Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 n.2 Johannesburg Jan. 2012

JOURNAL PAPER

Optimum Coal Mine: striving towards a 'zero effluent' mine

V.E. Cogho

Optimum Coal Mine, Pullenshope

SYNOPSIS

Optimum Coal Mine comprises numerous defunct, active, and future mining sections. The mine is primarily a large opencast coal mine; however, underground mining activities will be increasing steadily over the next five years. Opencast and underground mining activities have a significant impact on surface and groundwater resources. To ensure that the mine will be able to continue with its mining operations in the catchment, the extent of this impact requires that substantial intervention and mitigation measures need to be implemented to ensure the environmental integrity and economic use of the catchment's water resources.

In developing a sustainable long-term mine water management strategy, numerous scenarios had to be analysed. The various scenarios are a combination of water and land management activities. The main components of the mine's integrated water management strategy include:

From the mine's long-term water balance, it is evident that the continued implementation of numerous water management actions is required to mitigate the water resources impact in a sustainable manner. In addition, the installation of a water reclamation plant at Optimum Coal Mine (15Mℓ/day) is a key step for the mine to achieve a zero impact target.Management of water recharge by continual and appropriate rehabilitation of disturbed land

Beneficial re-use of impacted mine water for coal plant process water and mining operations

Reclamation and desalination of remaining excess impacted mine water to potable standard.

Keywords: opencast mining, water management, water balance, water treatment, desalination, zero effluent.

Background

Optimum Coal Mine is a multi-product mine with a contract to supply Hendrina Power Station with coal until 2018. The mine also exports a significant quantity of coal. Optimum lies in the upper reaches of the Middelburg Dam Catchment. The dam has a maximum water holding capacity of 48 Mm3. It receives run-off from the Klein Olifants catchment with a total drainage area of 1 550 km2. Run-off from this catchment is in the order of 5.5% of the average annual rainfall, coming to a total of some 60 Mm3/a. The mean annual rainfall for Optimum Coal Mine based on a 80-year rainfall record is 687 mm, while the annual potential evaporation for the area is estimated at roughly 1 700 mm.

The mine lease area for Optimum Coal Mine is 383 km2. The average annual run-off prior to mining from the mine lease area was 14.7 Mm3/a, which constitutes about 25% of the natural catchment run-off. The mine clearly plays a dominant role in modifying the natural hydrology and run-off to Middelburg Dam. To date, the mine has disturbed roughly 6 870 ha of land and plans to disturb an additional 3 136 ha over the remaining life of the mine. Furthermore, the mine has mined 1 532 ha via underground board and pillar mining and plans to mine an additional 2 687 ha via board and pillar mining. Figure 1 depicts the mine's locality within the Klein Olifants River Catchment, as well as the layout of the relevant mining areas.

The opencast and underground mining activities have a significant impact on surface and groundwater resources. To ensure that the mine will be able to continue with its mining operation in the catchment, the extent of this impact requires that substantial intervention measures are implemented to ensure the environmental integrity and economic use of the catchment's water resources.

History of mining activities

Optimum Coal Mine commenced mining activities during the 1970s as an underground bord and pillar mine in the Pullenshope area. During 1971 the mine initiated an opencast strip mine, with mining activities commencing in the Optimus mining area. At that stage, very little legislation existed that could guide the opencast mining activities towards environmentally responsible mining. Strip mining activities started within the Woestalleen East Spruit and proceeded in an easterly and westerly direction. No stream diversion was legally required at that time to mine through a stream. In addition to this, the stripping of topsoil prior to mining an area was also not required, which implied that the rehabilitation of the opencast mining areas received little attention. Figure 2 represents a closer view of the earlier mining activities at Optimum Coal Mine.

Mining within the Woestalleen East Spruit also resulted in voids that were left open and these features formed the Lapa Dam, which is currently one of the mine's affected water storage facilities. During the late 1980s to early 1990s, significant changes to the relevant legislation were made, requiring mining companies to take cognisance of environmental issues during mining and address all identified impacts in an environmental management programme (EMP). This document received input from all regulators, to ensure impacts were managed on a continuous basis in line with regulatory requirements.

