Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.113 no.3 Johannesburg mar. 2013

PLATINUM CONFERENCE 2012

The basic resource equations (BRE and BR2RE) - a new approach to the definition and reconciliation of mineral resources and reserves at Anglo American Platinum Ltd

D.H. Diering; D.C. Andersen; G. Langwieder; G.L. Smith

Anglo American Platinum Limited

SYNOPSIS

Definition of mineral resources and reserves forms the basis for effective mine planning and reliable public reporting of mineral assets. Historically, the mineral resource and reserves declaration process has been the domain of the geology and surveying disciplines, with the declaration of the reserves by the surveyor being based on the application of modifying factors to the declared resources available for mining. As part of an ongoing process to improve efficiency, reliability, and reproducibility of results, this approach has been revised and enhanced through the introduction of a revised process and reconciliation tools.

The revised approach to reserve definition is based on the definition of scheduled resources, at an appropriate confidence estimate in the context of an approved business plan, over the anticipated life of the mineral asset being applied to define reserves. This planning and scheduling is developed, during the annual business planning process, by the mine planning department using tools such as CADSMineTM. The scheduled area together with the application of revised modifying factors is tabulated in the BME (basic mine equation) and reflects the mine production plan over time.

Simplification of the modifying factors to dilution and losses underpins the simple yet robust approach to improved definition of reserves in this process and in the basic resource to reserve equation (BR2RE). Dilution intrinsically affects grade but not metal content, whereas the losses reflect both the efficiency of mining and planning and are reflected in metal losses, area losses, or both. Reconciliation of the derived 'resource converted to reserve' area (which is based on the business plan from CADSMineTM) versus the 'resource available for mining' (which is derived from DatamineTM) underpins the robustness and auditability of the reserves declaration. This R&R accounting and reconciliation approach is transparent and facilitates interrogation of the logic and rationale of long-term business planning and project strategy.

These numbers are processed and reported in the logic of the basic resource equation (BRE), which also addresses aspects such as white areas (future and historic), tail management, and partial extraction (non-scheduled pillars, etc.) in compliance with SAMREC definitions. Areas that do not have the necessary confidence and data support to be declared as resources find their space as pre-resource (outside the domain of public reporting), outlining existing potential for future extraction and reporting. Use of the BRE leads ultimately to a complete, refined accounting and reconciliation-oriented approach for all production entities.

The revised resource and reserve process includes the discipline of mine planning as intrinsic to the definition and declaration of resources and reserves. Subsequent to the change in process, the resources and reserves have truly become the domain of the mineral resource management discipline.

This paper defines the logic of the basic resource equations and outlines their application in the definition and reconciliation of mineral resources and reserves at Anglo American Platinum Limited.

Keywords: mineral resources, mineral reserves, mine planning, scheduling

Introduction

Anglo American Platinum first implemented an integrated business planning approach in 2003 under the direction of the then Strategic Long Term Planning department. The business planning (BP) process starts with the establishment of the mine extraction strategy (MES), followed by the short-term planning phase over a three year budget period. The production scheduling from the short-term planning is then extended from year four of the plan to end of life to create the life-of-mine (LOM) plan. Reserve declaration is an outcome of the business plan towards the end of the BP cycle. The BP process has continued to evolve with advances in technology and an improved appreciation of the business value chain with full implementation of the mineral resource management (MRM) philosophy at Anglo American Platinum in 2009.

As part of an ongoing process to improve efficiency, reliability, and reproducibility of reserve declarations, a full review of the Resource and Reserve (R&R) process was initiated during 2010, with the prime objective of implementing a reconciliation process that meets or even establishes global best practice in R&R reporting.

This review led to the development and implementation of the BRE (basic resource equation) and the BR2RE (basic resource to reserve equation) as part of an integrated, cross-functional BP process.

