Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 n.5 Johannesburg May. 2012

TRANSACTION PAPER

Feasibility study on triboelectrostatic concentration of < 105 µm phosphate ore

S.O. BadaI, II; L.M. FalconI; R.M.S. FalconI; C.P. BergmannII

ISchool of Chemical and Metallurgical Engineering, Faculty of Engineering and the Built Environment, University of the Witwatersrand, Johannesburg South Africa

IIMineral Processing Division, Mintek, South Africa

SYNOPSIS

Fine phosphate feed is considered to be slime and normally disposed of as a discard in settling ponds or dumped as landfill. The purpose of this research was to establish whether commercially acceptable qualities and yields could be obtained from this material using dry separation methods. The results obtained from the electrostatic separation of <105 µm phosphate ore are presented. An existing separator was upgraded in order to improve on product and flotation concentrate recovery, to test different mineral, and to reduce particle residence time between the charging chamber and the separating zone of the separator. The operating conditions were varied according to the charges imparted to the particles in the electric field, and according to other device parameters. Parameters such as splitter position, charge reversal, rotation speed, charging voltage and separating voltage. The <105 µm phosphate feed was concentrated under both triboelectrification and inductive charging. The use of inductive charging and charge reversal resulted in a significant increase in grade for <105 µm phosphate feed, with the P2O5 grade increasing from about 12 per cent to 20.50 per cent, and a recovery of 26.30 per cent under a single stage of separation. It was found that better separation was achieved at rotation speed of 6000 r/min, -8 kV charging voltage, and 25 kV separating voltage.

Keywords: dry beneficiation, electrostatic separation, particle charging, phosphate, triboelectrostatic.

Introduction

Advanced wet mineral beneficiation techniques have been developed and reported on for the concentration of various South African fine ores. However, information in the field of dry beneficiation using triboelectrostatic technique is lacking. The distinct advantage of this technique is that water is not used as a medium for separation, whereas wet processes require a supply of water and dewatering of the clean products and discards. Recent research conducted on the feasibility of triboelectrostatic separation on South African fine coals provides significant information on the separation efficiency of this technique (Bada et al., 2010). This process was therefore tried for the separation of African phosphate fines.

The degree to which an ore can be upgraded by electrostatic techniques depends on the differences in conductivity and surface work function of the constituents. The combination of both triboelectrification and inductive charging, which is a significant benefit in terms of imparting different surface charges to particles with closer work function, made it possible to utilize this separator for phosphate concentration. The fire phosphate feed to be upgraded is known as slime. This material normally disposed of as a discard in settling ponds or dumped as landfill. The technique has proved to be a promising approach due to its ability to beneficiate fractions smaller than <105 µm, which was considered as the minimum beneficiable particulate limit for flotation in the phosphate industry. An approach that could significantly beneficiate the <105 µm fraction, which does not respond to flotation, would reduce the cost of disposing of this fraction and would also be of economic benefit to the industry. Moreover, one of the major disadvantages of upgrading phosphate fines through the conventional froth flotation technique is the high collector consumption and susceptibility of collectors to slimes. Therefore, the motivation for investigating the triboelectrostatic application arises as a technique which could remove the fines in the <105 µm fraction and also provide flotation feed of higher grade at >105 µm.

Ciccu and Ghiani (1992) showed that desliming of phosphate feed before it is fed into the separator could be beneficial for the electrostatic separation of phosphate ore. Whereas, the integration of the separator used in this study could provide a means for particle desliming at <105 µm without using water, and could also be applied for separating phosphate ores at the same time with a reduction in cost of dumping this fraction as landfill.

The aim of this study is to determine the extent to which the <105 µm fraction could be upgraded under different conditions and if flotation feed >105 µm could be produced using the same separator.

