Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.111 no.11 Johannesburg nov. 2011

JOURNAL PAPER

Fluidized bed roasting of micro-pelletized zinc concentrate: part II-particle entrainment and residence time

S. Heukelman; D. Groot

Department of Materials Science and Metallurgical Engineering, University of Pretoria, Pretoria, South Africa

SYNOPSIS

Zincor uses O2 enrichment (up to 26% O2 in the fluidizing air) to increase the processing rate of zinc concentrates in the fluidized bed roasters. The aim of this study is to determine whether O2 enrichment can be reduced by introducing micro-pelletized concentrate into the feed blend, while maintaining current roaster feed rates and calcine quality. It was found that, with a load of 20% micro-pellets introduced into the feed blend, that O2 enrichment could be reduced by 60%. It was determined that entrained particles spend on average between 0.46 hour and 2.44 hour in the roaster, compared to particles remaining between 3.93 hour and 4.00 hour in the bed overflow. This compares well with a radioactive tracer test performed by Spira. The required reaction time for micro-pellets was found to be less than the residence time inside a Zincor roaster. The result achieved indicated that the average particle residence time inside the roaster was increased successfully in order to compensate for the longer reaction time required to roast micro-pellets at lower levels of O2 in the fluidizing air.

Keywords: fluidized bed roaster, zinc concentrate, ZnO and ZnFe2O4, O2 enrichment, conversion, entrainment, average particle residence time, Geldart's correlation and micro-pelletization.

Introduction

Micro-pelletization of Zincor concentrates

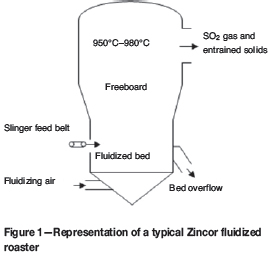

Zincor uses the conventional roast-leachelectrowinning process to produce zinc metal. The roasting process of ZnS concentrate makes use of four Lurgi fluidized bed roasters to produce calcine (which contains ZnO and ZnFe2O4 as zinc products) and SO2 gas. The roasting plant consists of two small roasters and two big roasters, with cross-sectional areas of 18 m2 and 35 m2 respectively. A typical Zincor roaster is shown schematically in Figure 1.

In an attempt to increase production, O2 enrichment was first tested and then introduced into the fluidizing air. The ability of O2-enriched air to increase the rate of the ZnS oxidation reaction allowed higher feed rates to the roasters, without increasing the flow rate of fluidizing air. This was very successful and O2 enrichment up to 26% (21% O2 in air and 5% O2 from a 99.5% O2 source) was implemented on all four roasters1.

Entrained solids are associated with gas leaving the roaster and are also called the carryover2,3. Should the fluidization velocity be increased above the terminal velocity of a particle, it will be entrained. Micro-pelletization of fine concentrates has previously been implemented to decrease entrainment in fluidized beds4-6.

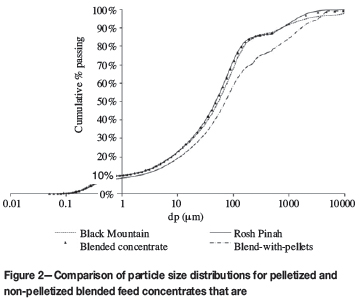

Heukelman and Groot7 (Part I of this paper) showed that micro-pelletizing a blend of concentrate reduced the content of particles passing 500 μm from 87% to 10% before roasting. Figure 2 shows the particle size distributions for a blend of feed concentrate with and without micro-pellets added.

The non-pelletized concentrate contained 52.7% -45 μm particles, compared to approximately 26% for the micropelletized concentrate.

Introducing micro-pellets into the Zincor roasters requires that the residence time of the added micro-pellets must be high enough, considering that larger particles require a longer time to convert7. Particle size has a significant influence on particle residence times and the ability to produce calcine of suitable quality1,8. This indicates that it will be important to use the smallest micro-pelletized concentrate size possible to reduce entrainment and increase particle retention time. At the same time, a small particle size allows faster reaction. This will ensure that quality calcine is produced, while entrainment rates are lowered sufficiently for O2 enrichment to be reduced.

