Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.3 Johannesburg Mar. 2012

JOURNAL PAPERS

Correlation between P-wave velocity and some mechanical properties for sedimentary rocks

R. Altindag

S.D.U. Engineering and Architecture Faculty, Department of Mining Engineering, Isparta, Turkey

SYNOPSIS

Engineers and researchers need to estimate the mechanical properties of rocks from P-wave velocity. In previous studies, the researchers have investigated either the limited values or all the data belonging to sedimentary, igneous, and metamorphic rocks together in the same statistical analysis. In this study, the raw data pertaining to only sedimentary rocks was taken from previous studies and evaluated. For this purpose, a total of 97 samples of sedimentary rock types were subjected to statistical analysis. First, the relationships between P-wave velocity and physical-mechanical properties were investigated by simple regression analysis. All the data were then subjected to multi-regression analysis. Some empirical equations with high correlation coefficients were derived for rock engineers. The equations obtained from the analyses are compared with previous equations found in literature.

Keywords: P-wave velocity, mechanical properties, sedimentary rocks, mechanical properties, brittleness.

Introduction

Seismic techniques, which are known as nondestructive geophysical methods, are commonly used by engineers working in various fields such as mining, civil, and geotechnical engineering. They are frequently employed to investigate certain properties of rocks. Ultrasonic measurements can be applied in various application areas such as rockbolt reinforcement1, blasting efficiencies in the rock mass2, the determination of degree of rock weathering3, determination of deformation and stress on rock masses4,5and rock mass characterization6,7. A number of studies8-13 investigating ultrasonic propagation in fractured rock have been carried out. Some researchers14-16used the P-wave velocity for the estimation of weathering depth of building stones. Many researchers have found that P-wave velocity is closely related to physical and mechanical properties of rocks17-25.

The main factors that influence P-wave velocity in rocks are lithology, texture, density, porosity, anisotropy, grain size and shape, water contact, stress, temperature, weathering, alteration zones, pores and microcracks, bedding planes, and joint properties (roughness, filling materials, water, dip and strike, etc.).

The relationships between P-wave velocity and rock density have been investigated by various researchers26-28who have reported an increase in the densty as the velocity increased. The influence of microcracks on P-wave velocity distribution has been studied by Babuska et al.29and Jech et al.30. The effect of crystallographic preferred orientation of rock-forming minerals on P-wave velocities was examined by various researchers. The effects of fracture roughness on P-wave velocity for granite, marble, and travertine was studied by Kahraman31, who stated that P-wave velocity decreased as the fracture roughness coefficient values increased. Kahraman32 derived empirical equations in order to predict P-wave velocity of wet rock from the P-wave velocity of dry rock.

Singh and Kripamoy33 revealed that P-wave velocity and uniaxial compressive strength (UCS) decreased as the quartz content increased, and decreased as the moisture content increased. They also reported a decrease in P-wave velocity as the silica content increased. Some of the empirical relationships between P-wave velocity and the UCS for different rock types found in the literature are summarized in Table I.

The goal of this study is to investigate the relationships between P-wave velocity and certain physico-mechanical rock properties such as unit weight, porosity, shore hardness, brittleness, UCS, tensile strength, point load index, and modulus of elasticity, considering the sedimentary rocks only.

Sampling of data

It was noticed in some of the previous studies that the rocks had all been subjected to the same statistical analysis, regardless of the differences in their geological origins. However, in this study, only the raw data of sedimentary rocks obtained from previous studies was taken into account in the statistical analysis. The properties of the rock samples employed in statistical analyses are illustrated in Table II.

Brittleness concepts

Brittleness has become an important rock property. Nevertheless, no standardized and universally accepted brittleness concept or measurement method defining or measuring the rock brittleness has yet been stated. Different researchers mean, express, and use the concept differently for different purposes.

The ratio H/Kc, where H is the hardness (resistance to deformation) and Kc is the toughness (resistance to fracture), is proposed as the index of brittleness34. Quinn and Quinn35 have studied on ceramics and proposed an index of brittleness, B=(HE)/K1c2, using hardness, Young's modulus, and fracture toughness. Determination of brittleness is largely empirical. Usually, brittleness measures the relative susceptibility of a material to two competing mechanical responses.

Morley36 and Hetenyi37 define brittleness as the lack of ductility. Ramsey38 expresses brittleness as follows: 'When the internal cohesion of rocks is broken, the rocks are said to be brittle'. Obert and Duvall39described brittleness as follows: 'materials such as cast iron and many rocks usually terminate by fracture at or only slightly beyond the yield stress'. Brittleness is defined as the property of materials that rupture or fracture with little or no plastic flow40. However, it may be stated that following phenomena may be observed41 as the brittleness increases:

Low values of elongation

Fracture failure

Formation of fines

Higher ratio of compressive to tensile strength

Higher resilience

Higher angle of internal friction

Formation of cracks in indentation.

