Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 n.7 Johannesburg Jul. 2012

JOURNAL PAPER

High pressure grinding moving ahead in copper, iron, and gold processing

F.P. van der MeerI; W. MaphosaII

IHumbolt Wedag GmbH, Cologne, Germany

IIWeir Minerals Africa (Pty) Ltd

SYNOPSIS

High pressure grinding roll (HPGR) technology is used in an increasingly diverse range of applications, predominantly iron ore , gold and diamonds. KHD Humboldt Wedag HPGRs are applied world-wide, and consistently prove to be well designed and reliable operating units, with their performance meeting the pre-set standards. This publication summarizes some of the features and experiences for recent applications in treatment of copper ore, coarse iron ore, and gold ore. Summary data of roll surface wear life and operating data are given, together with operational observations. In addition, effects of feed segregation and truncated feed are discussed, as well as the implications of a product recycle flow sheet.

Keywords: HPGR, KHD, stud lining, HPGR grinding, partial product recycle, feed segregation, truncated feed, truncation.

Introduction

High pressure grinding rolls (HPGRs, also known as roller presses) are becoming well accepted for coarse, abrasive, and hard rock applications. When the first HPGR for coarse ore was commissioned at Los Colorados in 1998, there were only 14 HPGRs installed in the minerals industry, mainly for grinding pellet feed to increase the Blaine value (Van der Meer et al., 1997), and only three KHD HPGR units were applied for crushing coarse ore. Nowadays, well over 100 HPGRs have been or are being installed in ore processing applications, and this number is expected to grow rapidly in the years to come.

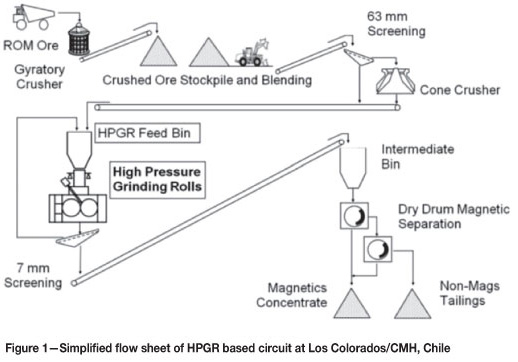

The Los Colorados plant of CMH in Chile was the first successful operation in which an HPGR was used to replace a conventional tertiary and quaternary crusher. At that time HPGR technology was considered new to this type of installation, and extensive test work and studies were conducted to support the plant design. The grinding circuit was designed to include primary gyratory crushing, secondary cone crushing, and a Humboldt Wedag HPGR Type RP 16-170/180 (roll diameter 1.7 m, roll width 1.8 m) in place of a tertiary crusher operating in closed circuit, with vibrating screens to recycle the oversize +7 mm fraction back to the HPGR circuit. The 7 mm undersize is fed to dry magnetic separation. The capacity of the HPGR is about 2 000 t/h.

Vasilkovka Gold Mining in northern Kazakhstan is the site of one of the recent applications in gold ore treatment. The ore has a high concentration of copper, which significantly complicates gold extraction. The Vasilkovskoye mine is estimated to contain 400 t of gold. In this gold plant, two Humboldt Wedag HPGRs Type RP 16-170/180 (roll diameter 1.7 m, roll width 1.8 m) have been operating in parallel since 2009, each in closed circuit with a partial product recycle, at a capacity of about 1200-1400 t/h.

At the Nurkazgan copper plant of Kazachmyss, Kazakhstan, two HPGR units Type RP 13-170/140 (roll diameter 1.7 m, roll width 1.4 m) are operating in series, each in closed circuit with a partial product recycle and a closing 5 mm aperture screening. The units effectively perform the duties of tertiary and quaternary crushing stages, and were commissioned at the end of 2007. The units have a capacity of about 900 t/h, at a product recycle of approximately 75-125 per cent (effective recycle mass in proportion to fresh feed) for an initial feed top size of 35 mm. Ultimate product size is 80% < 0.8 mm, with up to 60% < 74 (im, at a specific power consumption of 1.8 to 2.2 kWh/t.

Los Colorados operation iron ore

The crushing and pre-concentration plant is located near the mine. After rail transport to the pellet plant, the magnetic pre-concentrate is ground in ball mills to pellet feed fineness and further concentrated by wet magnetic separation. Figure 1 shows a schematic flow sheet of the Los Colorados HPGR circuit.

Operating experience at Los Colorados

The positive findings and downstream benefits observed in pilot testing paved the way for a successful installation of a HPGR at the Los Colorados plant (Table I), with the confidence that the unit would meet expectations in full scale industrial operation.

The Los Colorados Huasco pellet plant reported lower energy consumption in wet ball milling, as well as reduced circulating load in the mill circuits, due to a finer feed and improved Bond Ball Mill work index. The existing ball mill capacity could be increased by 30 per cent.

