Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.1 Johannesburg ene. 2012

TRANSACTION PAPERS

Effect of load variability on matching during continuous microwave treatment of crushed mineral ores

S.M. Bradshaw; R. Marchand

Department of Process Engineering, University of Stellenbosch, South Africa

SYNOPSIS

In order to assess the requirements for online matching when using a transverse electric field (E-field) applicator to treat mineral ores continuously, the effect of varying load properties on matching has been investigated by simulation. The effective permittivity of the ore to be treated is expected to show variation on both short (< 1 s ) and long (minutes) time scales. By modelling the ore as a series of slices with alternating effective permittivity values, it was shown that permittivity variations on the scale of the expected particle size are attenuated significantly and matching is not required. For variations in permittivity on the length scale of the free-space wavelength, variations in reflected power are at most within ±10% of the mean. This is not considered operationally significant, as extreme permittivity variation over this length scale is unlikely, given the expected distribution of ore particle sizes to be treated. At typical ore transport speeds through the applicator, these variations occur on a time scale an order of magnitude shorter than the response time of typical industrial online matching equipment. This implies that online matching is neither required nor possible for short time scale variation. Long-term variations in dielectric properties can be adequately compensated for by current matching technologies. It is concluded that the transverse E-field applicator is robust to changes in the dielectric properties of crushed ores within the expected range of their variation.

Keywords: microwave processing, ore, dielectric property variability, matching.

Introduction

The extraction of valuable minerals from mined ores proceeds through the steps of liberation and separation, with the liberation step being achieved by size reduction technologies. In general these are inefficient, with less than 1% of the input energy being used to create new surface area1. This clearly provides significant incentive to develop more efficient mineral liberation technologies. Extensive experimental work2-5 and supporting simulations6-9 have shown that microwave treatment of crushed ore can induce microfractures around the grain boundaries of the value minerals with potential benefits in terms of increased liberation and reduction in losses of unrecoverable, over-ground material.

Currently the technology operates at a pilot scale10, treating up to 30 t/h at microwave energy inputs of the order of 1 kWh/t. The transverse electric field (E-field) applicator used for this continuous treatment of ore at high power density (>109 W/m3 absorbing phase) was designed to work optimally with a uniform homogeneous load of specific dielectric properties. The reasons for designing the applicator for a homogeneous load have been reported previously11. In reality, the applicators used in this technology will be required to process inhomogeneous material with variations in particle size, shape, and composition, all of which will affect the dielectric properties of the load, and hence the behaviour of the entire microwave system. In this paper the effect of short- and long-term variability of the dielectric properties of the ore on the operability of the transverse E-field applicator is investigated using computer simulation. Attention has been focused on the effect of load variability on matching and the implications this has for online matching. Online matching is done to ensure that the largest amount of power is delivered to the required device, i.e. the applicator and load. Matching is typically done using electromagnetic (E-H) or stub tuners. These devices normally work by moving pins or plates by mechanical means, and are thus limited in response time. The question of whether the effect of reasonable ore variability is significant enough to require matching is addressed, and the time scale over which this variability occurs is considered in relation to the response time of mechanical matching equipment. For more practical details such as the material feed used, including particle size distribution and mineralogy, as well as the results of testing at various throughputs and energy inputs, the PhD thesis by Kobusheshe10 can be consulted.

The remainder of this paper consists of five sections. In the first section the transverse E-field applicator is briefly discussed. In the following section we examine the matching characteristics of the applicator for homogeneous loads with different dielectric properties. This analysis is useful in answering questions about the effect on matching of longterm sustained changes in ore properties (as might happen if the plant feed were to be sourced in a sustained fashion from a different mining block for an extended period). In the next section we examine the effect on matching of inhomogeneous loads. This analysis is used to examine the likely effect of inherent ore variability over short length (and time) scales. The results of this analysis can be used to set requirements for the response time of online matching equipment. This is considered in the penultimate section. Finally, the conclusions are presented.