Some brittleness index definitions obtained from stress-strain curves were introduced and used in literature42-44. a simple index of brittleness is the ratio of compressive strength to tensile strength, (b1= σc/σt). This definition is used in many studies45-50, although it remains only an indication and there is no physical basis for using the ratio as a brittleness indicator.

Evans and Pomeroy51showed theoretically that the impact energy of a cutter pick is inversely proportional to brittleness. Singh52 indicated that cuttability, penetrability, and the Protodyakonov strength index of coal strongly depend on the brittleness of coal. Singh53also showed that a linearly proportional relationship existed between in situ specific energy and the brittleness (B2) of three Utah coals. Goktan54stated that the brittleness concept (B2) adopted in his study might not be a representative measure of specific energy consumption during rock cutting. Kahraman55statistically investigated the relationships between three different brittleness indices and both drillability and borability using the raw data obtained from the experimental work of different researchers. Altindag56-58 found significant correlations between his proposed new brittleness concept (B3) and the penetration rate of percussion drills, the drilla-bility index in rotary drilling, and the specific energy in rock cutting. Kahraman and Altindag59correlated fracture toughness values with different brittleness values using the raw data obtained from the experimental works of two researchers. They indicated that the Altindag's brittleness concept (B3) can be used as a predictive rock property for the estimation of the fracture toughness value. Kahraman et al.60found a strong correlation between Los Angeles abrasion loss and the brittleness (B3) for 26 different rocks. Gunaydin et al61 reported a very strong correlation between hourly production and the brittleness B3, and they emphasised that the brittleness B3 is the most reliable index among the brittleness indices used in their study. Yilmaz et al.62 stated that the grain size seems to predominantly influence their relative brittleness index values in granitic rocks. Goktan and Yilmaz63investigated the relationships between brittleness (Bi) and specific energy (SE) and no meaningful correlations could be found between B1 and SE. However, after normalization of SE by uniaxial compressive strength and classification of test data for a particular rock group, the correlation is significantly improved.

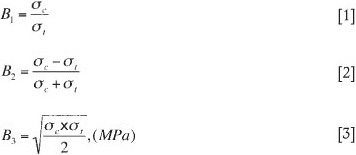

The brittleness concepts based on the compressive strength and tensile strength in this study are given as follows:

where B1, B2, and B3 brittleness indices, σc is the uniaxial compressive strength (MPa) and σt is the tensile strength (MPa). The calculated values of brittleness for the dataset prepared in this study are displayed in Table II.

Regression analysis applied to rock properties

Many equations, some of which are presented in Table I, are reported in literature to estimate the UCS of rock from the P-wave velocity. The majority of the equations yield linear and power relationships between the UCS and P-wave velocity. In each study, the amount of data was limited and the same statistical analysis was applied to various rock types, regardless of the differences in their geological origins. Thus, a concern arises as to the reliability of the empirical equations developed. In this study, only sedimentary rocks were taken into account to improve the reliability of the equations.

Statistical analyses used in this study relying on the relationship between Vp and other intact rock properties were based on the data obtained from different studies. Results of the basic descriptive statistical analysis performed on data set are given in Table III. The boxplot of the dataset is shown in Figure 1.

Simple regression analysis

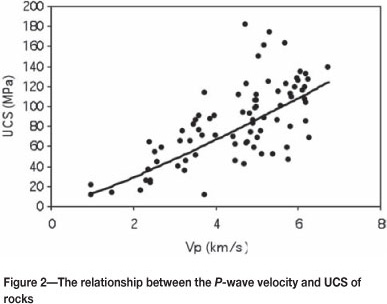

The raw dataset (Table II) was subjected to least squares regression analysis. Linear (y = ax+b), logarithmic (y = a + ln x), exponential (y = aex), and power (y = axb) curve fitting approximations were executed and the approximation equations that have the highest correlation coefficient were determined for each regression. A power correlation was found between the UCS and P-wave velocity for the entire dataset (Figure 2). The equation of the curve is:

where UCS is the uniaxial compressive strength (MPa) and Vp is the P-wave velocity (km/s). The correlation coefficient of the relationship is 0.76.

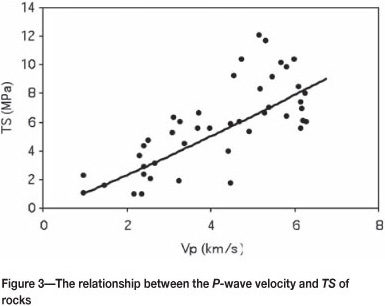

A plot of tensile strength vs. Vp is shown in Figure 3. The empirical equation of this relation is:

where TS is the tensile strength (MPa) and Vp is the P-wave velocity (km/s). The correlation coefficient of the relationship is 0.77.