During the early days of Optimum Coal Mine little was done in terms of appropriate water management, which meant the separation of clean and affected water, as well as the re-use of affected water, was not a high priority and led to frequent spills and discharges into the aquatic environment. In 1993, the mine needed to develop the Pullenshope mining area. In order to do this, the mine had to implement numerous water management controls (including flood prevention measures), which included the Pullenshope stream diversion, before mining could commence. Figure 3 depicts the extent of this diversion, which is still functional and is upgraded on an annual basis as mining progresses in the area.

In summary, legislation since 1991 required mines to conduct detailed environmental impact assessments and have approved EMPs before mining can commence. This applies to the extension of existing operations as well as new areas. In addition, the Department of Water and Environmental Affairs (DWEA) is currently implementing a Waste Discharge Charge System (WDCS) to promote waste reduction and conservation. This forms part of the Pricing Strategy, which was established under the National Water Act (NWA). The Pricing Strategy articulates the aims of the Waste Discharge Charge System which are to:

Promote the sustainable development and efficient use of water resources

Promote the internalization of environmental costs by impactors

Recover some of the costs of managing water quality

Create financial incentives for dischargers to reduce waste and use water resources in a more optimal way.

The upper Olifants catchment, including the Klein Olifants River catchment, is one of three priority areas targeted for implementation of the WDCS by DWEA.

Water management principles

The development of a water management strategy requires consideration of the DWEA's hierarchy of water management controls. This hierarchy of controls formed the basis of implementing water management on the mine. This approach is considered best practice, and in terms of water management cost, it makes sound financial sense.

The priorities in terms of this hierarchy are:

Keeping clean water clean. This applies to water upstream of mining, as well as water from rehabilitated areas

Containing impacted water with low risk of spilling

Maximized re-use of impacted water within the mining environment

Treatment of water to render it fit for use, where it cannot be re-used without treatment

Release of water in terms of a Water Use Licence where permitted by the authorities.

Managing the affected water make within a closed water circuit generally requires the following to be achieved:

The average water make for average rainfall should be balanced by either the average water usage, or else storage is required for the surplus water make

Storage is required to balance the wet and dry seasons

If the probability of spilling impacted water is to be 2% or less in any one year, additional storage may still be required to accommodate the very wet periods when there will certainly be an excess of water and dewatering is required to facilitate mining

The overall impacted water make must be managed and minimized

The re-use of impacted water for mining purposes must be maximized

The current use of clean water by the mine must be minimized.

These water management principles informed and directed the development of a water management strategy.

Water management strategy

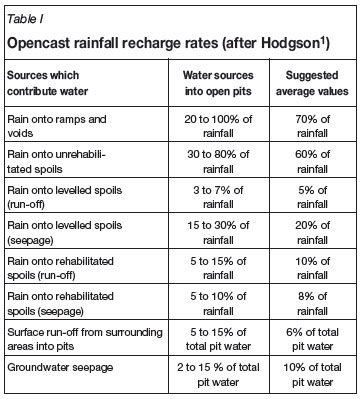

Water management on large opencast mines is intrinsically associated with the hydrological cycle. The hydrology and geohydrology are both components of the larger hydrological cycle, and can never be viewed in isolation. To manage water in an optimal manner on any mine, a clear understanding of all the components in the hydrological cycle is required. Rainfall recharge rates into the mining area were determined by Hodgson1 and are listed in Table I.

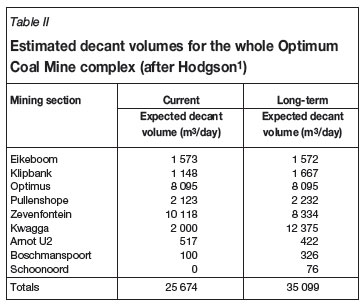

Based on the above, estimates of the expected current and future impacted water volumes were calculated and are reflected in Table II. To manage the current and future affected water make, the mine evaluated various options to reduce the overall water make. In addition to the water make, it is also important to note that significant portions of the mined-out opencast portions have accumulated large volumes of water. This water make is governed by the rainfall recharge rates listed in Table I. The rates are based on a history of opencast groundwater models within the Witbank Coalfield.