Transverse E-field applicator

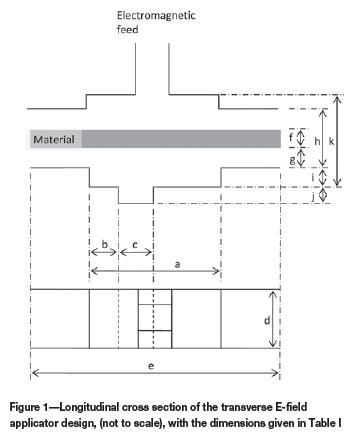

A transverse E-field applicator is used as the example applicator in this work. It consists of an applicator box section in which the desired field is setup using an off-centre compensating step12. The effect of this step is to give a more uniform treatment of the load moving through the applicator. The applicator box section is fed from the top in such a manner that the E-field is transverse to the direction of load movement. The feed enters the applicator box section through tunnel sections designed to attenuate the field strength to acceptable limits. For more information on the design of the applicator Bradshaw et al.11 can be consulted. A schematic diagram of the applicator is shown in Figure 1 with dimensions given in Table I. It is currently used to treat crushed ore, has a capacity of 30 t/h, and is equipped with a 30 kW, 2.45 GHz microwave power supply10. Operation at 915 MHz, as would be used industrially, requires a dimensionally scaled applicator as indicated in Table I.

Variation of homogeneous material properties and matching

Mineral concentrator feeds are frequently sourced from different mining blocks, with potentially differing mineralogies. The effect of this on the operation of a microwave unit can reasonably be approximated as a sustained change in dielectric properties on a time scale of minutes. The effect of this long-term dielectric property variation was investigated by looking at the effect on power absorption of homogeneous loads of different dielectric properties.

Simulations to assess the matching performance of the applicator were done using the finite difference time domain code QuickWave3D by QWED version 7.5, using the automatic meshing option (AMIGO) and a minimum of 12 cells per wavelength. The material properties of the homogeneous load were varied from the design base-case within the typical range of expected values for the effective bulk relative permittivity. Material properties were obtained using standard waveguide measurement techniques on a variety of crushed ores at 2.45 GHz, and for some ores at 915 MHz, as part of an industrial research project10. Variation over frequency was found to be negligibly small for this range. The effective permittivities used in the simulations are given in Table II. The diagram accompanying the table shows that the values are chosen at the expected extremes for the ore type investigated. The base-case value, in this case for a lead-zinc ore, is typical of crushed ores.

The power absorbed by the load was determined after the simulations at the desired frequency had reached steady state. Following this, the fraction of the input power absorbed by the load was determined. This is used as an indication of the ability of the system to deliver power into the load without matching being done and whether matching would be required to ensure efficient use of energy. In actual operation the amount of power absorbed is improved by using external matchers such as E-H tuners or stub tuners.

Results for homogeneous loads

Results from simulation, without external matching, are shown in Table III. From these results it can be concluded that an ore with a higher loss factor (the imaginary part of the relative permittivity) is inherently better matched, as would be expected. We note here that in practical application, the matching of the applicator to the source using an E-H tuner to achieve reflected power levels of less than 10% was found to be possible for a wide variety of stationary crushed ore loads10. The implication is that long-term variability of the ore, as would occur if the treatment unit were required to process ore mined from different parts of the orebody, can have a significant effect on matching, but that this can easily be compensated for with standard matching devices, due to the relatively lengthy time scale over which such variations in properties would be expected.

Matching variability of idealized inhomogeneous loads

In addition to the sustained changes in mineralogy described above, there will be local variations in properties of the ore on the feed belt that will affect the matching performance of the applicator on short time scales, typically less than a second. It is important to determine the ability to couple electromagnetic power into the applicator in this situation. Specifically, we need to ask what kind of matching, if any, is necessary while such an inhomogeneous load moves through the applicator. The question will be answered by determining the difference in the fraction of input power absorbed by an idealized inhomogeneous load, represented by slices of different material, as it moves through the applicator. This analysis will provide an indication of the response time required from the matching equipment.

Simulation set-up

In order to simulate the effect of ore variability on length scales of the order of that of the microwave wavelength, the load was simulated as a series of slices alternating with different effective permittivities. The simulation set-up can be seen in Figure 2. The alternating layers of material constituting the load are represented by the black and gray sections. The material properties used for this purpose are listed in Table IV. As can be seen in the data in the table, the pairs of materials making up the alternating load slices represent contrasting extremes of permittivities. The length of the material slices was varied from ~0.16 λ0 to λ0, where λ0 represents the free-space wavelength. In the 2.45 GHz system these are slices from 20 mm to 120 mm, while in the 915 MHz system these are slices from 55 mm to 330 mm. Hence the simulations encompass feed variation on length scales that are expected to have a significant influence on matching from an electromagnetic point of view.