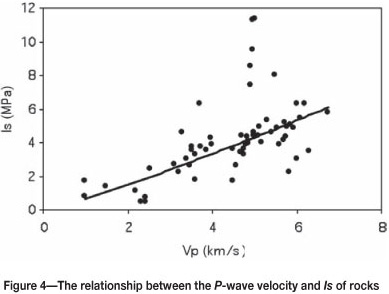

In Figure 4, a power relationship between point load index and P-wave velocity is shown. The equation of the curve is:

where Is is the point load index (MPa) and Vp is the P-wave velocity (km/s). The correlation coefficient of the relation is 0.70.

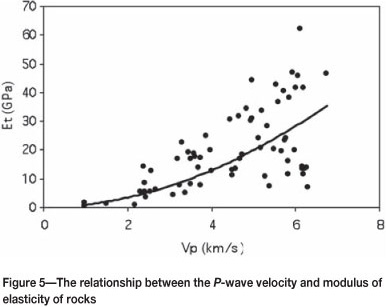

There is a power relationship between Modulus of elasticity (Et) and P-wave velocity (Figure 5). The equation of the curve is:

where Et is the modulus of elasticity (GPa) and Vp is the P-wave velocity (km/s). The correlation coefficient of the relationship is 0.79.

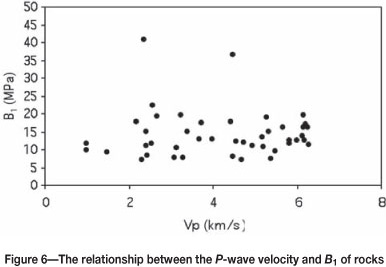

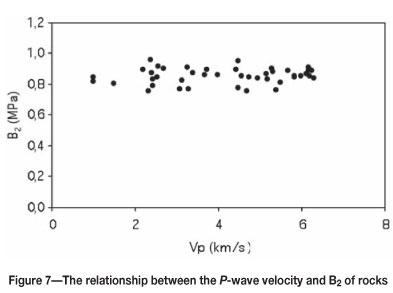

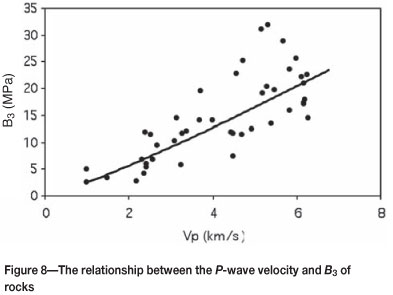

However, the relationships between brittleness B1 and B2 and P-wave velocity resulted in quite weak correlation coefficients, as seen in Figures 6 and 7. A power correlation between brittleness B3 and P-wave velocity was obtained, as shown in Figure 8. The equation of the curve is:

where B3 is brittleness and Vp is the P-wave velocity (km/s). The correlation coefficient of therelation is 0.84.

Figures 2-8 show the plots of P-wave velocity versus uniaxial compressive strength, tensile strength, point load index, modulus of elasticity and brittleness concepts. The results of such regressions also represented good correlations between the properties tested. Relationships are statistically significant according to the student's t-test with 95% confidence.

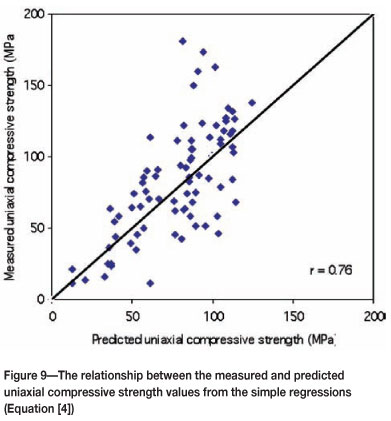

The scatter diagram of observed and estimated values of UCS of rocks is shown in Figure 9. In the plot of Equation [1], the points are scattered uniformly about the diagonal line, suggesting that the model is reasonable.

Multiple regression analysis

In the second stage of the regression analyses, a series of multiple regression analyses were performed. It may not be always possible to predict the rock strength from a particular rock index test only, owing to the reason that rock strength parameters are a function of physical, textural, and mineralogical properties of rock.

