Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.4 Johannesburg Abr. 2012

JOURNAL PAPERS

An investigation on underground transport roads and influence on safety and productivity at Khutala Colliery

L. Lehasa

Department of Mining Engineering, University of Pretoria

SYNOPSIS

The purpose of the project was to investigate the challenges faced by Khutala Colliery pertaining to underground road construction and maintenance. Furthermore the influence of these challenges on productivity and safety requirements were taken into consideration.

The operating standards required for the construction and maintenance of the 2 seam road transport infrastructure was investigated, together with reasons why the standards of operating procedure are not met. The Code of Practice put in place by Khutala Colliery was used to view the standard operating procedures.

Leading practices on underground road construction were researched. The project aims to discover the gaps that Khutala Colliery must bridge to implement enhanced practices with regards to underground road construction.

During the period of study, observations were carried out to determine whether the road construction standards of operating procedure were being adhered to at all times for both road construction and road maintenance.

Khutala Colliery has put in place a traffic management plan, which includes safety practices and work policies that must be adhered to while travelling on underground transport roads.

Keywords: road construction, maintenance, strategic road design.

Mine background

Khutala Colliery is a bord and pillar mine located in Mpumalanga 50 km west of Witbank and 100 km east of Johannesburg. The mine is owned by BHP Billiton Energy Coal Division. The site preparation for the operation of this mine started in 1984. The initial design was aimed at achieving 13.3 Mt run of mine per annum. Coal was first mined in 1986 and supplied to Kendal power station. In 2004 the life of mine of Khutala Colliery was predicted to extend to 2033.

Khutala Colliery operates both underground and surface mining sections. The total reserves as measured in 2004 were 601 Mt, 511 Mt of which were attributed to underground operations and 90 Mt to surface operations. Safe practices are a high priority at Khutala Colliery.

Khutala Colliery utilizes the bord and pillar mining method. Single pass continuous miners are used for coal extraction. This mining method is commonly used to extract near-horizontal coal seams in South Africa.

During coal extraction, roof bolters install permanent roof support. Shuttle cars and battery haulers are used to transport coal to the feeder breaker. The coal is then transported to 1050 mm trunk conveyors. From the trunk conveyors the coal is transferred to larger 1350 mm conveyor belts in the main development. The coal is then tipped into underground bins and transported to inclined conveyors, and finally conveyed to surface silos.

An introduction to road construction

During the road building process four machines are required namely the:

Toro/LHD and tractor - Road building material is stockpiled at surface mine batch silos. The material is fed down a borehole from the on- surface silo into the underground workings using a front- end loader

Grader - The second step is to spread the road building material around the road construction area and to grade over the area. Road graders are the primary machines used for new road construction and road maintenance. Graders are used for road levelling and to create smooth roads. Graders are also used for pothole maintenance

Compactor - A compactor is used to compress the material on the newly constructed road. The purpose of compacting is to ensure that the material particles stick firmly together, resulting in a tight adherence between the particles of the material. Compacting stabilizes the road stability and prevents road building material from moving

Spray tanker and tractor - Once the road has been built it is sprayed with a dust suppression product utilizing a spray tanker which is hauled by a tractor.

The road building process consists of interdependent services. If one of the abovementioned machines is unavailable the entire process is delayed.

At Khutala Colliery, the 2 Seam east mine and west mine utilize a single set of road building equipment. For a period of 2 weeks the machines are allocated to east mine and for the following two weeks to west mine.

An introduction to road maintenance

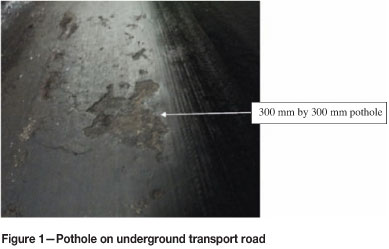

Road maintenance includes grading and pothole maintenance. Potholes (Figure 1) must be filled with rocks or a sand-gravel mix when necessary. During road maintenance the road must also be compacted and graded. It is the duty of the miner to perform road inspection and to observe the severity of potholes and water accumulation on roads. It is also the duty of the miner to report the road condition to the shift boss and to further delegate work to the team to maintain the required sections.

Roads must be constructed with due consideration for water damage, which is the main cause of road damage in Khutala 2 Seam east and west mine. A common problem that was observed is that of water accumulation at the splits (Figure 2) and water flooding into roads. The situation leads to slippery surfaces and this creates the risk of slips and falls and vehicle accidents.