Wear life

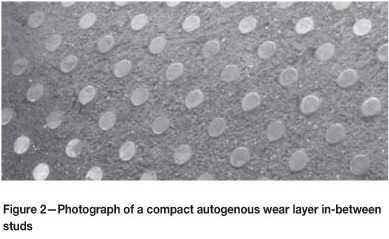

Based on test results, the wear life was guaranteed at 12 000 hours initially. The roll surface, as main wear component, met the guaranteed wear life right from the beginning. This was possible because of good compaction of the ore on the stud-lined surface. The quartz content was about 15 per cent during pilot testing and today varies between 15-30 per cent, depending on ore type. Three factors affect wear the most: quartz content, operating pressure, and quality of compaction of the autogenous wear layer between the studs on the roll surface (Figure 2). Of these, formation of a competent autogenous layer can make a huge difference in achievable wear life (Dunne et al., 2004). For example, when treating taconite material (excess pebbles from a fully autogenous mill circuit) at Cleveland Cliffs' Empire Mine a wear life of up to 17 000 hours was achieved, even though the machine was operated at a high specific pressure of 4.5-5.0 N/mm2 and the quartz content of the ore averaged near 37 per cent (Rose et al., 2002; Dowling et al., 2001; Maxton et al., 2006).

Obviously, the roll surfaces are the most critical parts of the HPGR, in terms of performance and investment. An accurate prediction of wear life of the roll surface during operation is essential, since this is the single largest factor that determines operating cost. It can determine whether a project is viable or not. Each manufacturer has developed its own in-house wear rate test suitable for its proprietary surface. The Humboldt Wedag wear rate tests were developed over the past decade. The result of this test is a wear rate index that is correlated to operating data of the Humboldt Wedag units in minerals operations. The test provides an accurate and reliable specification of wear rate data as basis for process guarantees for minerals applications.

Wear increases with pressure, thus reducing operating pressure would lead to a longer roll surface wear life. Pilot testing determines how product size is affected by operating pressure, and provides a basis to balance between operating pressure and power consumption, generation of fines, and wear rate. There generally is a level above which additional pressure results in excessive energy consumption, and a disproportional increase in the generated fines (Van der Meer et al., 2008). This is attributed to a lower incremental size reduction from a denser particle bed and higher relative proportion of fines within the bed. At Los Colorados it was observed that a decrease in pressure resulted in only a small increase in circulating load. Overall, operating at lower pressure than initially commissioned (2.5-3.0 N/mitf instead of 4.0-4.4 N/mm2) proved to be advantageous, especially when considering the overall energy consumption of the HPGR circuit.

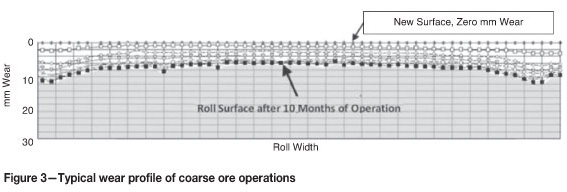

During the life of a set of tyres, wear measurements are taken periodically at, say, 2 month or longer intervals. Figure 3 shows the typical wear profile for coarse ore operations. This illustrates the progress of wear of surface expressed in millimetres of depth over the width of the roll. A total of 58 positions were measured, on four locations over the rolls' circumference (at 0°, 90°, 180°, and 270°). Eight measurement series are shown; one baseline of the new roll surface after installation, and one series each for 2, 4, 6, 8, 9, and 10 months of operation. The measurements indicate a moderate wear over 10 months of operation, in a pattern that is specific for the CMH coarse ore operation (other ores may show a different pattern, such as a 'bathtub' profile).

The end of the useful life for the rolls in the above example would be reached at about 25-30 mm wear, still some months away.

As shown in Figure 3, the shoulders of the rolls started wearing faster after two months of operation, and over the subsequent eight months. This higher wear leads to an uneven gap and lower pressure at the sides of the roll, where the material is crushed less efficiently and may even partly bypass the rolls.

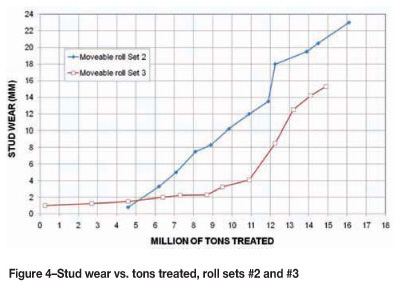

Eventually, a situation is reached where local wear increases due to the abrasive action of material bypassing the rolls at the edges. To overcome this problem for the next set of rolls (after wearing-out the existing ones), Humboldt

Wedag introduced a stud pattern with a modified distribution of stud hardness over the roll width, with harder studs nearer to the edges and harder lateral studs (which facilitate embedding an autogenous wear layer all the way up to the rim of the rolls). Such a continuing improvement of the roll surface design leads to a prolonged roll surface wear life. An example of improvement between roll set #2 and roll set #3 is show in Figure 4. This illustrates that for a wear of 16 mm on the studs, roll set #3 could treat 3 Mt of additional ore (Barrera, 2005). In total the studs can wear at around 40 mm.

Measures such as described above led to an increase in wear life at Los Colorados, which today is reported to be at about 14 600 hours.

Availability

When designing a HPGR circuit, matching capacity and availability with upstream and downstream crushing and grinding equipment is essential. The capacity of a HPGR can be varied by applying variable speed drives, as throughput is generally more or less proportional to roll speed.

The improvements, modifications, and increase in experience on part of the maintenance crew at Los Colorados resulted in an availability of well over 97 per cent. This correlates with the Humboldt Wedag HPGR installed at Argyle Diamonds, Australia where the availability over the last seven years is reported to be around 96 per cent (Maxton et al. 2002, Gerrard et al., 2004).