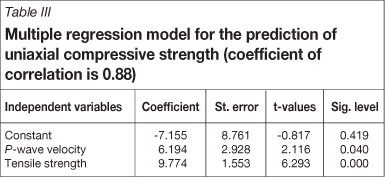

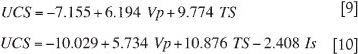

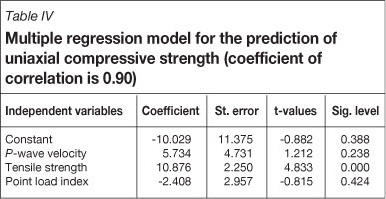

Multiple linear regression analysis was also undertaken, including tensile strength, point load index, and P-wave velocity values in the model. The equations derived to estimate the uniaxial compressive strength of sedimentary rocks can be listed as follows:

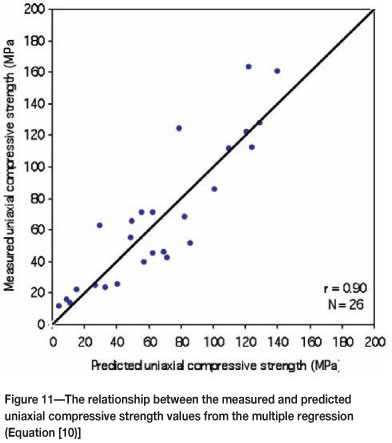

where UCS is the uniaxial compressive strength (MPa), Vp is P-wave velocity (km/s), TS is tensile strength (MPa) and Is is point load index (MPa). The correlation coefficients are 0.88 and 0.90, respectively.

The multiple regression models to predict the uniaxial compressive strength are summarized in Tables III and IV, and the regression equations obtained are given in Equations [9-10].

The relationships between the measured and the predicted values are illustrated in Figures 10-11. As can be seen, the prediction models appear to be more reliable than that of obtained by simple regression analysis. In addition, determination of P-wave velocity, tensile strength, and point load index requires relatively shorter core samples than those needed for uniaxial compressive test. Hence, the predictive models obtained in this study for sedimentary rocks can be suggested as useful tools for researchers and engineers.

Conclusion

The results of simple regression analyses may suggest that the relationships between P-wave velocity and uniaxial compressive strength, point load index, modulus of elasticity, and brittleness values are meaningful. Two equations with high prediction performance were developed by multiple regression analysis for the prediction of uniaxial compressive strength.

The relationship equation between the UCS, Vp, and TS is:

Equation [9] is simple and easier to use to predict the uniaxial compressive strength than other multiple regression equations.

Under certain conditions, it may be difficult and complicated to measure the uniaxial compressive strength of rocks. The use of empirical relationships to estimate the uniaxial compressive strength of rock can be more practical and economical.

The equations found in the literature are derived using the rocks from different geological origins to estimate the UCS from P-wave velocity. The author of this work believes that the geological origins of rocks should be taken into account separately in statistical analysis when seeking for the relationships between P-wave velocity and UCS of rocks.

In this way, more reliable predictions will be possible for project engineers and researchers.

References

1. Price, D.G., Malone, A.W., and Knill, T.L. The application of seismic methods in the design of rock bolt system. Proceedings of the First International Congress of the International Association of Engineering Geologist, vol. 2, 1970. pp. 740-752. [ Links ]

2. Young, R.P., Hill, T.T., Bryan, I.R., and Middleton, R. Seismic spectroscopy in trauure characterization. Quarterly Journal of Engineering Geology, vol. 18, 1985. pp. 459-479. [ Links ]

3. Karpuz, C. and Pa$amehmetoclu, A.G. Field characterization of weathered Ankara andasites. Engineering Geology, vol. 46, 1997. pp. 1-17. [ Links ]

4. Onodera, T.F. Dynamic investigation of foundation rocks. Proceedings of the Fifth US Symposium on Rock Mechanics, Pergamon Press, New York, 1963. pp. 517-533. [ Links ]

5. Gladwin, M.T. Ultrasonic stress monitoring tunnel underground mining. International Journal of Rock Mechanics and Mining Sciences, vol. 19, 1982. pp. 221-228. [ Links ]

6. Boadu, F.K. Fractured rock mass characterization parameters and seismic properties analytical studies. Journal of Applied Geophysics. vol. 36, 1997. pp. 1-19. [ Links ]

7. Turk, N. and Dearman, W.R. A suggested approach to rock characterization in terms of seismic velocities. Proceedings of the 27th US Symposium on Rock Mechanics. Hartman H.L. (ed.). Society of Mining Engineers, 1986. pp. 168-175. [ Links ]

8. O'Connel, R.J. and Budiansky, B. Seismic velocities in dry and saturated cracked rock. Journal of Geophysical Research, vol. 79, 1974. pp. 5412-5426. [ Links ]

9. Hudson J A, Wave speed and attenuation of elastic waves in material containing cracks. Geophysical Journal of the Royal Astronomical Society, vol. 64, 1981. pp. 133-150. [ Links ]

10. King, M.S., Chaudhry, N.A., and Shakeel, A. Experimental ultrasonic velocities and permeability for sandstones with aligned cracks. International Journal of Rock Mechanics and Mining Sciences, vol. 32, 1995. pp. 155-163. [ Links ]