If the ability to manipulate the particle size distribution fed to the roasters is incorporated into the process, it will undoubtedly be a significant advance towards improving control over the fluidization process.

The role of entrainment

Entrainment or the net flux of solids, Gs, is a result of solids leaving the fluidized bed together with the gas stream.9 Elutriation is the separation or removal of fines from a mixture of particles in the fluidized bed.

Elutriation will influence particle residence time, which in turn will influence full conversion of ZnS in the roaster.9 The introduction of O2 enrichment in the fluidizing air made it possible to increase roaster throughput because of an increase in the rate of the oxidation7 of ZnS. To be able to optimize the introduction of micro-pellets, the average residence time and entrainment of particles must be determined to ensure complete conversion while maintaining current production levels.

Both productivity and efficiency are affected by the decrease in particle size. The design entrainment:overflow ratio for the Zincor roasters is 70:30% as one of the parameters to ensure good fluidization. Roasters 3 and 4 also operate at higher fluidizing air rates of between 500 and 514 Nm3/m2/h consistently, but prior to 2000 they operated at the design values of between 442 and 463 Nm3/m2/h. The decrease in particle size and the higher fluidizing air rates meant that entrainment increased substantially. This increase in entrained solids is directly transferred to the SO2 gas cleaning equipment, and leads to additional manual cleaning.

Accurate sampling of the entrainment stream from the roasters cannot be performed because of the roaster overflow and entrainment streams are fed directly to the waste heat boiler. For this reason, entrainment in the roasters is calculated.

Attrition and agglomeration of particles also influence entrainment, but were not included in the calculation. Instead, the calculation method for entrainment used in this study was based on the particle size distribution of the concentrate alone. The influence of attrition and agglomeration was accounted for during the production of the micropellets7.

Many investigators have proposed correlations for the calculation of entrainment values; however, there is no correlation that is accepted as being completely accurate2,10-12. To determine the entrainment in the Zincor roasters Geldart's correlation was used as it is often used in practice2,11 and because conditions in the Zincor roasters closely resemble the experimental conditions under which the correlation was determined. The particle size (60 to 300 μm) and gas velocity (0.6 to 3 m/s) were the most important factors considered in making the choice2.

The gas leaving the roaster has a saturation carrying capacity that represents the largest flux of solids that can be carried out of the vessel through entrainment2. Thus, the saturation carrying capacity determines the maximum rate at which entrainment can occur. The extent of entrainment of any specific sized particles is given by

Any particle whose terminal velocity is smaller than the superficial gas velocity would be entrained, but entrainment is limited by the gas saturation carrying capacity. A particle's terminal velocity can be estimated from the principles of fluid mechanics:

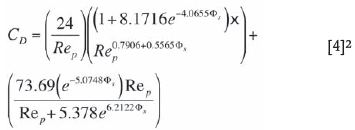

An experimentally determined correlation for the drag coefficient is given by

The particle Reynolds number is given by

The total entrainment of all particles up to size n that are elutriable can then be determined and is given by

If ∑in=1 xi = 1 the whole bed will be entrained.

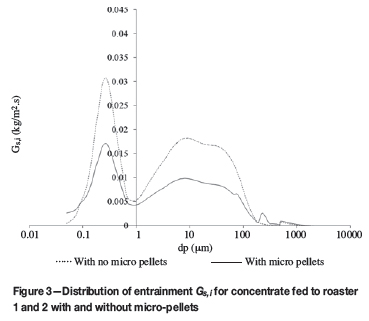

The distributions for Gs,i calculated in Equation [6] are shown for Zincor's roasters in Figure 3 and 4.

