Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.11 Johannesburg nov. 2012

Design and implementation of a multimodal transportation cost analysis model for domestic lignite supply in Turkey

E. Demir; C. Karpuz; N. Demirel

Mining Engeneering Department, Middle East Technical University, Ankara, Turkey

SYNOPSIS

Transportation cost is the dominant cost and accounts for almost half of the total mining cost in surface mining. Therefore, determining transportation cost is critically important for the economic feasibility of mining projects. Turkey produces around 85 million tons of lignite per annum. The biggest state-owned company, Turkish Coal Enterprises (TKI), accounts for 43 per cent of the country's total lignite production. Around 85 per cent of the produced lignite is used in power plants for electricity generation and 15 per cent is used for domestic heating in cities and urban areas. On behalf of the Turkish government, TKI distributes around 2 Mt of lignite annually, at no cost to poor needy families countrywide in accordance with Social Assistance and Solidarity Funding aid. Subcontractors are utilized for lignite transportation, and conflicts arise due to the different transportation cost calculations at different mines. A robust model that provides unbiased cost estimations is therefore of paramount importance. This paper presents the transportation cost estimation software, NAKMAL, that has been developed for estimating the transportation cost of lignite from the mine face, including excavation and loading, to various final destination points through five different transportation scenarios. NAKMAL was designed using Visual Studio.NET, validated using field data and some case studies, and it is currently being used by TKI for calculation of transportation cost country-wide.

Keywords: lignite, fuel demand, transportation cost, software development, VisualStudio.NET.

Introduction

Lignite is one of the primary energy resources in Turkey. The country has a total lignite reserve of 11.5 billion tons and accounts for 7.7 per cent of the world's lignite reserves. Almost 52 per cent of lignite production is governed by state-owned Turkish Coal Enterprises (TKI), which produces around 40 Mt of lignite annually at around 30 opencast and nine underground operating mines. Around 85 per cent of the lignite produced is used in power plants for electricity generation, and 15 per cent for domestic heating. Furthermore, in accordance with the relevant provisions of the Constitution and the SOE (State Owned Enterprise) Act, a minimum of 500 kg of lignite per year is supplied free of charge to poor families, funded through fees from the Treasury, and carried out through the offices of provincial governors under the coordination of the TKI since 2003. From 2003 to 2008 a total of 7.4 Mt of lignite was delivered to the needy. Lignite is transported from the TKI mines to different cities using different transportation methods, such as rail, ship, and highway transportation. Since the lignite distribution is financed by the TKI and not charged in response to the distribution, the cost of transportation becomes a critical problem to be analysed in detail to minimize the economic burdens on TKI while satisfying the lignite demand. This is especially important when subcontractors are utilized for transportation and conflicts arise between TKI and the subcontractor due to different estimated costs for transportation. In many cases, these conflicting cases are settled through the courts. Therefore, developing a rigorous model that provides accurate and unbiased cost estimations is of paramount importance for maximizing efficiency of handling material and minimizing transportation cost.

This paper presents the cost analysis model developed for TKI lignite transportation operations to estimate the transportation cost of lignite from the mine face to the final destination point. The model was developed to provide a simplified, consistent method for estimating the lignite transportation costs imposed on TKI by the central government. It provides a practical approach to estimating various costs incurred during the transport of lignite through various alternatives methods and allows the decision-makers to choose the most economical transportation alternative.

In order to develop the model, initially the components and types of the transportation system were analysed in detail. The lignite transportation alternatives from a mine to a destination point were divided into subsystems and each cost component in the system, for instance the required amount of lignite, project duration, the method of transporting lignite (packed and unpacked), etc. were investigated quantitatively. Secondly, a database containing technical and economic information was generated to be utilized in the program for computations. The cost analysis model, NAKMAL, was then developed using Visual Studio.NET 2005 (Demir, 2009). In the NAKMAL program, 19 modules were designed to compute the cost of these subsystems. Excavation and loading costs are calculated utilizing the DEKMAL program (Paşamehmetoğlu et al., 1988; Çelebi et al., 1998).

