Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.7 Johannesburg Jul. 2012

JOURNAL PAPER

Large-scale design and testing of an improved fine coal dewatering system

M. le RouxI; Q.P. CampbellI; W. Smit

ICSIR Mining Technology

SYNOPSIS

Fine coal (-500 |m) is notoriously difficult to dewater. It is not uncommon for a dewatered product to have a moisture content as high as 30 per cent after vacuum filtration. This poses several handling and financial problems to such an extent that a lot of fine coal is discarded onto slurry waste ponds. A novel way of dewatering fine coal was developed at North-West University. It entails deliberately damaging the filter cake during dewatering to allow for an increased flow of air through the cake at the expense of the applied pressure differential. This method resulted in an average improvement in final cake moisture of between 3 per cent and 5 per cent when executed in the laboratory under controlled conditions. A device was designed that could be fitted onto existing belt filters that would damage the filter cake as it passes by. This device was tested on a vacuum belt filter installation at a coal beneficiation operation in the Waterberg coal field in South Africa. The results showed a 3 per cent reduction in final moisture of the cake, proving the validity of the method at full industrial scale.

Keywords: fine coal, dewatering, filtration.

Introduction

South Africa has an abundance of coal reserves and is currently one of the leading producers of coal in the world. Since most of the southern hemisphere's coal deposits have a high ash content, beneficiation plays an important role in the upgrading of coal. However these washing methods are responsible for the generation of fine (-500 |xm) and ultrafine (-100 |xm) material. It has been reported that as much as 14 per cent of all ROM coal can report to the fines fraction while 2-3 per cent will end up being classified as ultrafine1.

These fine fractions have a lot of associated moisture and are normally in slurry form, or at best, a very moist solid stream. Over the years, the fine coal has been discarded into slurry ponds, but now that the value of it can be realized, either it is added to the final product as is, or alternatively, it is upgraded, dried, and sold. This has led to rapid improvement in fine coal processes like spirals, froth floatation, and fluidization. The main reason for not fully optimizing these processes is the amount of moisture in fine coal. Removing the moisture efficiently will yield definite benefits in finances and the handling of fine coal, and will have a positive impact on the environment.

Background

Rong2 defined three types of moisture in coal: namely, surface or free moisture, inherent or capillary moisture, and chemically bound moisture. Of these only the free moisture fraction can be removed using mechanical means like filtration or centrifuging. Studies done on fine coal showed that it is not uncommon for a fine coal filter cake to have a moisture content up to 30 per cent after filtration. Such a high moisture content impacts negatively on the possible revenue from the coal. Tao et al.3 showed that a 1 per cent reduction is the moisture content of 3 million tons of clean coal will lead to a saving of US$300 000.

Le Roux and Campbell4 showed that by deliberately perforating a fine coal filter cake during dewatering, the increased the airflow through the cake will yield a drier product. A reduction of up to 7 percentage points has been reported. This phenomenon is shown in Figure 1.

From Figure 1 it is clear that the dewatering rate increases rapidly at the point where the filter cake was perforated. The end result yielded a filter cake that was about 5 per cent drier than for the standard filtration test. This process was optimized by Le Roux et al.5, who showed that any type of perforation applied through the top third of the thickness of the filter cake will be sufficient to obtain the additional decrease in moisture content of the coal.

Scope

The project was done in two parts:

The first part of the project entailed a detailed laboratory study to determine the validity of the process on a sample of coal and to optimize the procedure

The second was the design, building, and commissioning of a full-scale rig to be added to current filters to enable full scale testing of the method.

Part 1: Laboratory setup and results

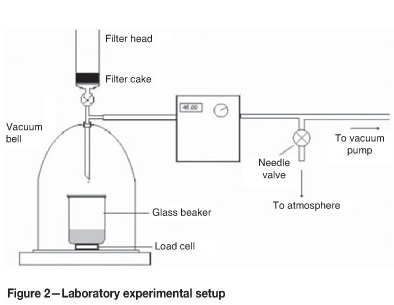

A 25 kg coal sample (proximate analysis shown in Table I) from the Waterberg coal field was used. The belt filter product was sampled, sealed, and taken back to NorthWest University. The sample was divided to make up the feed of 350 g for each test run, which delivers a similar cake thickness as for the full-scale filter. The divided samples were remixed with water, flocculated, and fed to the system shown in Figure 2.

Figure 2 shows the filtration system, which consisted of a glass bell jar that could be evacuated, with a filter head fitted onto the top of the bell. A glass beaker, situated inside the bell jar on a load cell, was used to collect the filtrate and measure its mass continuously. Real-time data was captured on a computer. The setup was operated to emulate full-scale belt filters, having a retention time of 300 seconds and an applied vacuum differential of 60 kPa. Damage to the cake was inflicted at several time intervals during the course of dewatering by cutting slits into the surface to a certain depth using a spatula to determine the optimum positioning of the designed rig on the belt filters.

Summarized results from the above tests are shown in Figure 3. The solid line on the graph represents the final cake moisture obtained for the standard filtration test, where no cuts were made in the filter cake. It is used to draw a comparison to the data points that represent the moisture levels obtained in the final filter cake, when damage was inflicted to the cake at certain times after 100 per cent saturation in the dewatering cycle. The lowest moisture level was obtained when the cake was damaged at the point of 100 per cent saturation, i.e. when all the inter- and intraparticulate voids were completely filled with water, without any excess water present. This test yielded a final cake moisture of 21.8 per cent, compared to 24.9 per cent for the standard filter test. This serves as an indication of the positioning of the test rig on the belt filters. The tests were repeated three time, and the results gave a standard deviation of ± 0.68 per cent.