When considered from the point of view of a typical process, the range of length scales over which properties could be expected to vary so extremely is smaller than used in the simulations. It is reasonable to assume that the most extreme variation in properties of the feed on the belt would result from large, adjacent particles being barren of the microwave-absorbing minerals in the one case, and containing massive metallic mineralization in the adjacent particle. The maximum particle size in the feed to the applicator is limited by the optimal bed thickness, which at 915 MHz is of the order of 100 mm. Thus 100 mm represents the likely upper bound on the length scale of extreme property variation. In the preferred process operation, feed to the applicator will not contain a significant fraction of material below 20 mm, and this can be considered a lower bound. As will be seen in the following results section, property variation on scales below 20 mm at 2.45 GHz (or 55 mm at 915 MHz) results in a constant matching condition as the load travels through the applicator.

Simulations were done with a specific set of material parameters (dielectric property variation and slice size) at various positions. Each position simulated coincided with a specific fraction of the material variation cycle as shown in Figure 3.

Results for inhomogeneous loads

The results of the simulations are shown in Figures 3-8 and in Table V. It is important to note the variation in fractional power absorbed through the cycle of movement of the load, and not just the fractional power absorbed. For example, if the long-term mean fraction power absorbed were too low, this situation could be rectified by use of a suitable matching device in a semi-fixed position. The results of the simulations thus serve rather as an indication of the need to retune the system dynamically as the load moves through the applicator. It should be noted that the matching variation for a given simulation is cyclic, as expected from the cyclic load variation. It is, however, not a symmetric sinusoid due to the non-symmetry of the applicator structure.

Figures 3 and 4 show the variation for the 2.45 GHz applicator. It can be seen that material variations on shorter length scales result in smaller variations in matching, as would be expected from the size relative to the wavelength. Clearly, on-line tuning would not be required for property variations on a length scale of 20 mm at 2.45 GHz. The greatest range of variation can be seen to be about ±10% around the mean value, and this occurs for length scales that are close to the free space wavelength. When comparing Figure 3 and Figure 4 it can be seen that a similar trend is evident for both material variation Set 1 and Set 2. The absolute and relative values change but the behaviour relative to wavelength is similar. This same behaviour in respect of matching variation is also evident when results relative to wavelength obtained from simulation at 915 MHz are taken into consideration (Figures 5 and 6.)

Results for material variation in the 915 MHz applicator on the maximal scale of variation possible in the processing environment are shown in Figures 7 and 8. It can be seen that the variation around the mean is a lot less than for the wavelength-related variation. This is obvious when considering that the more realistic variation is at the shorter end of the wavelength variation.

The time taken for one 'cycle' of material property change has been computed for a belt speed of 1m/s, which corresponds to the typical transport velocities used in practical applications. This data can be seen in the final column of Table V. If online tuning is to be possible it should be done with hardware that responds several orders of magnitude more quickly than this time.

Matching hardware limitations

The objective of applicator design and subsequent tuning is to maximize the amount of power that is absorbed by the load. When matching is used to increase the amount of power absorbed by the load, it is required that this happens on a time scale that is faster than the power variation. It has been noted13 that current autotuning technology for industrial applicators cannot cope with variations on the scale of 1 Hz. This implies that the autotuner cannot cope with variations that happen over time scales of 1 second or shorter.

All the variations in power absorbed that were encountered in simulations were of an order of less than 1 second, as can be seen in Table V. This is due to the practical bed speeds that would be required for industrial use. It is concluded that online matching is currently not possible for industrially-feasible applications.

If the variation in power absorbed is scrutinized it becomes apparent that the maximum variation in power absorbed is 20.1%, from a minimum of 79.1% to a maximum of 99.2% power absorbed. It can be argued that this level of applicator performance is acceptable for successful industrial treatment of mineral ores.

Conclusion and recommendations

The effect of load variability on the matching characteristics of a transverse E-field applicator was investigated in this paper. First, the effect of variability in dielectric properties for a homogeneous load was investigated to simulate the effect of a sustained change in load properties. It was found that the percentage of power absorbed ranged between 50.0% and 95.3%. This level of mismatch can be easily compensated for by external tuners if it occurs on a long-term basis.