In coarse ore operations, care has to be taken in the design of the materials handling facilities around the HPGR circuit in order not to create bottlenecks that would have a negative effect on HPGR performance. Adequate tramp metal protection as well as appropriate feed bin capacities ahead of the HPGR are prerequisites to ensure uninterrupted choke-fed conditions at all times. A proper protection against tramp metal in the feed, both by a self-cleaning magnet above the belt conveyor feeding the HPGR and a metal detector, must be installed. The metal detector system, as a safeguard against non-magnetic metal components, must provide a fast response to activate a tramp metal rejection system. Various systems are available, including some that can be operated reliably with iron ore. The best arrangement involves metal detection immediately in front of the HPGR feed bin. The design may be such that the metal detector activates a bypass flap gate that diverts the metal-containing portion of the feed stream to a chute or to a separate bin.

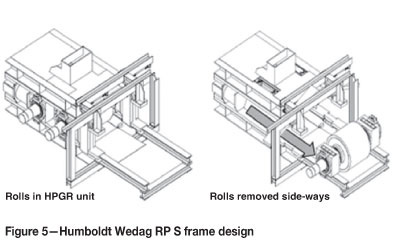

Minimizing downtime during roll changes would require two complete roller assemblies of a shaft with tyre and bearings, each of which is a long-delivery item. The exchange procedure then becomes a simple matter of opening the frame, extracting the worn set and installing the new one (as shown in Figure 5 for a current design unit). Depending on site conditions the time required is approximately 24 to 36 hours (Maxton et al., 2005, 2006). The worn set is then refurbished off-line and serves as ready emergency spare in case of accidental failure.

A standard supply of parts for commissioning and operation is generally provided with the machine. However, minimizing the capital locked up in critical or strategic spares, while still ensuring an operational continuity, may differ for each individual mine site. For Los Colorados a complete set of spare roller assemblies was purchased with the machine, and the bearings and shafts of these have been operating successfully since 1998. It should be noted that no premature bearing, shaft, or tyre failure has ever occurred at the Los Colorados operation, or at any Humboldt Wedag HPGR in a minerals application overall. To a large part this is the success of the closed-circuit oil lubrication system and the patented support concept utilizing a rubber pad to distribute the forces evenly onto the whole bearing.

Influence of HPGR on downstream processes

The positive influence on wet ball milling demonstrated in testing was also observed in full scale operation. For example, in ball milling a 27-44 per cent increase in capacity from about 203 t/h to between 254 t/h and 295 t/h was obtained, depending on ore type, for the same applied energy consumption of 4 MW, when grinding HPGR material to a ball mill product of 80 per cent passing 44 (im (Westermeyer et al., 2000; Gallardo, 2007). This was attributed to both a higher fines content and the generation of microcracks in the particles. The Bond Ball Mill Work Index reduced from 11 kWh/t to between 8 kWh/t and 9 kWh/t, depending on the HPGR pressure applied.

In magnetic separation, a higher quality pre-concentrate at constant yield was achieved. Both of these effects can be attributed to the same two factors: the generation of more fines and the generation of microcracks. The amount of < 150 (im material produced in the HPGR grinding stage was twice as high as what cone crushing would have produced.

Variations in HPGR product particle size distribution also led to side effects in other areas of plant performance. Due to the higher fines content the angle of repose was enhanced by 6 per cent. Consequently, the capacity of stockyards and material handling systems was increased as well.

The particle shape after grinding in the HPGR is somewhat more irregular compared with cone crusher products. This should be considered when designing the screen in a HPGR circuit to ensure sufficient screening efficiency and to avoid excessive moisture carry-over in the oversize of wet screening applications. The influence of feed moisture content on HPGR operation will be discussed in more detail in subsequent paragraphs.

Disagglomeration

An HPGR can be used effectively in place of tertiary crushers for preparing a suitable ball mill feed. This can be accomplished either by operating the HPGR in open circuit, in closed circuit with edge recirculation, or by operating in closed circuit with dry or wet screening. Each circuit configuration has its own benefits and drawbacks (Van der Meer and Dicke, 2008). Due to the high pressure applied by HPGR, the material is discharged partially as a compacted agglomerate (called flakes or cake), which may fall apart easily, but also may require further disagglomeration. When a screening circuit is considered, the proportion and strength of the flakes will influence the screening efficiency and circulating load.

The strength of flakes is ore-specific, and is also influenced by e.g. feed moisture, clay content, and operating pressure. So as to be able to evaluate flake strength and predict disagglomeration requirements, flake strength tests and disagglomeration tests were developed by Humboldt Wedag in conjunction with the Los Colorados project. At present, these tests are standard procedure included in pilot test programmes at Humboldt Wedag's laboratories.

At Los Colorados the decision was made to install two disagglomerators to ensure high dry screening efficiency, since testing had shown compact flakes. However, with changes in ore type and increasingly dry feed material the flakes became more brittle and were observed to fall apart readily upon material transfer and dry screening. The disagglomerators were thus decommissioned.

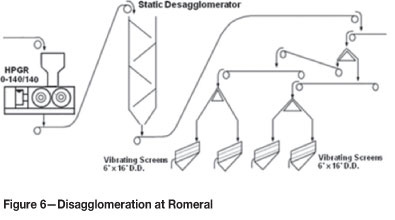

With the operating experience from Los Colorados the standard flake test and its relation to plant data was greatly improved. When CMP installed another HPGR at their El Romeral Plant utilizing the same circuit layout as Los Colorados, standard flake tests were carried out and the results suggested that a mild disagglomeration step would be required. With the advice of Humboldt Wedag, the client designed a belt transfer point, consisting of a tower with internal baffle plates, to break the flakes and ensure in this simple way sufficient screening efficiency (Figure 6).

