Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 n.12 Johannesburg Jan. 2012

Optimal cut-off grade determination based on variable capacities in open-pit mining

J. AbdollahisharifI; E. BakhtavarII; M. AnemangelyI

IFaculty of Engineering, University of Urmia, Urmia, Iran

IIDepartment of Mining and Metallurgical Engineering, Urmia University of Technology, Urmia, Iran

SYNOPSIS

Optimal cut-off grade is one of the most critical parameters in open-pit mine design because it defines the ore and waste and thus determines the maximum net present value possible from the mining operation. Although the algorithm presented by Lane (Choosing the optimum cut-off grade. Colorado School of Mines Quarterly, vol. 59, no. 4, 1964. pp. 811-829) is the most common one in the literature, it does assume constant capacities of the mine, processing, and refinery. In this paper, Lane's original algorithm has been modified to consider variable processing capacities in order to determine the optimal cut-off grade in open-pit mines. The new algorithm proposed here is compared to both Lane's original algorithm and to a previous modification that incorporated rehabilitation costs into the cut-off grade estimation. The algorithm proposed here that permits variable processing capacities is shown to be superior for the determination of optimal cut-off grade to both these previous versions. In addition, a computer-based program was developed in Microsoft Office Excel© to calculate the optimal cut-off grade as proposed here.

Keywords: optimization, cut-off grade, variable capacity-based, NPV, open-pit mining.

Introduction

Ore and waste are defined by means of cut-off grade, such that material with a grade less than the cut-off is transported to waste, and that with a grade higher is transported to the processing plant. However, blending opportunities between high- and low-grade ore mean that the determination of the optimum cut-off grade not only dominates mining economics, but is also a crucial decision in the efficient and effective utilization of the mineral resources.

Determination of too high a cut-off grade will result in a smaller overall resource as well as economic material being send to the waste dump, whereas conversely, the mine and processing plant capacity will be unjustifiably overextended in case of too low a cut-off (Bascetin and Nieto, 2007). Therefore, optimization of cut-off grade is the most significant economic parameter in mining.

Cut-off grade optimization in open-pit mining has been the subject of much research, but more work is needed if it is to cover all essential practical mining considerations.

The original algorithm introduced by Lane (1964), which has been applied frequently, is based on the maximization of net present value (NPV) in which the mine, processing plant, and refinery capacities are considered constant. During the past decade, much research effort has been devoted to optimizing cut-off grade of mono- and polymetallic deposits, especially in open-pit mining. In this study, the most significant researches, which are modified versions of the original Lane's algorithm emphasising the cut-off grade optimization in the monometallic deposits, have been reviewed.

Several computer packages were developed using Lane's original algorithm in order to determine optimal cut-off grade (Lane, 1988; Dagdelen, 1992; Whittle, 1999). Dagdelen (1992) stated that breakeven cut-off grades in open-pit mine planning may maximize the undiscounted profits. Therefore, the cut-off grade can be introduced as a function of economic parameters and the grade distribution within the deposit, together with mining, milling, and refinery capacity limitations.

Whittle and Wharton (1995) proposed the idea of opportunity cost utilization in cut-off grade optimization in monometallic deposits by introducing two pseudo costs, named delay and change costs. Majorly, Cairns, and Shinkuma (2003) represented a model to determine the influence of certain economic factors, such as price net of interest rate on cut-off grade and grade distribution. For this purpose, they incorporated optimal choices of the capacities and their allocations at the margin during the model. Then, Minnitt (2004) re-examined the Lane's original algorithm for the optimization of cut-off grade of a Wits-type gold deposit.

The major efforts belong to Asad's contributions during 2005 and 2007. First, Asad (2005a) developed Lane's algorithm for cut-off grade optimization of two-mineral deposits with an option to stockpile. Subsequently, he improved the algorithm by considering dynamic metal prices and cost escalation (Asad, 2005b and 2007).

From a different viewpoint, Bascetin and Nieto (2007) developed Lane's algorithm by adding an optimization factor on the basis of the generalized reduced gradient algorithm, and presented a Windows© based program to determine the maximum NPV.

Next, Osanloo et al. (2008) found environmental issues to be crucial parameter in cut-off grade optimization; hence, they improved Lane's algorithm on the basis of maximization of NPV simultaneously with minimization of environmental costs. They claimed that their algorithm is more effective in long-term production planning. Following this process, Gholamnejad (2009) incorporated rehabilitation cost into cut off grade optimization.

