Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.12 Johannesburg Jan. 2012

Optimization of the transition from open-pit to underground operation in combined mining using (0-1) integer programming

E. BakhtavarI; K. ShahriarII; A. MirhassaniIII

IDepartment of Mining & Metallurgical Engineering, Urmia University of Tech., Urmia, Iran

IIDepartment of Mining & Metallurgical Engineering, Amirkabir University of Tech., Tehran, Iran

IIIDepartment of Mathematics & Computer Science, Amirkabir University of Tech., Tehran, Iran

SYNOPSIS

There are many near-surface deposits with considerable vertical extent that have the potential to be mined by a combined method of open-pit and underground methods. In this regard, there is often a point called 'transition depth' where a decision has to be made whether to continue deepening the pit or change to underground methods. Recently, optimization of the transition from open-pit to underground operation has become an important challenge in mining engineering. Optimally, to model the transition problem on the basis of maximization of the profit from open-pit and underground mining, (0-1) integer programming has been used. In this method, block economic values of open-pit and underground methods should be imported to the transition model. A hypothetical example is presented in order to assess the model in detail.

Keywords: open-pit, underground, transition depth, optimization, (0-1) integer programming, combined mining.

Introduction and problem definition

Open-pit mining is the most widely applied surface mining method and is by and large regarded to be economically superior to most underground methods, due mainly to higher recovery and production capacity. However, underground mining can be considered as being more acceptable than open-pit mining from the environmental and social perspectives, since it often leaves a smaller footprint.

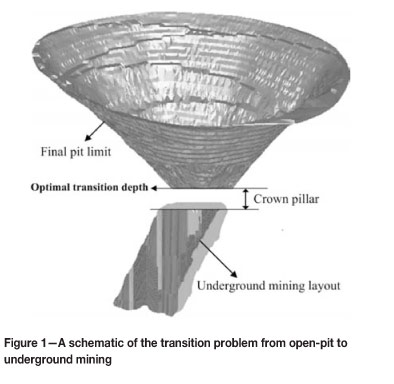

There are some near-surface deposits that extend to considerable depths. Development of such deposits often starts by adopting a surface mining method and then changing to an appropriate underground method when the mining depth reaches a predetermined maximum value. The transition depth is the point at which economic considerations dictate the change of mining method from open-pit to underground. Accurate determination of this depth is of utmost importance. In combined open-pit and underground mining, it is likely that block, mass, or panel caving systems are the most practicable underground methods, achieving high production rates and low costs (Fuentes and Caceres, 2004). A general view of the transition problem is shown in Figure 1.

In the past few decades, limited research has been carried out in order to solve the transition problem of some mines that have the potential of using both surface and underground methods. Some of the mines worldwide with potential to use a combination of open-pit and underground operations are Chuquicamata copper mine in northern Chile, Grasberg copper-gold mine in Indonesia, Diavik diamond mine, Kanowna Belle gold mine in Australia, Argyle diamond mine in Australia, Ekati diamond mines in Canada, Meng-Yin diamond mine, Bingham Canyon in the USA, Mansa Mina in Chile, Venetia in South Africa, Mount Keith and Telfer in Australia, and Kiruna in Sweden (Bakhtavar et al. 2009b).

Related research

For many large mines on the world scale, optimization of the transition depth from open-pit to underground mining is now considered as being a serious planning concern in the mine design stage. Determination of the optimized transition depth from open-pit to underground mining has therefore been the subject of some academic research, although much more work is required if it is to encompass all possible situations with acceptable accuracy.

The first method for such evaluation was the 'allowable stripping ratio', which defines a relation between the cost of winning 1 t of ore in underground (and in open-pit) mining and the cost of waste removal in relation to 1 t of ore won by the open-pit method (Soderberg and Rausch, 1968).

Nilsson (1982) presented an algorithm based upon cash flow and net present value (NPV), which was later reviewed in order to emphasize the importance of transition depth (Nilsson, 1992). To further enhance the analysis of the transition depth problem, discount rate was recognized as the most sensitive parameter in the process (Nilsson, 1997).

