Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 n.3 Johannesburg Mar. 2013

PLATINUM CONFERENCE 2012

The minerals plant of the future - leveraging automation and using intelligent collaborative environment

D.G. Almond; K. Becerra; D. Campain

FLSmidth Inc.

SYNOPSIS

Low-grade, complex mineral deposits have resulted in the need for complicated large-throughput processing plants delivering increased productivity, reliability, and utilization, together with reducing operational costs. Complex mineralogy has resulted in complicated process flow sheets designed to recover minerals as efficiently as possible. In addition, the remote location of many minerals-processing plants, continuously rising energy costs, and fierce competition pose significant challenges to the modern mine, compounded by a global scarcity of qualified and experienced operational personnel.

Over the last decade the Internet and automation technologies have undergone major advancements. Automation technologies, solutions, and concepts that existed, but were considered risky or unreliable prior to the year 2000, have now gained acceptance and matured. Furthermore, new technologies and different collaboration schemes have appeared, offering innovative solutions to the mining industry to address many of the challenges described. These advancements in reliable remote systems that access technology through the Internet provide significant opportunity to support mining operations, enhance process performance, provide engineering services, and proactively anticipate and execute maintenance services.

This paper references a global survey of automation trends in the mining industry and the potential for an intelligent collaborative environment using automation technologies to exploit opportunities in operating the plant of the future, increasing effectiveness, and reducing operational costs. A variety of possibilities are described, including asset management solutions, remote access capabilities, performance monitoring solutions, advanced process control technologies, and the formation of an intelligent collaborative environment. A real example where this technology is used to support the operation and maintenance at a cement plant in Egypt is given to underpin the concepts described in this paper.

Keywords: plant automation, process control, remote access, intelligent collaborative environment.

Introduction

The technology used in mining processes has changed little over the past twenty years. However, rising cost and fierce competition have stimulated global consolidation and the incessant search for new opportunities in operating the mine of the future, increasing effectiveness, and reducing operational cost. Fluctuating markets, cost control, and low- grade complex mineral deposits have driven the need for delivering increased productivity, reliability, and utilization.

Automation was necessary to maintain continuous safe production in mining plants during the 1970s and 1980s. This approach changed during the 1990s, when automation was also seen as a way to increase efficiency and improve quality. Advanced process control also provided a good opportunity to improve process performance, but mixed results and the poor availability/reliability of some of these early solutions negatively affected the general acceptance of advanced process control systems as a way to optimize operations.

During the 1990s, most automation developments were carried out at the plant level. Concepts such as remote monitoring, asset management, remote optimization, remote engineering, and collaborative environments began to appear, but their application was limited, with mixed results. The technology of the time did not succeed in getting the most from these solutions and concepts. However, automation became essential for mining operations seeking effective plant control, and companies realized the potential opportunities offered by automation technologies, especially for multinational and global companies looking for consolidation, standardization, and the utilization of shared resources across their organization.

Over the past decade there have been significant developments in plant automation and information systems. Automation technologies, solutions, and concepts that existed but were considered risky or unreliable prior to the year 2000 gained acceptance and matured. In this decade, the Internet has played a major role in supporting innovative solutions for the mining industry. Information can be available anywhere and at any time, leveraging scarce expertise and remotely supporting and enhancing mining processes. Services and opportunities only envisioned during the 1990s are now reality. Figure 1 illustrates the evolution of automation in a mining plant.

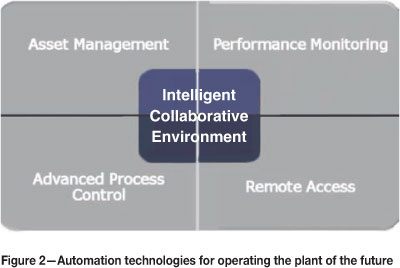

This paper reviews a global survey of automation trends and describes various automation possibilities that have the potential to address industry demand for increased effectiveness and reduced operational costs. Some of the technologies referred to are asset management solutions, remote access capabilities, performance monitoring solutions, advanced process-control technologies, and the formation of an intelligent collaborative environment.