DEKMAL is a computer model developed for determining the optimum combination of machines on the basis of cost and duration of the excavation and loading operations. DEKMAL permits the combination to be determined either from among the choices that are available in databases in the computer or from options defined by the user. Additionally, the overall cost of a defined stripping operation can be determined for selected equipment from information held in the databases.

The developed NAKMAL model was validated using real case data and simulations. The software is the first attempt to be developed for cost analysis purposes, and this study is important for determining the cost of alternative transportation methods in maximizing the economic efficiency of coal mining in Turkey.

Previous studies

Before developing the model, the previous research studies related to cost estimation modelling and optimization were extensively reviewed. As stated by Alarie and Gamache (2002), one of the most important aspects of open-pit mine operation is material transportation, which represents 50 per cent of the total operating cost, and can sometimes reach up to 60 per cent. Therefore, cost models to estimate the transportation costs throughout the mine life are significant for sustaining the economic feasibility of mining projects.

Equipment selection and cost analyses in an open-pit mine area were studied by Paşamehmetoğlu et al. (1988). The model developed in this study was utilized by TKI to prepare and evaluate contractual bidding agreements. Shih (1997) studied planning of fuel coal imports using a mixed integer programming method. The author generated his objective function to minimize the total cost of procurement, transportation, and holding (Shih, 1997). The equipment selection problem was also studied by Haidar et al. (1999). The point is stressed that optimum equipment selection for a mine is complex and can be broken down into a series of relatively well-defined variables directly related to the general mine conditions.

Naoum and Haidar (2000) developed a program, XSOME, to assist the decision-maker by producing an intelligent support system, in the form of a hybrid knowledge based on genetic algorithms, to select the type, make, number, and operating life of the excavating and haulage equipment in order to minimize the total cost of the overburden removal operation in an opencast mine. Gül and Elevli (2006) studied the solution of transportation problems of a cement plant with linear integer programming. The cost analysis was conducted and costs for different modes of transportation were compared by Sahin et al. (2009). The change in the total transportation cost per cargo was based on the route length and fill factor for a 20 t capacity truck.

Cost estimation modelling and database generation

In the following sections, the cost modelling and database generation as a whole and for its subsystems or components are presented.

Excavation and loading modelling

Although the equipment combinations available worldwide for stripping operations are quite numerous, they are more limited in Turkey. The following combinations, therefore, being the most common, are considered and defined in DEKMAL: electrically powered shovel and truck; hydraulically powered shovel and truck; backhoe and truck; and front-end loader and truck (Çelebi et al., 1998). Although ripper-bulldozers are widely used together with bulldozers, scrapers, and front-end loaders (depending on the diggability of the ground), they are not included because ripping is regarded as the equivalent of drill-and-blast operations. Ripping and blasting are, therefore, included in DEKMAL as alternatives in the diggability sub-system. The first step in determining just the cost of equipment already defined or in selecting suitable equipment from the available combinations or from a defined subgroup is to choose a suitable number and capacity of excavators. The numbers and capacities of the trucks that will operate with the excavators are then determined. After a suitable drilling machine has been selected according to the breakage required, or a suitable ripper-dozer if loosening is necessary, the final step is to perform a cost analysis and to calculate the unit cost if the equipment selected is technically suitable (Çelebi et al., 1998).

Excavator production sub-models in DEKMAL are defined individually as a different module for each kind of excavator. The hourly capacity of an excavator is found by one of these sub-models. In these models the annual stripping amount, annual and daily working times, and system efficiency parameters are evaluated as the basic inputs. Other parameters, such as material swell factor, bucket fill factor, and cycle periods, are also evaluated and effects of diggability characteristic of the ground are taken into consideration (Çelebi et al., 1998).