11. Watanabe, T. and Sassa, K. Velocity and amplitude of P-waves transmitted through fractured zones composed of multiple thin low velocity layers. International Journal of Rock Mechanics and Mining Sciences, vol. 32, 1995. pp. 313-324. [ Links ]

12. Kahraman, S. A correlation between P-wave velocity, number of joints and Schmidt hammer rebound number. International Journal of Rock Mechanics and Mining Sciences, vol. 38, 2001. pp. 729-733. [ Links ]

13. Kahraman, S. The effects of fracture roughness on P-wave velocity. Engineering Geology, vol. 63, 2002. pp. 347-350. [ Links ]

14. Zezza, F. Evaluation criteria of the effectiveness of treatments by non destructive analysis. Proceedings of the 2nd Course of CUN University School of Monument Concervation, Heraklion, 1993. pp. 198-207. [ Links ]

15. Christaras, B., Mariolakos, I., Foundoulis, J., Athanasias, S., and Dimitriou, A. Geotechnical input for the protection of some Macedonian Tombs in Northern Greece. Proceedings of the 6th International Symposium Conservation of Monuments in the Mediterranean Basin, Rhodes, 1997. pp.125-132. [ Links ]

16. Christaras, B. P-wave velocity and quality of building materials. Proceedings of the International Symposium Industrial Minerals and Building Stones, Istanbul, 2003. Yuzer, E., Ergin, H., and Tugrul, A. (eds.). pp. 295-300. [ Links ]

17. D'Andrea, D.V., Fischer, R.L., and Fogelson, D.E. Prediction of compressive strength from other rock properties, US Bureau of Mines Report of Investigations 6702, 1965. [ Links ]

18. Deere, D.U. and Miller, R.P. Engineering classification and index properties for intact rock. Air Force Weapons Laboratory Technical Report, AFWL-TR 65-116, Kirtland Base, New Mexico, 1966. [ Links ]

19. Youash, Y. Dynamic physical properties of rocks: part 2, experimental result. Proceedings of the 2nd Congress of the International Society for Rock Mechanics, vol. 1, Privredni Pregled, Beograd, Yugoslavia, 1970. pp. 185-195. [ Links ]

20. Gardner, G.H.F., Gardner, L.W., and Gregory, A.R. Formation velocity and density: the diagnostic basis for stratigraphic traps. Geophysics, vol. 39, 1974. pp. 770-780. [ Links ]

21. Lama, R.D. and Vutukuri, V.S. Handbook on Mechanical Properties of Rocks. Trans. Tech. Publications, Clausthal, vol. 2, 1978, Germany. [ Links ]

22. Inoue, M. and Ohomi, M. Relation between uniaxial compressive strength and elastic wave velocity of soft rock. Proceedings of the International Symposium on Weak Rock, Tokyo, 1981. pp. 9-13. [ Links ]

23. Gaviglio, P. Longitudinal wave propagation in a limestone: the relationship between velocity and density. Rock Mechanics and Rock Engineering. vol. 22, 1989. pp. 299-306. [ Links ]

24. Yasar, E. and Erdogan, Y. Correlating sound velocity with density, compressive strength and Young's modulus of carbonate rocks. International Journal of Rock Mechanics and Mining Sciences, vol. 41, 2004. pp. 871-875. [ Links ]

25. Saito, T., Mamoru, A.B.E., and Kundri, S. Study on weathering of igneous rocks, Rock Mechanics, Japan, vol. 2, 1974. pp. 28-30. [ Links ]

26. Brich, F. The velocity of compressional waves in rocks to 10 kbars: Part 1. Journal of Geophysical Research, vol. 65, 1960. pp. 1083-1102. [ Links ]

27. Babushka, V. Elastic anisotropy of igneous and metamorphic rocks. Studia Geophysica et Geodaetica, vol. 12, 1968. pp. 291-303. [ Links ]

28. Kopf, M., Muller, H.J., and Gottesmann, B. Correlation between pyroxene content and Vp and Vs under high pressure. Kapicka, A., Kropacek, V., Pros, Z. (eds.). Physical properties of the mineral system of the Earth's Interior. Union Czech. Math. Phys., Prague, 1985. pp. 168-172. [ Links ]

29. Babuska, V., Pros, Z., and Franke, W. Effect of fabric and cracks on the elastic anisotropy in granadiorite. Publications of the Institute of Geophysics, Polish Academy of Sciences, A-6 117, 1977. pp. 179-186. [ Links ]