The entrainment distributions for size dp,i for roasters 1 and 2 are different to those for roasters 3 and 4. The reason for this is the differences in operating conditions, roaster size, and fluidizing air rates. Zincor currently operates roasters 1 and 2 at a fluidizing air rate of 400 Nm3/m2/h and roasters 3 and 4 at 514 Nm3/m2/hr. These air rates translate to fluidizing air velocities of 0.606 m/s and 0.742 m/s respectively. Total entrainment at these velocities for roasters 1 and 2 was calculated to be 87.3% and for roaster 3 and 4 at 91.5%. The slight difference in entrainment between roasters 1 and 2 versus roasters 3 and 4 is mainly due to the amount of fluidizing air per square meter of roaster bed area.

According to Equation [1] the elutriation constant κ* is proportional to the fluidizing air velocity u0, therefore roasters 1 and 2 will yield lower entrainment values. The largest particle size that could be entrained in roasters 1 and 2 was calculated to be 409 μm; and in roaster 3 and 4, 500 μm.

Average particle residence time in fluidized bed roasters

Manipulating average particle residence time by improving entrainment levels and controlling particle size during micropelletization is the goal of this study, in order to reduce O2 enrichment while maintaining current production levels.

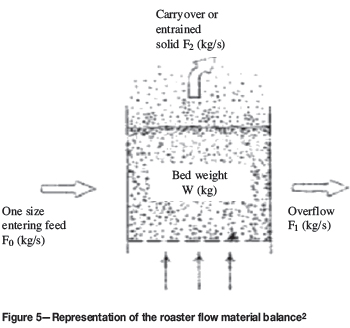

A mass balance over a fluidized bed roaster as shown in Figure 5.

For complete mixing of solids, backmix flow of solids in the roaster bed holds2, which means that the size distribution in the overflow is the same as that of the bed.

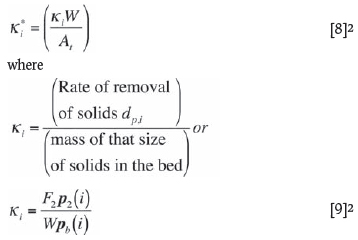

Kunii and Levenspiel2 provide two definitions for the elutriation constant, κi* and κi, which are functions of particle size. By determining κi* from Geldart's correlation9 (Equation [1]), one can calculate κi. κi is used to determine the average particle residence,  (i). κi* and κi are related as follows:

(i). κi* and κi are related as follows:

where

The average particle residence time,  (i) can be calculated as follows (its derivation is set out in Kunii and Levenspiel2)

(i) can be calculated as follows (its derivation is set out in Kunii and Levenspiel2)

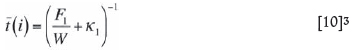

The average particle residence time distributions of the blend, calculated using Equation [10] for the Zincor roasters, are shown in Figure 6.

The average particle residence time shown in Figure 6 is a theoretical calculation based on the empirically determined κi *. Spira14 performed a radioactive tracer test on a 6.4 m CEZ roaster and measured the average particle residence time. For the entrainment stream it was found to be 1.1 hour for the cyclone product and 1.9 hour for the coarser boiler product. For the bed overflow material it was 5.3 hour.

The bed diameter (6.7 vs. 6.4 m), fluidizing air rate (514 vs. 528 Nm3/m2/hour) and equivalent feed rate (7.3 vs. 7.5 t/d.m2) of Zincor roasters 3 and 4 are similar to the CEZ roaster. The largest particle size entrained on roasters 3 and 4 (500 μm) was calculated to have an average residence time of 2.5 hour, while that for the bed overflow was calculated as 4 hour. The calculated times for entrainable particles are somewhat higher and for the bed overflow lower than the values measured by Spira14.

Figure 6 shows the average particle residence times for all particles inside the Zincor roasters i.e. non-pelletized as well as micro-pelletized particles. The average particle residence time of micro-pellets is higher than for the non-pelletized particles. Figure 6 shows that the average particle residence time increases almost logarithmically with increasing particle size and then reaches a plateau around 1000 μm. Particles smaller than 100 μm spend the shortest time inside the roaster and on average similar lengths of time. Particles bigger than 500 μm spend on average more than 2.5 hour inside the roaster, which is more than the time required to fully oxidize these particles.