Lignite transportation system and its subsystems for cost modelling

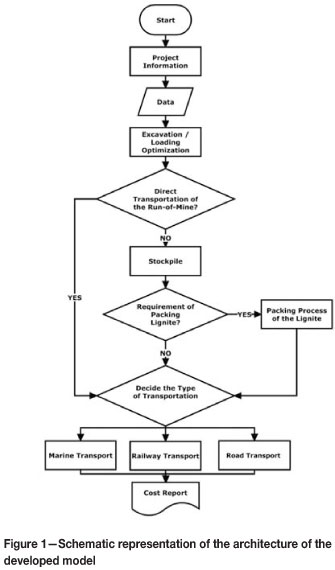

In order to develop a generic and robust cost analysis model, each alternative method for transportation should be considered within the program. For this purpose, various alternative methods of transportation for delivering lignite from the mine site to a destination point are determined. In this sense, it was determined that there are five different transportation methods to be utilized for lignite transportation, depending on the location of the supply and demand points. Each transportation alternative was divided into its subsystems, which also constitute the modular structure of the developed software. These subsystems, the costs of which are computed through the software, are presented in Figure 1.

Through the main transportation ways and their subsystems, the lignite loaded at the mine is transported by the following methods:

By trucks to the packing plant, followed by

- Delivery to the final destination by trucks.

- Trucking to a railway station, rail teransport to an intermediate destination, and delivery to the final destination by trucks

- Trucking to a port and transport by ship to an intermediate destination, then delivery to the final destination by trucks.

By trucks to a stockpile area, followed by

- Delivered to the final destination by trucks

- Trucking to a railway station and rail transport to an intermediate destination, from where it is delivered to the final destination by trucks

- Delivery to a port by trucks and transport by ship to an intermediate destination, then delivered to the final destinationby trucks.

Final destination point. The road conditions at the mine and on various highway segments are considered

A railway station without packing and stockpiling. The coal is railed to another station, from where it is delivered to final destinationby trucks.

A port without packing and stockpiling. The lignite is loaded and shipped to another port, from where it is delivered to the final destination by trucks.

In addition to loading and unloading operations, the railway transportation subsystem includes applying bale cloths to wagons. Transportation by ship includes loading of lignite to a ship in a port, transportation by ship, and unloading at another port. Lignite may also be transported in powder form in the case of power plant feeding or packing. Therefore, there are also cost components regarding powder coal handling methods. The first method is applied when packing is used and includes all work involved in loading of powder coal onto trucks at the packing plant. The second method is the transportation of powder coal to power plant. This subsystem includes both mine road segments and highway segments. Loading and transportation of powder coal is illustrated as double-sided white arrow in Figure 1.

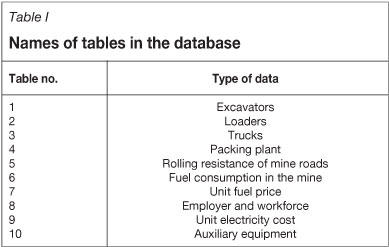

Database generation for the NAKMAL transportation cost program

The database of the developed software is separate from the code, and hence can easily be updated. The database was created using Microsoft Access and is stored in drive C of a computer so as to be able to run the software. The types of the data and the names of the tables in the database are listed in Table I.

Data for the equipment in the fleet was collected through contact with various manufacturers, and was used to specify the features of equipment. In selecting the excavation type, the diggability classification scheme, as illustrated in Table II (Karpuz, 1990), was utilized by the DEKMAL program.