Integrated business planning

The BP process, as part of strategic long-term planning of the mineral asset portfolio, is conducted on an annual cycle comprising the following sequence of events:

Development and review of a mine extraction strategy for the mining right area

Development and review of a production profile for a three-year budget period

Development and review of an operation labour plan for a three-year budget period

Development and review of operating cost and capital estimates for the budget period

Development and review of the production profile for the LOM plan (year four onwards)

Development and review of a LOM labour plan

Development and review of operating cost and capital estimates for the LOM

Reconciliation and declaration of mineral resources and reserves associated with the business plan.

This process is inclusive of current projects in execution and anticipated projects (expansion and replacement) that support the planned production profile developed through the mine extraction strategy. Throughout the business planning process, multidisciplinary reviews (MDRs) are conducted at the conclusion of each phase to ensure quality of outputs. The review team comprises technical discipline heads from within MRM coupled with the mining engineer and discipline head specific to the review e.g. planning, human resources, and finance.

The mine extraction strategy is a physical depletion plan that covers the area over which mining rights have been granted. As such it is not time-limited and has a life, which is a result of the optimal scale of operations, technology selection, mining layouts, existing asset base, and constraints. The multi-discipline review conducted on the MES reviews all extraction options for the mining right, with selection of a final option based on value accretion and integration into the company portfolio. The operation then implements the approved MES option into the short-term (three-year budget period) and long-term (LOM) plans.

The long-term plan (LOM) extends from year four of the optimized extraction option through to exhaustion of the mineral resource contained in the mining right. The LOM plan thus comprises investment centres at different levels of confidence estimate and mineral resource classification.

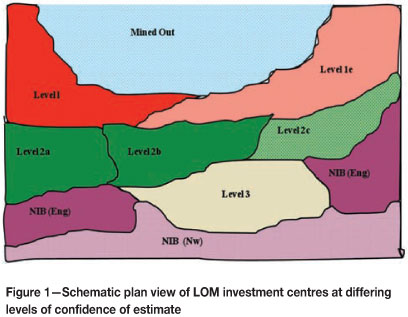

These levels of confidence estimate for the various investment centres that make up the plan are:

Level 1 - existing operations not requiring project capital (only stay-in-business capital)

Level 1e - approved capital project in execution (expansion or replacement projects)

Level 2a - feasibility study with capital estimates within ±10 per cent.

The minimum proportion of mineral resources and confidence level required in the payback period footprint, at the end of a feasibility study, is:

More than 60 per cent in the measured category

Less than 30 per cent in the indicated category

Less than 10 per cent in the inferred category

Level 2b: pre-feasibility study with capital estimates within ±15 per cent.

The minimum proportion of mineral resources and confidence level required in the payback period footprint, at the end of a pre-feasibility study, is:

More than 70 per cent in the indicated category

Less than 30 per cent in the inferred category

Level 2c: conceptual study with capital estimates within ±25 per cent.

The minimum proportion of mineral resources and confidence level required in the payback period footprint, at the end of a conceptual study, is:

Not less than 100 per cent in the inferred category

Level 3 - scoping study with capital estimates within ±30 per cent.

Level 3 plans effectively cover the remaining extent of potentially exploitable resource within the area covered by the current mining authorization and are generally not subjected to a rigorous stage-gate review process. Two sub-categories exist in level 3: 3a and 3b:

- Level 3a (Scoping study at ±30 per cent estimate confidence)

- Level 3b (Scoping study at >30 per cent estimate confidence based on pre-resource material 'blue sky' opportunities).

Despite the best efforts to plan and find viable means of extraction, an investment centre (project) may not form part of the business plan for two reasons: economics or insufficiency of engineering work. This gives rise to two other categories:

Not in business plan - NIB (eng) - these are uneconomic investment centres that may have been subject to extensive study work through to pre-feasibility level but are uneconomic for current long-term planning parameters

Not in business plan - NIB (nw) - these are investment centres that have not had any study work done on them to date or where exploitation is planned well in the future (>30 years).

The relationship between the different levels of confidence for a LOM plan is represented schematically, in plan view, in Figure 1.