Natesan and Philbrook9 showed that complete conversion of 1 mm particles in a 4-inch bed in air requires approximately 30 minutes. Converting a 1.73 mm particle from ZnS to ZnO in air requires approximately 1 to 1.5 hour according to test work performed by Sanchuan6.

The average residence time for a 1 mm particle calculated in this study is 3.5 hour. This is long enough to ensure that a reduction in O2 enrichment will allow full conversion. That this is the case was shown previously7 on the laboratory scale, and will also be shown on semi-industrial scale in a subsequent section.

Experimental procedure

Micro-spellets were produced with an 8t/h pilot-scale pelletizer7. The micro-pellets were roasted in the industrialscale roasters at Zincor over a period of 14 days.

This part of the test work was performed on roasters 3 and 4, both having the same operational settings, as shown in Table I. No additional moisture was added to the roaster 3 feed and the moisture in the feed to roaster 4 was controlled at 10%. Thus roaster 4 served as control during the test on roaster 3.

The Zincor roasters at present operate with entrainment values in excess of 90%. The design entrainment ratio is 70%, and this determined the ratio of micro-pellets that had to be introduced. Ideally, 48% of the non-pelletized concentrate must be micro-pelletized to restore the total entrainment from 90% to the design entrainment ratio of 70%. This figure includes particle attrition and degradation during roasting. Although the pelletizer was fed at its maximum feed rate of 8 t/h, this represented only 20% of the concentrate feed rate. However, this feed containing 20% micro-pellets was still used to show whether micro-pelletization would influence particle residence time to such an extent that O2 enrichment could be reduced. Thus 20% of roaster 3 concentrate was micro-pelletized and 100% unpelletized concentrate was fed to roaster 4.

The O2 in the fluidizing air to roaster 3 was reduced from 25.6% to 22.8% from the first day micro-pellets were introduced into the roaster 3 concentrate storage bin. This 60% reduction of O2 in the fluidizing air was set as the goal for the study. Although micro-pellets were introduced to the feed bin from the first day, they were fed to the roaster only 24 hours later. This was the time delay between the concentrate being fed to the bin and to the roaster.

The calcine quality indicator used at Zincor15 is that Fe2+ < 1.2% and represents a sulfide conversion of 98.8%. This indicator was also used to show whether the introduction of micro-pelletization was successful.

Results and discussion

Semi-industrial scale micro-pellet roasting

The goal of the test work was to feed micro-pelletized concentrate for a continuous period of 14 days. A failure on the plant during days 5 and 6 resulted in the roasters not receiving any concentrate feed, and on day 15 the feeding system to the pelletizer failed. This resulted in micro-pellets being fed for 3 days from days 2 to 4 and a further 8 days from days 7 to 14 (see Figure 7).

Several operational parameters can be adjusted to improve the calcine quality to below 1.2% Fe2+. The most widely used adjusts the % O2 enrichment in the fluidizing air to a maximum value of 26% O2. If this limit is reached, the feed to the roaster has to be reduced. The concentrate feed moisture must also be controlled between 10% to 11% as it aids agglomeration1.

The trends for both roasters were similar for the duration of the test period. This is expected as both roasters always receive the same concentrate feed blend except for the micropellets. Initially the O2 in the fluidizing air in roasters 3 and 4 was 25.6% and 26% respectively. The remaining control variables on the roasters were kept the same for the period of the test work of 14 days, except for introducing micro-pellets and changing the O2 enrichment in roaster 3. Both roasters 3 and 4 operated above the quality limit on the first day of the test work, at 1.67% and 1.64% respectively. From day 2 to day 4 the quality in both roasters improved to the same extent and showed that the introduction of micro-pellets to roaster 3 allowed the calcine quality to be maintained at the lower O2 enrichment level.

Calcine quality was poor during restarting on day 7, as is normal until roasting conditions stabilize with time. This normally lasts between 12 hours and 24 hours after which steady state is reached. The decreased O2 enrichment of 22.8% O2 in the fluidizing air from day 2 was maintained and the calcine quality from both roasters improved, with roaster 3 improving more rapidly. The introduction of micropellets may well expedite the achievement of steady state, a condition favoured by higher average particle residence time.

