Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 n.8 Johannesburg Jan. 2012

JOURNAL PAPER

The development of a remote-controlled highwall rockbroom-a world first for the open-pit mining industry

D. van RensburgI; L. MelisII

IAngloAmerican Platinum, Mogalakwena Mine, Rock Engineering Department

IIMelis & Du Plessis Consulting Engineering (Pty) Ltd, Rock Slope Engineering

SYNOPSIS

Jointed rock slopes are generally stable, as there is no freedom of movement for blocks of rock. In an open- pit mining environment, blasting opens up space into which blocks of rock can fail, resulting in the common occurrence of slope failure.

Prior to the blasting of a trim pattern, the immediate highwall is scaled, where loose rock material is removed by means of a mechanical scaler. As mining of the pit progresses, the height of the scaled highwall from the pit floor progressively increases. These highwalls are never scaled again for the remainder of the pit life, and time-dependant deterioration contributes to these highwalls becoming subject to rockfall and, sometimes, slope failure.

This paper documents the development of a South African innovation, a remote-controlled mechanical highwall scaler, a world first for the mining industry. The scaler will enable open-pit highwalls to be scaled from crest to toe whenever the need arises. It will reduce the risk associated with highwalls and deliver on the Anglo American promise of producing safe, profitable platinum.

Keywords: open-pit mining, rockfall, slope stability, mechanical scaling.

Introduction

The Safety, Health and Environmental Policy at Anglo American's Mogalakwena Platinum Mine has identified highwall stability as one of the major safety risks of the operation. At Mogalakwena, slope instability and rockfall risk are highlighted as the major focus areas in reducing highwall risk. A comprehensive slope-monitoring strategy has been implemented and refined over the past decade and includes technologies such as automated prisms and laser systems, and slope stability radar systems. These are all very effective methods in reducing the risk posed by large-scale slope instability; however, none of them can monitor or forewarn of the much smaller and frequent but dangerous rockfalls from the highwalls.

An innovative method of significantly reducing the rockfall risk at Mogalakwena is being developed for the rock engineering department at Mogalakwena Platinum Mine, as a collaborative initiative between Wepex, a South African geotechnical contracting company, and consulting engineers Melis and Du Plessis, both companies specializing in aspects of the civil and mining industries in Southern Africa.

This paper presents the results of tests conducted with the prototype in Lafarge's Ridgeview quarry in Durban between 7 and 10 February 2012.

Rockfall risk in the open-pit mining environment.

Overall open-pit slope stability and inter-ramp stability are governed by the local geological structure, the quality of the rock mass, and its stability within the prevailing stress regime. They are generally analysed using numerical modelling methods. The geological structure controls the overall and inter-ramp stability, as well as berm stability, and may be analysed using kinematic methods. Berms are designed to intercept and contain rockfalls that originate from higher up the slope. In this manner, they prevent falling rock from continuing further down the slope and possibly endangering the lives of personnel and damaging equipment working in close proximity to the slope face.

Rockfall hazards in the open-pit environment occur for a number of reasons. The main contributory factors are aggressive pit slope design, time dependent deterioration of the rock mass, poor limit blast performance, full-depth ramp blasting, and not cleaning to the mining limit. All of these factors result in overall poor trim blast performance and an immediate loss of a portion of the designed catchment width of the berms. To compensate for these realities, and to reduce the danger arising from falling rocks, adequate measures have to be taken to reduce the risk to personnel and equipment. These measures include increasing the berm width, improved mining methods, building windrows, and installing drape mesh or rockfall barriers. These measures lead to more conservative designs and mining methods, thus increasing cost and maintenance requirements.

Managing rockfall risk at Mogalakwena

Mogalakwena Platinum Mine has adopted a proactive approach in managing and reducing the risk associated with rockfall. Some of these measures include limit blasting techniques, which include the use of pre-splits; bench face scaling using scaling rigs; the use of drape meshing and gabions; and the enforcement of a 15 m exclusion zone at the toe of the slope. Although these measures are very effective, they ultimately add to cost and impact on production, and it is for this reason that Mogalakwena embarked on a quest to find a system that would remove, or at least significantly reduce, the rockfall risk from the highwalls. Various attempts were made in the past to accomplish this, including the use of water jets and dragging heavy chains down the slope, but none of these proved to be very effective.