Experimental

Material

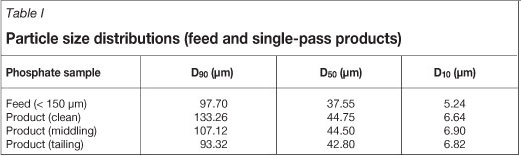

The sample utilized in this test was an undeslimed phosphate feed obtained from Mintek. The ore was crushed and dry-screened to <150 µm. The particle size distribution results show that the feed had a 90% of the feed less than 100 µm, which is less than >105 µm used as flotation feed. X-ray fluorescence (XRF) analysis showed the head grade was about 11.5 per cent P2O5 (Table I). The elemental analysis (XRF) conducted on the feed sample shows a high concentration of calcite and quartz in the ore. These are the major constituents found in a sedimentary phosphate ore, and both influence the electrostatic charges imparted on phosphate. Prior to the test work on the separator, the undeslimed phosphate feed was vacuum-dried between 800°C and 1000°C before being fed through a vibratory feeder into the separator.

Electrostatic separator and instrumental methods

A triboelectrostatic separator with the following distinctive features was utilized in this research:

A copper-plated rotor mounted in a cylindrical chamber, with the inner wall of the chamber tilted at 2.0 cm from the cylindrical body of the chamber and coated with copper

A vibratory feeder fitted with heater to mitigate sticking of the particles, a sample collecting funnel with a hot air inlet and an outlet for discharging particles

An output power source connected to the chamber's wall and the rotor, providing an inductive charging as an external applied voltage was connected to the chamber

A separation zone consisting of two movable electrodes with different polarity, where the distances between the two electrodes could be adjusted depending on the required product grade. The air flow within the separating compartment was monitored and regulated using a thermo- anemometer and gate valve connected just after the cyclones

An adjustable splitter connected below the separating zone and the cyclones for collection of three different product grades, including clean product, middlings, and tailings.

The positively charged particles (P2O5) deflected towards the negative electrode (R plate), while the negatively charged particles (SiO2) were attracted towards the positive electrode (L plate. The uncharged particles fell in-between the two electrodes and were collected as the middlings under the influence of an external electric field in the separation chamber. The three products were obtained at a certain splitter distance and further subjected to a second stage of separation to generate more highly graded separated products. The data reported here were generated from both the single and the second stage of separation, with the results based on different sets of parameters. The feed and products were analysed for phosphate elemental composition and particle size distribution. The performance curves generated were used to evaluate the separation performance with the undeslimed <105 µm phosphate ore.

The phosphate sample particle size distribution was determined using a laser-based particle size analyser (Mastersizer 2000E, from Malvern Instruments Ltd) with a measuring range of 0.1 to 1000 µm. The major element analysis was determined by energy-dispersive X-ray fluorescence (EDXRF) spectrometer, with X-LabPro software for element identification.

Results and discussion

Particle size distribution

The surface charge imparted on the different minerals has an effect on the particle-size distribution on the products collected in different bins. Table I shows the characteristic particle size distribution of single-stage separation products obtained from the tribo-electrostatic tests conducted on <105 µm phosphate feed. The highest grade products were collected at the negative electrode and found to be coarser than the tailings obtained at the positive electrode for all phosphate feed. The difference in particle size can be attributed to the differences in the composition of phosphate and tailings. Quartz and clay minerals associated with phosphate ore are known to be finer in size and their higher concentration in tailings will inevitably result in a finer size distribution at the positive electrode.