30. Jech, J., Babuska, V., and Pros, Z. Quantitative correlation of velocity anisotropy with the distribution of microcracks in rocks. Kapicka, A., Kropacek, V., and Pros, Z. (eds.), Physical Properties of the Mineral System of the Earth's Interior. Union Czech. Math. Phys., Prague, 1985. pp. 175-183. [ Links ]

31. Kahraman, S. The effects of fracture roughness on P-wave velocity. Engineering Geology, vol. 63, 2002. pp. 347-350. [ Links ]

32. Kahraman, S. The correlations between the saturated and dry P-wave velocity of rocks. Ultrasonics, vol. 46, 2007. pp. 341-348. [ Links ]

33. Singh, T.N. and Kripamoy, S. Geotechnical investigation of Amiyan landslide hazard zone in Himalayan region, Uttaranchal, India. Geotechnical Engineeringfor Disaster Mitigation and Rehabilitation, 2005. [ Links ]

34. Lawn, B.R. and Marshall, D.B. Hardness, Toughness and Brittleness: An Indentation Analysis. Journal of the Ceramic Society, vol. 62, no. 78, 1979. pp. 347-350. [ Links ]

35. Quinn, J.B. and Quinn, G.D. Indentation brittleness of ceramics: a fresh approach. Journal of Materials Science, vol. 32, 1997. pp. 4331-4346. [ Links ]

36. Morely, A. Strength of materials, Longman. Green, London, 1944. p. 35. [ Links ]

37. Hetenyi, M. Handbook of experimental stress analysis. John Wiley, New York, 1966. p. 15. [ Links ]

38. Ramsey, J.G. Folding and Fracturing of Rocks. McGraw-Hill, London, 1967. p. 289. [ Links ]

39. Obert, L. and Duvall, W.I. Rock mechanics and the design of fractures in rock. John Wiley, New York, 1967. p. 278. [ Links ]

40. Glossary of Geology and Related Sciences. American Geosciences Institute. Washington DC, 1960. [ Links ]

41. Hucka, V. and Das, B. Brittleness determination of rocks by different methods. International Journal of Rock Mechanics and Mining Science & Geomechanics, Abstracts. 11, 1974. pp. 389-392. [ Links ]

42. Baron, L.I. Determination of properties of rocks (in Russian), Gozgotekhizdat, Moscow, 1962. [ Links ]

43. Coates, D.F. Experimental criteria for classification of rock substances. International Journal of Rock Mechanics and Mining Sciences, vol. 3, 1966. pp. 181-189. [ Links ]

44. Bishop, A.W. Progressive failure with special reference to the mechanism causing it. Proceedings of the Geotechnical conference, Oslo, 2, 1967. pp. 142-150. [ Links ]

45. Ribacchi, R. Mechanical tests on pervasively jointed rock material: Insight into rock mass behaviour. Rock Mechanics and Rock Engineering, vol. 33, no. 4, 2000. pp. 243-266. [ Links ]

46. Hajiabdolmajid, V. Mobilization of strength in brittle failure of rocks, Ph.D. thesis, Queen's university, Kingston, Canada, 2001. [ Links ]

47. Zang, B., Bicanic, N., Pearce, J.C., and Phillips, V.D. Relationships between brittleness and moisture loss of concrete exposed to high temperatures. Cement and Concrete Research, vol. 32, 2002. pp. 363-371. [ Links ]

48. Hajiabdolmajid, V. and Kaiser, P. Brittleness of rock and stability assessment in hard rock tunnelling. Tunnelling and Underground Space Technology, vol. 18, 2003. pp. 35-48. [ Links ]

49. Aubertin, M. and Gill, D.E. Une methodologie d'evaluation du potential de coups de terrain dans les mines d'Abitibi. Proc. Colloque sur le Controle de Terrain, (AMMQ), Val d'Or, 1988. pp. 47-77. [ Links ]

50. Aubertin, M., Gill, D.E., and Simon, R. On the use of the brittleness index modified (BIM) to estimate the post-peak behaviour of rocks. Rock Mechanics. Nelson and Laubach (eds), Balkema, 1994. pp. 945-952. [ Links ]

51. Evans, I. and Pomeroy, C.D. The strength fracture and workability of coal. Pergamon Press, oxford, 1966. [ Links ]

52. Singh, S.P. Brittleness and the mechanical wining of coal. Ministry of Science and Technology, vol. 3, 1986. pp. 173-180. [ Links ]

53. Singh, S.P. Criterion for the assessment of the cuttability of coal. Underground Mining Methods and Technology. Szwilski, A.B. and Richards, M.J. (eds.). Amsterdam: Elsevier, 1987. pp. 225-239. [ Links ]

54. Goktan, R.M. Brittleness and micro-scale rock cutting efficiency. Mining Science and Technology, vol. 13. 1991. pp. 237-241. [ Links ]