When (wet) screening is used in the HPGR circuit the issue of flake strength may become more severe. Flakes or flake fragments may survive breakage during transport, and a large proportion may also survive the screening stage unbroken, thus significantly reducing screening efficiency and contributing to an increased circulating load. Moreover, when oversize material from wet screening is recycled back to the HPGR, the contribution to higher moisture content in the HPGR feed may lead to difficulties in material flow in and out of the HPGR feed bins, extrusion during compression, and generally may contribute to a deteriorating performance of the HPGR. Testing for flake competency and moisture effects thus is of importance, and these findings should be taken into consideration when designing the (wet) screening circuit.

Vasilkovka operationgold ore

The Vasilkovsky region is one of world's largest gold fields and the site of the largest gold deposit in Central Asia. It is located in Akmola Oblast in north-eastern Kazakhstan and has been producing gold for more than 30 years. Vasilkov Gold JV (Vasgold GOK) is developing this deposit, which has an estimated total gold reserve in excess of 400 t, and is the operating company under the umbrella of KazZinc. KazZinc is a major producer of copper, precious metals, zinc, and lead, with some 21 000 people in mining, ore dressing, metallurgy, power generation, and mechanical production. The company was established in 1997 through the merger of Eastern Kazakhstan's three main non-ferrous metals companies.

Vasgold has recently commissioned a new mine and processing plant, for a capacity of about 9 Mt of ore per year. The Vasilkovka plant treats a complex ore, where the gold is present as free gold, as inclusions to and in sulphide minerals, and as refractory gold. The plant incorporates a complex flow sheet including gravity separation, fine grinding, and a number of new technologies, such as Leachox intensive leaching (Flatman et al., 2010), stirred mills for ultrafine grinding, and HPGR as the third crushing stage, ahead of ball milling.

HPGRs proved to be attractive as the final crushing stage due to their large unit capacity (design over 1 400 t/h per unit), fine crushing performance, low specific energy (Gerrard et al., 2004), and additional advantages in gold liberation. The current application of HPGRs at VasGold is to provide a final crushing stage and increase ball mill throughput by providing a mill feed at a reduced grindability and a high fines content, as a feasible alternative to SABC circuits (Maxton, Morley, and Bearman, 2003.

Operating Experience at Vasilkovka

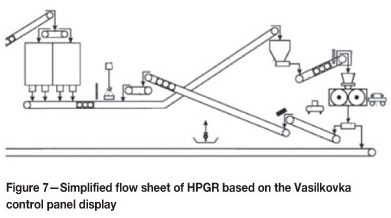

Steered by the above performance indicators, KHD Humboldt Wedag was contracted for the supply of two HPGR RPS 16170/180 units for the tertiary crushing stage. The units are operating in parallel, in closed circuit with a partial product recirculation (Figure 7). The machines each process 1 500 t/h (HPGR effective feed rate), generating a product of 80% < 5 mm from a 40-50 mm top size feed (Table II).

The circuit does involve recirculation of a part of the HPGR discharge, at a recirculation ratio of up to 180 per cent (recycled material in proportion of fresh feed).

Circuit design with partial product recycle

Depending on the application, a variety of arrangements can be applied for HPGR circuits. This is a result of the inherent process of HPGR grinding, where the size reduction takes place in a particle bed, as disintegration of ore particles through interparticle crushing in the bed created between the rolls. In contrast, conventional crushers rely on single particle breakage for size reduction, as a contact crushing between grinding media (rods, balls, jaw crusher, or cone compartment surface). Thus, in HPGR crushing the particle to be crushed can be, and preferably should be, smaller than the applied operating gap.

One direct effect is that the crushed particles can be recycled through the same HPGR unit, either directly, or after classification, or after intermediate beneficiation. In conventional crushing, this would require a subsequent separate crushing stage in a unit or in multiple units with a smaller gap setting (tertiary and quaternary crushers), or rod mills.

In an HPGR unit, fresh feed with a top size of, for instance, 40 mm could be combined with a recycle stream of crushed material of near 5 mm from a product recycle arrangement without classification, and still be subjected to a very effective grinding at an operating gap of about 35 mm (Van Der Meer and Gruendken, 2008). This does save in additional screening facilities, and still allows for a fine feed suitable for subsequent ball milling.

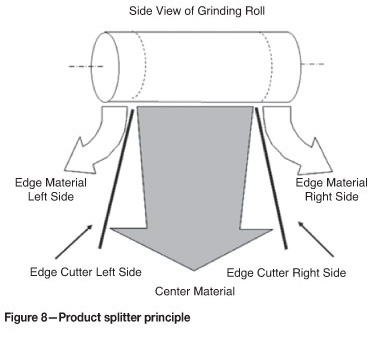

At Vasilkovka, the latter approach is successfully applied. This is achieved by installing a product splitter following the HPGR, allowing for a partitioning of the product material. The edge material (the relatively coarse material generated at the left and right shoulders of the rolls (Figure 8) and a portion of the centre material are split out by mechanical cutters and returned to the HPGR feed conveyor for re-crushing. This recycle mass also smoothes out any feed fluctuations. The centre portion from the rolls discharge, which contains the finer and more compressed material, is cut out by the splitter and forms the final HPGR product. Obviously, a different arrangement (such as splitting the full HPGR discharge stream after mixing of the centre and edge material) could be applied as well.

