Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 n.12 Johannesburg Jan. 2012

Advances in high-temperature heap leaching of refractory copper sulphide ores

S.W. Robertson; P.J. van Staden; A. Seyedbagheri

Mintek

SYNOPSIS

Acid heap leaching has been extensively applied to the processing of copper oxide ores, with recovery of copper by solvent extraction and electrowinning. Heap leaching has also been extended to the treatment of secondary sulphide copper ores, where oxidative conditions are generated in aerated heaps by the bacterially-assisted oxidation of ferrous iron to ferric iron. The treatment of low-grade chalcopyrite ores has recently been the focus of research, with Mintek playing a prominent role. When processing chalcopyrite ores, more complex column test work is performed, which incorporates the prediction and simulation of temperature behaviour in pyrite-containing heaps. Mintek has devised a trade-marked column leaching apparatus (SmartCohimnTM) for the simulation of the natural temperature profile development in pyrite-containing heaps. As heap leach applications are becoming more complex, the parameters that need to be built into the design and operation of heap leach plants are growing in number, and the amount of data to be collected and processed, and the number of decisions to be taken daily, are also increasing. Mintek has therefore developed the HeapStar® administrative advisory software, as a guidance system to ensure that the correct protocols are implemented at various stages of the leach cycle.

Keywords: heap bioleaching, chalcopyrite, simulation, process design, operation.

Introduction

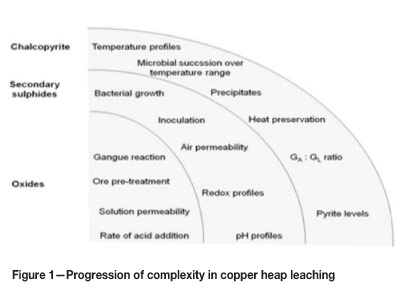

Heap leaching is used extensively for the processing of copper and gold ores, but there has also been renewed interest in uranium ores, as well as recent application to nickel laterites, and more frequently the application of heap leaching needs to be considered as part of a larger process in combination with other leaching steps. Each application introduces complexities particular to its requirements. Heap leaching typically involves simple atmospheric leach processes and well-established recovery steps such as solvent extraction (copper), ion exchange (uranium), and hydroxide precipitation (nickel laterites). Disadvantages of heap leaching include lower metal extractions, long ramp-up times, and lengthy experimental programmes!. With the depletion of higher grade resources, metallurgical testwork will be focusing increasingly on lower grade, more complex, and refractory ores, as well as smaller deposits. As a result, the level of sophistication that needs to be built into the design and operation of the heap leaching process also increases.

The heap leaching of copper ores is an example of such a trend, where heap leaching was initially applied only to the acid leaching of oxide ores. The most important factors to be considered in oxide heap leaching are the copper dissolution, acid consumption, and gangue chemistry. The rate at which acid can be supplied to the heap is constrained by the increase in undesirable gangue reactions that may occur. By introducing forced aeration and bacterial activity to the heaps, an oxidative environment suitable for sulphide conversion can be created. This has allowed heap leaching to be extended to treat secondary copper sulphides, where lower acid strengths are typically employed and sufficient air permeability becomes a requirement.

The application of bacterial heap leaching to refractory chalcopyrite ores introduces further complexity, such as the need to improve leach kinetics by raising the heap temperature. High leach temperatures (>50°C) are required to achieve meaningful chalcopyrite leach rates and extractions, which may be attained by the bacterial oxidation of co-occurring pyrite and by the preservation of heat through the manipulation of irrigation and aeration rates. The concentration of pyrite in the ore is therefore of primary importance, as well as the need to generate suitable conditions for bacterial activity in the heaps. Specially designed column tests are required to simulate the natural dynamic temperature behaviour in a large-scale heap, by accounting for all the terms of a large-scale heat balance. Figure 1 shows the increase in the number of design parameters that need to be considered when progressing from copper oxide to chalcopyrite heaps.