In this study, the authors have modified and rearranged Lane's algorithm through the inclusion of variable capacities for the mine, processing plant (concentrator), and refinery. All results are compared with the original algorithm and with a modified version suggested by Gholamnejad (2009).

Materials and methods

Variable capacities-based algorithm

In Lane's original algorithm all capacities in the mine, concentrator, and refinery are assumed to be constant for all grades, although the capacities depend on the cut-off grade selected for each stage. As an extension to this algorithm, this paper modifies the cut-off grade optimization calculation on the basis of variable capacities in order to maximize NPV. Hence, this new 'variable capacities-based algorithm' is an attempt to reset all capacities according to the selected cut-off grade for each stage.

An initial assumption is that the refinery capacity is equal to the market demand, and mine and concentrator capacities are then considered as a function of cut-off grade and the refinery capacity.

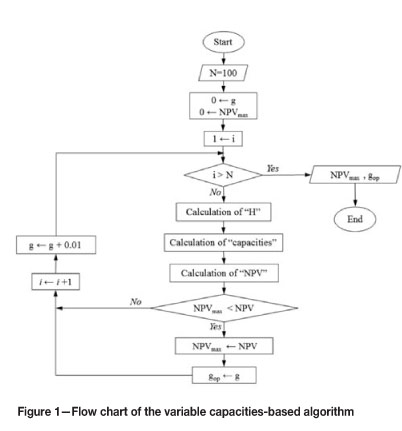

A computer program has been developed using Microsoft Excel© for implementation of the variable capacities-based algorithm (Figure 1).

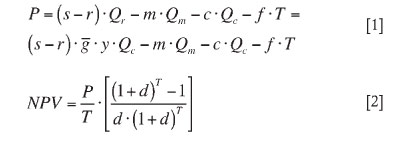

The basic premise of the variable capacities-based algorithm is the same as in Lane's original algorithm; that is, maximization of net present value (NPV). According to Lane's algorithm, the profit and NPV are calculated by Equations [1] and [2]:

Where

P is total profit ($) s is selling price ($ per pound)

r is costs due to the smelting, refinery and selling stage ($ per pound)

g is the average grade of material sent to the mill

y is recovery of material in the refinery (metallurgical recovery)

Qc is the amount of ore to be sent to the concentrator (tons)

m is mining cost ($ per ton)

Qm is the amount of material to be mined (t)

c is concentrating cost ($ per ton);

f is fixed costs over the production period ($ per year)

T is the production period or mine-life (years)

d is interest rate (%).

As shown in Figure 1, the algorithm includes the following steps:

Step 1-Start

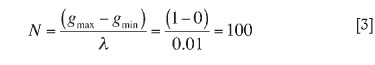

Step 2-Determination of the number of loops using Equation [3].

where

N is number of loops

gmax is the maximum possible grade (considered here to be equal to 1)

gmin is the minimum possible grade (considered here to be equal to 0)

λ is an incremental amount added to the grade value after each loop ( considered here to be 0.01).

Step 3-Cut-off grade is considered to vary between minimum (0) and maximum grade (1) in the loop as mentioned above. In first pass (i=1), cut-off grade is assumed to be equal to 0. It is increased by adding the amount of 0.01 during next loop

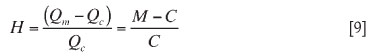

Step 4-Using an initial cut-off grade equal to 0, the amount of waste and ore can be determined. Furthermore, waste to ore ratio (H) is calculated using Equation [4].

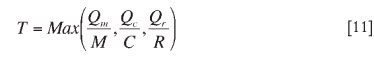

Step 5-Calculation of mining, processing, and refinery capacities as variable parameters. It is notable that in Lane's original algorithm, cut-off grade is restricted by the capacities of mining, processing, and refinery, which are considered as being constant. As a result, there are six different cases, on the basis of which constraint is the limiting factor (Lane, 1964). According to Lane's algorithm, Equation [5] introduces a relationship between total concentrating material and the metal produced during the mine-life. Therefore, if the maximum capacities of processing and refinery are used, this relationship is applicable between annual concentrating and refining material, hence it can be rewritten as Equation [6]. In this case, the maximum efficiency of the investment can be obtained.

where

QR is the amount of material recovered from the processing

C is maximum concentrator capacity (tons per year)

R is maximum refinery capacity (pounds per year).

Mining and processing capacities are calculated through Eqations [6] and [7] to be variable. Let us assume the refinery capacity equals the market demand, which is also variable.

where M is the maximum mining capacity (tons per year).