Since contractors mostly use hydraulic excavators and rubber-tyred loaders, research has been focused on the specification of this type of equipment. Hydraulic excavators and rubber-tyred loaders having 2-7 m3 bucket capacities and off-highway trucks up to 40 t are included in the database for selection. The reason for limiting the capacity of trucks to 40 t in the database is the maximum allowed vehicle capacity on the national highways. The equipment matching was performed by the program in an effort to optimize production. The criterion behind the equipment matching is 4-7 cycles of shovel dipper per truck. In the case of any change in capacity or other features of the trucks or the packing plant, the data can easily be updated. Roads were classified according to their grade and rolling resistance values in different road conditions. A dozer may be used as auxiliary equipment to support the loading process, and its specifications were also included in the database. The fuel consumption rates of trucks in the mine with respect to total resistance were tabulated in the fuel consumption tables in the database. Unit fuel cost, unit electricity cost at the packing plant, and worker salaries were also integrated. The fixed and variable operating cost items were verified based on TKI's long years of experience.

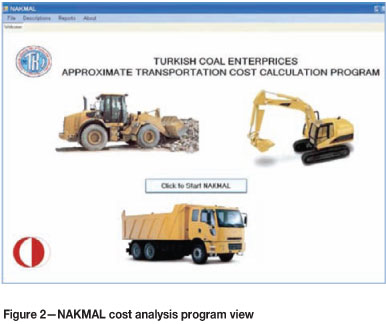

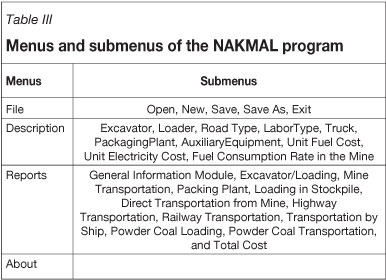

Development of the NAKMAL program

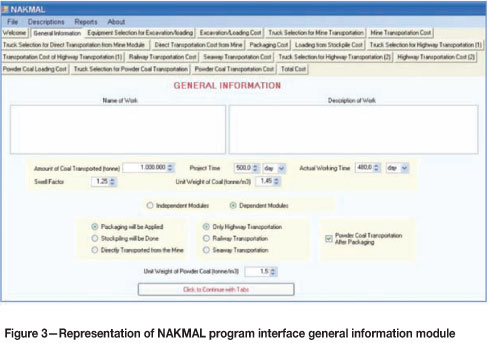

The NAKMAL program runs to find and minimize the transportation cost under several constraints such as the available lignite supply, demand, and spatial locations to optimize the problem. The program (Karpuz et al., 2008) has four menus: File, Descriptions, Reports, and About, as illustrated in Figure 2. File operations are verified through the File menu, the database is reached through the Descriptions menu, and print reports are displayed through the Reports menu. The About menu gives the brief information about the program. The submenus of these menus are given in Table III.

The program has a total of 19 modules to calculate the cost of subsystems of all transportation alternatives as listed in Table III and illustrated in Figure 3.

The view of the general information module is shown in Figure 3. The specifications of the work are defined by checking the radio boxes or check boxes. For instance, the unit weight of the lignite panel is displayed and the value in tons per cubic metre is entered when the general information module is selected. The 'Click to Continue with the Tabs' button is selected and corresponding tabs are displayed just below the menu bar as shown in Figure 3.

There are two text boxes at the top of the window for naming and describing the project. The inputs of the module are the production amount, actual working time, project time, swell factor, and the unit weight of the lignite and powder lignite. The software has two distinct capabilities that permit the combination to be determined either from among the choices that are available in the databases in the computer or from options defined by the user.

The first option is called Dependent Modules and is used to compute optimum cost. If 'dependent algorithm' is selected, the output of the previous subsystem is taken as input to the current subsystem. It affects especially the equipment selection. Since proper equipment selection is a major factor in decreasing cost, the program should be run dependently to arrive at an optimum cost. The dependent module algorithm is modelled in a way such that the relations between the successive subsystems are taken into consideration. Idle time for equipment is minimized and the number of equipment items for a subsystem is specified with respect to the equipment productivity of the previous subsystem.

Hence, greater efficiency is achieved and cost is minimized with respect to the dependent module algorithm.