When designing a bacterial heap leach process for sulphide ores, the rate and schedule of air delivery to the heap becomes an important parameter. During heap leaching of chalcopyrite ores, maximization of the heat accumulation in heaps also becomes important. In order to minimize heat losses and optimize the temperature profile in the heap, it is necessary to control the ratio of the irrigation rate to the aeration rate in the heap. At the same time it is necessary to supply oxygen and acid to the heap at a fast enough rate for the gangue and pyrite reaction to take place. In addition, the use of intermittent irrigation during at least part of the life of a heap holds several advantages regarding drainage of the pores of large lumps, drainage tenor control, and aeration of the heap, as well as the control of precipitation reactions.

The simplest heap leach scheme involves the irrigation of all heaps with return raffinate from solvent extraction, and collection of all drainage liquors in a pregnant leach solution (PLS) pond. Countercurrent operation can be introduced by the addition of an intermediate leach solution (ILS) pond. Solutions with copper tenors high enough for solvent extraction are directed to the PLS pond, and lean liquors are directed to the ILS pond for recycle over the heaps. 'Old' heaps are irrigated with raffinate, and 'fresh' heaps with ILS. Additional solution management is therefore required to track the plant data for deciding which irrigant (ILS or raffinate) to use on each heap, and which drainage liquors report to the PLS or ILS ponds.

As heap leach applications are becoming more complex, the parameters that need to be built into the design and operation of heap leach plants are growing in number. The amount of data to be collected and processed, as well as the number of decisions to be taken daily by the plant operator, is also increasing. Mintek has developed a computerized heap administration, management, and advisory system, HeapStar®, which keeps record of all the heaps in operation, at different stages in the leach cycle. It provides daily guidance to the plant operator with respect to solution management, irrigation and aeration schedules, and other changes in the operating parameters.

SmartColumnTM for high-temperature heap leaching

Chalcopyrite is the most abundant copper mineral, comprising about 70% of the world's known copper reserves. However, due to the slow leach kinetics, meaningful extractions cannot be obtained at ambient conditions. The chemical leach rate is a strong function of temperature, and temperatures of above 50°C are required to achieve economical rates of extraction. If the ore contains sufficient pyrite, bacterial oxidation of the pyrite generates heat exothermically, and by manipulation of aeration and irrigation rates the retention of heat can be optimized. Being biologically driven, the process requires the maintenance of conditions suitable for bacterial growth.

To determine the design parameters for a high-temperature heap bioleaching process, it is necessary to predict and simulate the natural temperature progression that would occur in an actual heap. Ideally, a laboratory column should represent a cylinder of ore away from the sides of a large commercial heap (Figure 2), where the ore is well insulated on all sides by material of similar temperature which also generates its own heat, thereby eliminating sideways conduction2.

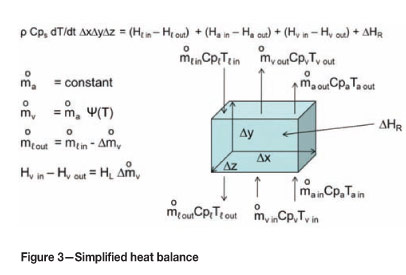

As indicated in Figure 3, the temperature change in a unit control volume can be expressed in terms of the mass flows, heat capacities, and temperatures of the liquor, gas, and vapour streams3-6. The gas stream is assumed to be saturated with vapour at any given temperature within the heap. The flow rate of gas is assumed to be constant.

Set out below is a explanation of the symbols in Figure 3.

Ψ(T) = saturated humidity at temperature

S = volumetric rate of heat generation inside heap

ml = flowrate of liquor

mv = flowrate of vapour

ma = flowrate of gas

Cpl, Cpv, Cpa = heat capacity of liquor, vapour, air

HL = latent heat.

Mintek has developed the SmartColumnTM concept, consisting of a number of individual vertical sections, each fitted with a control system governed by calculation algorithms, whereby the natural temperature progression inside a commercial heap can be simulated, illustrated in Figure 4.