The application of a product splitter arrangement is a feasible arrangement, but relies to a large extend on a strict control of the feed rate to the roller press. At Vasilkovka the filling of the pre-bin, to provide choke feed conditions, was warranted by an adequate arrangement of a steady and uninterrupted feed supply from the intermediate feed bin by installation of variable-speed vibratory feeders and a short variable-speed conveyor belt. It was recognized that no short reaction control could be applied to the return flow (approximately 912 t/h) of splitter product, and that the major control available comes from control of the crushed feed supply (approximately 530 t/h). The belt conveyor from the intermediate bin has a relatively short retention time (< 10 seconds), which thus does allow for an adequate control and response time over the filling level of the pre-bin.

Flakes

One of the phenomena that take place during compression in a HPGR is the generation of compacted material in the HPGR product. This compacted material, also referred to as 'flakes', is generated by a the high compressing force on the bed of particles in the gap between the rolls, causing part of the ground product to discharge in the form of cake-like briquettes (Figure 9).

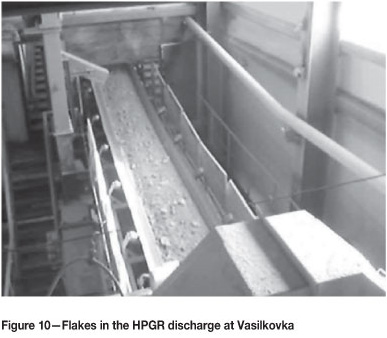

Thus the HPGR product often is composed of a mixture of loose product and a proportion of flakes and flake fragments, the latter ranging from 0 per cent to 80 per cent by volume, depending on ore, particle size, moisture content, and pressing conditions. At Vasilkovka, the proportion of flakes in the centre product was modest; some 10-20 per cent by volume (Figure 10). Also, the flakes proved to be relatively brittle, and partly fell apart on handling and transfer (on belt conveyors, transfer points, and bins).

A series of standard tests for flake competency was carried out during confirmation testing. These flake competency tests are based on the disintegration of flakes in a tumbling mill, and return a so-called 'tumbling factor' on a scale of zero to 100 per cent, in which zero represents very hard flakes and 100 per cent indicates total disintegration of the flakes. The flakes generated at Vasilkovka scored near 70 per cent.

As the downstream process does not include classification, but only product splitting, with the final product being directed to the ball mill (sump), it is seen that the flakes at the indicated strength do not pose any problems and no disagglomeration stage is required to assure optimum product handling. The flake material disintegrates almost instantly when entering the mill or a pump sump ahead of a hydrocyclone cluster. This was one more reason to apply a product recycle arrangement for Vasilkovka, as disagglom-eration ahead of an eventual screening did was shown to be a less attractive alternative.

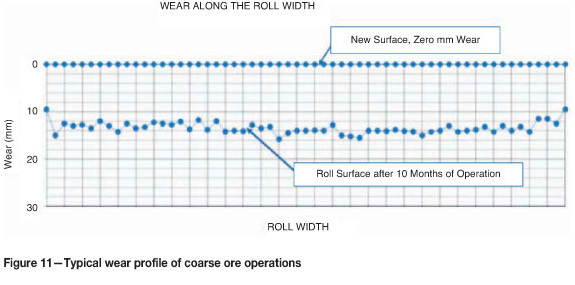

Wear life

As with the Los Colorados unit, wear measurements are taken periodically during the life of a set of tyres. Figure 11 shows the typical wear profile for one of the rolls after operation of 10 months. This illustrates the progress of wear of surface expressed in millimetres of depth over the width of the roll. A total of 58 positions were measured, on four locations over the rolls circumference (at 0°, 90°, 180°, and 270°). The measurements indicate a low wear over 10 months of operation, in a pattern that is specific for the VasGold coarse ore operation (Figure 11). The end of the useful life for the rolls in the above example would be reached at about 30 mm wear, still some 10-12 months away at the time of measurement.

The shoulders of the rolls were wearing slower, leading to the roll edges standing higher. These would need to be ground off to avoid the roll surfaces touching at the edges, and to maintain an optimum operating gap. In future roll sets, the roll edges will be designed with a softer stud quality to avoid this type of uneven wear. Measures such as described above led to an increase in wear life at VasGold, which today is expected to increase to about 12 000 hours.

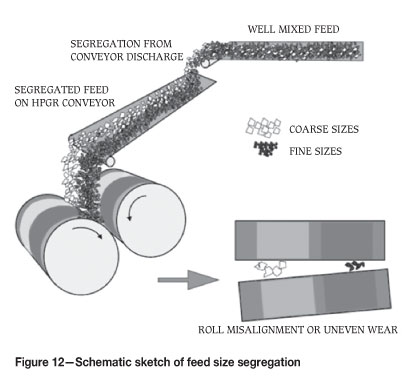

Feed presentation and segregation

In all cases where coarse ores are processed, but particularly in cases where a significant circulating load is maintained, a strong emphasis and attention must be given to a proper layout in the feed system upstream of the HPGR. An ill-designed bin and conveyor system may rapidly lead to feed size segregation on conveyor belts and in bins. In such a case, arranging the feed belt discharge lengthwise to the rolls' axis promotes particle size segregation in the HGPR feed bin. Size segregation in the feed bin invariably results in improper material particle size distribution across the width of the rolls, such as coarse feed on one side and fine feed on the other. With most crusher types (cone crushers, impact crushers) or ball mills this is of much less significance, but for HPGRs this may lead to an uneven wear of the roll surface, an impaired size reduction, and roll skewing.

