumption of trucks hauling certain average tonnages was calculated for each truck in terms of litres per ton hauled, using measurements of fuel consumption and tonnages hauled that were made at the diesel filling station and weighbridge, respectively. The round trip by the trucks, described below, was followed in the time-motion study.

Trucks leave Uitvlugt Mine carrying a load of iron ore to offload at the Mapochs Mine crusher:

1. Offload at the Mapochs Mine crusher

2. Fill the tank with diesel at the Mapochs Mine filling station

3. Travel back to Uitvlugt mine

4. Load the truck with ore. The tonnage was carefully controlled so that an assessment of the fuel consumption for a 20 t load meant that the truck was actually loaded with 20 t, no more and no less

5. Travel to Mapochs Mine crusher stockpile, offload the iron ore, and travel back to Uitvlugt Mine to reload. This round trip is repeated until the end of the day shift. Although there may have been slight variations see column two in Table II, the target for each truck was to complete the round trip approximately seven times per shift

6. On entering Uitvlugt for the last time during the day shift, at approximately 16:00, the truck would load with ore to be transported to Mapochs Mine at the start of the night shift

7. The night shift driver offloads the load (step 6) and then fills up with a full tank of diesel at the Mapochs Mine filling station

8. The number of loads after the first day shift fill-up and before the night-shift fill-up is recorded, as are the corresponding tonnages. The total tonnage hauled and the total litres burned is divided by the number of loads to give the average tonnage and the litres per ton for a specific average tonnage e.g. 20 t.

Results

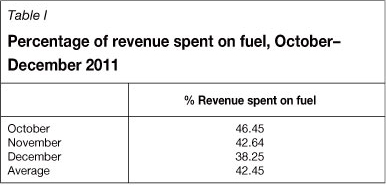

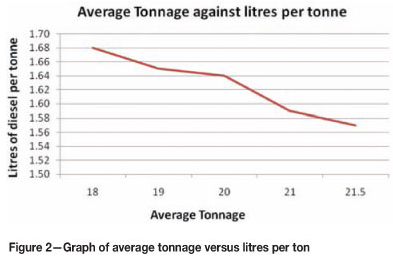

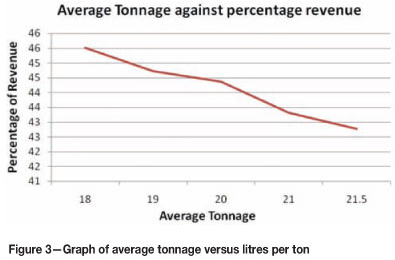

The number of round trips, fuel consumption, and total tons delivered for various trucks were determined. From this data it was possible to calculate the litres of diesel per ton, as well as the percentage of revenue spent on fuel, as listed in Table II. The fuel consumption, average tonnages hauled, and the percentages of revenue spent on fuel listed in Table II have been compiled in Figures 2 and 3.

The declining trend of litres per ton with increasing average tons (Figure 2) confirms the findings reported by the South African Sugar Technologies Association and Coyle -that there is a general decline in fuel consumption (l/t) with increasing tonnages hauled. In the range examined, from 18 to 21.5 t, the fuel consumption for the trucks under study declined from 1.68 to 1.57 litres of diesel per ton.

As a consequence of declining fuel consumption with increasing average tonnage hauled (Figure 2) there is a complementary decline in the percentage revenue that is spent on diesel fuel as the average tonnage increases, as shown in Figure 3.

Analysis of results

The iron ore mined at Uitvlugt has a bulk density of 4.5 t/m3 and a loose density of 2.5 t/m3. This means that the trucks with a load capacity of 12 m3 are able to carry a maximum of 30 t. The results reported in Table II and Figure 3 indicate an inverse relationship between tons hauled and the percentage of revenue spent on fuel in the range between 18 t and 21.5 t. This does not mean that tonnage can be added indefinitely; there will come a point where fuel costs begin to increase with increasing tonnage, but in the range examined in this study there are significant economies of scale that can be exploited. This means the company would benefit most by loading their trucks to the maximum capacity so that they carry the largest possible tonnage.

The truck chassis are able to carry up to 30 t; however, in the interests of care and maintenance of the vehicles and the haul roads, mine management has deemed it best not to let the trucks carry more than 22 t. With this constraint, and the limits of the study being at 21.5 t and accounting for the legally acceptable limit, the proposed ideal tonnage for the trucks to haul in order to optimize fuel consumption would be 21 t.