Camus (1992) introduced an algorithm using block models and considering net economic value of blocks for both open-pit and underground mining. This approach basically consists of running the open-pit algorithm, taking into account different cost values applicable in underground mining.

Subsequently, Whittle programming (4-x) was developed to calculate the transition depth from open-pit to underground mining. Using this method, decisions can be made by comparing operational scenarios of the open-pit to underground transition (Tulp, 1998).

Next, an approach on the basis of 'allowable stripping ratio' method was developed. In this approach, volumes of ore and waste within the open-pit limit were considered being a function of ultimate open-pit depth (Chen et al. 2001, 2003).

A computer program with a heuristic-based algorithm was introduced to find an optimal transition depth (Visser and Ding, 2007). Bakhtavar and Shahriar (2007) proposed a heuristic-based approach using the economical block models of open-pit and underground methods. In this approach, the total value obtaining from open-pit mining is compared to the value from underground mining for each level.

Further research resulted in a heuristic-based approach to determining the transition depth (Bakhtavar et al., 2008a). A variation of the heuristic-based method using the economical block models of open-pit and underground methods was developed after performing some essential modifications to the original algorithm proposed by Nilsson (1982 and 1992) in order to solve the transition problem (Abdollahisharif et al., 2008; Bakhtavar et al., 2009a).

A methodology was represented using the allowable and overall stripping ratios theory, which generated some formulae for calculating the transition depth from open-pit to underground mining (Bakhtavar et al., 2008b). A heuristic model was presented based on comparing block economic values of open-pit and underground methods together with the NPV attained through mining on similar levels (Bakhtavar et al., 2009b).

It is evident that the problem of transition from open-pit to underground mining is considering as a new critical challenge in the mining industry. The research associated with this problem is not considerable, and it is therefore essential that a major effort is devoted to the issue. A methodology based on mathematical programming is required owing to the deficiencies of the few methods developed to date, which are not able to find constantly an optimal transition depth. For these reasons, in this study to solve the transition problem on the basis of maximizing the profit gained by open-pit and underground mining, (0-1) linear integer programming has been used. Therefore, block economic values of open-pit and underground methods as the profit parameter have been imported to the transition model. Finally, to assess the model in detail a hypothetical example is used. The model proposed in this study can solve the transition problem by considering the technical and economic issues of both open-pit and underground mining.

Problem formulation

In mathematical programming using binary variables, a value of '0' will be attributed to a decision 'no' and a value of '1' to 'yes'. The transition problem can be defined as a decisionmaking process in form of 'extracting' (one) or 'non-extracting' (zero) in each block. It is evident that all of the decision variables of the transition problem are restricted to take on only integer (or discrete) values of 'zero' and 'one'. Therefore, the mathematical programming model introduced in this paper is based on (0-1) linear integer programming, and takes into account the economical block models with open-pit and underground block values (Bakhtavar, 2009). In order to mathematical model the transition problem some of the following assumptions have been considered:

The problem should be modelled on the basis of maximization of the overall profit achieved through open-pit and underground mining

Each block and also each row (level) can be mined at most once, and through at most one mining method (open-pit or underground)

At most one uniform crown pillar with constant height should be defined, being a multiple of row height considering the selected underground mining method and geotechnical criteria

At most one underground method focusing on 'overhand' stoping methods can be used, which is known

All open-pit and underground rows are contiguous

The required constraints of open-pit and underground mining methods should be considered.

In both open-pit and underground two-dimensional economical block models, dimensions (width and height) of the blocks are considered as being a multiple of the bench height, which is more common in open-pit mining and must also be applicable in underground stope mining. Furthermore, according to the wall slope of 45 degrees that has been conventionally considered in open-pit optimization algorithms, both the width and height of the blocks are assigned equal values. For example, if the bench height is designed to be 15 m, it would be better to consider the dimensions of blocks as 15*15 m2, 30*30 m2, or 45*45 m2 according to the volume of ore deposit. Although small size blocks can increase the accuracy of the model, the number of blocks and decision variables as well as size of the model may be increased. Therefore, in order to avoid this problem the most suitable dimension must be used for the blocks in the model. In the case of an ore deposit with a large volume (in the shape of massive and vertical or near-vertical thick veins), large size of blocks (45*45 m2) should be considered. However, for small ore deposits a size of 15*15 m2 can be effectively used for the blocks.