As an example of a condition where a pronounced particle size segregation was present (Figure 12), a particle size analysis for the right side of the a conveyor belt indicated 40% > 20 mm, with 30% < 5 mm, whereas the left side showed a much finer composition of only 10% > 20 mm, with 50% < 5 mm (Figure 13).

Such feed segregation results in uneven process conditions and roll skewing (a condition where the rolls are not parallel to each other, but form a wedged gap opening across the width of the rolls). Although an automated control system is in place to correct temporary skewing, a structural feed segregation does generate a difference in operating pressure, material packing, and gap opening over the width of the rolls. These led to operation away from the specifications, with a coarser product (from lower-than-required specific pressure and a wider operating gap), a lower throughput, and an irregular operation. Moreover, aggravated by uneven nipping conditions, an uneven static pressure from the feed chute above, and relatively high particle mobility, uneven local wear results, leading to a significant reduction in operating life of the rolls' surface and thus higher operating cost.

At Vasilkovka, the feed system includes four vibratory feeders from the holding bunkers, and a recycle of the splitter product from the HPGR discharge, which is loaded on top of the layer of feed mass on the conveyor. The throw of the four feeders was carefully aligned, and a system to ensure an even distribution of the returned fines over the fresh feed was designed to avoid segregation of coarse and fine material.

The filling of the HPGR feed chute was arranged perpendicular to the rolls' axis. Additional baffle plates may be built into the feed bin to enhance proper mixing.

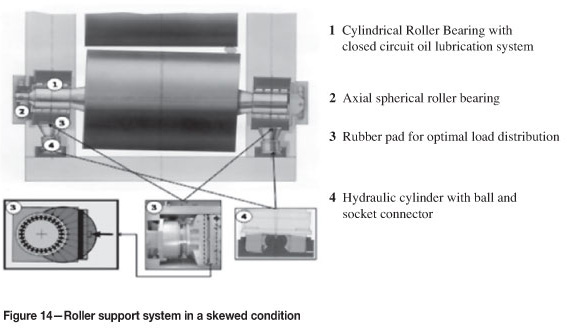

Plant operators have reported that particularly at low feed rate conditions (at maintained roll speed), at low feed bin levels, an imbalanced feed supply and distribution over the rolls occured, promoting a skewed situation, leading to material bypass or coarse material from incomplete compression grinding. A smaller-than-desired operating gap implied a very low effective pressure, and a low grinding efficiency. Figure 14 shows the KHD hydraulic system designed to control roll skewing and distribute the forces equally on the cylindrical roller bearings.

One of the main functions of the KHD control system is to maintain a parallel gap, especially in the more difficult-to-grind coarse and hard rock applications (Maxton and Van Der Meer, 2005; Maxton, Van Der Meer, and Gruendken, 2006).

Nurkazgan operationcopper ore

At the Nurkazgan copper plant of Kazachmyss, Kazakhstan, two HPGR units are operating in closed circuit with product recycle. The units effectively perform the duties of tertiary and quaternary crushing stages, and were commissioned at the end of 2007 (Figure 15).

The units have a capacity of 850-950 t/h, at a product recycle of approximately 75-125 per cent (effective recycle mass in proportion to fresh feed) for an initial feed top size of 35 mm. Ultimate product size is down to 80% < 0.8 mm, with up to 60% < 74 i m, at a specific power consumption of 1 .8 to 2.2 kWh/t. Anticipated roll wear life for Humboldt Wedag's Stud-PlusTM tyres is 8 000 operating hours.

The HPGR centre product is led over a scalping screen to break up any large agglomerates, and is subsequently classified by hydrocyclones to remove the finished product at about 95% < 0.2 mm for flotation. The hydrocyclone overflow is further ground in the primary ball mill (Figure 15).

The high proportion of fines in the HPGR central discharge fractions, which stems from the high circulating load over the product splitters, allows a significant proportion of the ore to bypass the primary ball mill. In addition, the HPGR pre-ground product does reflect a lower ball mill work index, and the energy input in ball milling is reduced.

At the time of writing, a further evaluation of the process and effects of HPGR grinding for the copper plant was being carried out. Where benefits from a high reduction ratio and low energy input achieved by the HPGR units are being recognized, the operation of the two-stage circuit is being reconsidered. Particularly the effect of disagglomeration and wet screening after the first HPGR are subjects of study.

Disagglomeration of the compressed copper ore is a requirement for effective and efficient screening at the 5 mm aperture employed. For this, the initial scrubber was replaced by an impact crusher to avoid introduction of high moisture content in the screen overflow returning to the second HPGR. This high moisture content was recognized as cause for a less-than-optimum performance of the second-stage HPGR.