Problem statement

The challenges experienced by Khutala Colliery with regards to underground transport road construction were investigated. The project aims to identify the various aspects of underground transport road infrastructure that influence productivity and safety.

Project objectives

To research and benchmark leading practices in road construction.

To understand how underground road construction and road maintenance processes influence safety and productivity.

To establish whether Khutala Colliery is currently practicing the correct procedures with regards to building and maintaining underground transport roads.

To make recommendations on how Khutala Colliery can improve their procedures with the aim of achieving leading practices with regards to underground transport roads, safety and productivity.

Methodology

The following method was followed to acquire the data necessary to indicate the primary problems that are faced by Khutala Colliery with regards to road construction and road maintenance.

Road construction/maintenance and the influence on safety

Analyse how Khutala Colliery has incorporated the four steps of safety to identify and minimize accidents on underground transport roads

Analyse the traffic management plan and the adherence there to.

Road construction/maintenance and the influence on productivity

Compare the road construction process to the road building standard operating procedure (SOP)

Analyse the statistics that are recorded by the mine planning department on road building machine utilization

Collect and compare daily field reports to the MES (mine electronic system) data

Research and propose possible solutions to the challenges faced by Khutala colliery with regards to underground transport roads and their influence on productivity and safety.

Results

Khutala has focused all employees and contractors on being alert to all hazards and risks around them. The first and most critical step is recognising these hazards and risks and instituting the necessary controls to eliminate them. This is in line with the HIRA training currently being undertaken at the operation.

Hazard identification is important because it is fundamental to personal safety. Employees and contractors are continuously urged to be alert to the things that can hurt them, and either avoid them completely or institute the necessary controls. At the end of the day, employees and contractors need to get home - safe, healthy, and happy - to those who need and love them. An individual's Personal Big 5, or PB5 are the five people, things or reasons important to each and every employee or contractor.

Productivity

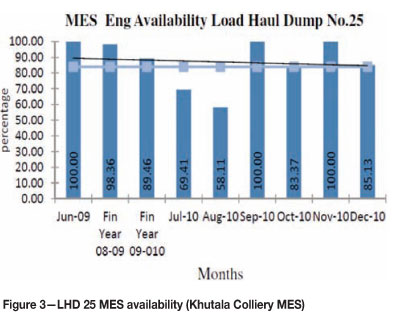

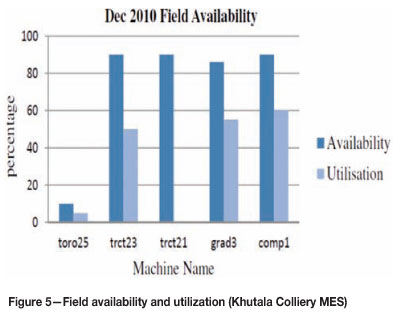

Figures 3 to Figure 5 indicate the road building machine availability and utilization as recorded by the mine Mine Electronic data System (MES) as compared to the results collected during the period of study.

The conditions of the roads with regards to water and potholes affects the deterioration of the equipment that travels on the roads. Table I indicates the road building machinery maintenance history.

Equipment has a technological life cycle. It is important that road building machines are serviced and overhauled according to the maintenance plan in order to sustain the machine performance.

Table II indicates the requirements of the mines' road building material SOP and the actual field practices.

The mine supplies a sandstone mix as road building material at Khutala Colliery. The road building crews underground use duff (a muddy waste material) for road construction. Duff is used because of the low availability of the LHD. When the LHD is on breakdown the road building material cannot be transported from the underground silo. Duff is easily available in the old working areas.

Figure 6 indicates the required time and the actual time taken to travel to section 23. The lost time is approximately 6 minutes.

Section 23 is approximately 9 km from the shaft. The road regulation speed at Khutala Colliery underground is 30 km/h (Makgala, 2010).

Tons win = (minutes saved) * (50%)* 7.5 t/min

= 6 min*50%*7.5

= 22.5 t.

50% chance of the calculation being accurate and that the CM cutting rate is ideally 7.5 t/min, the 6 minutes that is lost while travelling towards sections can result in a tons win of 22.5 t per shift.

Evaluation of results

Compliance to the road building SOP could be improved. Duff is used to build and maintain roads instead of the sandstone mix provided by the mine

The numerous road building machine breakdowns that are currently experienced at the mine affect production adversely

Water accumulation in the transport roads results in hazardous working environments

Loss time while travelling to production sections affects productivity negatively.

Conclusion

The is a lack of adherence to the road building SOP

Numerous factors affects road construction negatively:

- Road flooding

- The lack of a formal road design

Road defects e.g. potholes and water accumulation results in unsafe working conditions

Shift time lost on travelling to sections affects productivity and results in production losses.