Definition of symbols and terms

In addition to 'variable' and 'constant' factors as the basic concepts for the transition model definition, some required indices, counters, and sets are defined in the Appendix.

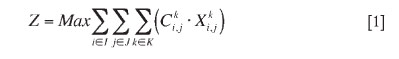

The objective function

The authors seek to optimize the transition problem on the basis of maximization of the overall profit achieved through open-pit and underground mining. For this reason, the objective function of transition model is expressed as follows (Bakhtavar, 2009):

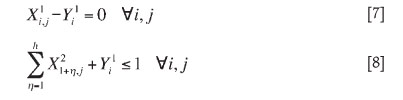

The model constraints

Both equality and inequality types of constraints have been modelled. They can be mathematically defined as the following (Bakhtavar, 2009):

Extracting or non-extracting constraints (reserve restriction)

A block is mined at most once and through at most one mining method (open-pit or underground). This constraint allows a block to be left in form of waste or in the crown pillar. It also ensures that if a waste block is located within the open-pit limit or underground layout, it inevitably has to be mined.

According to inequality [2], these constraints can be formulated to ensure that each block in the economical block model can be mined at most once and through at most one method.

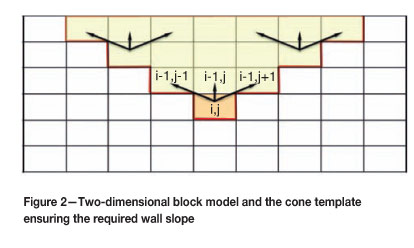

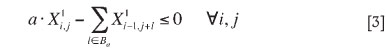

Slope stability and contiguous open-pit rows constraints

These constraints ensure that the open-pit wall slope restrictions hold. All the overlying blocks that must be mined before mining a given block have to be determined. This can be effectively imposed through one or more cone templates representing the required wall slopes of the open-pit mine (Figure 2). These constraints also ensure that all open-pit rows are contiguous. It is notable that these types of wall slope constraints are referred to as numerous constraints in this model. The constraints are defined mathematically as the following inequalities:

In Equation [3], on the basis of two-dimensional block models and considering conventional wall slope of 45 degree, a equals to 3 and Ba ={-1, 0, 1}. This means that for extracting block (ij), three overlying blocks {(i-1,j-1) , (i-1,j), have to be mined.

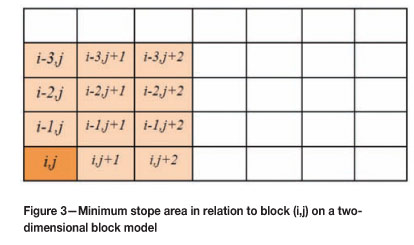

Minimum stope width and height constraints

From the economic and technical points of view, extraction of each block in underground stope mining is often conditional upon extracting all of the adjacent blocks within the stope layout. On the other hand, a block can be mined only if the other blocks within the stope layout have the potential to be mined. In this regard, the minimum applicable dimensions of the stope, namely width and height, are of the utmost importance in optimizing the underground layout.

It is supposed that minimum stope width and height are equal to three and four contiguous blocks respectively. In this case, in order to extract block (ij) it is necessary to mine all of the highlighted blocks shown in Figure 3, thus ensuring the minimum stope area and layout.

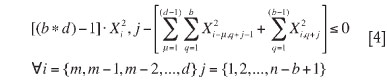

Mathematically, minimum stope width and height constraints can be merged in the form of a set of constraints. These constraints ensure the minimum applicable stope dimensions considering the underground mining sequence, which are defined on the basis of mathematical logic as below:

These constraints can be used in relation to all of the underground 'overhand' stoping methods.