An asset management system (AMS) is neither a single product nor a unique solution; it is a framework to measure performance, plan, and to execute preventative and corrective actions. Although vendors and companies may agree on the basic definition and scope of an asset management system, there remain many interpretations for asset management.

Remote monitoring and performance monitoring solutions provide a great opportunity to measure and enhance mining operations. Global companies can support operations lacking highly skilled resources and located in remote areas by using remote monitoring technologies. Performance monitoring solutions can be used to automatically measure performance of processes and solutions, identifying opportunity areas.

Advanced process control is now widely accepted as a way to optimize mining operations. Existing advanced process-control technologies are consolidated to optimize mining processes, and the combination of process control techniques has proven successful.

More recently, the formation of intelligent collaborative environments combining local and remote resources and automation systems are being considered for operating the plant of the future. Figure 2 illustrates available automation technologies for increasing the effectiveness and reducing costs in a mining plant. Examples of existing applications and operating systems are described in this paper, including the operation and management of a cement plant in Egypt.

Best practices for automation in the mining industry

In 2011, FLSmidth, in collaboration with ARC Advisory Group, conducted a confidential survey aimed at developing a better understanding of the best practices in process automation currently employed by the mining, minerals, and metallurgical processing industry. One hundred and ten respondents from around the world contributed to the survey, which examined the challenges encountered in mining operations, strategies for automation, technologies employed, and the benefits they yield. Research included how people inform themselves on automation, their plans for implementing automation in the future, and how they adapt their strategies. The resulting report based its findings on the answers of three defined groups of respondents, described as Strategists, Implementers, and Adopters.

Strategists - Strategists are well-informed; regard automation as a strategic issue; have already implemented a high degree of automation and stress functionality, in-house serviceability, local support, and reliability; and have quantified benefits as the main solution selection criteria

Implementers - Implementers are fairly well-informed, use a mix of strategic and tactical processes in their approach to process automation, have installed an average degree of automation with medium to large gaps, and regard functionality and reliability as the main solution selection criteria

Adopters - Adopters have fair knowledge, varying between areas, have installed a lower degree of automation with large gaps, have aggressive plans for extensions and new installations, and regard functionality and reliability as the main solution selection parameters.

The survey identified seven major areas of interest:

- Operational challenges

- Knowledge of automation and strategy

- Current automation practices

- Benefits obtained

- ppreciation and future plans

- Approach, rationale, and criteria for investment

- Strategy adaptation.

Operational challenges

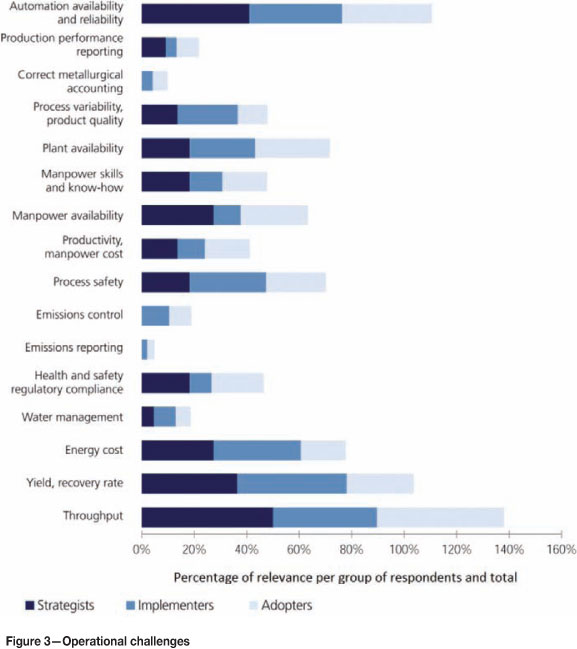

Overall, the trend is for factors that affect production value, such as throughput and yield, to be considered more important than cost factors such as energy and personnel costs. The top three challenges are throughput, automation availability and reliability, and yield or recovery rate. These three challenges are all related to total, sellable production quantities - i.e. production value.