A collaborative effort between Wepex and Melis and Du Plessis, facilitated by the rock engineering department at Mogalakwena, has resulted in the development of a concept and a prototype that will greatly reduce rockfalls from highwalls. The result is a remote-controlled and steered highwall scaler and berm cleaner, aptly named the SmartBroomTM (with intellectual property and copyrights protected). The SmartBroom simply dislodges and brushes away loose rocks as it traverses the highwalls and berms. It will now be possible for the first time to safely scale highwalls of any height. This concept and customized technology being developed is a world first. It will benefit the Anglo American Group, and the broader open-pit mining industry, in terms of greatly mitigating and managing rockfall risk, and will be an example of industry best-practice in achieving the goal of zero harm in our mines.

The SmartBroom can be used without interfering with the mining sequence or production while maintaining the highest levels of safety. It can be used continuously or periodically as and when required.

The SmartBroom

The prototype of the SmartBroom was mounted as an attachment to a carrier, namely a mesh-decoiler.

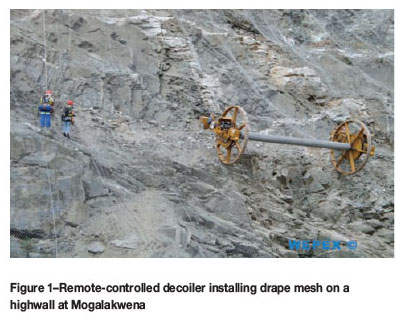

The decoiler was originally developed two years ago as a remote-controlled and steered unit that enabled drape mesh to be safely and quickly installed on open-pit highwalls (Figure 1). It has been used at Debswana's Jwaneng diamond mine in Botswana and at Mogalakwena, where it proved to be very reliable and extremely safe to operate.

It soon became apparent that the decoiler could serve as a platform for mounting the prototype SmartBroom for the initial trials. Only minor technological adjustments were necessary to convert the decoiler to a SmartBroom carrier.

The decoiler consists of a long shaft with a 3 m diameter wheel on each end. The wheels are flanked by a cable drum and cantilever arm on the outside of either wheel. Control cables that are wound onto the cable drums are anchored at the top of the highwall. The cable drums are free-spinning with a damper control unit to prevent excessive de-winding. The cables pass through a double conical brake mechanism mounted on the inside of the cantilever arms.

The brakes are hydraulically activated and are remotely controlled via a radio-servo systems. The system is speed-sensitive, and will automatically engage the brake system to stop the decoiler if a speed threshold is exceeded. The system also has an 'anti-bump' function that will automatically engage the brakes if any of the controls on the remote-control unit are excessively moved or accidentally bumped. The decoiler has a backup brake system comprising parallel cable clamps that allow the operator to stop the system remotely if the primary systems fail on both sides.

Two power packs power the main wheels. These are internal combustion units that power hydraulic pumps. Drive to the main wheels is via reduction gearboxes with chain drives coupled to hydraulic motors. The wheels are radio-servo remote-controlled and can be manoeuvred independently of each other. This allows the decoiler to be steered left or right or even reversed.

The decoiler has a maximum GVM of 8 t, is able to carry a load of 5 t, and can currently operate on highwalls up to 500 m high.

The SmartBroom was centrally mounted on the main shaft of the decoiler. Free rotation of this shaft allows the SmartBroom to sweep surfaces at any angle as it engages with the rock. The SmartBroom is fitted with a height control mechanism consisting of an arm and wheel and hydraulic cylinder. The arm can be raised and lowered to ensure that the brushes stay in contact with the rock surface. It also allows the broom to be raised when negotiating obstacles.

The SmartBroom itself consists of a hydraulically-driven heavy rotating shaft with 17 'brushes' which are screwed into the shaft. The prototype has a heavy upper protective steel shield with the lower half open to allow the brushes to engage with the rock surfaces. The brushes are made of heavy cable, and for the tests 40 mm diameter cable was used. Being consumable items, the cables can be changed and replaced quickly. The system allows cables of various diameters, ranging from 20 mm to 100 mm, to be fitted, depending on the contact energy and stiffness of brush required for dislodging and moving rocks of various sizes.

The smaller diameter brushes are more flexible and will impart relatively low energy levels on the face compared to the larger diameter brushes, which are stiffer and will impart relatively high energy levels onto the rock surface and loose rocks. The decision on which energy level to use on a particular face will be site-specific, and will take into account rock mass strength, amount of time-dependent deterioration, geometry and orientation of geological structures, and fracture frequency.