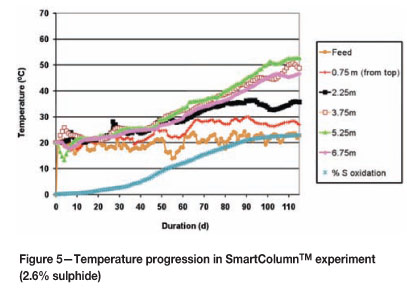

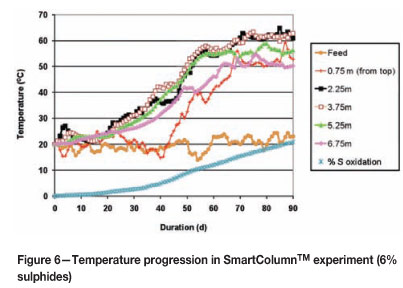

Figures 5 and 6 illustrate the progression of temperatures in SmartColumnTM experiments performed on a chalcopyrite ore. Temperatures of above 50°C were achieved for an ore containing 3% pyrite and 3% chalcopyrite (2.6% total sulphides), and temperatures of above 60°C were achieved after the addition of an admixture (6% total sulphides). The ratio of irrigation rate to aeration rate (GL/Ga) affects the shape of the axial temperature profile. If the aeration rate is too high, heat losses due to gas advection from the top of the column will increase. At the same time, sufficient air has to be supplied so that the pyrite oxidation is not limited. A faster irrigation rate may also speed up the acid addition to the heap, which is necessary to reduce the pH gradient so that conditions for bacterial growth can be established. However, high irrigation rates may cause greater solution advective heat losses from the bottom of the heap.

SmartColumnTM test results have been validated on 6 m pilot heaps of typically 20 000 t each. Good correlation has been found, and the SmartColumnTM concept was shown to identify conditions under which heat accumulation would not occur, and should therefore be avoided. Irrigation and aeration schedules thus developed during the SmartColumnTM tests are implemented, possibly to be further refined and modified during the test heap programme.

During chalcopyrite heap bioleaching, higher aeration rates are required than are customary for secondary sulphide ores, due to the requirement for pyrite conversion. During secondary sulphide heap bioleaching, it is necessary only to convert the sulphur species associated with copper. Column test work on secondary sulphide ores is normally performed without temperature simulation. Hence some scope exists for

Mintek's high-temperature methology to be applied to secondary sulphide and mixed sulphide ores, where higher aeration rates and pyrite conversion may speed up kinetics and improve overall recoveries. Geomechanical testing of air conductivities will form an important part of such test work.

HeapStar® administration and guidance software

The HeapStar® administrative and guidance system was developed during pilot plant trials on bacterial chalcopyrite heaps. The control package serves as an administrative tool to guide the irrigation and aeration schedule of each heap throughout its life cycle, as well as the decisions regarding the allocation of irrigation liquors (either ILS or raffinate) to each heap, and the allocation of drainage liquors (to either the ILS pond or the PLS pond). At the same time, the control actions remain consistent with the requirements for the copper tenor in the PLS. HeapStar® is set up as an advisory system, rather than a automated control system. It could also find application in the administration of heaps and solutions on oxide and secondary sulphide heap leach plants.

Operation of HeapStar®

HeapStar® holds in its database a set of rules according to which the different ore cells in a heap leach plant are operated. These rules can be specified by the plant operator (with the assistance of Mintek) if they are known, or would need to be determined experimentally for a new type of ore. The task of the HeapStar® software is to guide the operational staff through the daily actions required to ensure that each cell is steered according to the pre-determined processing rules, from commissioning via the various life-cycle phases, through to decommissioning. However, the system still leaves the operator with maximum flexibility to either follow his own operational strategy, or to follow the advice of the computerized system, and to change between the two at any time, as long the software is kept updated of the various actions.

