Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.112 no.1 Johannesburg Jan. 2012

TRANSACTION PAPERS

Improving financial returns from mining through geostatistical simulation and the optimized advance drilling grid at El Tesoro copper mine

J.M. OrtizI; E.J. MagriI; R. LíbanoII

IALGES Laboratory, Advanced Mining Technology Center, University of Chile, Department of Mining Engineering, University of Chile

IIMinera El Tesoro, currently at Minera Esperanza, Chile

SYNOPSIS

Grade control and short-term planning are usually based on the samples obtained from blastholes. These samples may carry a large sampling and sample preparation error. At El Tesoro copper mine in northern Chile, an advance drilling grid is used for short-term planning and grade control. These drill holes are sampled well in advance, and a short-term model that incorporates several variables and sophisticated estimation methods can be prepared for decision making. An additional advantage of the advance drilling samples is that reverse circulation can be used instead of conventional downthe-hole equipment, and a very careful sampling and sample preparation process can be implemented, reducing the total sampling error.

Advance drilling can be performed on a wider grid than blasthole drilling, hence the decision about the grid requires assessing the economic benefit of different sampling grids. Furthermore, this process allows the cost of poor sampling and the effect of different estimation procedures to be quantified.

We demonstrate the optimization of the drilling grid for shortterm planning and grade control at El Tesoro mine by means of the economic evaluation of the performance of different drilling grids, with different drilling techniques (which differ in the sampling error). The methodology is based on creating dense (exhaustive) geostatistical simulations of the grade distribution over a volume defined for a production period in respect of the geological model, and assuming each simulation as the true grade distribution. Then, samples are obtained from the exhaustive simulations at a spacing similar to the advance grid to be evaluated, and a sampling error is added. The short-term estimation procedures used on the mine are applied to determine the destination of each block and the profit obtained. This profit can be compared with the maximum profit (unachievable) and with the profit under different sampling errors and grids.

The results show that the current 8 × 8 m drilling grid is appropriate and by reducing the sampling error, misclassification is also reduced, leading to an increase in profit of about US$ 5 million in 4 years.

Keywords: geostatistics, conditional simulation, misclassification, grade control.

Introduction

Grade control and short-term planning are based on the information provided by samples, usually taken from blastholes, which are used to estimate the grade of selective mining units (blocks). These samples may be subject to large sampling and sample preparation errors1,2, which impact the classification of the blocks. Blocks are sent to different destinations such as the processing plant, low grade stockpile, or waste dump, usually depending on their grade, mineral characteristics, and other geometallurgical variables. If grade control incurs large errors, significant departures from the short-term plan are expected with respect to the medium- and long-term plan.

Blasthole sampling procedures3,4 have several weaknesses. Firstly, it is common to have poor sample recovery in the first part of the blast hole due to fracturing caused by the subdrill of the bench above; secondly, the subdrill length at the bottom of the blasthole is rarely separated from the sample, leading to a delimitation error; thirdly, production is always the first priority in the mine, hence blasthole sampling may be seen as a problem, since it interferes with production. If sampling is done poorly, high levels of errors and/or systematic biases are expected, which can lead to significant losses, reaching millions of dollars per year4,5. One of the main problems about poor sampling is that the losses are invisible to management, since they are not reflected in the financial balances of the company6.

Estimation methods are used to forecast the block grades, to decide their destination. These methods can be purely geometric, or can be based on geostatistical techniques7,8,9. In short-term planning, block grade estimation is done under a tight time framework, since blasthole sampling is done shortly before blasting and loading the material. This leads to poor short-term models. In fact, it is quite common to see cases where the laboratory analyses are not returned in time to create the classification polygons for the shovel to load the material, and grade control ends up being done by visual inspection of the face.

Sampling should be given its right priority in a mining operation, and best practices should be applied rigorously following sampling theory1,10,11. Sophisticated methods to account for the variability in the sample information to optimize grade control practices should also be considered3,12. Since production contingencies often overrule sampling and blasthole sampling does not receive the necessary attention, a valid alternative is to approach the grade control problem from a different perspective.

Grade control based on an advance grid that uses reverse circulation drilling for sampling purposes is an alternative to the conventional approach to grade control. Reverse circulation drilling allows better control of the sample quality, and can be done in advance of blasting, giving enough time to construct a short-term model that includes multiple variables and that utilizes more sophisticated estimation techniques12,13. In addition, the advance grid may be sparser than the blast hole grid, requiring fewer samples to satisfy the requirements of short-term planning.