The SmartBroom can rotate both forwards and backwards.

Summary specification of the SmartBroom:

Broom dimensions:

Width: 2350 mm

Diameter: 1950 mm

Weight: 3000 kg

Hydraulic requirements

Max hydraulic pressure: 700 bar

Hydraulic control: Proportional remote control

Max torque broom shaft: 1900 Nm

Properties of the 40 mm diameter cable brushes usedfor prototype:

Max Bristle Head Speed: 42 m/s

Broom element lock-off torque on shaft 1050 Nm

Broom element weight: 9.8 kg

No. of brushes: 17

The prototype SmartBroom fitted with 40 mm diameter cable brushes is illustrated in Figure 2.

Test site

The tests were conducted in the Lafarge Ridgeview quarry in Durban, KwaZulu-Natal from 7-10 February 2012. The test site covered the immediate horizontal and vertical sections of the pit crest (Figure 3).The rock type was slightly-weathered to unweathered Dwyka tillite with a rock quality designation (RQD) of 65 per cent, classifying the rock quality as 'fair'. The RQD was calculated based on a 'virtual drill core' being taken over a 5 m horizontal stretch of open rock face. The estimated rock strength using the ISRM, 1981 classification is 'very strong rock', UCS 100-250 MPa.

Bertoe Meyer, the lead designer of both the decoiler and SmartBroom, and his team from Wepex conducted the tests. The tests were monitored by Dave van Rensburg, chief rock engineer from Mogalakwena, who was in attendance throughout, while Louis Melis from Melis and Du Plessis, was in attendance for the crest brooming part of the trials.

Test results

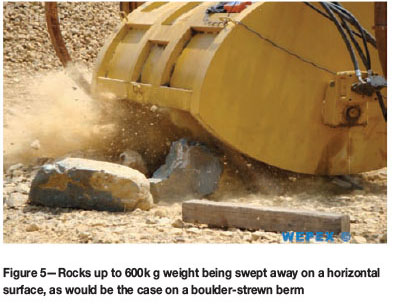

The first part of the trials comprised a flat test section away from the crest, in which rocks ranging up to about 0.25 m3 (i.e. up to about 600 kg were placed in front of the SmartBroom, and brushed along the horizontal surface (Figure 4).

The results obtained were very encouraging. The SmartBroom managed to effectively sweep all the rocks placed in its path (Figure 5). The largest rock, which had a mass of 600 kg, was moved 2 m in a time of 3 minutes.

The second part of the trial comprised a test to sweep a 7 m horizontal section back from the crest edge. The purpose of this test was to obtain an understanding of the degree of cleaning and dislodgement of partially-wedged rocks, that could be brushed away. The results exceeded expectations, as a virtually clean surface free of any rock fragments was produced within 2 minutes. This is clearly illustrated in Figure 6, where the bottom half of the plate illustrates the swept section, with the crest edge to the left, and the unswept section in the top half of the plate.

The third and final part of the trial comprised brushing the 5 m vertical face below the crest. To assist in evaluating the effectiveness of the SmartBroom, the face was marked with continuous white lines and all high-risk rocks/areas were individually marked, as may be seen in Figure 7.

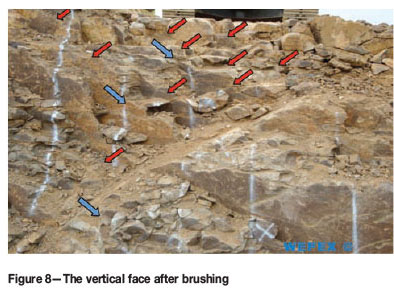

This part of the trial was not as successful as the initial two tests, as there were problems in controlling the lowering of the decoiler over the crest of the highwall due to the sudden take-up of slack in the temporary anchorage behind the crest. As a result, the decoiler started slipping and only the uppermost part of the vertical crest edge was brushed for any length of time before the decoiler started accelerating downslope. In Figure 8, the same areas as indicated in Figure 7 can be compared, showing clearly that the rocks and debris near the crest were very effectively removed. The SmartBroom also managed to reach areas up to 700 mm behind the average crest line, demonstrating that the intact rock profile was very effectively followed on a relatively uneven edge. This achievement would, however, vary according to the length of the cable brushes employed and the rock face characteristics of different sites.