Energy cost, process safety, and plant availability are secondary. Energy is a highly visible financial cost factor. Next is manpower availability, which affects production quantity, supporting the focus on production value. Scarcity of skilled personnel is an issue, particularly in remote regions, at a time when production needs to be maximized in order to realize buoyant commodity prices. Figure 3 illustrates the operational challenges when operating a mine.

Knowledge of automation and strategy

Strategic focus is highest among Strategists, with 40 per cent considering it to be a strategic enterprise issue, while this factor is lowest among Adopters. Tactical, case-by-case application of automation is strongest among Adopters, who look to general application of automation with highly visible applications. Implementers focus more on only general application.

Current automation practices

Generally, Strategists have more knowledge than Implementers, with 80 per cent claiming expert knowledge. Strategists automate more than Implementers, with Adopters automating the least. Seventy per cent of Strategists make clear choices and automate most domains well, with the exception of operator training simulation and material accounting domains, where automation is as yet rare.

Over 90 per cent of Strategists have well-automated PLC-based process control, historization and visualization, on-line analysis, and advanced instrumentation, while at least 70 per cent have well-installed advanced process control, remote plant monitoring, operation, support, diagnostics, and maintenance.

Benefits obtained

The areas where respondents hope to gain the biggest benefit from automation are throughput, yield/recovery rate, energy cost, plant availability, and automation reliability and availability. These areas correspond closely with the main operational challenges. Strategists rate the benefits obtained in almost all performance areas as either critical or very important. These ratings are less common among Implementers and in the minority in Adopters. Figure 4 illustrates the findings for benefits obtained through implementing automation technologies.

Approach, rationale, and criteria for investment

More than 70 per cent of Adopters and 80 per cent of Strategists feel comfortable assessing the possible gains associated with investments in automation and their economic impact, but feel they need additional information. There is a need for information about available solutions to be continuously updated. This includes knowledge about economic benefit assessments. Aligning workers and motivating them are top areas where there is a lack of information. Figure 5 illustrates the findings for approach, rationale, and criteria for investment in automation.

Appreciation and benefits

Based on this industry research and survey, the conclusion is that the minerals industry in general agrees that throughput, yield/recovery rates, reduction in energy costs, and plant availability are the main benefits expected through leveraging plant automation. Safety through reduction in the numbers of people in production areas, as well as reduction in wage costs and overcoming skills shortages, are also recognized benefits possible through innovative use of automation technology.

Asset management

According to Campbell1, asset management excellence is many things, done well. It is when a plant performs up to its design standards and equipment operates smoothly when needed, with maintenance costs tracking on budget, and with reasonable capital investment.

Asset management excellence facilitates a high service level and fast inventory turnover, and most of all; asset management excellence is the balance of performance, risk, and cost to achieve an optimal solution.

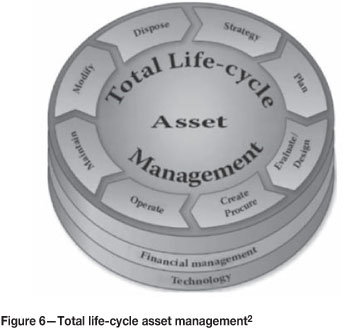

Maintenance strategies have drastically changed over the decades; from no maintenance, to preventive, planned, and condition-based maintenance. This has changed the way equipment is operated: from run-to-failure to prevention and then to predictable breakdowns.

The challenge of maintenance excellence is to provoke thought on strategic issues around maintenance and to develop tactics that minimize breakdowns and maximize the rewards of planned, preventive, and predictive work. The asset management life-cycle model (Figure 6), also introduced by Campbell2, should be considered to ensure that each organization understands the full impact of an asset purchase or disposition and the role maintenance can play to promote the length and quality of the asset's life.

Asset management is a systematic process for maintaining, upgrading, and operating physical assets. There is no single and unique definition of an asset management system (AMS); each supplier has its own interpretation and scope, but in general all agree that an asset management system is a framework for measuring the health and performance of physical assets to identify potential problems before they escalate, allowing the proper short-, medium- and long-range planning.