Appearance of HeapStar®

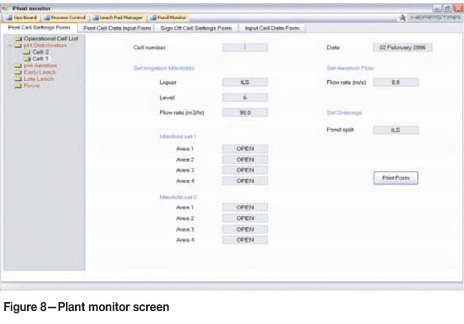

A few of the screens encountered in HeapStar® are shown below. A 'plant operations board' (Figure 7) provides a view of which tasks have been completed and which tasks or data inputs are still lacking. It also provides a condensed overview of the current status of a cell that is highlighted on this screen. The buttons provide shortcuts to the respective input/output screens.

The main input/output interface is the 'plant monitor' (Figure 8), which provides graphical summaries of the status, alarms, and the required actions and inputs related to each individual cell. A more condensed tabulated summary of all cells is also provided in a single report. The trends of selected parameters can also be viewed on charts. HeapStar® is configured to communicate to a particular irrigation manifold and valve system to control the flow to different parts of the irrigation system. The daily HeapStar® report suggests the valve settings on each manifold, and the task of the operator is then simply to ensure that the actual valve settings correspond to those on the daily HeapStar® report.

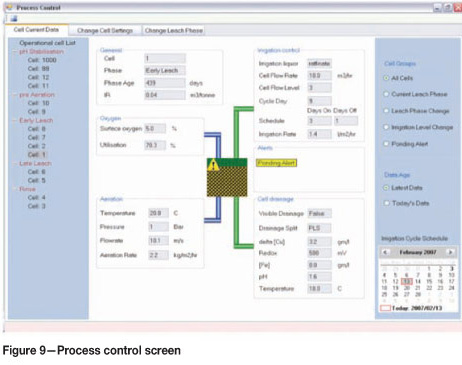

The logic and results of control actions (whether proceeding to the next operational phase, or adjusting flows) are visualized on the 'process control' screens (Figure 9).

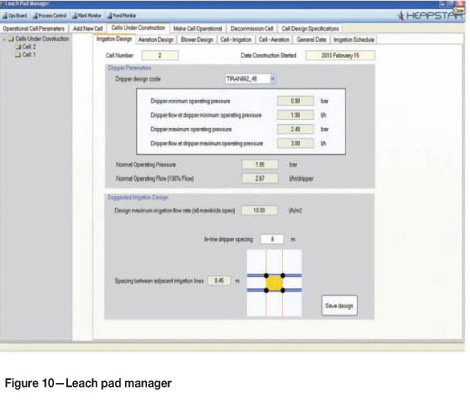

HeapStar® also includes a 'leach pad manager' (Figure 10), which registers new cells and archives the records of decommissioned cells. It also includes features for the selection of dripper spacing and aeration piping design for each new cell during stacking, to ensure that the required ranges of irrigation and aeration flows can indeed be achieved with the selected type and spacing of piping, drippers, and aeration orifices.

Automation of HeapStar®

In its simplest form HeapStar® functions on a stand-alone PC, with manual entry of instrument readings and chemical analyses in the 'Plant Monitor', and manually executed valve switching to give effect to the daily actions to be taken. However, it can be customized for a particular application to automate data entry (either by remote-sensing instruments or by sharing data from a SCADA database). Similarly, the required actions can be automated.

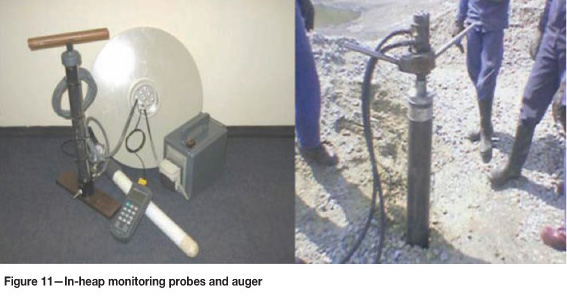

Instrumentation

Depending on the particular application, the rules whereby the ore needs to be heap leached may require only externally observed parameters (such as chemical analyses of drainage and off-gas) for guiding the leach operation. However, more complex cases may require measurements or samples to be obtained from one or more points inside the ore heap. For this purpose, in-heap instrument bundles can be employed to obtain liquor samples, gas samples, and temperature readings from inside an ore heap. Instruments are installed either during stacking or in holes augered in existing heaps, using auguring equipment normally used for dump and dune drilling (Figure 11).