Idling

The studies conducted at Uitvlugt Mine recorded that drivers tend to leave their trucks idling while queuing to be loaded with ore. This behaviour is attributed to 'folklore' claims that idling a vehicle is good for the engine and that a truck uses less diesel during idling than it would if the engine was to be switched off every time the truck was queuing. During a study on this aspect of the research, the data in Table III was collected.

Trucks are loaded at the Uitvlugt Mine stockpile, but some of them may have to queue if other trucks are ahead of them or are being loaded when they arrive. Table III shows that on average a truck spends 4 minutes at the stockpile provided there are no other trucks ahead of it. None of this four-minute period is considered to be idling time, as the truck will be spotting and then loading. Trucks spend more than 4 minutes at the stockpile only if upon arrival there are other trucks already at the stockpile.

When average values are calculated it is generally found that a truck will indeed find another truck ahead of it in the queue at the stockpile. This means that it will spend 6 minutes at the stockpile; 2 minutes idling, and 4 minutes of productive work spotting and loading.

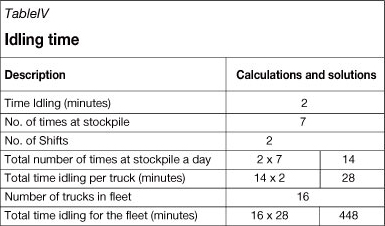

On average the trucks idle for 2 minutes each time they arrive at the stockpile. The trucks go to the stockpile on average seven times in a shift and there are two shifts in a day with 16 trucks. The calculation of the total amount of time that trucks spend idling is shown in Table IV.

The calculations in Table IV show that in one day each truck will idle for 28 minutes, and with 16 trucks in the fleet the total time spent idling increases to 7 hours 44 minutes.

If a truck can burn 3.79 litres of diesel for one hour of idling as stated by the EPA study, the fleet at ATH will burn 28.20 litres (3.79 χ 7 hours 44 minutes) of diesel in a day while idling. At R10.02 for a litre of diesel, ATH will lose R282.57 per day as a result of idling.

Apart from the idling time at the stockpile as shown in Figure 4, there are a number of other occasions during the day when the trucks are forced to idle. These are reported here in chronological order. At the start of the shift trucks are left idling so that they can warm up their engines. In order to prevent fuel wastage it is important that the trucks are idled only for the time required for warm-up. Once the trucks leave Uitvlugt Mine for the first time at the start of the shift, they all have to cross the weighbridge where a considerable bottleneck results in a long queue of trucks. Waiting in this queue is the equivalent of waiting in traffic, and although the idling wastes diesel it is not practical for drivers to turn their engines off and on, just as it is not practical for a car to switch off its engine at every traffic light.

There are a number of areas at the Mapochs Mine crusher stockpile where the trucks can dump their load, so there is no idling time as one driver waits for another to offload ore. Trucks may also be parked in an area around the fuel bay while they are waiting to fill up. If there is a queue at the filling station when they arrive, drivers note the order in which they arrived; they park, shut down their engines, and wait for their turn to fill up with diesel. Thus there is no fuel wastage as a result of unnecessary idling. One other occasion for idling the engine occurs at the end of the shift, when drivers allow the engine to cool down before switching off.

Changing fuel price

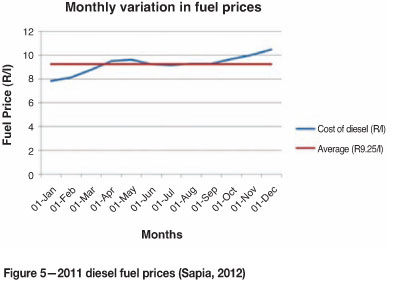

Data in Table II indicates that even if carrying the optimal 21 t, 42% of the revenue was spent on diesel fuel, which is still considerably higher than the targeted 35%. This percentage was calculated on a fuel cost of R10.02 per litre of diesel and a set amount received for every ton of iron ore delivered to the crusher.