At this point, the only difference between the two roasters was the O2 enrichment setting and micro-pellets in the roaster 3 feed. From days 12 to 13 calcine quality stabilized at 1.5% Fe2+ for roaster 4, while roaster 3 improved further to 1.1% and 0.83%. From day 14, the quality dropped to 2% and 3.6% Fe2+ on roasters 3 and 4 respectively. Owing to the failure of the feeding system to the pelletizer, no more micro-pellets could be introduced into roaster 3. Both roasters' calcine quality started improving again, but roaster 4 improved at a higher rate than roaster 3. Steady state without micro-pellets being fed to roaster 3 was being established, but at the lower level of O2 enrichment. This result confirmed that the introduction of micro-pelletized zinc concentrate was responsible for maintaining the calcine quality.

The results achieved over the 11 days of micro-pellet introduction showed that it successfully allows a 60% reduction in the O2 enrichment. The introduction of micropellets resulted in a higher average particle residence time, and entrainment was reduced successfully.

Conclusion

Entrainment and particle residence time

O2 enrichment currently used at Zincor is very successful and will always be an option to maintain high production levels and adequate quality of the calcine. However, the zinc industry is competitive, and finding innovative ways to reduce operational costs is the key in being competitive in this market. O2 enrichment accounts for a substantial portion of the operational cost of the roasting and acid plant, while micro-pelletization costs a small fraction of this. Micropelletization increases the average particle residence time and reduces entrainment of particles. It has been shown that this enables a substantial reduction in O2 enrichment levels and can add significant value to the Zincor process.

The entrainment in roasters 1 and 2 (87.3%) as well as roasters 3 and 4 (91.5%) was calculated with Geldart's correlation. It was determined that at least 48% of the concentrate fed to the roasters needs to be micro-pelletized to restore the overflow:entrainment ratio to 30%:70%. The entrainment particle size distribution was determined and it was shown that the introduction of micro-pellets reduces these levels.

The elutriation constant (κi) was used to calculate the particle residence times in the Zincor roasters. The largest particle entrained (500 μm) on roasters 3 and 4 was calculated to have a residence time of 2.5 hours and the bed overflow particles as high as 4 hours.

Semi-industrial scale micro-pellet roasting

Roasting of concentrate containing 20% micro-pelletized concentrate was introduced in roaster 3 while O2 in the fluidizing air was reduced by 60% from 25.6% to 22.8%. Entrainment on roaster 3 for the pelletized feed mix was calculated by Geldart's correlation to be 82%. Non-pelletized concentrate was roasted in control roaster 4 and O2 enrichment was kept at 26% O2 in the fluidizing air.

The introduction of the micro-pellets had the intended effect, and the calcine quality of Fe2+ < 1.2% was maintained for the period that micro-pelletized zic concentrate was fed to roaster 3. The quality of the product reached 0.83% Fe2+, indicating that O2 enrichment could be reduced by more than 60%.

The result achieved in roaster 3 indicated that the average particle residence time inside the roaster was increased sufficiently to compensate for the longer reaction time required to roast larger particles at lower levels of O2 in the fluidizing air. From the results achieved in this test work, it can be concluded that micro-pelletized Zn concentrate can be used to reduce O2 enrichment in the fluidizing air, whilst maintaining current roaster feed rates.

Acknowledgements

I (SH) would like to express my gratitude to Exxaro Resources Limited for allowing me to undertake this study. The paper is published with the permission of Exxaro Resources Limited.