Recommendations

Water management

Khutala should monitor and ensure good housekeeping. Water services should be closed at the end of shift usage i.e. close conveyor belt water sprays

Dams must be well maintained to minimize leakages

Pumps should be installed at problem areas as a proactive water management plan

Water-containing fissures and veins should be sealed to reduce water accumulation on roads from natural water-bearing sources. This is usually done by concrete lining of shaft walls or through cementation. Cementation is a process whereby concrete is pumped into a borehole that intersect a water-bearing vein or fissure.

Road design

Roads must be built with the sandstone mix supplied as stated in the road building SOP.

Two road designs options are suggested for future work.

Suggestions for further work

The aim of external benchmarking is to research two road designs that may be applied at Khutala Colliery. The road design must offer high water resistance and level and stable road surfaces. The road designs are flexible, and Khutala Colliery can opt to modify road designs to best suit the challenges experienced in road construction.

Hyson Cell

Tyson cells, also known as geocells, are large connected patterns of moulded concrete slabs. The framework for casting the concrete is made from thin-walled plastic films. The cell form work remains in the concrete cast during installation, which serves as jointing. The standard cell sizes range from 150 mm x 150 mm to 400 mm x 400 mm. Minimum cell depth is 50 mm, while maximum depth is 4 m. The cells may contain granular fill for the construction of walls. The cells have a wide application, and can be used to line dams or streams and for the prevention of slope erosion. The Hyson Cell is also used as the pavement structure in the construction of surface mine roads, underground transport roads, and airport runways (Hyson Cells).

The side faces of the hyson cell are not straight flat planes, but are slightly curved and have small dome-shaped protrusions that fit into a hollow on the adjacent concrete cell. This design prevents shear movement between the cells and creates an interlocking effect. The Hyson Cell pavement can withstand heavy (600 t machines) loads without deformation.

The Hyson Cell has proved to be effective at:

Phalaborwa Mining Company, for the relocation of raw and potable water reservoirs. Havercroft Dam

Lebalelo Water Scheme. The dam was reported to be completely leak-free 7 years after construction

Finsch Mine underground roads. Kimberlite is a weak rock that is easily weathered by water. The Hyson pavement structure was used to stabilize the underground infrastructure at Finsch and to prevent further water damage in certain areas.

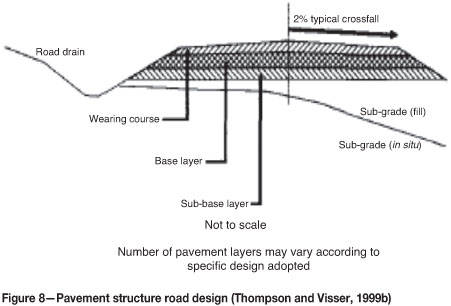

Pavement structural design

The pavement road design is a method of developing the most economical combination of pavement that is compatible with the underlying in situ material. The base layer, sub-base layer, and the sub-grade layer determine the structural strength of the road. The wearing course material affects the functional design of the road. Poor wearing course material results in poor ride quality, excessive dust, increased tyre damage, and increased vehicle damage. Thompson and Visser (1988, 1999a,b) have established suitable guidelines to select the correct type of road building material. The following are factors that affect the selection of material types:

The road geometrics

The environmental climate

Traffic volumes.

According to Thompson and Visser (1999b)3 the placement of a road surface over any material that cannot adequately support the weight of the traffic using the road and cannot prevent damage of the road surface to water will hamper the mobility and controllability of the vehicles. The road design depicted in Figure 8 consists of a 2% crossfall gradient. The crossfall (gradient) assists with water runoff. Thus water flows to the roadside were it accumulates and can be drained or pumped out of the mine. The pavement structural design is a flexible design and can be modified to suit the environment of road construction. The pavement structural design is extensively used on surface mines, but with the correct design and knowledge it can be applicable to underground transport roads (Thompson and Visser, 1999b)

Acknowledgements

Mr. Freddie Hunter and the 2# seam team A special thanks to:

- My mentors Mr Clive Knobbs and Mr Johan Steyn for their guidance and constant support

- The Mining Department of the University of Pretoria and the staff for their assistance

- BHP Billiton for granting me the opportunity and learning experience. My greatest gratitude to the men and women working at Khutala Colliery 2 seam east and west for their help and support.