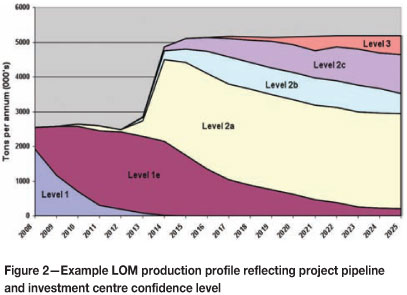

However, typically the LOM plan is represented as a production profile (see Figure 2), which represents planned output and indicates the sequencing of anticipated projects.

Examination of these profiles can give insight into inherent risk e.g. production ramp-up rates and relative proportions of production from projects at a given time, as well as the confidence aspects of the operations and project pipeline, as indicated in Figure 2.

Resources and reserves

By SAMREC (2007) definition 'a "Mineral Reserve" is the economically mineable material derived from a Measured or Indicated Mineral Resource or both. It includes diluting and contaminating materials and allows for losses that are expected to occur when the material is mined. Appropriate assessments to a minimum of a Pre-Feasibility Study for a project and a Life of Mine Plan for an operation must have been completed, including consideration of, and modification by, realistically assumed mining, metallurgical, economic, marketing, legal, environmental, social and governmental factors (the modifying factors).'

At Anglo American Platinum this definition has been interpreted into the BP process as being that a reserve is an estimate of the quantum of ounces to be delivered to the mill in a business plan, as derived from the scheduled resource (Measured and Indicated but excluding Inferred) at level 2a (feasibility study) or better estimate of confidence. Scheduled resources at pre-feasibility study level (level 2b) are included in reserves only where there is a high probability that the project will move to feasibility study during the following planning cycle.

Prior to 2010, the conversion from resource to reserve was based on the application of the appropriate modifying factors (considering dilution and content loss) to the resource that covered the five-year mining plan footprint, plus approved projects in execution and projects in feasibility or pre-feasibility study, with the work being conducted primarily by the survey and geology disciplines. In this process no real consideration was given to resources left behind as a result of the extraction rate, or remaining resources inside the reserve footprint that were unlikely to have reasonable prospects of eventual economic extraction (RPEEE). These resources were removed from the resource statement to retain integrity of reporting, but were then difficult to track for planning purposes.

During 2009 a full review of the resource-to-reserve definition process was conducted in order to enhance effectiveness of resource utilization, reporting, and reconcil- iation. Critical changes to the reserve definition process that were implemented as a result of this review were as follows.

Process

Reserves are based on a scheduled resource, ensuring that the planning discipline is integral to process

Appropriate mine design and layouts are applied to the resource areas as dictated by current mining methods and mine design criteria to derive a mineable resource

The mineable resource is scheduled according to production requirements to develop a scheduled resource

Only current operations (level 1), approved projects in execution (level 1e,) and projects in feasibility study (level 2a) included in the business plan are defined as reserves (in Proved and Probable categories according to SAMREC)

The remaining scheduled area of the LOM plan is termed scheduled exclusive resource and includes projects from Level 2b, 2c, and Level 3 with the objective of optimally extracting the available resources

Resource categories have been increased to cater for exclusions and confidence levels (e.g. mineral resources above the geothermal gradient cut-off are moved to mineral inventory)

The introduction of mining losses pertaining to resources left in pillars. The mineable resource excludes material locked up in mine-design related pillars

Uneconomic production plan 'tails' revert to mineral resource or mineral inventory (depending on position in plan) through a 'tail management' process

The application of modifying factors (technical, mining, geotechnical, processing and recovery, legal, market, and social/government factors) is implemented in three distinct phases:

- Mine design and scheduling-Those modifying factors that impact on dilution of the resource (i.e. stope width versus resource width, tertiary development and other waste mining done on the reef horizon etc.) and modifying factors that define mining losses (i.e. non-mineable pillars and RIH/RIF mining inefficiencies etc.) are applied to the criteria included in establishing the mine design and scheduling

- Processing - Those modifying factors that influence the efficiency of processing and recovery are applied to the scheduled resource, and the result is a mineable reserve

- Economic - The subsequent application of modifying factors that influence the economic aspects of the mining operation results in the tail management requirement.