55. Kahraman, S. Correlation of TBM and drilling machine performance with rock brittleness. Engineering Geology, vol. 65, 2002. pp. 269-283. [ Links ]

56. Altindag, R. The role of rock brittleness on the analysis of percussive drilling performance (in Turkish). Proceedings the Fifth Turkish National Rock Mechanics Symposium, Isparta, Turkiye, 2000. pp. 105-112. [ Links ]

57. Altindag, R. The evaluation of rock brittleness concept on rotary blast hole drills. Journal of the South African Institute of Mining and Metallurgy, vol. 102, no. 1, 2002. pp. 61-66. [ Links ]

58. Altindag, R. Correlation of specific energy with rock brittleness concepts on rock cutting. Journal of the South African Institute of Mining and Metallurgy, vol. 103, no. 3, 2003. pp. 163-171. [ Links ]

59. Kahraman, S. and Altindag, R. A brittleness index to estimate fracture toughness. International Journal of Rock Mechanics and Mining Sciences, vol. 41, 2004. pp. 343-348. [ Links ]

60. Kahraman, S., Gunaydin, O., Fener, M., and Bilgil, A. Correlation between Los Angeles abrasion loss and uniaxial compressive strength. Proceedings of the International Symposium on Industrial Minerals and Building stones, istanbul, Turkiye, 2003. pp. 577-581. [ Links ]

61. Gunaydin, O., Kahraman, S., and Fener, M. Sawability prediction of carbonate rocks from brittleness indexes. Journal of the South African Institute of Mining and Metallurgy, vol. 104, no. 4, 2004. pp. 1-6. [ Links ]

62. Yilmaz, N.G., Karaca, Z., Goktan, R.M., and Akal, C. Relative brittleness characterization of some selected granitic building stones: Influence of mineral grain size, Construction and Building Materials, vol. 23, 2009. pp. 370-375. [ Links ]

63. Goktan, R.M. and Yilmaz, N.G. A new methodology for the analysis of the relationship between rock brittleness index and drag pick cutting efficiency. Journal of the South African Institute of Mining and Metallurgy, vol. 105, 2005. pp. 727-733. [ Links ]

64. Cheng, H. and Hu, Z.Y. Some factors affecting the uniaxial strength of weak sandstone. Bulletin of Engineering Geology and the Environment, vol. 62, 2003. pp. 323-332. [ Links ]

65. Sharma, P.K. and Singh, T.N. A correlation between P-wave velocity, impact strength index, slake durability index and uniaxial compressive strength. Bulletin of Engineering Geology and the Environment, vol. 67, 2008. pp. 17-22. [ Links ]

66. Tucrul, A. and Zarif, I.H. Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey. Engineering Geology, vol. 51, 1999. pp. 303-317. [ Links ]

67. Cobanoclu, i. and Celik, S.B. Estimation of uniaxial compressive strength from point load strength, Schmidt hardness and P-wave velocity. Bulletin of Engineering Geology and the Environment, vol. 67, 2008. pp. 491-498. [ Links ]

68. McCann, D.M., Culshaw, M.G., and Northmore, K.J. Rock mass assessment from seismic measurements, Field Testing in Engineering Geology. Bell, Culshaw, Cripps, and Coffey (eds.). Geological Society Publishing House, London, vol. 6, 1990. pp. 257-266. [ Links ]

69. Entwisle, D.C., Hobbs, P.R.N., Jones, L.D., Gunn, D., and Raines, M.G. The relationships between effective porosity, uniaxial compressive strength and sonic velocity of intact Borrowdale volcanic group core samples from Sellafield. Geotechnical and Geological Engineering, vol. 23, 2005. pp. 793-809. [ Links ]

70. Vasconcelos, G., Lourenco, P.B., Alves, C.A.S., and Pamplona, J. Ultrasonic evaluation of the physical and mechanical properties of granites. Ultrasonics, vol. 48, 2008. pp. 453-466. [ Links ]

71. Sousa, L.M.O., Rio, L.M.S., Calleja, L., Argandona, V.G.R., and Rey, A.R. Influence of microfractures and porosity on the physico-mechanical properties and weathering of ornamental granites. Engineering Geology, vol. 77, 2005. pp. 153-168. [ Links ]

72. Goktan, R.M. Theoretical and practical analysis of rock rippability. Ph.D. thesis, Istanbul Technical University, istanbul, Turkey, 1988. [ Links ]

73. Chary, K.B., Sarma, L.P., Lakshmi, K.J.P., Vijayakumar, N.A., Lakshmi, V.N., and Rao, M.V.M.S. Evaluation of engineering properties of rock using ultrasonic pulse velocity and uniaxial compressive strength. Proceedings of the National seminar on Non-destructive evaluation, Hyderabad, India, 2006. pp. 379-385. [ Links ]