Figure 4 depicts current and future mined-out areas and associated volumes of water stored within them. Thus from a long-term water management point of view it is crucial to take cognisance of this when sustainable management options are implemented.

Figure 5 summarizes Optimum's detail water balance and includes the optimized re-use of affected water by the mining operation. From the mine's water balance, it is evident that the continued implementation of numerous water management actions is required to mitigate the catchment water resources impact in a sustainable manner. It is also clear that the accumulation of water has now reached a situation where approximately 15Mℓ/day of excess affected water is generated that needs to be managed on a daily basis. The respective water uses on the graph are depicted by the red bars, whereas the green bars reflect additional water makes.

As such, the water management strategy will thus be a dynamic and ongoing process that involves risk assessment and quantification, and adaptation of plans to meet changing circumstances. Bearing this in mind, the long-term water management strategy should enable the mine to manage the overall water balance in a sustainable way, to ensure legal compliance, and to suit the requirements at mine closure.

In developing a long-term strategy, numerous scenarios had to be analysed. The various scenarios were a combination of several water management activities, which were categorized into two major groupings, namely:

Water management alternatives, and

Mine water reclamation scheme.

Combinations of activities within these groupings were evaluated and rated to satisfy the problem statement. Six scenarios were investigated, evaluating various combinations of water control activities, which included the 'Do Nothing Case'. Five scenarios, excluding the 'Do Nothing Case', included actions such as:

Reduce water make and minimize the cost of the WTP by accelerating the mine rehabilitation

Reduce water make and minimize the cost of WTP by implementing other low-cost water management measures such as re-use, irrigation, and dust suppression

A combination of the above two actions

Treat all excess water from all the sections without implementing any other water management measure

Keep WTP small and ensure that life of mine provides gradual water storage for the Kwagga section.

The recommended scenario going forward is based on a combination of the first two actions, i.e. accelerating the rehabilitation of mined-out areas, optimizing clean and dirty water separation systems, optimizing the re-use of affected water for the mining operation, and treating the remaining excess affected water. The 'Do Nothing Case' is not feasible, as it threatens the mine's license to operate and will certainly lead to prosecution by the regulator.

Water treatment of surplus affected water

The key components of the Optimum Water Reclamation Project (OWRP) include raw water collection, treatment, treated water storage and distribution, sludge and brine disposal, and bulk support services, as shown in Figure 6.

With the implementation of the OWRP, two additional alternatives were evaluated with respect to the implementation of the sustainable long-term management control of such a facility:

Option 1-Fit-for-purpose simple solution to mitigate excess affected water (i.e. treat water and discharge directly into receiving water body)

Option 2-Value-add opportunity to recover some of the operational costs (i.e. stabilize and disinfect treated water and supply to the local municipality, to generate revenue).

The different components of the OWRP are briefly described

Mine water collection

The mine water evaporation dam is the central depository of impacted water on the Optimum Mine complex. All excess impacted water not utilized by mining operations and coal washing is diverted to the evaporation dam. It provides a large storage capacity to even out the short-term and seasonal variation in excess mine water production.

The mine water is gravity-drained from the evaporation dam to the mine water reclamation plant.

The impacted mine water is near neutral and contains mainly calcium magnesium sulphate salts with a relatively low metals content. It therefore represents a brackish water which is relatively easy to treat and reclaim.

Mine water treatment

The mine water treatment technology is based on Aveng Water's high-recovery desalination technology. The key components of the mainstream treatment process include the following:

Pretreatment for solids and metals removal

Filtration using selective granular media for manganese polishing

Ultrafiltration for suspended and colloidal solids removal

Reverse osmosis/nanofiltration (RO/NF) membrane treatment for desalination.

The integrated mine water treatment process is shown in Figure 7. The overall treatment process is aimed at maximizing water recovery and minimizing waste production. The target water recovery is more than 98%. This is the second application of this membrane based treatment technology, the first such project being the eMalahleni Water Reclamation Project.

Water polishing and distribution

The desalinated water targeted for potable use is further polished by stabilization (using limestone) and disinfection (using chlorine). This good quality water is pumped to surrounding communities, with the excess water discharged to the clean water diversion canal upstream of the Pullenshope mine workings.