In-heap lysimeters and instrument bundles allow solution and gas-phase samples to be taken for daily analysis at various depths in the heap, as well as thermocouple temperature measurements, which assist the site engineer in making operational decisions and verifying the models and simulations used during the laboratory phase. This allows the site engineer to draw conclusions related to chemical and gangue reaction, bacterial activity, heat generation, and solution and air permeability. For example, a low oxygen concentration towards the top of the heap may indicate insufficient air permeability or too low an aeration rate, whereas uneven solution profiles along the width of the heap may indicate uneven irrigation.

Conclusions

With heap leaching continuing to be considered for more challenging applications, more sophisticated laboratory procedures become necessary to assess the amenability of ores to heap (bio-) leaching, and to provide more quantitative specifications for the engineering of the scaled-up process

Heap bioleaching of low-grade chalcopyrite introduces a greater degree of complexity into the test work programme in terms of the requirement for bacterial growth at a range of temperatures, heat balance modelling, and optimization of parameters such as irrigation and aeration rates to maximize heat retention and maximize copper return while at the same time minimizing gangue reaction and precipitate formation. Mintek's SmartColumnTM concept enables the natural temperature progression inside a commercial heap to be simulated. Test work performed to date provides reasonable confidence in terms of scale-up from column tests to pilot heaps

Whereas chalcopyrite bioleaching design requires high aeration rates to supply oxygen for pyrite oxidation, aeration rates for secondary sulphide ores are lower since only sulphides associated with copper are targeted. Column test work on secondary sulphide ores is normally performed without temperature simulation. Hence some scope exists for application of high-temperature methology to secondary sulphide and mixed sulphide ores, in an attempt to convert pyrite and raise temperatures, which should speed up the leach kinetics and improve overall copper recoveries. Geomechanical testing of air conductivity will form an important part of such test work

As heap leach applications are becoming more complex, the parameters that need to be built into the design and operation of heap leach plants are growing in number. The amount of data to be collected and processed, as well as the number of decisions to be taken daily by the plant operator, is also increasing. Mintek has developed a computerized heap administration, management, and advisory system, HeapStar®, which keeps record of all the heaps in operation at different stages in the leach cycle. It provides daily guidance to the plant operator with respect to solution management, irrigation and aeration schedules, and other changes in the operating parameters.

References

1. TAYLOR, A. Heap leaching and its application to copper, uranium and nickel ores. Short course, ALTA Metallurgical Services, Perth, 2008. [ Links ]

2. VAN BUREN, C. BHP Billiton SA Ltd. Method of and apparatus for simulating a biological heap leaching process. PCT WO 2005/061741 A1, 7 July 2005. [ Links ]

3. BARTLETT, R. (ed.) Solution Mining: Leaching and Fluid Recovery of Materials. Gordon and Breach, New York, 1995. pp. 76-107. [ Links ]

4. DIXON, D.G. Analysis of heat conservation during copper sulphide heap leaching. Hydrometallurgy, vol. 58, 2000. pp. 27-41. [ Links ]

5. DIXON, D.G. Conservation of heat during thermophilic biooxidation of low-grade copper sulphide concentrates via Geocoat® Heap Leaching. Presentation, Chalcopyrite Think Tank 2000. Phelps Dodge Mining Company, Phoenix, Arizona, 19-20 october 2000. [ Links ]

6. PETERSON, J. and DIXON, D.G. Thermophilic heap leaching of a chalcopyrite concentrate. Minerals Engineering, vol 15, 2002. pp. 777-785. [ Links ]

© The Southern African Institute of Mining and Metallurgy, 2012. ISSN2225-6253. This paper was first presented at the Percolation Leaching Conference, 8-9 November 2011, Misty Hills, Muldersdrift.