It is evident that the material extracted from the mine on the basis of the assigned cut-off grade will be send to either the processing plant, where the material has a grade greater than the cut-off, or the waste dump for material with a lower grade. Therefore, an amount of material (C) can be sent to the processing plant, expressed as a fraction of the total material extracted annually from the mine (M) according to the assigned cut-off grade and considering the maximum efficiently utilization of the investment. Hence, the amount of waste rock can be determined using Equation [8]:

In this case, the waste to ore ratio can be rewritten as Equation [9]:

Hence, the following relation is derived to calculate waste rock amount.

Step 6-calculation of NPV using Equation [2].

For this purpose, total profit (P) is first calculated by Equation [1], and Equation [11] used to estimate the mine life ( T) which is required for NPV calculation.

Step 7-Checking for maximum NPV in each loop. If the calculated NPV in loop i is greater than the previous iteration, it is considered as new maximum NPV (NPVmax) and the associated cut-off grade is taken into account as the optimum grade (gop) and then step 8 is followed. Otherwise, step 9 must be followed.

Step 8-The initial value assumed as zero for cut-off grade is increased by adding the value of 0.01 and it is replaced to the initial value for next loop (¿+1).

Step 9- Checking for all loops to be considered.

If all loops > N) are taken into account, the NPVmax and its related optimum cut-off grade (gop) are considered the final answer, otherwise, step 4 is repeated.

Step 10: End.

Case example

In this section, the authors used a case example previously employed by Gholamnejad (2009) in order to describe and analyse the 'variable capacities-based algorithm' proposed here.

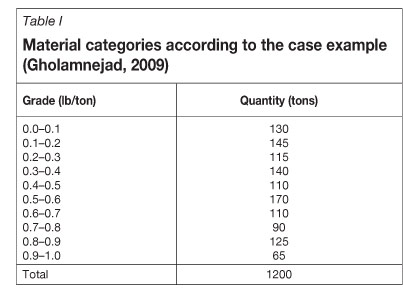

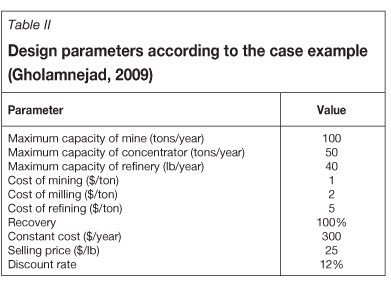

The example illustrates an open-pit mine which includes 1200 t of ore and waste rocks within its pit outline. Table I summarizes the grade distribution in equal grade intervals of 0.1. All data required for the analysis such as operating costs, selling price, capacities, and so on are given in Table II.

Results and discussion

In Lane's original algorithm, the mining, processing, and refinery capacities are constant, which does not result in realistic optimum cut-offs. The veracity of the new algorithm proposed in this paper can be judge by comparison with results from both Lane's original algorithm and a modified version proposed by Gholamnejad (2009) employing the data given in Tables I and II for the example.

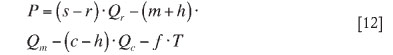

Gholamnejad (2009) developed Lane's original algorithm by adding rehabilitation costs to the equation. In the example given here, this rehabilitation cost was assumed to be equal to 0.5 ($/ton). Originally, in Gholamnejad's algorithm the rehabilitation cost was incorporated into determination of the optimum cut-off grade by Lane's algorithm. According to the developed Lane's algorithm, Equation [1] was rewritten as Equation [12] in order to find the total profit.

where h is the rehabilitation cost.

All the results obtained by the variable capacities-based algorithm proposed here are given in Table III, from which it can be seen that the optimum cut-off grade is estimated to be 0.2 pounds per ton, and equivalent to an NPV of $1737.992. In this case, optimal capacities of mining and processing are 90.95 t and 70.11 t, respectively. As previously mentioned, the refinery capacity is assumed to be equal to the market demand, i.e. 40 pounds per year.

The results of three compared algorithms are summarized in Table IV, from which it can be seen that the NPV achieved by the variable capacities-based algorithm is greater than that from both previous algorithms. The variable capacities-based algorithm determined the optimum cut-off grade to be 0.2 at a NPVmax of $1737.992. By comparison, cut-offs in Lane's and Gholamnejad's algorithms are 0.4 (pounds per ton) and 0.375 (pounds per ton), equivalent to an NPVmax of $1185.07 and $1064.75 respectively. The cut-off value determined using the variable capacities-based algorithm is less than those obtained from the both versions of Lane's algorithm, and indicates that the amount of the waste sent to the dump is less than that derived from both Lane's and Golamnejad's algorithms. Mining capacity in the new algorithm proposed here is approximately 90.95 t, again less than the other two other algorithms, whereas processing (mill) capacity at 70.11 t in new algorithm includes more value.