The scheduled reserves are multi-discipline peer-reviewed and signed off by the competent person(s).

Reporting

Resources are declared inclusive and exclusive of reserves.

Reconciliation

The reserve definition process is readily auditable

Reconciliation between the level 2a plan and declared reserves is possible

Reconciliation between declared reserves and scheduled resources converted to reserve is possible.

This reconciliation process is facilitated by the use of the basic mining equation logic (Table I) and a data tabulation known as the 'production ounce to reserve reconciliation' (Table II), both of which integrate with the BRE (Table III) and BR2RE (Table IV) tools.

Implementation of the enhanced process during 2010 and 2011 occurred largely through the development and introduction of two tools; the basic resource equation (BRE -see Table III) and the basic resource to reserve equation (BR2RE - see Table IV).

The BRE and BR2RE

The BRE (basic resource equation) and the BR2RE (basic resource to reserve equation) provide the means to logically record and track the progression of the mineral asset from pre-resource through to reserve in a logical and systematic manner that could also be related spatially. Critically, the methodology defines numbers but also relates numbers to spatial location to facilitate reconciliation. The approach also facilitates the declaration of an exclusive resource (exclusive resource = total resource - resources converted to reserves by application of modifying factors).

Both tools are built using 'equation' logic:

e.g. area (m2) x stope width (m) x density (t/m3) = tons (t) x value (g/t) = content (g)

In the tables that comprise the BRE and BR2RE, the equation logic flows from left to right, with mathematical operators indicated in the second column with logic flow running top to bottom.

The ratios in the BRE are applied to allow quick review of the efficiency of critical parameters and to identify areas for additional focus in increasing resource utilization and conversion.

A comprehensive explanation of the line-by-line logic and workings of the BRE and BR2RE is contained in the Appendix

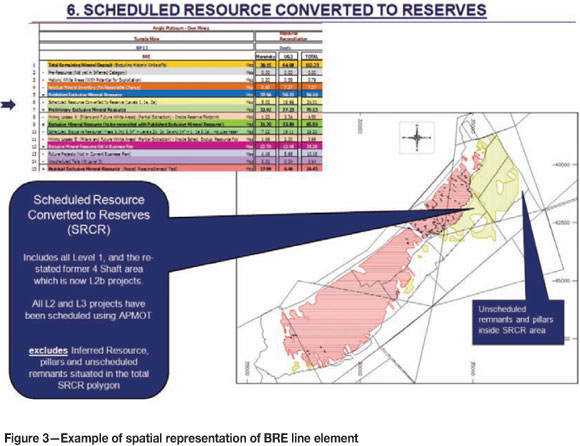

The spatial relationships of each of the line elements of the BRE are represented in plan to facilitate understanding and allow visual reconciliation. For example, line 6 (scheduled resource converted to reserves) is represented in Figure 3.

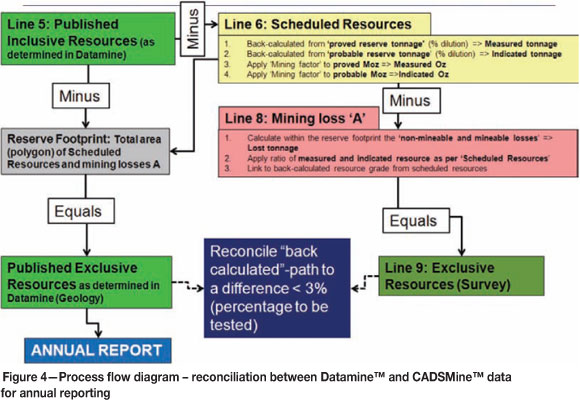

Reserve to exclusive resource calculation for reconciliation

Although the exclusive resources are calculated through the CADSMineTM - based BRE approach, the annual declaration of exclusive resource numbers is still derived from DatamineTM. The BRE approach and the back-calculation of exclusive resources from reserves provide a unique reconciliation between DatamineTM-generated resources and CADSMineTM-generated resources, as indicated in Figure 4.