Effect of charging potential

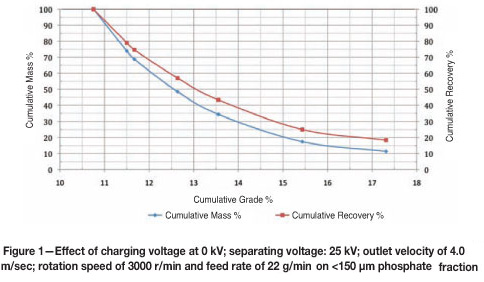

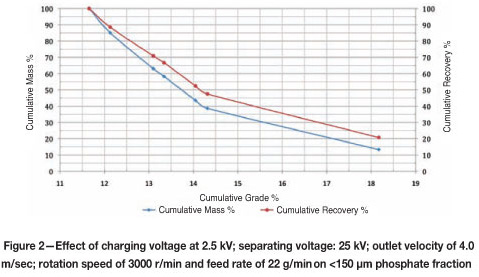

The potential of the rotary charger of the separator was controlled as one of the means of enhancing particle charging and subsequent separation efficiency by applying an electrical field to the charger. An external applied voltage compared with zero potential may allow an increase in the charge density imparted on the phosphate ore, depending on the phosphate rock type tested. Figure 1 shows the results wit zero external potential, while Figure 2 shows an increase in phosphate grade as the applied charging potential was increased from 0 kV to 2.5 kV, indicating higher charging potential was beneficial for this phosphate ore. This result is in agreement with the findings reported by Tao and Jiang (2006) on the separation of quartz from phosphate, where an increase in external voltage was found to be more efficient in the charging and separation of phosphate from quartz.

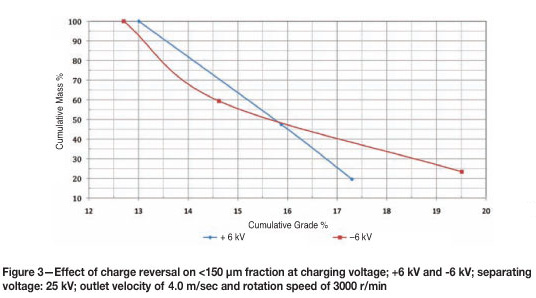

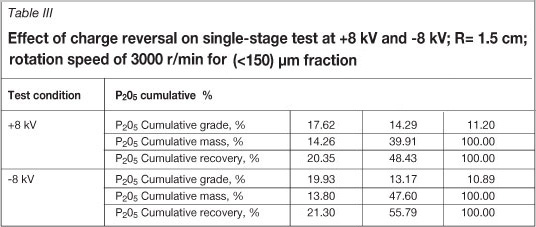

Effect of charge reversal on product P2O5 grade

Prevoius investigations conducted by Tao and Mohammad (2010) showed that when the phosphate ores are charged with a negative potential, the surface charge on the SiO2 remained negative, while a positive surface charge is imparted on the P2O5. This phenomenon made it possible to increase the differential surface charges on the phosphate ore and so to increase the P2O5 grade. The effect of differential surface charges on the particles at positive and negative potentials on separation efficiency was investigated.

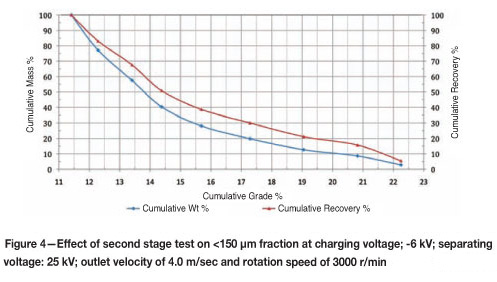

From the results in Table III and Figure 3, it can be observed that reversing the charge results in an increase in the grade of the phospate product. Figure 3 shows an increase in grade from about 17.33 per cent to 19.60 per cent as the charge was reversed under single stage of separation. The Recovery - Grade profile in Figure 4 reported a highest phosphate grade of approximately 22.33 per cent under the second stage of separation compared to that obtained in Figure 3 but at the expense of cumulative recovery.