A fraction of the treated water is released to a tributary of the Klein Olifants River to support the environmental water requirements, as established by the DWEA's aquatic ecosystem reserve determination.

Waste generation and disposal

The mine water treatment process produces two waste streams:

A sludge stream containing mainly calcium and magnesium salts with limited metal content, since the feed mine water is not acidic and does not carry a high metals load

A brine stream containing high soluble salts, mainly sodium and some magnesium salts.

The sludge is disposed to a sludge lagoon for interim storage, until the co-disposal with mining wastes can be authorized and by-products recovery can commence.

The small brine stream is disposed to a lined evaporation dam, constructed to satisfy and comply with all the relevant legal requirements for hazardous waste disposal sites.

The integrated project represents the state of the art in terms of mine water desalination, and will produce highquality product water complying with all the requirements of the DWAE Guidelines for Drinking Water Use, 1996.

Potential water supply market

The water resources of the Upper Olifants River Catchment are over-utilized and under stress, with the local municipalities and power generation industry relying heavily on inter-basin water transfer schemes, (i.e. from the Komati, Usutu, and Vaal catchments). Mining activities in the catchment have the ability to generate large volumes of affected water, which could be re-used by the above sectors to reduce the reliance on inter-basin transfers.

It is also important to note that future mining projects in the region will have difficulty receiving water allocations from the DWEA, due to the current deficit of water in the entire catchment. Based on this, the OWRP has also the potential to supply future mining projects in the region with treated water.

The DWEA is aware of the critical water supply situation to the surrounding communities. The Department has compiled a water resources management strategy for the Upper Olifants River Catchment that incorporates the use of reclaimed mine water. This strategy therefore includes the Optimum reclaimed mine water as the preferred supplier of water to the surrounding communities. In addition to the above, the DWEA is unlikely to issue a water use license for a water reclamation project that does not include a municipal water supply component. The Department is certainly considering the beneficial use of the available water resources in the approval and granting of water use licenses. Bearing this in mind, it is therefore important that the OWRP considers the supply of treated water to the local municipality in their long-term water management strategy.

During December 2010 a water supply agreement between Optimum Coal Holdings (OCH) and the Steve Tshwete Local Municipality was finalized, resulting in the supply of treated water to the town of Hendrina/KwaZamakhule.

Conclusions

Optimum's long-term water management strategy is based on the following approach:

Minimization of the production of impacted water by responsible mining and land use practices

Collection and use of impacted water on the mine complex to satisfy the entire mine's own needs. The objective is to have the mine independent of imported water sources

Excess impacted mine water still remaining will be treated to a standard fit for discharge or use by the surrounding communities

The excess reclaimed water will be managed as a resource and the mine will position itself as a local and regional water supplier

The water resource will continue to be available in the post-mining era to the local and regional water users.

It is also important to note that in terms of water management, there are various uncertainties that need to be managed on an ongoing basis:

Variables that cannot be controlled such as future rainfall events

Technical uncertainties such as the actual recharge through rehabilitated spoils

The long-term value of potable water

Mining-related uncertainties such as the mine plan, strategies around water management, and the possible use of storage available in mined-out areas.

The water management strategy will thus be a dynamic and ongoing process that involves risk assessment and quantification, and adaptation of strategies to meet changing circumstances.

References

1. HODGSON, F., LUKAS, E., and VERMEULEN, D. Mine water balance and intermine flow for Optimum Colliery. Report Number: 2006/012/FDIH. The Institute for Groundwater Studies, University of the Free State, 2006. [ Links ]

2. GOLDER. Engineering basis of Design, Optimum Water Reclamation Project. Technical Memorandum. 2008. [ Links ]

3. AVENG WATER. Proposal for minewater treatment plant. Report Number: E07/1071, Revision 2. 2008. [ Links ]

This paper was first presented at the, MineSafe Conference, 15-18 August 2011, Emperors Palace, Hotel Casino Convention Resort, Johannesburg.

© The Southern African Institute of Mining and Metallurgy, 2012. SA ISSN 0038-223X/3.00 + 0.00.