The effect of short time scale variability in load properties was also investigated using an idealized inhomogeneous load for applicators operating at 2.45 GHz and 915 MHz. Percentage power absorbed varied between 79.1% and 99.2% for the 2.45 GHz applicator and between 76.3% and 99.6% for the 915 MHz applicator. This variation in power is considered small and should not preclude effective treatment. For a typical belt transport velocity these changes will take place on a time scale of < 0.25 s for the 2.45 GHz applicators and < 0.66 s for the 915 MHz applicator.

Current automatic matching technologies were investigated and it was found that they are not currently suitable for online matching, as they are not able to respond to changes occurring on a time scale of less than 1 s. In industrial operation the particle size distribution of the crushed ore is expected to result in property variation on rather short length scales. As it has been shown that these are inherently well-attenuated by the system, and as online matching equipment currently cannot respond to changes on these time scales, it is concluded that for this application rapid online matching is not required, but will be adequate for long-term variations in ore properties.

References

1. FUERSTENAU, D. W., and ABOUZEID, A-Z. The energy efficiency of ball milling in comminution. International Journal of Mineral Processing, vol. 67, nos. 1-4, 2002. pp. 161-185. [ Links ]

2. KINGMAN, S., JACKSON, K., BRADSHAW, S., ROWSON, N., and GREENWOOD, R. An investigation into the influence of microwave treatment on mineral ore comminution. Powder Technology, vol. 146, no. 3, 2004. pp. 176-184. [ Links ]

3. KINGMAN, S., JACKSON, K., CUMBANE, A., BRADSHAW, S., ROWSON, N., and GREENWOOD, R. Recent developments in microwave-assisted comminution. International Journal of Mineral Processing, vol. 74, nos. 1-4, 2004b. pp. 71-83. [ Links ]

4. SCOTT, G., BRADSHAW, S., and EKSTEEN, J. The effect of microwave pretreatment in the liberation and size distribution of a copper carbonatite ore after milling. International Journal of Mineral Processing, vol. 85, no. 4, 2008. pp. 121-128. [ Links ]

5. SAHYOUN, C., ROWSON, N., KINGMAN, S., GROVES, L., DORFLING, J., and BRADSHAW, S. The influence of microwave pre-treatment on copper flotation plant performance. Transactions of the Southern African Institute of Mining and Metalurgy, vol. 105, no. 1, 2008. pp. 7-17. [ Links ]

6. WHITTLES, D., KINGMAN, S., and REDDISH, D. Application of numerical modelling for prediction of the influence of power density on microwaveassisted breakage. International Journal of Mineral Processing, vol. 68, nos. 1-4, 2003. pp. 71-91. [ Links ]

7. JONES, D. A., KINGMAN, W., WHITTLES, D., and LOWNDES, I. Understanding microwave assisted breakage. Minerals Engineering, vol. 18, no. 7, 2005. pp. 659-669. [ Links ]

8. JONES, D., KINGMAN, S., WHITTLES, D., and LOWNDES, I. The influence of microwave energy delivery method on strength reduction in ore samples. Chemical Engineering and Processing: Process Intensification, vol. 46, no. 4, 2007. pp. 291-299. [ Links ]

9. ALI, A., and BRADSHAW, S. Quantifying damage around grain boundaries in microwave treated ores. Chemical Engineering and Processing: Process Intensification, 2009. pp. 1566-1573. [ Links ]

10. KOBUSHESHE, J. Microwave Enhanced Processing Of Ores. PhD Thesis. The University of Nottingham, June 2010. [ Links ]

11. BRADSHAW, S., LOUW, W., VAN DER MERWE, C., READER, H., KINGMAN, S., CELUCH, M., and KIJEWSKA, W. Techno-economic considerations in the commercial microwave processing of mineral ores. Journal of Microwave Power and Electromagnetic Energy, vol. 40, 2007. pp. 228-240. [ Links ]

12. MEREDITH, R. Engineers' Handbook of Industrial Microwave Heating. The Institution of Electrical Engineers, London, 1998. [ Links ]

13. BILIK, V., and BEZEK, J. Automatic Impedence Matching under high power complex signal conditions. RADIOELEKTRONIKA '09. 19th International Conference, Bratislava, Slovakia, 22-23 Apr 2009, Institute of Electrical and Electronics Engineers, 2009. pp. 141-144. [ Links ]

Paper received Aug. 2010; revised paper received Sep. 2011.

© The Southern African Institute of Mining and Metallurgy, 2011. SA ISSN 0038-223X/3.00 + 0.00.