The second option is called Independent Modules and is prepared for use of available equipment combinations. No restrictions arising from the previous operation are imposed on the user. All parts of the work are considered independently and the duration of all subsystems is extended to the working duration of the project. Since some parts of the whole work were assigned to a contractor, the modules were run independently. When the results of these algorithms are compared, it is obvious that the unit costs are lower, and thus optimized, for the dependent model algorithm.

The program allows the decision-maker to estimate material handling costs for different paths (segments) of the same transportation routes as well as various transportation alternatives. The program accommodates trucks and loaders of various capacities for highway and in-pit transportation. The capacities of trucks range from 17 t to 40 t and the capacities of excavators range from 1.11 m3 to 7 m3 in the generated database. Delivery times are important for meeting the contract requirement and for material handling efficiency, and therefore operating cost. The NAKMAL program considers the delivery times through project start and end times. Cycle times are calculated for estimating the overall cost efficiencies.

Validation of the program

The developed NAKMAL transportation cost model was validated through field data. For this purpose, various transportation projects were examined and onsite investigations were conducted to obtain real data. A transportation cost problem studied by TKi was solved in NAKMAL, and the calculated results were very close to the real cost values. The result of a case study is given below.

Lignite coal of 5300 t was transported from the face to a packing plant 9 km away. The inputs for the sample case were:

Distance: 9000 m

Rolling resistance: 2%

Efficiency factor: 1

Number of shifts: 3

Grade resistance: 2%

Fill factor: 100%

Manoeuvring and dumping time: 40 min

Amount of lignite: 5300 t.

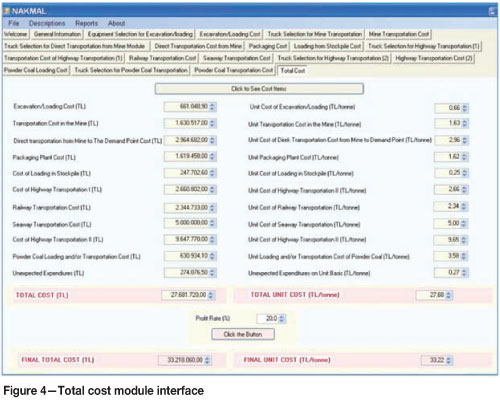

The output results are represented by Figure 4.

NAKMAL computed the transportation cost as 2.02 TL per ton ($1.12 per ton), whereas the cost calculated by using the real data taken in the field was 2.11 TL per ton ($1.17 per ton). This result showed that NAKMAL may also be utilized effectively to achieve better cost analysis.

The NAKMAL program was also verified by comparing the output results for highway segments to the similar studies such as Sahin et al. (2009), and it was observed that the results are quite compatible. NAKMAL provided US$28 per ton for 420 km if the fill factor of the truck is 1.0, while Sahin et al. computed a value of US$30 per ton.

After implementing the model for three years, a noticeable improvement has been observed in the lignite handling and distribution operations in TKI. The program that they used previously has not been utilized since NAKMAL was adopted. However, five arbitrarily selected cases have been considered with the previous calculation method to compare with the costs provided by NAKMAL. Considering those cases, NAKMAL provided 38 per cent cost reduction during the years of 2009 and 2011.

The details of the calculation of these cases are presented in Table IV.

As can be seen, there is a significant cost reduction for various amounts of lignite at different distances as calculated by NAKMAL. Considering the total amount of coal distributed by TKI, which is around 1.7Mt/a, the contribution of the program is evident. In addition to the substantial economic benefits, the number of conflicts and complaints involving TKI and its subcontractors has decreased significantly. There have been no court cases reported between TKI and its subcontractors since the program was put in service, although there were six previously.