Part 2: Full-scale test rig design and results

The full-scale test rig had to serve two purposes: it should act as a test apparatus to check if the practical results agree with the laboratory results; and it should serve as a prototype to test the mechanical design. The apparatus was designed according to the following specifications:

It should be easy to fit the apparatus to an existing belt filter

It should operate with minimal maintenance

It should run without external power

It should be easy to move the apparatus along the length oi the iiler in order to modiiy the point oi perioration

The apparatus should fit in a small delivery vehicle.

The results in Figure 3 showed that the best time to inflict the damage is at the onset of 100 per cent saturation. Translated to a full-scale belt filter operation, this will be at the point on the belt where the superficial water disappears from the filter cake surface. Le Roux et al.5 further determined that the best way to damage the cake in the laboratory was by pressing a cylindrical object axially into the cake. It was, however, also shown that the method for inflicting the damage had little effect on the final cake moisture, and was required to disturb only the top third of the cake.

The mechanism to achieve exactly the same effect in the plant is somewhat complex. It was decided to use a polyurethane roller with grooves (see Figure 4), which would damage the cake in a manner qualitatively similar to the laboratory tests. The damage was inflicted by disturbing the surface in such a way that fine cracks form throughout the cake. It is important to notice that the surface should not be ploughed. A ploughing operation would form large slots in the top layer of the cake, which in turn would cause a significant drop in the applied pressure differential across it.

The set of profiled rollers spanned the width of the filtration belt. The height of the rollers above the belt could not be set constant as the height of the filter cake varies throughout the length of filter. The roller geometry was chosen so that the base of the rollers should follow the surface of the coal layer to obtain the necessary penetration. This simplifies the control of the roller height significantly. Compression springs force the roller into the coal layer. As the layer thickens, the spring force increase somewhat, but not to the point where it can force the base of the rollers to penetrate the coal layer. The force that the springs exert on the rollers can be adjusted. This allows the apparatus to be placed anywhere along the filter belt. The spring force will be low in areas where the coal layer is soft (the water content is high) and high in areas where the coal layer is hard (the water content is low). The operator has to manually adjust the spring force so that the rollers have the necessary penetration. The apparatus is equipped with a mechanical stop to prevent the rollers from coming into contact with the filter belt. During the first test runs, it was found that coal buildup occurs in the grooves of the roller. This coal buildup compacted inside the groves and effectively changed the roller operation from cutting the cake to only compressing it. Static scrapers were designed and retrofitted to remove the coal from the rollers. A detailed drawing of the apparatus is shown in Figure 5.

Installation and commissioning of the rig went without any problems (Figure 6). It was placed at several intervals along the length of the belt to obtain the most suitable operating point in terms of stability and final cake moisture content. This position was found to be as close as possible to the onset of 100 per cent saturation, similar to the laboratory results shown in Figure 3. At this position, the operation on the belt was stable, yielding a grooved belt discharge as shown in Figure 7. The dewatering impact is shown in Figure 8.

Figure 8 shows a similar trend to that of Figure 3. The solid line represents the final cake moisture content obtained for standard operating conditions on the filter, while the data points represent the final cake moisture obtained by running the apparatus on the filter at different positions in relation to the 100 per cent saturation point. It was again possible to reduce the final cake moisture by almost three percentage points, resulting in a cake moisture of 23.8 per cent, compared with 26.7 per cent obtained during normal operations. Tests were not repeated due to time constraints. However, the setup was left to run for more than ten minutes at each setting, ensuring that steady state was reached before sampling.

The test rig complied with all the preset design criteria, as it was easy to fit onto the filters and delivered the required damage to the filter cake without it harming the belt.

Conclusions

It was possible to simulate the belt filters in the laboratory and to determine the positioning of the rig, which was found to be at the point of 100 per cent saturation. The laboratory-scale rig reduced the filter cake's final moisture content by three percentage points. The full-scale rig was designed as a set of rollers with grooves that inflicted the damage to the cake. Apart from coal buildup that hindered the bearings, for most part the rig ran smoothly, and complied with all the design specifications. During full-scale testing, the final cake moisture was again lowered by three percentage point, the same as was achieved in the laboratory, therefore proving the validity of the method.

Acknowledgements

The authors would like to thank the following persons and organizations for contribution to the project:

The final-year students at the School for Mechanical Engineering and the School for Chemical and Minerals Engineering, North-West University

Exxaro, in particular Grootegeluk Collieries.

References

1. BREED, W.A. Beneficiation of fine coal using the air-sparged hydrocyclone. M.Sc. Dissertation, University of Cape Town, 1992. pp. i-ii. [ Links ]

2. RONG, R.X. Advances in coal preparation technology. Vol. 2: Literature review on fine coal and tailings dewatering. JKMRC report on AMIRA Project P239C. University of Queensland, 1993. p. 130. [ Links ]

3. TAO, D., GROPPO, J.G., and PAREKH, B.K. Enhanced ultrafine coal dewatering using flocculation filtration processes Minerals Engineering, vol. 13, no. 2, 2000. pp. 163-171. [ Links ]

4. LE ROUX, M. and CAMPBELL, Q.P. The investigation into an improved method of fine coal dewatering. Minerals Engineering, vol. 16, 2003. pp. 999-1003. [ Links ]

5. LE ROUX, M., CAMPBELL, Q.P., WATERMEYER, M.S., and DE OLIVEIRA, S. 7he optimisation of an improved method of fine coal dewatering. Minerals Engineering, vol. 18, 2005. pp. 931-934. [ Links ] ♦

Paper received Dec. 2011

Revised paper received Feb. 2012.