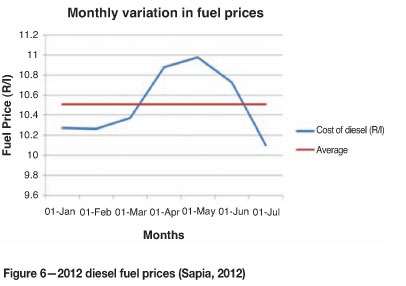

Figures 5 and 6 show the monthly variation in the price of the diesel fuel used by ATH. These prices were substituted for the R10.02 fuel price, so as to determine the price that will result in 35% of revenue being spent on fuel. From the calculations, these prices fell in the range of R8.14 per litre to R8.78 per litre. These prices are 18.76% and 12.34% respectively lower that the actual fuel price of R10.02. It can thus be seen that for the company to spend 35% of their revenue on fuel, they would have to pay on between 18.76% and 12.34% less for fuel than they currently paying, which will be possible only if fuel prices dropped and stayed low. The other option may be for the company to negotiate an increase in price for each ton delivered. However, at current prices and costs the company will not be able to lower the percentage of revenue they spend on fuel to 35%.

Filling up to the brim

ATH had the option of allowing drivers to fill up with diesel each time they were at the fuel bay, or filling up with the rationed 200 litres. These options were studied in detail, but only the effect of a full tank on fuel efficiency is discussed here.

Following the insights provided by Lewis (2012), the extra weight attributed to a full 400 litre fuel tank at a density of 900 kg/m3 is 360 kg or 0.36 t, which would be 2.29% of the total weight of the truck. If the trucks are filled with only 200 litres the mass of the fuel is 0.18 t, which would contribute 1.15% to the total mass of the 15.7 t trucks.

The mass of fuel decreases as the vehicle runs and these small percentages are unlikely to have a meaningful effect on fuel efficiency.

Conclusion

This study of payloads and fuel efficiency has identified that the best load for the trucks currently being used is 21 t. This is an upper boundary set by mine management in the interests of good maintenance of the fleet. The fact that the litres of diesel per ton of load decrease with increasing tons in the range investigated does not imply that this behaviour will continue ad infinitum. There must be a point where the litres of diesel per ton will begin to increase as the limit to the efficiency of the trucks is approached. The percentage of revenue spent on diesel also decreases with increasing tonnage. The fleet of trucks owned by ATH loses R282.57 per day from diesel that is burnt as trucks are left idling as a result of queuing. The company will not be able to lower the percentage of revenue it spends on fuel to 35% at the current prices and costs. Filling the truck to the brim or putting in 200 litres each time has a negligible impact on the fuel efficiency.

Acknowledgements

The authors would like to thank Basil Read Mining, Blasting and Excavating, Mapochs Mine, and Africa Truck Hire for the opportunity to complete this project at Uitvlugt Mine and allowing the publication of these results.

References

California Energy Commission. 2012. Should I shut off the motor when I'm idling my car. http://wwww.consumerenergycenter.org/myths/idling.html [Accessed 5 December 2012] [ Links ].

Coyle, M. 2007. Effects of payload on the fuel consumption of trucks. UK Department of Transport. http://www.freightbestpractice.org.uk/effects-of-payload-on-fuel-consumption-of-trucks [Accessed 23 May 2012] [ Links ].

Environmental Protection Agency (EPA). 2002. What you should know about truck engine idling. http://www.epa.gov/region1/eco/diesel/pdfs/Diesel_Factsheet_Truck_Idling.pdf [Accessed 26 March 2012] [ Links ].

LEWIS, M. 2012. Cheap petrol and diesel. Cut your fuel spend by a third. http://www.moneysavingexpert.com/travel/cheaper-fuel [Accessed 26 March 2012] [ Links ].

Murray, T.J., Boevey, T.M.C., and Meyer, E. 1980. The effect of load and tractor size on tractor trailer fuel consumption. Proceedings of the South African Sugar Technologists'Association, June 1980. pp. 26-31. http://www.sasta.co.za/wp-content/uploads/Proceedings/1980s/1980_Murray_The%20Effect%20Of%20Load.pdf [Accessed 26 March 2012] [ Links ].

South African Petroleum Industry Association (SAPIA), 2012. Petroleum products prices in cents per litre. http://www.sapia.co.za/industry-overview/old_price.html [Accessed 26 July 2012] [ Links ].

Paper received May 2012

Revised paper received Feb. 2013.

Paper written on project work carried out in partial fulfilment of B. Eng (Mining)

© The Southern African Institute of Mining and Metallurgy, 2013. ISSN2225-6253