Open pit operations

The same principles are applied to open pit mining operations with minor modifications to the BRE categories. However, given that the resources as well as the reserves are derived through the DatamineTM software, direct checking and public reporting through the BRE rather than simply for reconciliation purposes is possible. Similarly to the underground operations, the resources are reported per pit and with the plan view being accompanied by a section view in order to clarify the 3D relationships for review purposes.

Conclusion

The basic resource equation (BRE) and the basic resource to reserve equation (BR2RE) are reconciliation tools that facilitate the understanding of the numerical and spatial relationship of the mineral resource to the resultant mineral reserve after scheduling and the application of modifying factors. Increased understanding of the interrelationship of resources to reserves and planned extraction creates an appreciation of the mineral assets and the overall extraction strategy. The technique and tools facilitate understanding of mineral resource utilization and conversion to reserves, both numerically and spatially, and enables effective review and audit processes.

The benefits of both templates can be summarized as follows:

The reconciliation of resources and reserves (both spatially and numerically) is facilitated

The process is simple, transparent, and repeatable

The extent of resource utilization is evident

Opportunities for further resource extraction (location and quantum) can be readily identified.

Acknowledgements

The authors gratefully acknowledge the permission of Anglo American Platinum Limited to publish this work. They further acknowledge the contributions of Quartus Snyman, Dietmar Nowak, Paul Stevenson, and Chris de Jager in the development and refinement of these tools.

References

Andersen, D.C., Pearson-Taylor, J., and Smith, G.L. The strategic long term planning process at Anglo Platinum. Proceedings of the First International Seminar on Strategic versus Tactical Approaches in Mining, Johannesburg, South Africa, 19-21 September 2005. Symposium Series S40. Southern African Institute of Mining and Metallurgy, Johannesburg. pp. 9-22.

Dohm, C., Harney, D., and McCracken, S. Study deliverables and gate criteria for the geosciences discipline. The Platinum Way (Corporate Policy). Anglo American, June 2010. [ Links ]

Smith, G.L., Andersen D.C., and Pearson -Taylor, J. Strategic long-term planning at Anglo Platinum. Journal of the Southern African Institute of Mining and Metallurgy, vol. 109, no. 3, 2009. pp. 191-203. [ Links ]

Smith, G.L., Andersen D.C., Pearson-Taylor, J., and Marsh A.M. Project valuation, capital investment and strategic alignment - tools and techniques at Anglo Platinum. Journal of the Southern African Institute of Mining and Metallurgy, vol. 107, no. 1, 2007. pp. 67-74. [ Links ]

South African Mineral Resource Committee (SAMREC). The South African Code for the Reporting of Exploration Results, Mineral Resources and Mineral Reserves (the SAMREC Code). SAMREC Working Group, Johannesburg, 2009. www.samcode.co.za [Accessed 30 July 2012] [ Links ].

Smith, G.L. Presidential address: Strategic long term planning in mining. Journal of the Southern African Institute of Mining and Metallurgy, vol. 112, no. 8, 2012. [ Links ] pp. 761-774.

Appendix

BRE and BR2RE-explanation of the internal workings

Overview of the BRE and BR2RE

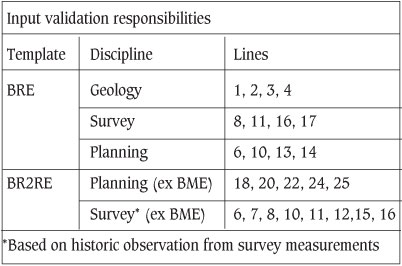

The following table reflects the input validation responsibilities of geology, planning, and surveying into the BRE and BR2RE

The BR2RE (see Table IV) is the primary tool used to determine and reconcile the inputs into lines 6, 16, and 17 of the BRE (Table III). The BR2RE also reflects the overall percentage dilution at the various points along the production planning process of the business plan (Levels 1, 1e, and 2a). The stope content factor indicates the difference in content with the conversion from resource to reserve, while the mining factor, is the stope content factor multiplied by the MCF. The mining factor indicates the general efficiency of the conversion from resource to reserve.