Automation and technological advances provide the opportunity to develop and implement cost-effective asset management solutions and strategies that increase effectiveness and reduce operational cost. In today's competitive environment, a properly implemented and applied asset management system can:

Maximize availability and utilization

Minimize the risk of breakdowns

Minimize operational and maintenance cost

Predict the failure of a critical part and facilitate prevention

Increase the time between failures

Decrease the time for repair

Decrease the cost of ownership

Reduce the safety risk to employees and the public as much as possible.

Nearly every asset in a processing plant can be classified into two major classes: production and automation. Asset management for production assets focuses on monitoring heavy machinery, electrical equipment, and motors. Asset management for automation assets focuses on field measurement devices, the networks that connect these devices, and process analysers.

The conclusion is that a complete and well-implemented asset management system comprises at least the following:

Preventive, predictive, and condition-based maintenance

Automatic notifications (process, alarms, events, etc.)

Advanced diagnostics (instrumentation, devices, actuators, etc.)

Downtime reporting and tracking

Performance monitoring (key performance indicators -KPIs) and web visualization

Integration with computerized maintenance management system (CMMS)

Asset/object information.

Performance monitoring

Rising costs and fierce competition represent a challenge and demand a change in how the mining industry is operated. To effectively tackle these challenges, an efficient way to measure and close the gap between the management goals and the performance of the process control must be established. A performance monitoring system is required to measure the process control performance and identify the gap with the management objectives, thus enabling the decision-making process to close this gap.

As mentioned, information technologies have emerged faster than any other technology during the past decade, providing tools to automate many tasks at the operation level. Plant information management systems allow the integration of process data, business data, and people, which are the foundation to measure plant performance and no longer an option for operating the plant of the future.

A plant information management system automatically gathers and archives data, converts this data into information, and makes it available to personnel with the authority to access it. Data is gathered from different sources such as process, production, quality, business systems, and manually-introduced data. Figure 7 illustrates typical plant information system architecture. In implementing an effective plant information management system, several components are required:

Real-time information management system or data historian

Tools to convert data into information

Reporting and analysis tools or applications

Web-based solution to monitor performance.

Real-time information management systems gather and historically record data from all the different sources, and include the interfaces to connect with other systems. Tools to convert data into information are required to calculate the process performance by applying business rules. As a result, KPIs are generated, which are used to measure the process performance.

Reporting and analysis tools are used by operators, metallurgical engineers, and managers to analyse real-time and historical data to identify problems and their root cause. The web-based solution for monitoring performance allows plant personnel to evaluate the plant performance indices and prepare strategic actions to close the gap with the management objectives. One such example of strategic action could be the implementation of an advanced process control system to address process instability or product quality.

The performance monitoring system works together with the asset management solution and provides the framework to measure the performance and health of the plant assets. This performance measurement must include individual machines and process areas, but should also be extended to cover the process control performance including any advanced process control systems.

Remote monitoring

An unfortunate fact of life for many companies involved in minerals processing is that exploitable deposits are increasingly located in remote locations that can have harsh climates and security concerns. The global shortage of experienced staff, combined with the location of new plants and high staff turnover, has created significant challenges in the operation and maintenance of these remote facilities. One potential viable solution is to use technology to enable tasks traditionally performed at the plant location to be performed at any location that can have a network connection to the plant. In some cases, remote access systems are already being used for remote monitoring and basic support for operations.

The complexity of information systems security is beyond the scope of this paper and is addressed only superficially to highlight the necessity. Any remote service strategy requires connections between the network of the plant control system and other networks, which create the potential for security risks, including:

Unauthorized ability to monitor and control equipment and processes

Unauthorized ability to change system programming or configuration

Unauthorized access to, and dissemination of, confidential information (production data, intellectual property, environmental emissions, etc.)

Loss of production, data, or equipment damage due to viruses, malware, and hacking.

These risks must be addressed by implementing technologies and procedures including, but not limited to:

Strong and fine-grained user access control for all systems

Confidentiality agreement between involved parties

Definition of, and agreement regarding, which information can be sent from the plant systems to the remote centre

Segmentation of networks with firewalls between segments

Installation and regular updating of antivirus software on all systems

Regular updates of process control systems and computer operating system software

Proactive monitoring of process control systems and networks

VPN tunnel with encryption between the mine and the remote centre.