Overall, results from the algorithm proposed here are considered preferable, and the algorithm is found to be robust and better in determination of the optimum cut-off grade than both versions of Lane's algorithm.

Conclusion

Cut-off grade determines material to be sent to the waste dump and to the processing plant. If the cut-off is high, there is a risk that some economic material is mistakenly considered as waste. Conversely, if the cut-off grade is too low, then some uneconomic material will be erroneously defined as ore. Therefore, determination of optimum cut-off grade is a critical issue in economic mining. To this end, Lane's algorithm has been applied extensively, even though the mining, processing, and refinery capacities are assumed to be constant. In this study, Lane's original algorithm has been modified by considering variable capacities in the determination of the optimum cut-off grade in open-pit mines. The results of this new algorithm show that the optimum cut-off grade, and maximal NPV, is determined to be less than that obtained from previous algorithms, and it is suggested that the proposed algorithm is more capable in determination of the optimum cut-off grade. It is also concluded that mine, processing plant, and refinery can all work with full capacities during of the mining project.

The results indicate that the variable capacities-based algorithm is preferable for utilization in optimum cut-off grade determination. In order to facilitate use of the new proposed algorithm, a computer-based program was developed in Microsoft Office Excel©.

References

ASAD, M.W.A. 2005a. Cut-off grade optimization algorithm with stockpiling option for open pit mining operations of two economic minerals. International Journal of Mining, Reclamation and Environment, vol. 19, no. 3. pp. 176-187. [ Links ]

ASAD, M.W.A. 2005b. Cut-off grade optimization algorithm for open pit mining operations with consideration of dynamic metal price and cost escalation during mine life. Proceedings of the 32nd International Symposium on the Application of Computers and Operations Research in the Mineral Industry, Tucson, Arizona, USA. pp. 273-277. [ Links ]

Asad, M.W.A. 2007. Optimum cut-off grade policy for open pit mining operation through net present value algorithm considering metal price and cost escalation. International Journalfor Computer-Aided Engineering and Software, vol. 24, no. 7. pp. 723-736. [ Links ]

BASCETIN, A. and NEITO, A. 2007. Determination of optimal cut-off grade policy to optimize NPV using a new approach with optimization factor. Journal of the Southern African Institute of Mining and Metallurgy, vol. 107. pp. 87-94. [ Links ]

CAIRNS, R.D. and SHINKUMA, T. 2003. The choice of the cut-off grade in mining. Resources Policy, vol. 29. pp. 75-81. [ Links ]

GHOLAMNEJAD, J. 2009. Incorporation of rehabilitation cost into the optimum cutoff grade determination. Journal of the Southern African Institute of Mining and Metallurgy, vol. 109. pp. 89-94. [ Links ]

LANE, K.F. 1964. Choosing the optimum cut-off grade, Colorado School of Mines Quarterly, vol. 59, no. 4. pp. 811-829. [ Links ]

LANE, K.F. 1988. The Economics Definition of Ore: Cut Off Grades in Theory and Practice. Mining Journal Books, London. p. 145. [ Links ]

MINNITT, R.C.A. 2004. Cut-off grade determination for maximum value of a small Wits-type gold mining operation. Journal of the South African Institute of Mining and Metallurgy, vol. 104. pp. 277-283. [ Links ]

OSANLOO, M., RASHIDINEJAD, F., and REZAI, B. 2008. Incorporating environmental issues into optimum cut-off grades modeling at porphyry copper deposits. Resources Policy, vol. 33. pp. 222-229. [ Links ]

WHITTLE, J. 1999. A decade of open pit mine planning and optimization- the craft of turning algorithms into packages. Proceedings of the 28th International Symposium on Application of Computers and Operations Research in the Mineral Industry, Colorado School of Mines, Golden, Colorado. pp.15-23. [ Links ]

WHITTLE, J. and WHARTON, C. 1995. Optimizing cut-offs over time. Proceedings of the 25th International Symposium on the Application of Computers and Mathematics in the Mineral Industries, Brisbane, Australia. pp. 261-265. [ Links ]

© The Southern African Institute of Mining and Metallurgy, 2012. ISSN2225-6253. Paper received Feb. 2012; revised paper received Oct. 2012.