Although the SmartBroom did not engage with the surface long enough to brush down the lower section of the wall adequately, a surprisingly large amount of rock debris was removed during the short time that it had engaged. It was also interesting to note that some of the rocks that were not removed (indicated with blue arrows) showed clear impact markings from the brushes, indicating that they were attached firmly to the rock face. Longer sweeping times, or brushes of larger diameter imparting higher energies, would have to be applied to dislodge themthese are all variables that can be designed and fine-tuned for each highwall or part thereof.

The overall view of the decoiler and the SmartBroom with the brushed crest edge are shown in Figure 9.

Conclusions and way forward

Rockfall hazards in the open pit environment pose a significant risk to personnel and equipment.

In spite of Mogalakwena Platinum Mine adopting a proactive approach in managing and reducing the risk associated with rockfall, rockfall risk is still highlighted as a major focus in the mine's safety, health, and environmental policy.

Although the measures introduced at Mogalakwena to combat rockfall are very effective, they do place constraints and limitations on the mining activity and overall highwall stability monitoring.

The prototype of the remote-controlled SmartBroom has provided, for the first time, an effective method of significantly reducing the rockfall risk in open-pit mines worldwide, by being able to safely scale highwalls of any height.

Although not advocated as a standalone rockfall mitigation option per se, the SmartBroom may very well be all that is required in many situations. Even so, scaling and removal of loose rock, prior to the installation of conventional rockfall mitigation measures such as drape meshes and catch fences, can greatly reduce their maintenance cost and life span. The SmartBroom will further allow the catchment berms on existing long-standing highwalls that have become choked with rock debris to be cleaned out and rehabilitated to the same level of service and functionality as they were initially designed for.

This technological innovation, when fully developed, will contribute enormously to the goal of making open-pit mines a safe working environment.

Following the success achieved with the prototype, Wepex will now proceed with the final design and manufacture of the production units. The main elements that need to be addressed, and for which concepts have already been indentified, will be:

An all-terrain remote-controlled carrier unit that will remain stable and controllable on all surfaces at any angle, and that can traverse all terrains and large obstacles, including rock-strewn berms

An all-terrain remote-controlled carrier unit that will remain stable and controllable on all surfaces at any angle, and that can traverse all terrains and large obstacles, including rock-strewn berms

The need for being able to achieve purchase on the near-vertical faces and even overhangs as the unit traverses downslope, to ensure maximum engagement of the broom with the rock surface at all times

The need for being able to achieve purchase on the near-vertical faces and even overhangs as the unit traverses downslope, to ensure maximum engagement of the broom with the rock surface at all times

Optimal brush diameter and length combinations, together with speed and power of the unit to achieve various energy ratings as applicable for different conditions and applications. This will also include optimizing the number and configuration of the attachment points of the brushes on the rotating shaft. These energy ratings and configurations could eventually be matched to rockmass rating systems used in open-pit design

Optimal brush diameter and length combinations, together with speed and power of the unit to achieve various energy ratings as applicable for different conditions and applications. This will also include optimizing the number and configuration of the attachment points of the brushes on the rotating shaft. These energy ratings and configurations could eventually be matched to rockmass rating systems used in open-pit design

Additional and alternative design of the brooming mechanism as may be more effective in certain applications. This will apply in particular to irregular and highly-broken faces

Additional and alternative design of the brooming mechanism as may be more effective in certain applications. This will apply in particular to irregular and highly-broken faces

The addition of remotely-operated tools on the decoiler platform, which could be used either as part of the brooming exercise or for other applications such as remote-controlled drilling and anchoring on the highwall as might be required.

The addition of remotely-operated tools on the decoiler platform, which could be used either as part of the brooming exercise or for other applications such as remote-controlled drilling and anchoring on the highwall as might be required.

Acknowledgements

The authors would like to acknowledge the lead designer, Bertoe Meyer from Wepex, for the creation of this innovative technology, which will revolutionize open-pit highwall safety. To the management of the Lafarge Ridgeview quarry, thank you for providing the test site, and thanks to the management of Mogalakwena Platinum Mine for permission to publish this paper.

© The Southern African Institute of Mining and Metallurgy, 2012.ISSN2225-6253. This paper was first presented at the, Southern Hemisphere International Rock Mechanics Symposium (SHIRMS) 2012, 15-17 May 2012, Sun City, South Africa.