Conclusions and recommendations

In this study a transportation cost analysis model, NAKMAL, for the supply of domestic lignite fuel in Turkey has been developed and implemented successfully. NAKMAL considers the suitable equipment combination for excavation and transportation and also calculates the corresponding cost for lignite handling. The software has been validated by field and related case studies, and the validation results showed that the software provides accurate and precise transportation cost information. The developed model also allows decision-makers to choose the best material handling alternative with a minimum operating cost. In addition, utilizing an objective decision support tool has reduced the number of conflicts between TKI and its subcontractors, and no court cases have been recorded during the past three years. NAKMAL is user- friendly software and can be easily updated using an outsource database created in Microsoft Access. TKI currently utilizes the program for the calculation of lignite transportation costs for bidding purposes. The generic algorithm behind the model can also be utilized for various projects by modifying the available database. In order to better present the physical characteristics of the highway segments, GIS can be utilized. Nowadays, lignite is transported from any available mine to the destination, but in future lignite supply amounts and lignite demands of cities may be optimized to create zones supplied by the TKI mines.

Acknowledgement

The authors kindly acknowledge Mustafa Özdingiş from Turkish Coal Enterprises, Turkey, for his support and help throughout the completion of the NAKMAL project.

References

ALARIE, S. AND GAMACHE, M. 2002. Overview of solution strategies used in truck dispatching systems for open pit mines. International Journal of Surface Mining. Reclamation and Environment, vol. 16, no.1. pp. 59-76. [ Links ]

ÇELEBI, N., PAŞAMEHMETOğLU, A.G., and KARPUZ, C. 1998. Unit cost analysis model for stripping of open pit lignite mines. Transactions of the Institution of Mining and Metallurgy Section A, vol. 107. pp. A1-62. [ Links ]

DEMIR, E. 2009. Developing a Coal Transportation Cost Estimation Model for Turkish Coal Enterprises. M.Sc. thesis. Middle East Technical University, Ankara. [ Links ]

GUL;ML, M.L. AND ELEVLI, S. 2006. Solution of a Cement Plant's Transportation Problem by using Integer Programming (Tamsayili Doğrusal Programlama ile bir Cimento Fabrikasinin Nakliye Probleminin Çözümü (in Turkish)). ErciyesÜniversitesi, Fen BilimleriEnstitüsüDergisi, vol. 22, no. 1-2. pp. 229-241. [ Links ]

HAIDAR, A., NAOUM, S., HOWES R., and Tah, J. 1999. Genetic algorithms application and testing for equipment selection. Journal of Construction Engineering and Management, vol. 125, no. 1. pp. 32-38. [ Links ]

KARPUZ, C. 1990. A classification system for excavation of surface coal measures. Mining Science and Technology, vol. 11. pp. 157-163. [ Links ]

KARPUZ, C., DÜZGÜN, Ş., DEMIREL, N., AND DEMIR, E. 2008. TKI Kömür NakliyeişlemiMaliyetModeli (Nakmal. Final Report (in Turkish) Project Code No: 2007-03-05-2-00-14. Middle East Technical University, Ankara. 60 pp. [ Links ]

NAOUM, S. AND HAIDAR, A. 2000. A hybrid knowledge base system and genetic algorithms for equipment selection. Engineering, Construction and Architectural Management, vol. 7, no. 1. pp. 3-14. [ Links ]

PAşAMETMEToğLU, A.G., KARPUZ, C., ÇELEBI, N., BILGINs, A., and Unal, A. 1988. Selection of optimum equipment combination, cost analysis and determination of unit stripping cost for the surface mines of Turkish Coal Enterprises. Final report of investigation (in Turkish), Project Code No: 83.03.05.01.02. Middle East Technical University, Ankara. 150 pp. [ Links ]

SAHIN, B., Yilmaz, H., Ust, Y., Guneri, A.F., and Gulsun, B. 2009. An approach for analysing transportation costs and a case study. European Journal of Operational Research, vol. 193. pp. 1-11. [ Links ]

SHIH, L.H. 1997. Planning of fuel coal imports using a mixed integer programming method. International Journal of Production Economics. pp. 243-249. [ Links ]

© The Southern African Institute of Mining and Metallurgy, 2012.ISSN 2225-6253. Paper received Feb. 2012; revised paper received Jun. 2012.