Maximum stope width and height constraints

From the technical point of view, dimensions of a stope layout have to be restricted through the number of contiguous blocks in the vertical and horizontal directions. Maximum stope width and height constraints are formulated separately according to inequalities [5] and [6] respectively.

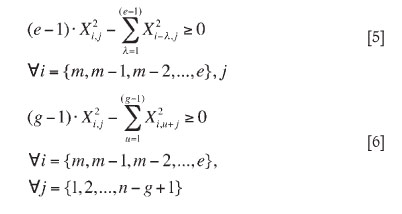

Crown pillar constraints

A crown pillar is often provided to prevent water entering from the open-pit floor into the stope, as well as to reduce surface subsidence and caving. Finding the most suitable crown pillar in a combined mining method using open-pit and underground operations, especially block caving, is one of the most interesting and useful problems for mining engineers today. With the increasing depth of open-pit mines, a combination of these two methods is gaining popularity and hence the importance of the problem is increasing. Leaving a pillar with adequate thickness will minimize detrimental interference between the two working areas, while maximizing ore recovery.

During this study, at most one uniform crown pillar with constant height being a multiple of the row (level) height is defined. For this purpose, the number of required rows is considered with reference to the selected underground stoping method, economic aspects, and geotechnical concerns.

Crown pillar constraints can be mathematically modelled through two set of constraints according to Equations [7] and [8].

'At most one method for each block' constraints

In addition to mining each block at most once and via at most one method (open-pit or underground), each row (level) also has to be mined according this rule. On the other hand, it is essential to define a set of constraints ensuring that each row can either be left as the crown pillar or mined through open-pit or underground methods. These constraints can be formulated according to Equation [9].

First, open-pit and underground block models must each be separately generated. Then, it is necessary to establish a long-range mining plan for the deposit.

The beginning of this economical comparison is level land it continues to level m, which is identified as the optimal final level of open-pit mining without considering any underground alternative.

Results and discussion

Generally, the two-dimensional ore deposit model contains many blocks, and it is very difficult or impossible to obtain a solution through linear binary integer formulations if they are applied to the block model including small blocks sizes (15*15 m2). Thus, it is often necessary to consider applying the formulations the blocks with larger dimensions such as 30*30 m2 and 45*45 m2. This can also be effective in reducing the processing (CPU) time required to solve the model.

The number of binary variables required for the presented linear integer model is equal to the number of blocks in the model multiplied by two (for open-pit as well as underground mining) plus the number of rows multiplied by two.

This section presents an application of the transition model on a 2D economical block model generated on the basis of a hypothetical ore deposit. The model embodies 204 square blocks of 30*30m2, with 17 and 12 blocks along the horizontal and vertical axes respectively.

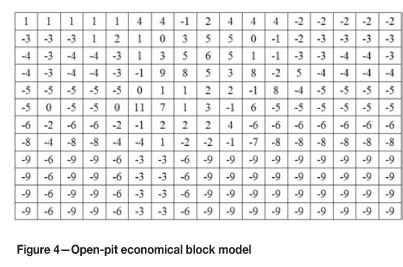

The economical block models and the block economic values achieved by open-pit and underground mining are shown in Figures 4 and 5 respectively.

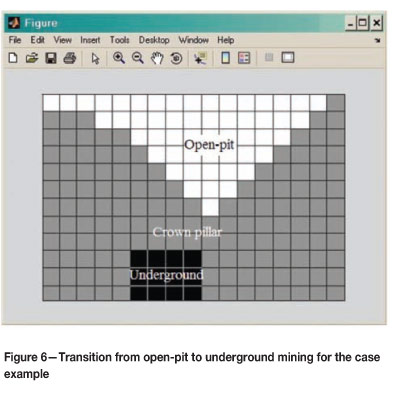

The model is solved using the optimization toolbox in MATLAB software after a running time of 14 seconds. The program output based on the model for the case example is shown in Figure 6. It is resulted in the initial seven levels being mined using open-pit method. This means that the transition depth equals 210 m. The minimum and maximum widths of the underground stopes are assumed to be four and five blocks respectively. Furthermore, four and five blocks are assumed to be the minimum and maximum heights of the underground stope. Two blocks are reserved for the crown pillar. As a result, the maximum total value due to the combined of open-pit and underground methods is determined to be 172 units of currency.