Reviewing the compilation of the company's long-term planning process requires that each of the 'outcome' milestones along the process fit into one of the classifications reflected in the BRE. For example, the mine extraction strategy (MES) is effectively the published inclusive mineral resource (line 5 of BRE). In most instances this is the starting point of the BRE and essentially the starting point of the BR2RE too.

The application of the BR2RE

In defining the MES, the mine planner schedules the extraction of the resource around known geological structures and within known resource blocks according to approved mining methods and benchmarked rates of achievement.

Scheduled resource converted to reserve (lines 1-3)

The outcomes of the areas with the confidence levels of 1, 1e, and 2a, form the basis of the business plan and also the 'scheduled resource converted to reserve' (line 3 of the BR2RE, and is also subsequently one of the primary inputs into the BRE on line 6 after reconciliation). If any inferred resource (line 2) is included in the business plan, then this is added to line 3 to reverse-calculate the 'scheduled resource at resource width' (line 1).

Mined from stopes at resource width (lines 4-5)

When reducing the 'scheduled resource converted to reserve' figure (line 3) with the expected resource from 'development at resource width' (line 4), the result is 'mined from stopes at resource width'. (Bear in mind the specific focus of the resource evaluator is to evaluate the resource for the best value at an optimized width for declaring the resource.)

Mined from stopes at stoping width (lines 6-9)

This optimized width is referred to as the 'resource width' and may be less than the prescribed geotechnical width (or minimum mining width). Added to this is the increase in the stoping width through the inaccuracies of mining practice, and this then constitutes the actual stope width at which the resource will be mined. Bear in mind also that not all dilution comes with no content.

The above aspects of 'dilution' are taken into account in lines 6 and 7 of the BR2RE, and when one further considers the vagaries of miners, then the 'losses' of metal accounted for as being left behind as RIH and RIF are also reflected in line 8 of the BR2RE. The result of the equation at this point (line 9) declares the quantities mined from stopes at stoping width.

Mined from stopes at stope tramming width (lines 10-13)

Further 'dilution' in the form of gully excavations, redevelopment, and waste from off-reef mining is considered in lines 10, 11, and 12 respectively. The result at this point (line 13) declares the quantities mined from stopes at the expected tramming width.

Mined from stopes and development at reserve width (lines 14-17)

Line 14 deducts the ore that will be left underground as part of the resource when scalping is practiced, and then the 'reef development at full development width' (line 15) is added back into the equation and 'waste trammed to reef (line 16) is included. The result at this point reflects 'mined from stopes and development at reserve width' (line 17).

Determination of reserves (lines 18-19)

The application of the MCF (line 18) results in the final RESERVE (line 19) which is to be published.

Reconciliation (lines 20-25)

Reconciliation of these figures is done both between the mine planner and the surveyor with the BME and the BR2RE. Considering lines 25 to 20, this is achieved with the BME's final milled tons and contents following the deduction of any extraneous sources of milled tonnage such as stockpile movement, tailings retreatment, and sifted material and previously called-for material such as historic vampings etc.

Other information (lines 26-31)

An important validation point, as these figures should agree with the inputs provided to the planners. one of the key inputs into the BRE is the mining factor (line 31).

Application of the BRE

Published inclusive mineral resource (lines 1-5)

The published inclusive mineral resource, as previously stated, should equate to the mine extraction strategy, which by definition would exclude any 'pre-resource (line 2), historic white area (line 3), and residual mineral inventory (i.e. that which has no reasonable chance of being economically exploited - line 4). When considering these exclusions in addition to the mine extraction strategy, the 'total remaining mineral deposit' (line 1) is derived.