The US National Institute of Standards and Technology recommends a defense-in-depth strategy that layers security mechanisms such that the impact of the failure in any one mechanism is minimized (Stouffer, Falco, and Scarfone3).

Provided the above is well addressed, it is possible for difficult-to-access sites or operations with small staff contingents or insufficient skills to be supported technically and consultatively by using remote monitoring technologies.

Advanced process control

In the operation of a mining plant, critical process variables oscillate and require the constant supervision of an operator who interprets the process conditions and makes adjustments to control the process to the desired targets. The complex dynamics and interactions among the process variables make the task of controlling a mining process a non-trivial activity, resulting in an unnecessary use of energy and resources. Advanced process control (APC) systems reduce process oscillations and lead the process to optimal points where a more stable operation is obtained, achieving better production throughput and quality.

APC systems designed using techniques specifically suited for control of multivariable processes are aimed specifically at stabilization and optimization of process control. The results delivered by these systems often achieve the desirable increased throughput, reduced energy costs, and improved product quality. Based on measured plant performance, strategic control actions are implemented to reduce the gap between the management objectives and the measured plant performance.

Older expert systems, which tried to emulate operator best practices, were used mainly during 1980s and 1990s as advanced process control solutions. Mixed results and the availability/reliability of the existing solutions negatively affected the general acceptance of those systems as an effective method for process control optimization. However, with the emergence of model predictive control (MPC) technology during the past decade it has been possible to employ a new approach involving mixing advanced control techniques to successfully control and optimize mining processes.

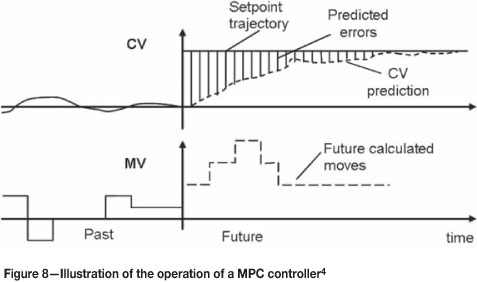

MPC technology uses a mathematical model of the process to predict future process behaviour and pre-plan actions in the future to attain desired targets. The controller output is a manipulated variable (MV) applied to the inputs of the process and the process model, and is a part of every MPC controller. The process model computes a predicted trajectory of the controlled variable (CV) that is the process output. After correction of this trajectory for any mismatch between the predicted value and an actual measured value of the controlled variable, the predicted trajectory is subtracted from the future trajectory of the set point to form an error vector4 (Figure 8).

Yutronic and Toro5 explained that MPC does not designate a particular control strategy, but a set of automatic control methods that uses explicit process models in order to calculate a control signal by minimizing an objective function, which according to Camacho6 offer some interesting advantages such as:

It is particularly attractive because its concepts are very intuitive and it is simple to tune

It can be used in a wide variety of processes, from the simple ones to processes with complex dynamics and large dead times, non-minimum phase, unstable or multivariable

The multivariable cases can easily be dealt with

It intrinsically has compensation for dead times

It introduces feed-forward control in a natural way to compensate for measurable disturbances.

Several successful implementations presented during the last few years reinforce the benefits provided by modern process control technologies7-10

Production performance and circuit stability can be significantly improved by using an APC solution. As an example, Table I illustrates the production improvements achieved in the grinding circuit of Nkomati Nickel Mine in South Africa10.

Practical application of the intelligent collaborative environment

A significant problem for many companies involved in minerals processing is that the resources available for exploitation are increasingly located in remote arid locations having little infrastructure and with security concerns. To counter this, many modern mining operations are now incorporating the use of remote services into their operating strategies to address the challenges of operating in these remote and difficult environments.