Most of the methods previously reported in the literature introduce the simply heuristic algorithms. They provide the majority of the essential factors to be considered, including the discount rate and time value of money in the NPV computations. However, while these algorithms have not been mathematically modelled and hence apply no limitations for the number of variables and constraints, the present paper introduces the complexities of the modelling and thereby circuments the limitations of the conventional and the current forms based on its mathematical model. Consequently, applying all the relevant factors contributes greatly to the complexity of the method, which has barely been discussed in this paper. It is worth mentioning here that an extension of the present work is in the authors' future plan to investigate the feasibility of applying some effective factors in the model. Furthermore, the authors are aware of 3D mathematical model benefits based on NPV that improve production scheduling. However, taking into consideration both open-pit and underground methods results in an increase in the number of variables in a way that make 3D modelling either inapplicable or infeasible. The extension of a 2D model to 3D should constitute an ideal solution; however, this has not been implemented as yet. The present paper considers a model that targets an optimal layout for both open-pit and underground design based on mathematical modelling. Ultimately, such optimization problems are initially modelled on 2D block model basis regardless of the NPV concept (including the time value of money and discount rate). For instances on this matter, the authors would like to refer to the work presented by Lerchs and Grossmann (1965) in optimum open-pit mine design, and by Riddle (1977) and Alford (1995) on the optimization of underground mine design. As stated earlier, applying the NPV concept in real applications would lead to a dramatic increase in the number of variables and constraints, since the mathematical model will embrace both open-pit and underground blocks. This prohibits defining an achievable specific scope for the problem. Due to this constraint, our projection focuses on a more realistic sub-problem to establish a mathematical model that at the same time provides new challenges in the combination of open-pit and underground methods.

The technique is proposed here with the hope that it will be used by the mining industry as a preferable mathematical model, which may be further refined and developed in further investigations into the optimization of the transition from open-pit to underground mining.

Conclusion

Due to the importance of optimizing the transition from open-pit to underground mining as a new challenge in mining engineering, a mathematical programming based model considering the block economic values of open-pit and underground methods together is presented. In this regard, all of the decision variables of the transition problem are restricted to take on only integer values of 'zero' and 'one'. Therefore, the transition model was established being a (0-1) linear integer programming base model.

Dimensions (width and height) of the blocks in two-dimensional economical block models were considered to be multiples of the desired conventional bench height for open-pit mining. This relationship is also applicable in underground stope mining.

It is notable that during the mathematical modelling of the transition problem, the objective function was expressed as maximization of the overall profit achieved through open-pit and underground mining. The objective function is subjected to a number of required constraints in relation to open-pit and underground mining, as well as a crown pillar between them.

In order to analyse the model in detail, a hypothetical example is used. After solving the model, the initial seven rows were considered for mining through the open-pit method. After leaving two rows as a crown pillar immediately below the final open-pit floor, the rows beneath the crown pillar were considered for underground mining. The transition depth from open-pit to underground mining for the case example was thus determined to be 210 m. The maximum total net value gained by combined mining was calculated to be 172 units of currency.

References

ABDOLLAHISHARIF, J., BAKHTAVAR, E., and SHAHRIAR, K. 2008. Open-pit to underground mining - where is the optimum transition depth? Proceedings of the 21st WMC & Expo 2008. Sobczyk, J. and Kicki, J. (eds.). Taylor & Francis, London, UK. pp.189-196. [ Links ]

ALFORD, C. 1995. Optimization in underground mine design. APCOM 25. Proceeding of the 25th International International Symposium on Application of Computers and Operations Research in the Minerals Industries, Brisbane, Australia, 9-14 July 1995. Townsville. Australasian Institute of Mining and Metallurgy. pp. 213-218. [ Links ]

BAKHTAVAR, E. 2009. A model for optimizing transition depth from open-pit to underground mining. PhD thesis, Amirkabir University of Technology, Tehran, Iran. [ Links ]