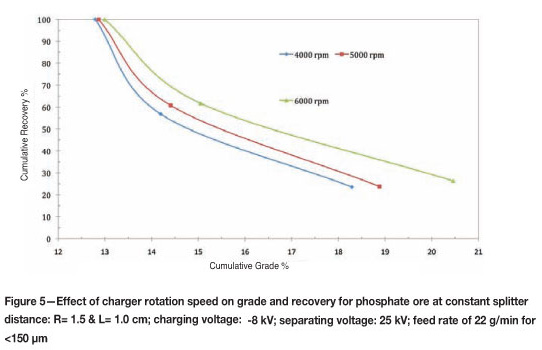

Effect of rotation speed in upgrading the fine feed phosphate ore

A single-stage separation test was conducted by varying the tangential speed of the octagonal rotary charger. The recovery - grade plot obtained for the cleaning of phosphate fine ore is presented in Figure 5. The plot was obtained for three different charger rotation speeds. At high rotation speeds better separation was observed as the curve moves towards the upper right corner. An increase in the number of particle contacts and impact force with high charge transfer might be responsible for such a significant performance within the rotation speed range tested. The best separation efficiency in terms of grade and recovery was achieved at 6000 r/min

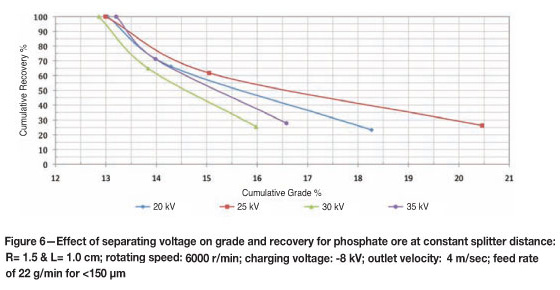

Effect of electric field intensity on the concentration of fine feed phosphate ore

The external electric field strength (kV/m) and the charge magnitude control the particle trajectory in the separation zone. The increase in the separation voltage is expected to produce clean phosphate products with better separation and grade. However, the electrical field intensity and the phosphate grade decrease for this separator as the applied potential increases above 25 kV, which might be as result of particle build-up on the surfaces of the two electrodes.

Conclusion

The present study had shown that African phosphate feed at <150 µm could be dry beneficiated through the application of triboelectrostatic separation. Some of the system parameters were varied in order to achieve about 22.4 per cent phosphate grade from fine feed reported in this study. However, different types of phosphate feed such as rougher flotation feed, rougher concentrate, and amine concentrate will be subjected to further electrostatic separation tests in order to determine the best feed at which a marketable upgrade could be achieved, and the results presented in a future publication. In summary, the conclusions are as follows:

Fine phosphate slurry products can be upgraded to about 22 per cent phosphate product using triboelectro-static separation

A higher rotation speed in the charging chamber resulted in better separation efficiency

Inductive charging through the application of a negative external voltage was found to be more efficient in the charging and separation of phosphate from quartz

The clean phosphate product was found to be coarser than the tailings, since the minerals in the tailings, such as clay and quartz, are finer in size than the phosphate particles and therefore are elutriated with the fines.

Acknowledgements

The authors acknowledge with thanks the financial support of the South African National Energy Research Institute (SANERI) and the University of the Witwatersrand. Our thanks also to the Mineral Processing Division, Mintek for granting access to some of their research facilities.

References

1. BADA, S.O., TAO, D., HONAKER, R.Q. FALCON, L.M., AND FALCON, R. M.S. Parametric study of electrostatic separation of South African fine coal. Mining Science and Technology, vol. 20, 2010. pp. 0535-0541. [ Links ]

2. CICCU, R. AND GHIANI, M. Phosphate beneficiation with electrostatic techniques. Proceedings of First International Conference on Modern Process Mineralogy and Mineral Processing, Beijing. International Academic Publishers, 1992. pp. 379-384. [ Links ]

3. TAO, D. AND JIANG, X. Electrostatic Particle Charger, Electrostatic Separation System, and Related Methods. US patent 2006/0213760 A1. 2006. [ Links ]

4. TAO, D. AND MOHAMMAD, A. Beneficiation study of Eshidiya phosphorites using a rotary triboelectrostatic separator. Mining Science and Technology, vol. 20, 2010. pp. 0357-0364. [ Links ]

Paper received Nov. 2011

Revised paper received Jan. 2012