In this paper we present a methodology to optimize the financial returns from mining, by improving the sample error and finding the advance drilling grid that maximizes the returns. The methodology is presented as practised in the El Tesoro copper mine in Chile, using actual operational and economic parameters.

Methodology

Quantifying the losses due to poor sampling practice is not a simple task. Knowledge about the actual values is required, and usually, we do not have access to them. Geostatistics provides a set of tools to characterize a phenomenon and simulate the spatial distribution of attributes. These simulated models can be used as an analogue of the reality. Certainly, none of the models built will exactly replicate reality, but we can replicate reality's characteristics with several equally probable models.

Geostatistical simulation techniques are available to model the distribution of categorical variables, such as geological units, and of continuous variables, such as grades. Each simulated model can be subject to the same process that will be applied to the actual blocks in the mine. Sampling, grade control, and mine planning can be applied to each simulated scenario, providing one possible response of the deposit to that particular practice. Pooling the results over a set of simulated models gives a good idea of the fluctuations and the expected result10,11,12.

The following methodology is applied to infer the effect of changing the sampling grid or changing the sampling technique:

Infer from available data the sampling and sample preparation errors of reverse circulation and conventional down-the-hole drilling samples. This is done by considering the precision of duplicate data obtained during the exploration and operation phases

Consider the geological model interpreted by the exploration team or generate alternative scenarios by means of a conditional simulation approach of categorical variables

Generate scenarios of the grade distributions in a dense grid, through geostatistical conditional simulation within the geological units specified in the previous point. Each of these scenarios can be viewed as a possible truth

For each scenario:

- Block average to selective mining units size the grades to obtain the block grades distributions. These block grades represent the true grades, which are always unknown in practice, but provide a basis for comparison

- Determine the optimum destination of each block, by considering all economic factors currently used to make that decision, and compute the profit of processing the ore

- Simulate the advance drilling sampling on regular grids of different size by extracting the exact simulated value. The spacing of the drilling grids should be a multiple of the spacing used for the dense simulation

- Add the sampling error to these samples, representing the current error in the conventional drilling of advance holes. These sampling errors can be either positive or negative, as they represent variability around the true value. These sets of data represent the sample information used to construct the short-term plan and perform grade control.

- Compute the estimated block grades following the conventional procedure for short-term planning and determine the destination of each block through the grade control process used in the mine, and compute the profit of processing the blocks estimated as ore. This is done twice in each scenario: the first time, using the samples without error, and the second time, using the samples with added error

- Perform an economic evaluation and compare with the optimum destination of each block, to find the best spacing of the advance drilling grid and the losses due to poor blasting.

Case study: El Tesoro copper mine

Presentation of the data

The case study concerns the Chilean copper mine El Tesoro, located 190 km north-east from the city of Antofagasta in northern Chile, 2 300 m above sea level. El Tesoro mine exploits an exotic copper deposit, and operates at a current rate of 10.5 Mt of processed ore per year, producing 98 000 t of copper in cathodes. The mine operates two open pits, Tesoro and Tesoro Noreste, and the metallurgical process consists of crushing, leaching and solvent extraction and electrowinning (SX-EW).

El Tesoro mineralization occurs in manto-type structures. Geological units are therefore defined based on grade intervals. The relevant variables for the metallurgical performance are total copper grade (CuT) and carbonate grade (CO3). Four geological units are defined for copper, based on grade cutoffs, and five geotechnical units are defined based on the CO3 grade. Geological and geotechnical units are defined as depicted in Table I.

Datasets of composites for CuT and CO3 grades are available from exploration drillholes. These include diamond drillholes (DDH) and reverse circulation (RC) samples. Although the samples volumetric supports are slightly different, we concluded after a statistical analysis that their spatial and statistical distributions are similar, and they are combined into a single dataset for each variable. The composite length is 7.5 m. A volume of interest for the next four to five years of production was defined. Only composites within that volume are considered for the study. In the case of CO3, geotechnical units are separated into 1 (calcareous conglomerate) and the union of all others for modelling purposes. Basic statistics are presented in Table II.

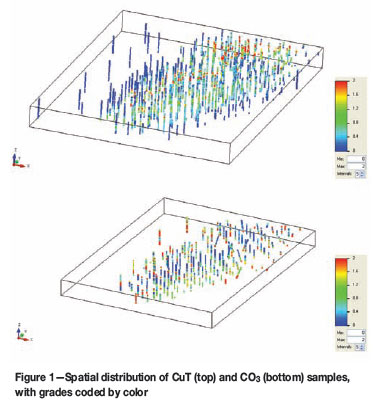

Figure 1 shows the spatial distribution of the CuT and CO3 grades over the study domain.