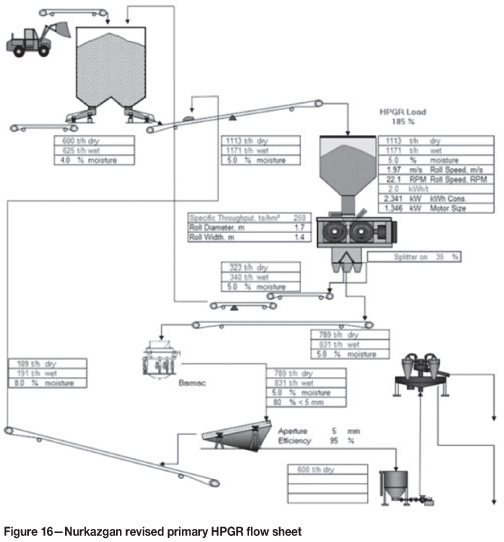

As an intermediate solution, Nurkazgan selected to run the HPGR circuit as a single-stage operation, with both a partial product recycle and a product screening as-was, at 5 mm aperture.

The screen oversize is re-directed to blend in with the fresh feed, thus keeping the moisture content of the effective

HPGR feed within controllable and acceptable boundaries. This circuit is illustrated in Figure 16.

Truncated feed

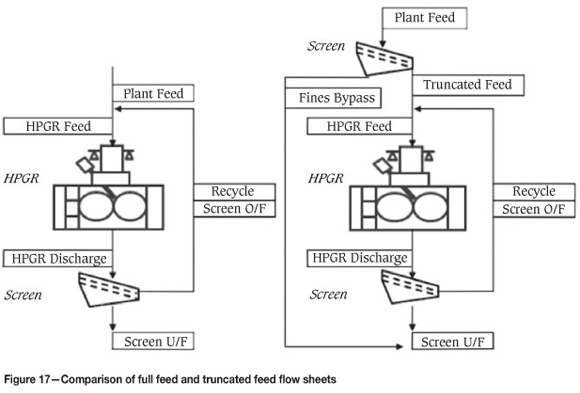

In some instances, a proportion of fines can be removed from the final (HPGR) crushing stage feed by screening, in an attempt to bypass the stage with already-finished material, such as feed for the subsequent ball milling, or to avoid a further size reduction and generation of ultra-fines from fines already present in the feed.

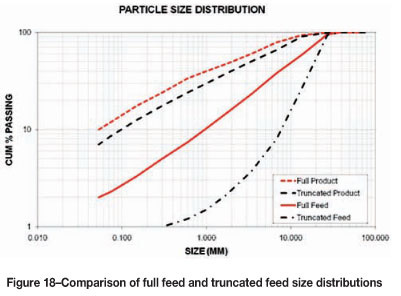

Depending on the initial fines content in the feed, the product particle size for a truncated feed in many cases is relatively similar (though slightly coarser) to that from a full feed crushing. This implies that the size reduction from a truncated feed might be more efficient, with a higher net fine product generation.

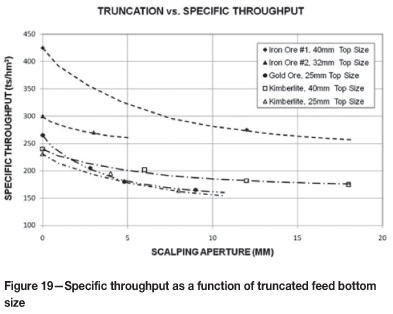

This so-called truncated feed, however, also generally results in a strongly reduced specific throughput, as a lower bulk density and fewer fines to fill the void space between the ore grains results in a decrease in specific throughput. There is a relationship between the screen size used to prepare the feed and the specific throughput of the HPGR, where the HPGR specific throughput drops by up to e.g. 35-40 per cent with increasing screen size (the top size of the fines removed). This relationship is illustrated in Figure 19.

As the quantity of fines removed from the HPGR feed increases, the apparent trends in performance are that the specific throughput of the HPGR drops due to the increase in void space in the HPGR feed, with a resulting reduction in the operating gap. The efficiency of the grinding increases, in terms of fine particle production. In some cases, the overall HPGR product may become finer, and energy consumption increases with increasing specific energy input and with a finer pre-HPGR screen size.

The shifting balance in a lower mass flow to the HPGR may in some cases make it possible to use smaller equipment, even though a lower specific throughput is achieved, but may also generate a more complex plant layout, with more conveying and screening. The balance of possible advantages (smaller equipment, less ultra-fines) and disadvantages (higher wear, more recycle and screening) must, however, be evaluated for each plant design and ore situation.

As a consequence of the lower specific throughput, from a similar applied press force and overall energy consumption, the net specific energy consumption generally increases, in some instances by up to 50 per cent. In an overall assessment, the advantage of reduced plant and equipment size that would be obtained by bypassing the fines is frequently offset by the reduction in specific throughput and increase in net specific energy consumption. These effects often result in similar required HPGR dimensions and therefore, to compensate for the lower specific throughput, the rolls sometimes have to be operated at a higher peripheral speed, which would increase roll surface wear. In addition, a truncated feed generally generates a less strong 'autogenous wear layer', where the relatively coarse fragments tend to break away the coating on the roll surface. This also increases the roll surface wear rate. Thus operating cost (from a more frequent replacement of worn grinding rolls) may increase for a truncated feed.

Overall, the balance for justification of a truncated circuit is determined mainly by the effects of a truncated feed on the reduction of mass flow to the HPGR (proportion of fines in the HPGR section feed), the additional requirements in conveying and screening, the reduced specific throughput and increase in specific energy, and the anticipated increase in roll surface wear rate.