BAKHTAVAR, E. and SHAHRIAR, K. 2007. Optimal ultimate pit depth considering an underground alternative. Proceedings of Fourth AACHEN International Mining Symposium- High Performance Mine Production, Aachen, Germany. pp. 213-221. [ Links ]

BAKHTAVAR, E., SHAHRIARAND, K., and ORAEE, K. 2008a. A model for determining optimal transition depth over from open-pit to underground mining. Proceedings of the 5th International Conference on Mass Mining, Lulea, Sweden. pp. 393-400. [ Links ]

BAKHTAVAR, E., SHAHRIAR, K., and ORAEE, K. 2008b. An approach towards ascertaining open-pit to underground transition depth. Journal of Applied Sciences, vol. 8, no. 23. pp. 4445-4449. [ Links ]

BAKHTAVAR, E., SHAHRIAR, K., and ORAEE, K. 2009a. Mining method selection and optimization of transition from open pit to underground in combined mining. Journal of Archives of Mining Sciences, Poland, vol. 54, no. 3. pp. 481-493. [ Links ]

BAKHTAVAR, E., SHAHRIAR, K., and ORAEE, K. 2009b. Transition from open-pit to underground as a new optimization challenge in mining engineering, Journal of Mining Science, vol. 45, no. 5. pp. 87-96. [ Links ]

BRUMMER, R.K., LI, H., MOSS, A., and CASTEN, T. 2006. The transition from open pit to underground mining: an unusual slope failure mechanism at Palabora. Proceedings of the International Symposium on Stability of Rock Slopes in Open Pit Mining and Civil Engineering. Southern African Institute of Mining and Metallurgy, Johannesburg. pp. 411-420. [ Links ]

CAMUS, J.P. 1992. Open pit optimization considering an underground alternative. Proceeding of the 23rd International International Symposium on Application of Computers and Operations Research in the Minerals Industries, Tucson, Arizona. Kim, Y.C. (ed.). Societyfor Mining, Metallurgy and Exploration, Englewood, Colorado. pp. 435-441. [ Links ]

CHANGYU, X. 1984. A study of stope parameters during changing from open pit to underground at the Meng-Yin diamond mine in China. Journal of Mining Science and Technology, vol. 1. pp. 179-188. [ Links ]

CHEN, J., GUO, D., and LI, J. 2003. Optimization principle of combined surface and underground mining and its applications. Journal of Central South University of Technology, vol. 10, no. 3. pp. 222-225. [ Links ]

CHEN, J., LI, J., LUO, Z., and GUO, D. 2001. Development and application of optimum open-pit software for the combined mining of surface and underground. Proceedings of CAMI Symposium, Beijing, China. pp. 303-306. [ Links ]

FUENTES, S.S. and CACERES, S. 2004. Block/panel caving pressing final open pit limit. CIM Bulletin, vol. 97. pp. 32-34. [ Links ]

LERCHS, H. and GROSSMANN, I.F. 1965. Optimum design of open pit mines. CIM Bulletin, no. 58. pp. 17-24. [ Links ]

NILSSON, D.S. 1982. Open Pit or Underground mining. Underground Mining Methods Handbook (Section.1.5). AIME, New York. pp. 70-87. [ Links ]

NILSSON, D.S. 1992. Surface vs. Underground Methods. SME Mining Engineering Handbook (Section 23.2). Hartman, H.L. (ed.). pp. 2058-2068. [ Links ]

NILSSON, D.S. 1997. Optimal final pit depth: once again. International Journal of Mining Engineering, pp. 71-72. [ Links ]

RIDDLE, J. M. 1977. A dynamic programming solution of a block-caving mine layout. Proceeding of the 14th International Symposium on Application of Computers and Operations Research in the Minerals Industries. Society for Mining, Metallurgy and Exploration (SME), Colorado. pp. 767-780. [ Links ]

SODERBERG, A. and RAUSCH, D.O. 1968. Surface Mining (Section 4.1). Pfleider, E.P., (ed.). AIMM, New York. pp. 142-143. [ Links ]