The Ramliya cement factory, owned by Arabian Cement Company and located in Egypt, commenced production in 2008. The plant produces 6000 tons of cement per day. All major production equipment at the plant was supplied by FLSmidth A/S, who also executed the Engineering, Procurement and Construction Management (EPCM) services, including process control and quality control systems. Before starting production at the facility, the plant owner signed an operations and maintenance (O&M) contract with NLS Supervision, an FLSmidth Group company, under which the plant operator provides all staff required to operate and maintain the facility. The contract includes a bonus/penalty payment agreement to ensure alignment of the parties' goals under the contract and to provide incentives for the plant operator to improve operational efficiency and optimize maintenance of the plant.

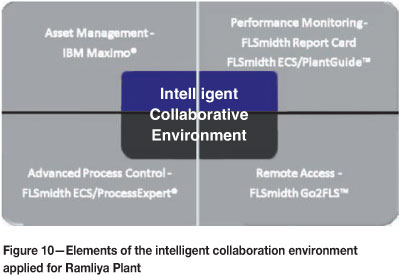

To leverage advantages provided by automation technology and to support the goals of O&M contracts, FLSmidth inaugurated an Intelligent Collaborative Environment (ICE) Center in 2011. The facility comprises an operations room and meeting rooms located at the company's headquarters in Copenhagen, Denmark. The operations room has an operator's console similar to that normally installed in the control room of a plant, and enables engineers in Copenhagen to monitor and support the operations of plants anywhere in the world. The meeting rooms allow groups of engineers to meet to solve any potential mechanical, process, or control issues indentified by the systems and communicated to the ICE Center.

Robust and reliable audio and visual communications systems are installed to facilitate remote collaboration, including VOIP phone, video conferencing, text chat, and web meetings. CCTV cameras are installed in the plant and are accessible via VPN connection. Figure 9 illustrates one of the ICETM Center operations consoles.

Although the initial focus of the ICE Center is to support plants with O&M contracts such as Ramliya, the ICE Center concept will be fine-tuned and based on the experience gained, rolled out to other locations in support of client's plants around the world. Figure 10 illustrates the different elements of the ICE Center.

Zamora11 also introduced a multi-site remote support centre for knowledge management and long-term process performance improvement. This centralized support centre provides real-time monitoring of open-platform process automation systems, and online access to process data and control applications information for multiple sites.

Asset management at Ramliya

The IBM Maximo® Enterprise Asset Management system (AMS) is used to manage the maintenance of the plant production assets and the plant operator's maintenance tools and parts inventory. The AMS has an interface to the plant Management Information System (MIS) to gather equipment operating hours and production volume. The MIS receives that information from the Process Control System (PCS).

The AMS is used to schedule and record preventative maintenance activities. As the AMS has records of actual equipment operating hours and production volumes, the frequency of maintenance services can be optimized to match wear based on actual usage. In contrast, schedules based on time can result in under- or over-scheduling of maintenance work, resulting in waste or reduced asset life.

The AMS is also used for management of spare parts utilized in the maintenance programme. The use of actual equipment operational data in planning of wear part replacement intervals can help to optimize the replacement interval planning and reduce the risk of not having the needed spare parts in inventory. The replenishment of inventory can be triggered by using a set interval of equipment run hours or production volume.

Performance and condition monitoring at Ramliya

Online performance and condition monitoring at Ramliya uses a combination of the PCS, MIS, and a ReportCard system. Key process variables (temperature, vibration, flow etc.) and equipment status are gathered by the PCS. Exceeding alarm limits or changes in equipment operating status triggers an event in the alarm/event system to notify the operator that corrective actions may be required. If the alarm was triggered by equipment shutdown, a downtime reason can be noted in the event system along with the event data generated by the PCS.

Events are used to trigger notifications by SMS to staff and contain specific equipment and process variables that they are interested in. For example, a stack emission value that exceeds permitted limits can trigger a message to the environmental manager that contains the current stack emissions levels. High temperature on a critical bearing can trigger a message to a maintenance scheduler so an inspection of the bearing can be planned. In addition to real-time data, all information collected in the MIS can be used to generate a report. Access to this type of information allows the maintenance staff to move to predictive rather than preventative maintenance.