Note: The pre-resource category accounts for all potential areas or reefs that may be potential economic targets, but are not yet at a confidence level that indicates future potential for extraction or are not yet owned by the company, but a reasonable, non-speculative chance exists. Historic white areas are areas 'left behind' in the past for unknown or economic reasons at the time and which may represent potential future mining targets.

Residual mineral Inventory represents a category that reflects areas/property deemed to have no reasonable chance of ever being exploited. This classification obviously requires adequate geological data/information. However, it also relates to areas within the mining right area that, under the current known technology, cannot be accessed, such as mining below the 75°C isotherm. Should technology and/or economic circumstances change, these assets can be brought back into the public resource domain. These comprise the mineralized inventory not reported in the public domain.

Preliminary exclusive resources (lines 6 -7)

The 'Preliminary exclusive resources' (line 7) is derived by subtracting the reconciled figure of the 'scheduled resource converted to reserve' (line 6) as obtained from line 3 in the BR2RE.

Exclusive mineral resource (lines 8-9)

In order to arrive at the actual exclusive resources (line 9), mining losses, termed 'mining losses A' (line 8), in form of pillars are deducted from the 'preliminary exclusive mineral resource' (line 8).

Note: Mining losses A are either calculated from both mine design polygons or factorized from historic reconciliation work based on the mining method applied and the overall mining extraction percentage. These include pillars such as ventilation pillars, boundary pillars, regional pillars, crush pillars (as per mine design), as well as shaft pillars.

Exclusive mineral resource not in business plan (lines 1012)

Further excluding the 'scheduled exclusive resources' (line 10) in areas with Levels 2b, 2c and Level 3, as well as all inferred resources from the 'Reserve window' (which are not convertible according to SAMREC), and 'mining losses B' (line 11) according to the same principles of 'mining Losses A', results in the 'exclusive mineral resources not in business plan' (line 12).

Note: There can be numerous reasons as to why these areas have not been included in the business plan of the company for a particular year, but these are typically related to simple economic valuation of these areas as business Investment centres. NPV and IRR hurdle rates, as well the company's top-down goals in terms of required production from the various operation and JVs, are amongst the main considerations. However, this can be and is generally tested on an annual basis and would typically happen early in the year by means of mine extraction strategy reviews.

Residual exclusive mineral resource (lines 13-15)

Both 'future projects (not in current business plan)' (line 13) and 'unscheduled tails (at Level 3)' (line 14) are typically not part of the business plan, showing no sign for future project potential, are geologically very complex and/or not well enough understood to interest the company under the current economic environment. Further work or a 'fail' assessment would warrant their 'transfer' to the residual inventory (line 4).

Deducting these areas results in the 'residual exclusive mineral resource (passed the reasonableness test)' (line 15).

INFO (lines 16-17)

The reserves are reflected as the result of the resource converted to reserves in line 3 multiplied by the mining factor (line 17) as obtained from the BR2RE.

RATIOS (lines 18-30)

Each of the primary constituents of the business planning process reflected above have a relationship with either the scheduled resource converted to reserve, the published inclusive or published exclusive resource. Understanding these relationships and how they compare from one area to another facilitates an appreciation of the drivers and challenges in various aspects of mineral resource management process.

The reasonableness test

The resulting residual exclusive resources at the end of the BRE undergo the reasonableness test for RPEEE. If the requirements for resource reporting are fulfilled and well supported by company economics, the portion of resource remains in the published domain as part of the published exclusive resources. If no reasonable chance exists for future mining, neither on a technical nor on an economic level, a transfer will be initiated to residual mineral inventory. This process of interrogation of economic viability of investment centres as well as resource definition criteria for public reporting, occurs on an annual basis and is deemed an industry best-practice approach to business planning.

© The Southern African Institute of Mining and Metallurgy, 2013.

ISSN 2225-6253. This paper was first presented at the 5th International Platinum Conference 2012, 18-20 September 2012, Sun City, South Africa.