Conclusions

Installation and commissioning of HPGRs in coarse iron ore, gold, and copper processing plants was concluded successfully, with the 1.7 m diameter KHD Humboldt Wedag HPGR units performing well on specification. The HPGR product recycle arrangement provides a means for size reduction of the feed material without requirement of a screening facility.

The operations confirmed the moisture content of the feed to be a critical controlling variable. Maintaining this moisture at a well-defined range ensures an effective size reduction, as well as steady operating conditions, low wear from an effective autogenous coating of the KHD stud-lined rolls, and minimal difficulties in material transport and hold-up in bins, feed chute, and on conveyor belts.

Feed segregation was identified as another important issue to address. A well-designed feed circuit provides for a well-tuned HPGR feed without significant segregation. In combination with a well-controlled hydraulic pressure and roll positioning system, this allows the units to operate with an optimized gap control and parallel roll surface setting.

The quick exchange facility of the 'SWING' frame of the HPGR allows for a fast roll exchange procedure, reducing downtime to less than 24 hours and requiring a minimum of installed auxiliary maintenance facilities.

Justification of a truncated circuit depends on the effects of a truncated feed on the reduction of mass flow to the HPGR (proportion of fines in the HPGR section feed), the extra requirements in conveying and screening, the reduced specific throughput and increase in specific energy, and the anticipated increase in roll surface wear rate.

References

1. BARRERA, R.R. Comparativo Comportamiento Desgaste. Internal communication of CMP, Power Point Presentation, 3 January, 2005. [ Links ]

2. DOWLING, E.C., et al. 2001. Applications of High Pressure Grinding Rolls in an Autogenous-Pebble Milling Circuit. Proceedingsfrom the SAG Conference, 30 September-3 October, 2001. Vancouver, Canada. [ Links ]

3. DUNNE, R., MAXTON, D., MORRELL, S., and LANE, G. 2004. High pressure grinding rolls - the Australian experience. SME Annual Conference, Denver, February 2004. [ Links ]

4. FLATMAN, S., BATTERSBY, R.M., IMHOF, R. BATTERSBY M., and IBRAYEV, S. 2010 The Leachox refractory gold process - the setting, design, installation and commissioning of a large scale plant at the VASGOLD gold mine, Kazakhstan. Precious Metals 2010, Falmouth, Cornwall, UK, 15-16 June 2010. [ Links ]

5. GALLARDO, V.H. 2007. Uso de Prensa de Rodillos en Planta Beneficia Mina Los Colorados. Internal communication of CMP, Power Point Presentation, 8 March 2007. [ Links ]

6. GERRARD, M., COSTELLO, B., and MORLEY, C. 2004. Operating experiences and performance assessment of HPGR technology at Argyle Diamond Mine. Proceedings of the Rio Tinto Comminution Workshop 2004, Perth, Australia. [ Links ]

7. MAXTON, D., MORLEY, C., and BEARMAN, R. 200. Recrush HPRC Project - The Benefits of High Pressure Rolls Crushing. Proceedingsfrom the Crushing and Grinding Conference, 29 October-1 November 2002. Kalgoorlie, Australia.

8. MAXTON, D. and VAN DER MEER, F.P. 2005. KHD Humboldt Wedag high pressure grinding olls - developments for minerals applications. Proceedings of the Randol Gold Forum, Perth, Australia, August 2005. [ Links ].

9. MAXTON, D., MORLEY, C., and BEARMAN, R. 2003. A quantification of the benefits of high pressure rolls crushing in an operating environment. Minerals Engineering, vol. 16, no. 9, pp 827-838. [ Links ]

10. MAXTON, D., VAN DER MEER, F.P., and GRUENDKEN, A. 2006. KHD Humboldt Wedag. 150 years of innovation. New developments for the KHD HPGR. Proceedings SAG 2006, Vancouver, Canada, September 2006. [ Links ]

11. ROSE, D.J., KORPI, P.A., and DOWLING, E.C. 2002. High Pressure Grinding Roll Utilization at the Empire Mine. Proceedingsfrom the Mineral Processing Plant Design Conference, 20-24 October 2002, Vancouver, Canada. [ Links ]

12. VAN DER MEER, F.P. 1997. Roller Press Grinding of Pellet Feed. Experiences of KHD in the Iron Ore Industry. Proceedingsfrom the AusIMM Conference on Iron ore Resources and reserves estimation, 25-26 September, 1997, Perth, Australia. [ Links ]

13. VAN DER MEER, F.P. and DICKE, R. 2008. High pressure grinding; how high can you go? Procemin 2008, Fifth International Minerals Processing Seminar, Santiago, Chile, 22-24 october 2008. [ Links ]

14. VAN DER MEER, F.P. and GRUENDKEN, A. 2008. Flow sheet considerations for optimal use of high pressure grinding rolls. Comminution 2008, Falmouth, Cornwall, UK, 17-20 June 2008. [ Links ]

15. WESTERMEYER, C.P. and CORDES, H. 2000. Operating Experience with a HPGR at the Los Colorados Iron Ore Dressing Plant in Chile. Aufbereitungs-Technik /Mineral Processing, vol. 11, 2000. pp. 497-505. [ Links ] ♦

Paper received Aug. 2011

revised paper received Mar. 2012.