All of the process and status variables can be used for calculation of KPIs, including overall equipment effectiveness (OEE). This can be done either in the PCS, MIS, or ReportCard applications, depending on the user's role. Control room operators use the PCS system; users requiring periodic reports (daily, monthly) or customized reports use the MIS system, and users needing to see a quick overview of KPIs use the ReportCard web interface. Data can be exported from the MIS to Excel or text files for further analysis. Figure 11 illustrates a typical MIS report.

Remote access at Ramliya

Remote access systems are in place to enable remote monitoring, support, and operations. Although remote operation is possible and has been tested, control of the plant remains with the local staff at Ramliya for practical reasons. Remote performance and condition monitoring is enabled by the web interface of the MIS and the ReportCard systems. Data is sent from the MIS at the plant to servers located at the ICE Center in Copenhagen using FLSmidth's LiveConnectTM system through a secure VPN connection.

Troubleshooting, support, and modification to the PCS, automated quality control, and APC systems can be carried out remotely by enabling remote control of systems engineering workstations. At Ramliya a Go2FLS remote support system is used both reactively and proactively to allow control system engineers located at any FLSmidth office to provide support. If an issue is found by the local plant staff that requires attention of a specialist engineer not available at the plant, the local staff can initiate a secure remote connection to allow the remote engineer to provide support.

The system is also used proactively when an engineer monitoring the plant KPIs from a remote location finds there is some system that needs attention. If the engineer has the appropriate user rights, they are able to log in and take control of the engineering workstation to resolve the issue causing the KPI to be below target value. These actions include programming and configuration changes, control loop tuning, software updates, antivirus definition updates, system backups, and investigative troubleshooting.

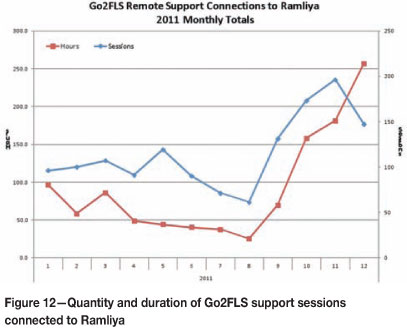

The support provided by the ICE Center to the Ramliya plant is evidenced by the quantity and duration of remote support connections to the plant using the Go2FLS system. The data in Figure 12 shows that there were an average of 115 connections made to the plant each month and an average of 91 hours supporting the activities at Ramliya. This data is an indication of the support level, but does not include time spent monitoring data sent from the plant systems or providing support by phone, video conference, or email.

Advanced Process control at Ramliya

The FLSmidth ECS\ProcessExpert® (PXP) is used to provide advanced process control of the milling and pyro-processing production units. The system uses model-predictive control and fuzzy logic technologies to implement consistent operational strategies that maximize production, minimize energy consumption, and maintain quality objectives.

In operations where there can be continuous changes in the plant feed characteristics, experience has shown that it is necessary to occasionally adjust process strategies in the APC systems. Maintaining good system tuning is crucial to maximizing the value provided by the systems. The performance monitoring and remote access systems described allow specialist engineers to monitor system KPIs and log in remotely as needed to adjust tuning parameters and implement strategy changes. This eliminates the need to have on-site experts at the plant and ensures continued optimal process performance through this proactive involvement.

Building teamwork in virtual teams

When a group of people are working together on a common goal from different physical locations, they are considered to be a virtual team. Building successful virtual teamwork is more challenging than in the traditional team that works physically close together. A study of 70 virtual teams found that only 18 per cent were considered highly successful, and the remaining 82 per cent fell short of their intended goals12. The success of a remote support strategy is as dependent on the success of the virtual team as it is on technology. A successful implementation of technology will fail if sufficient consideration and planning is not given to addressing the potential hurdles to effective virtual teamwork. If the local plant team does not support the goals of the strategy, it will likely be a failure. The local and remote teams must accept working together as one team towards a common goal. Issues to consider in strategy planning include, but are not limited to:

Language

Cultural differences

Resistance to change

Fear of job loss

Lack of trust

Lack of understanding of the strategy and tactics

Difference between the goals of the remote and local teams

Lack of systems training

Time zone differences.