Production started at El Tesoro in 2001. Short-term planning was based on blast hole sampling using an automatic sampler manufactured by Metal Craft, equipped with dust recovery and a static cone divider. This methodology was far superior to conventional blasthole sampling with radial buckets, tubes, etc. It was replaced in 2002 by advance RC drilling, since it decreased the productivity of the blast hole drilling equipment. RC was used for drilling one or two benches well ahead of production.

Short-term planning models are built including a total of 8 variables that permit the calculation of parameters such as acid consumption, recovery, etc. Due to operational problems with RC drilling in high humidity areas, this equipment was replaced by a conventional down-the-hole (DTH) drilling rig, which is being used to date.

An additional dataset provides duplicate data from advance drilling samples obtained with the DTH drilling rig. The relative sampling error can be inferred from these duplicates (Table III).

Dense simulation

GSLIB9 is used to simulate the dense scenarios using sequential Gaussian simulation. The simulation grid is shown in Table IV.

The deterministic geological interpretation is used to control the distribution of grades. Simulation is performed for the geological units 2, 3 and 4 for CuT. Points within unit 0 are assigned a CuT grade of 0, since these are waste and their grades are far from the cutoff, hence misclassification should not occur for these blocks. In the case of CO3, the modelling was done for unit 1 and for all the other units combined. For each unit, normal score transformation after cell declustering was performed to obtain Gaussian values7,9,13. Variograms are calculated in the directions of anisotropy defined by the orientation of the manto-type structures that contain the mineralization. For inference purposes, data from units 3 and 4 are combined for the calculation of the normal scores CuT variogram.

Variogram models are fitted to the experimental variograms, as presented in Table V. The experimental curves along with the fitted models are presented in Figure 2.

Ten simulated scenarios are built on the dense grid, conditioned by the exploration RC and DDH composites within the domain.

Reference block grade scenarios

The dense simulations are block-averaged to block size to represent selective mining units in the reference scenarios. Block size for grade control is 6.25 × 6.25 × 7.5 m. Each of the models can be considered as the truth, hence the correct destination of each block can be determined and the profit of processing the ore and discarding the waste can be assessed with the true block grades. Averaging the economic profit for each of the reference models provides a maximum value that represents the actual unachievable value of the volume under study. These values can be used to compare the performance of different sampling grids, drilling methodologies, and grade control practices. In our case, we limit our study to the drilling grid and drilling methodology.

Simulating advance drilling grids with sampling error

From the dense models, the exact values simulated in each scenario at spacings of 6 × 6 m, 8 × 8 m, 10 × 10 m, 12 × 12 m, and 14 × 14m are retrieved. These values represent, in each scenario, samples in an advance drilling grid at the specified spacing without error.

A random relative error is added (or subtracted) to each sample value, using a Gaussian distribution with zero mean and a standard deviation determined by the grade and the sampling error for the corresponding variable4,13. For example, for a sample with a CuT grade of 1.2%, a 16% sampling error is added. This means, a random deviate from a Gaussian distribution with mean zero and standard deviation 0.192 (obtained as the product of the relative error of 16% and the grade of 1.2%). For CO3 the relative sampling error added is 20%. These relative errors were obtained from the analysis of duplicate data.

Simulating short-term planning and grade control practice

The short-term plan at El Tesoro is built by ordinary kriging using the information from the advance drilling samples on 6.25 × 6.25 × 7.5 m blocks. Grade control consists of evaluating each block based on the estimated CuT and CO3 grades to decide its destination; the processing plant or waste dump. Dilution is not incorporated in this analysis.

Figure 3 shows all important steps in the methodology. First, a plan view of one realization of the dense simulated model is presented, which is consistent with the geological model used at El Tesoro mine and reproduces the spatial continuity of grades. The same model is presented after block averaging. This represents the true block grade values, which are unknown in practice. Then, the samples on a regular grid of 14 × 14 m are extracted from the dense simulation. These represent advance drilling samples without error. Next to these are the same samples, but with the error added, representing samples from the DTH drilling rig. Finally, two short-term models are shown, the first constructed based on the samples without error (representing RC advance drilling samples), and the second based on the samples with error (representing DTH advance drilling samples).

Profit for each block is computed by accounting for the income from processing it and the costs involved, which include acid consumption, expected recovery, operational costs at the mine and the processing plant, and costs involved in the sales.