SRIKANT, A., BRANNON, C., FLINT, D.C., and CASTEN, T. 2007. Geotechnical characterization and design for the transition from the Grasberg open pit to the Grasberg block cave mine. Proceedings of the 1st Canada-US Rock Mechanics Symposium, Vancouver, Canada, 27-31 May 2007. Eberhardt, E., Stead, D., and Morrison, T. (eds.). Taylor & Francis, London. pp. 1277-1286. [ Links ]

TULP, T. 1998. Open Pit to Underground Mining. Mine Planning and Equipment Selection. Balkema, Rotterdam. pp. 9-12. [ Links ]

VISSER, W.F. and DING, B. 2007. Optimization of the transition from open pit to underground mining. Proceedings of the Fourth AACHEN International Mining Symposium- High Performance Mine Production, Aachen, Germany. pp. 131-148. [ Links ]

Appendix

Indices and counters

i Index for rows

j Index for columns

i,j Index specifying location of a block within the economical block models

k Index to indicate possible mining methods for blocks (1 for open-pit; 2 for underground)

l Counter for blocks overlying ore-block (i, j) considered for assigning the slope constraint

q Counter for blocks (in a row) considered for setting the minimum width of an underground stope constraint

u Counter for blocks (in a row) considered for setting the maximum width of an underground stope constraint

μ Counter for blocks (in a column) considered for setting the minimum height of an underground stope constraint

λ is counter for blocks (in a column) considered for setting the maximum height of an underground stope constraint

η Counter for rows considered for setting the crown pillar between open-pit and underground stope mining constraint

Sets:

K Set of possible mining methods for blocks; K= {1,2}

B Set of blocks considered in modelling

Ba Set of blocks overlying ore-block (i,j) considered in modelling

BR Set of blocks that should be successively mined in a row through underground method; BR= ((i,1),(i,2).....(i,b).....(i,c)]

BC Set of blocks that should be successively mined in a column through underground method; Bc = ((1, j ),(2, j).....(d, j).....(e, j)]

I Set of rows; I = {1,2..., m}

J Set of columns; J = {1,2..., n}

Ih Set of contiguous rows that should remain immediately below open-pit mining; Ih = {1,2,..., h}

Constant parameters:

a Number of blocks overlying ore-block (i,j) considered in modelling

b Minimum number of blocks that should be successively mined in a row through underground method

c Maximum number of blocks that should be successively mined in a row through underground method

d Minimum number of blocks that should be successively mined in a column through underground method

e Maximum number of blocks that should be successively mined in a column through underground method

h Number of rows that should successively remain below the open-pit mining

m Number of rows considered in modelling

n Number of columns considered in modelling

Economical net value of block (i,j), of which

Economical net value of block (i,j), of which  is considered for open-pit and

is considered for open-pit and  for underground mining

for underground mining

Decision variables:

Binary variable representing block (i,j) mined through open-pit; it is assigned 1 if block (i,j) is mined through open-pit and assigned 0 otherwise.

Binary variable representing block (i,j) mined through open-pit; it is assigned 1 if block (i,j) is mined through open-pit and assigned 0 otherwise.

Binary variable representing block (i,j) mined through underground; it is assigned 1 if block (i,j) is mined through underground and assigned 0 otherwise.

Binary variable representing block (i,j) mined through underground; it is assigned 1 if block (i,j) is mined through underground and assigned 0 otherwise.

Binary variable representing row i mined through open-pit; it is assigned 1 if

Binary variable representing row i mined through open-pit; it is assigned 1 if  is one and assigned 0 otherwise.

is one and assigned 0 otherwise.

Binary variable representing row i mined through underground; it is assigned 1 if

Binary variable representing row i mined through underground; it is assigned 1 if  is one and assigned 0 otherwise.

is one and assigned 0 otherwise.

© The Southern African Institute of Mining and Metallurgy, 2012. ISSN2225-6253. Paper received Jan. 2010; revised paper received Jun. 2012.