74. Tercan, A.E., Unver, B., Tiryaki, B., and Ózbilgin, D. A study of relationships among mechanical, index and petrographic properties of some sandstones using canonical correlation analysis, (in Turkish). Mining, vol. 44, 2005. pp. 3-14. [ Links ]

75. Ya$ar, E. and Erdocan. Y. Yapi-kaplama kayalarinin P dalga hizi ile fiziko-mekanik ozellikleri arasindaki ili§kilerin istatiksel analizi (in Turkish), Turkiye IV. Marble Semposioum (Mersem'2003), 2003. pp. 353-362. [ Links ]

76. Zukui, L., Xinxu, Z., Jinhai, Z., Daixu, T., Yongsong, T., Jing, Y., and Yanqing, L. The experiment investigation of the correlation of acoustic logging and rock mechanical and engineering characteristics. Frontiers of Rock Mechanics and Sustainable Development in the 21st Century. Sijing, Bingiun, Zangkui (eds.), 2001. pp. 89-92. [ Links ]

77. KiLic, A. AND Teymen, A. Determination of mechanical properties of rocks using simple methods, Bulletin of Engineering Geology and the Environment, vol. 67, 2008. pp. 237-244. [ Links ]

78. Matsui, K. and Shimada, H. Rock impact hardness index for predicting cuttability of roadheader, Mine Mechanization and Automation, 1993. pp. 265-270. [ Links ]

79. Karakus M, Kumral M, Kilic A, Predicting elastic properties of intact rocks from index tests using multiple regression modelling. International Journal of Rock Mechanics and Mining Sciences, vol. 42, 2005. pp. 323-330. [ Links ]

80. Basarir, H. and Karpuz, C. A ripability classification system for marls in lignite mines. Engineering Geology, vol. 74, 2004. pp. 303-318. [ Links ]

81. Tecen, O. and Fowell, R.J. Hybrid rock cutting: fundamental investigations and practical applications. Proceedings of the Second US Water Jet Conference. Summer, D.A. and Haston, F.F. (eds.), Missouri-Rolla, 1983. pp. 368-380. [ Links ]

82. Demou, S.G., Olson, C.R., and Wingquist, C.F. Determination of bit forces encountered in hard rock cutting for application to continuous design. US Bureau of Mines, RI 8748, 1983. p. 24. [ Links ]

83. Zarif, i.H. and Tucrul, A. Aggregate properties of Devonian limestones for use in concrete in Istanbul, Turkey. Bulletin of Engineering Geology and the Environment, vol. 62, 2003. pp. 379-388. [ Links ]

84. Lashkaripour, G.R. A statistical investigation on mudrocks. ISRM Regional Symposioum- Advancing Rock Mechanics Frontiers to Meet the Challenges of 21st Century, II-79-II84, 2002. [ Links ]

85. Basarir, H., Karpuz, C., and Bozdag, T. Rippability assessment studies at tuncbilek coal mine: a case study. Panagiotou and Michalakopoulos (eds.). Proceedings of the Ninth International Mine Planning and Equipment Selection, Nov. Balkema, Rotterdam, 2000. pp. 515-520. [ Links ]

86. Kahraman, S., Balci, C., Yazici, S., and Bilgin, N. Prediction of the penetration rate of rotary blast hole drills using a new drillability index. International Journal of Rock Mechanics and Mining Sciences, vol. 37, 2000. pp. 729-743. [ Links ]

87. Ersoy, A and Atici, U. Correlation of P and S-waves with cutting specific energy and dominant properties of volcanic and carbonate rocks. Rock Mechanics and Rock Engineering, vol. 40, 2007. pp. 491-504. [ Links ]

88. Huang, S.L. and Wang, Z.W. The mechanics of diamond core drilling of rocks. International Journal of Rock Mechanics and Mining Sciences, vol. 34, nos. 3-4, 1997. [ Links ]

89. Balci, C. and Bilgin, N. Mekanize kazi makinalarinin sejiminde ktifiik ve tam boyutlu kazi deneylerinin kar§ila§tmlmasi, (in Turkish). ITU Dergisi/d, Muhendislik, vol. 4, 2005. pp. 76-86. [ Links ]

90. Holmgeirsdottir, T.H. and Thomas, P.R. Use of the D-762 Shore hardness sclerescope for testing small rock volumes. International Journal of Rock Mechanics and Mining Sciences, vol. 35, 1998. pp. 85-92. [ Links ]

91. Howarth, F.D., Adamson, W.R., and Berndt, J.R. Correlation of model tunnel boring and drilling machine performances with rock properties. International Journal of Rock Mechanics and Mining Sciences, vol. 23, 1986). pp. 171-175. [ Links ]