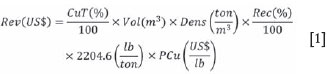

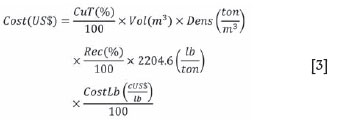

The revenue (Rev) is calculated as a function of CuT:

where:

volume of a block, Vol = 6.25 × 6.25 × 7.5 m3

density of the ore, Dens = 2.27 t/m3

copper price, PCu (US$/lb)

Metallurgical recovery Rec, is a function of CuT and CO3 grade, provided by the metallurgical team, as a result of a nonlinear regression:

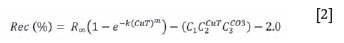

where R∞, k,m,C1, C2, and C3 are particular constants obtained from historical data (Table VI).

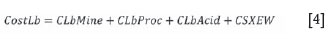

Costs of processing a block are calculated as:

where the cost per pound (in CUS$/lb) is a combination of the following costs:

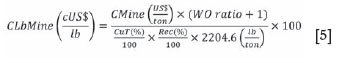

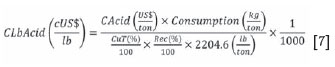

These costs are calculated as:

where WO ratio is the waste-to-ore ratio of the mine, CMine is the operational cost of extracting 1 ton of material from the pit, CProc is the cost of processing 1 ton of ore, which includes primary and secondary crushing, agglomeration, stocking, leaching, and exhausted heap disposal. CAcid is the cost of 1 ton of sulphuric acid. Finally, CSXEW represents the solvent extraction, electrowinning, management, general expenses, royalty, and sales costs (Table VI). Acid consumption is calculated as a function of CuT and CO3 grades (Table VII).

If the profit is positive, the block is assigned to the processing line; otherwise, it is sent to the waste dump. It should be emphasized that this decision is taken based on the estimated block grade, and that this value depends on the samples and the estimation method. Plant capacity constraints are not incorporated in the decision making process.

Results

The construction of simulated models allows processing each realization as if it were the truth. The same processes and decisions that are made over actual grades can be replicated on each of the simulated models. Sampling the deposit with an advance drilling grid, adding sampling and sample preparation error to the actual grade, constructing a short term model for grade control, and then assessing the profit of mining out the domain under study can be replicated for each realization. The economic performance of drilling and sampling practices is assessed for every realization. The fluctuation in this response variable gives insight regarding the uncertainty, while the average profit obtained over all realizations indicates the expected situation. The effect of changing the drilling grid, or of improving sampling by returning to a RC drilling for the advanced sampling grid, can be evaluated.

The profit from exploiting the volume under study, with each sampling grid spacing and with the sampling and sample preparation error attached to DTH drilling, is obtained. This profit considers the cost of drilling and chemical analysis, which will depend on the grid used for the advance drilling campaign.

The profits obtained with different drilling grids are computed under two scenarios: assuming that samples do not have an additional sampling error, which corresponds to RC drilling; and considering a sampling error (16% relative error for CuT and 20% for CO3), which corresponds to the current DTH drilling. Results are presented in Table VIII.

The first scenario shows the effect of information quantity, while the second scenario adds the effect of poor data quality. For comparison purposes, the maximum achievable profit is computed from the dense simulations, which is unattainable in practice, as this would require exhaustive knowledge of the block grades. Currently, drilling for the advance grid is carried out by a contractor. Due to the presence of moisture in the holes, the contractor moved from RC drilling to DTH, which carries large sampling errors. The current grid spacing is 8 × 8 m. From the study, it can be seen that by changing drilling practices and reducing the sampling error, the profit could increase from US$ 669.32 million to US$ 674.50 million over the production period considered (4 to 5 years). This signifies approximately US$ 5.2 million. Furthermore, it is apparent that the current 8 × 8 m sampling grid is appropriate to achieve maximum profit.

Conclusions

Blasthole sampling has always been problematic in mining operations. Most attempts to improve the quality of these samples are hindered by the priority that production has over most other activities in a mine. Sampling devices are adapted to try to interfere as little as possible with the operation of the drilling rigs. This results in ill-conceived methods for sampling, poor quality of the sampling results, and economic losses that can reach millions of dollars per annum.

Advance drilling for short-term planning and grade control is a valid alternative to blasthole sampling. Advance drilling can be better controlled to obtain good quality samples, since it does not interfere with production, it can be done well in advance of blasting, and short-term plans can be constructed with sophisticated methods, such as simulation, and including many relevant variables. Furthermore, the advance grid is usually sparser than the blasthole grid, offsetting the cost of drilling with fewer sampling and sample preparation costs.