Conclusion

Rising cost and fierce competition have stimulated global consolidation and the incessant search for new opportunities in operating the mine of the future, increasing effectiveness, and reducing operational cost. Over the past decade there have been significant developments in plant automation and information systems. The Internet has played a major role in supporting innovative solutions for the mining industry. Information can be available anywhere and at any time, leveraging scarce expertise and remotely supporting and enhancing mining processes.

Industry research and surveys confirm that the minerals industry in general agree that throughput, yield/recovery rates, reduction in energy costs, and plant availability are the main benefits expected through leveraging plant automation. Asset management solutions, remote access capabilities, performance monitoring solutions, advanced process control technologies, and the formation of an intelligent collaborative environment are among the various automation possibilities that have the potential to address industry demand for increased effectiveness and reduced operational costs.

The example presented in this paper demonstrates the potential opportunities in supporting the operation of a plant using an intelligent collaborative environment through the combination of several automation technologies. The result has realized savings in support travel costs and time loss that traditional support entails. The operation and management contract has proven to be mutually beneficial, and the plant owner has subsequently contracted the supply of a second cement production line at Ramliya to be operated under a similar contract.

References

1. Campbell, J.D., Jardine, K.S., and McGlynn, J. Asset Management Excellence. Optimizing Equipment Life-Cycle Decisions. Taylor & Francis Group. Boca Raton, FL, 2011. p. 1. [ Links ]

2. Ibid. pp. 2. [ Links ]

3. Stouffer, K., Falco, J., and Scarfone, K. Guide to Industrial Control Systems (ICS) Security. National Institute of Standards and Technology, Gaithersberg, MD, 2011. [ Links ]

4. Blevins, T.L, McMillan, G.K., Wojsznis, W.K., and Brown. M.W. Advanced Control unleashed. ISA - The Instrumentation, Systems, and Automation Society, 2003. p. 309. [ Links ]

5. Yutronic, I. and Toro, R. Design and implementation of advanced automatic control strategy based on dynamic models for high capacity SAG mill. 42nd Annual Meeting of the Canadian Mineral Processors. Canadian Institute of Mining, Metallurgy and Petroleum, Ottawa, ON, 2010.pp. 461-472. [ Links ]

6. Camacho, E.F. and Bordons, C. Model Predictive Control. 2nd edn. Springer-Verlag, London, 2004. p. 2.

7. Sims, S., Lacouture, B., and McKay, J. Grinding expert system operation at Red Dog Mine. International Autogenous and Semiautogenous Grinding Technology 2006, vol. III. Department of Mining Engineering, University of British Columbia, 2006. pp. 242-252). [ Links ]

8. Parker, S., Thong, S., Sloan, R., Pass, D., and Lam, M. Comparative study of grinding expert control on two SABC circuits at Barrick Gold Corporation. International Autogenous and Semiautogenous Grinding Technology 2006, vol. III. Department of Mining Engineering, University of British Columbia, Vancouver, B.C., 2006. pp. 207-222. [ Links ]

9. Rogers, M., Almond, D.G., Maru, T.D., and Becerra, K. Model predictive control application at Lumwana Copper Concentrator. Automining 2010. 2nd International Congress on Automation in the Mining Industry, Santiago, Chile, 10-12 November 2010. [ Links ]

10. Almond, D.G., Becerra, K., Maru, T.D., and Smit, D. Model predictive control as a tool for production ramp-up and optimization at the Nkomati Nickel Mine. 5th International Conference on Autogenous and Semiautogenous Grinding Technology, Vancouver, B.C., Canada, 25-29 September 2011. [ Links ]

11. Zamora, C., Codelco Chile., and Honeywell Chile. Kairos Mining: a comprehensive approach to sustained long-term benefits in copper processing plant automation. 42nd Annual Meeting of the Canadian Mineral Processors, ottawa, ontario, Canada, 19-21 January 2010.

12. Govindarajan, V. and Gupta, A. Building an effective global business team. MIT Sloan Management Review, 2001. p. 63. [ Links ]

© The Southern African Institute of Mining and Metallurgy, 2013.

ISSN 2225-6253. This paper was first presented at the 5th International Platinum Conference 2012, 18-20 September 2012, Sun City, South Africa.