References

HYSON CELLS. http://wwww.Hysoncells.co.za [accessed 21 April 2011] [ Links ]

THOMPSON, R.J., Visser, A.T. et al. 1998. http://www.docstoc.com/docs/71353427/Designing-and-benchmarking-mine-roads-for-safe-and-efficient-hauling Benchmarking haul Road Design Standards to Reduce Transportation Accidents.[accessed 21 April 2011] [ Links ].

THOMPSON, R.J. and Visser, A.T. 1999a. https://mining.curtin.edu.au/people/staff_profiles/roger_thompson_profile.cfm Designing and Maintaining open Cast Mine Haul Roads. [ Links ]

THOMPSON, R.J. and Visser, A.T. 1999b. University of Pretoria http://environ-mental.herculessealcoat.com/ResourseFolder/13 Integrated_Asset_Manage ment_Strategies.pdf Designing and Managing Unpaved Mine Haul Roads for optimum Performance.[accessed 21 April 2011] [ Links ].

THOMPSON, R.J. 2008. https://mining.curtin.edu.au/people/staff_profiles/roger_thompson_profile.cfm Haul Road Design Consideration.[accessed 21 April 2011] [ Links ].

THOMPSON, R.J. 1995. http://mineravia.com/Summary of Agencies that Attribute to Transport and Tramming Accidents. [accessed 21 April 2011] [ Links ].

http://www.bhpbilliton.com/bbcontentrepository/reports/khutala2004sitehse-creport.pdf [accessed 5/01/2011] [ Links ].

http://www.bhpbilliton.com. k. drive [accessed 5/01/2011] [ Links ].

http://www.emgold.com/s/ldaho-maryland_project.asp [accessed 7/01/2011] [ Links ].

http://www.eskom.co.za/live/content.php [accessed 12/01/2011] [ Links ].

http://www.homelandenergygroup.com/i/pdf/techreportapr09.pdf [accessed 6/04/2011] [ Links ].

http://www.infomine.com.publiclations/docs [accessed 7/01/2011] [ Links ].

http://www.keatonenergy.co.za/im/files/cpr_2_geology_01apr08.pdf [accessed 6/04/2011] [ Links ].

http://www.mqdata.com/data/show_mineral.aspfcoal [accessed 5/01/2011] [ Links ]. http://onlinewebstudio.co.za/online_repoerts_/murrob [accessed 7/01/2011] [ Links ]. http://www.qaproject.org/methods/resglossary.html[accessed 5/01/2011] [ Links ]. http://searchsoftwarequality.techtarget.com/definition/best-practice [accessed 5/01/2011] [ Links ].

http://www.directminingservices.com/wfpcontent/uploads/2010/06/SME_Mine_Haul_ Roads_99-090.pdf [accessed 7/04/2011] [ Links ].

http://www.capsa11.co.za/capsa07/CapsaDocs/PowerPoints/ST8S%20Don%20Ross%20opt.pdf [Accessed 6/04/11] [ Links ].

http://www.e-mj.com/index.php/features/659-haul-road-design-consider-ations.pdf [accessed7/04/2011] [ Links ].

http://pdfserve.informaworld.com/93696_751309423_777785684.pdf [accessed 7/04/2011] [ Links ].

http://www.engineeringnews.co.za/article/maintenance-system-is-being-developed-at-grootegelukand-Jwaneng-2004-03-05 [accessed 6/04/11] [ Links ].

http://www.exxaro.com/pdf/icpr/ip/mining/coal.htm [accessed 7/04/2011] [ Links ].

http://pdfserve.informaworld.com/93696_751309423_777785684.pdf [accesse d 7/04/2011] [ Links ].

http://www.womp-int.com/story/2009vol05/story024.htm [accessed 7/04/2011] [ Links ].

http://www.minesub.nsw.gov.au/SiteFiles/minesubnswgovau/MSBguidlines [acessed 7/04/2011].

http://www.sentula.co.za/pdf/Koornfontein_Mine_site_visit_presentation_08_ September_2009.pdf [accessed 10/01/2011] [ Links ].

http://tutor2u.net/business/strategy/benchmarking.htm10/01/2011. [ Links ]

http://upetd.up.ac.za/thesis/available/etd-02142011-170102/unrestricted/01chapter1-3.pdf [Accessed 7/04/2011] [ Links ].

JACKSON, A. 2008.Khutala Road building Standard of Operating Procedure. [ Links ]

MAKGALA, C. 2010. Khutala Traffic Management Plan. Khutala Colliery. [ Links ]

Paper received Feb. 2012

Revised paper received Mar. 2012

Paper written on project work carried out in partial fulfilment of B. Eng (Mining Engineering)