We present a case study at El Tesoro mine, an operation extracting copper ore from an exotic ore deposit, in northern Chile. A geostatistical simulation approach is implemented to assess the optimum drilling grid for the advance sampling, and the cost of poor sampling, as currently the contractor drills with a down-the-hole rig, rather than a reverse circulation drilling rig.

The methodology consists of simulating several distributions of total copper and carbonate grades, consistent with the geological model, on a dense grid. Each of these models represents the true grades and can be used as one possible reference for comparison. These dense models are then sampled at the spacing of the advance drilling grid being assessed and sampling errors are added (or subtracted) to the grades obtained from the 'truth'. These samples with errors are then used to construct the short-term plan and decide upon the destination of each block, using the grade control practices of the mine. Since the actual block values are known in the dense simulated model representing the true destination and benefit reported by each block, comparisons can be undertaken and decisions made.

The case study shows that for El Tesoro, the current advance drilling grid of 8 by 8 m is appropriate, but a reduction in the sampling error would have an impact in benefit of over US$ 5 million for the production volume that was considered, which represents a 4 to 5 year production period.

Similar applications of geostatistical simulation are easy to imagine, such as improving grade control, assessing dilution, and assessing the effect of the size of the selective mining units.

Acknowledgements

The authors would like to recognize the effort and vision of the management of the El Tesoro Copper mine for its concern about quality sampling and best short-term planning practices. Permission to publish this work is gratefully acknowledged. We also are thankful to the Department of Mining Engineering at University of Chile.

References

1. PITARD, F.F. Pierre Gy's Sampling Theory and Sampling Practice -Heterogeneity, Sampling Correctness and Statistical Process Control. 2nd edn. CRC Press Boca Raton, Florida, 1993. [ Links ]

2. ASSIBEY-BONSU, W. Summary of present knowledge on the representative sampling of ores in the mining industry. Journal of the South African Institute of Mining and Metallurgy, vol. 96, no. 6, 1996, pp. 289-293. [ Links ]

3. DEUTSCH, C.V., MAGRI, E., and NORRENA, K. Optimal grade control using geostatistics and economics: methodology and examples. SME Annual Meeting & Exhibition, Denver, Colorado, 1999. [ Links ]

4. MAGRI, E. and ORTIZ, J. Estimation of economic losses due to poor blast hole sampling in open pits. Geostatistics 2000, Proceedings of the 6th International Geostatistics Congress, Cape Town, 10-14 April 2000, Kleingeld, W.J. and Krige, D.G. (eds.). vol. 2, 2000. pp. 732-741. [ Links ]

5. ROLLEY, P. Geologic uncertainty in the development of an open pit mine: A risk analysis study M.Sc. Thesis, University of Queensland, 2000. 164 pp. [ Links ]

6. MAGRI, E. Some experience in heterogeneity tests and mine sampling. Proceedings of the Third World Conference on Sampling and Blending, Porto Alegre, Brazil, 23-25 October 2007. J.F. Costa and J.C. Koppe (eds.). pp. 329-348. [ Links ]

7. GOOVAERTS, P. Geostatistics for Natural Resources Evaluation. Oxford University Press, 1997. [ Links ]

8. ISAAKS E. H. and SRIVASTAVA, R. M. An Introduction to Applied Geostatistics. Oxford University Press, 1989. [ Links ]

9. DEUTSCH, C.V. Journel A.G. GSLIB: Geostatistical Software Library and User's Guide. 2nd edn., Oxford University Press, New York, 1998. [ Links ]

10. FRANCOIS-BONGARCON, D.M. The practice of sampling of broken ores. CIM Bulletin, vol. 86, no. 970, 1983. pp. 75-81. [ Links ]

11. PITARD, F.F. Pierre Gy's theory of sampling and C. O. Ingamells' Poission process approach - pathways to representative sampling and appropriate industrial standards. Doctoral thesis, Aalborg University, Campus Esbjerg, Denmark, 2009. [ Links ]

12. GLACKEN, I.M. Change of support and use of economic parameters for block selection. Geostatistics Wollongong '96. Vol. 2, Kluwer Academic Publishers, 1997. [ Links ]

13. JOURNEL, A.G. and KYRIAKIDIS, P.C. Evaluation of mineral reserves-a simulation approach. Oxford University Press, 2004. 216 pp. [ Links ]

Paper received Jan. 2011; revised paper received Sep. 2011.

© The Southern African Institute of Mining and Metallurgy, 2011. SA ISSN 0038-223X/3.00 + 0.00.