Notation

| At | Roaster bed area (m2) At = 18 m2 for roasters 1 and 2, 35 m2 for roasters 3 and 4 | |

| CD | Drag coefficient (dimensionless) | |

| dp,i | Particle diameter (m) | |

| F0 | Feed rate to roaster (kg/s) | |

| F1 | Roaster overflow (kg/s) | |

| F2 | Roaster entrainment (kg/s) | |

| g | Acceleration due to gravity (9.81 m2/s) | |

| Gs | Roaster total entrainment (kg/m2.s) | |

| Gs,i | Roaster entrainment from a bed of pure i (kg/m2.s) | |

| κi | Alternative elutriation constant for i (s-1) | |

| κi* | Elutriation constant for i (kg/m2.s) | |

| Rep | Particle Reynolds number (dimensionless) | |

| Particle average residence time (s) | |

| u0 | Superficial gas velocity when the roaster is empty (m/s) | |

| ut | Particle terminal velocity (m/s) | |

| W | Mass of roaster bed (kg) | |

| xi | Mass fraction of i (dimensionless) | |

| Φs | Fraction sphericity of the particle (0.75, dimensionless)16 | |

| μ | Viscosity of the gas (kg/m.s) | |

| ρf | Gas density (0.26 kg/m3) | |

| ρs | Solid density (4000 kg/m3)16 |

References

1. MACLAGAN, C., CLOETE, M., MEYER, E.H.O., and NEWALL, A. Oxygen enrichment of fluo-solids roasting at Zincor. Proceedings of Lead-Zinc. 2000. Dutrizac, J.E., Gonzales, J.A., Henke, D.M., James, S.E., and Siegemund, A.H-J. (eds). Warrendale, PA, The Minerals, Metals and Materials Society, 2000. 417-426. [ Links ]

2. KUNII, D. and LEVENSPIEL, O. Fluidization Engineering, 2nd edition. Butterworth-Heinemann, Boston, 1991. [ Links ]

3. LEVA, M. Fluidization, 1st edition. McGraw-Hill, New York, 1959. [ Links ]

4. BROWN, P., BOX, T., BROWNLEE, K., and GOLDSWORTHY, T. Pilot roasting of zinc concentrates. Lead & Zinc '95. Proceedings of the International Symposium on the Extraction and Applications of Zinc and Lead. Azakmi, T., Masuko, N., Dutrizac, J.E., and Ozberk, E. (eds). pp. 239-249. [ Links ]

5. DENOISEUX, R., WINAND, R., WILLEKENS, H., and VOS, L. Metallurgy Hoboken-Overpelt process for roasting zinc concentrates in a fluid bed. Proceedings of a World Symposium on Metallurgy and Environmental Control. Cigan, J.M., St. Joe Minerals Corporation, Monaca, Pennsylvania, Mackey, T.S., Key Metals and Minerals Engineering Corporation, Texas City, Texas, O'Keefe, T.J., and University of Missouri-Rolla, Rolla, Missouri. (eds.). Metallurgical Society of AIME, February 24-28, Las Vegas, Nevada, 1980. pp. 69-84. [ Links ]

6. SANCHUAN, T., CHAO, B., and JIANE, S. Oxidation kinetics of marmatite and fluidization roasting of concentrate pellets. Proceedings of International Symposium on Extractive Metallurgy of Zinc, Tokyo, Japan, 14-16 October 1985. Tozawa, K. (ed.) Tokyo, Mining and Metallurgical Institute of Japan, 1985. pp. 157-169. [ Links ]

7. HEUKELMAN, S. and GROOT, D. Fluidized bed roasting of micro-pelletized zinc concentrate. Part I. Pellet strength and roasting kinetics. Journal of The Southern African Institute of Mining and Metallurgy , vol. no. , 2011. pp. 759-766. [ Links ]

8. NATESAN, K. and PHILBROOK, W.O. Oxidation kinetic studies of zinc sulfide pellets. Transactions of the Metallurgical Society of AIME, vol. 245, October 1969. pp. 2243-2250. [ Links ]

9. NATESAN, K. and PHILBROOK, W.O. Oxidation kinetic studies of zinc sulfide in a fluidized bed reactor. Metallurgical Transactions, May 1970. pp. 1353-1360. [ Links ]

10. CHEN, G-Q., SUN, G-L., and CHEN, G-T. Freeboard phenomena in a turbulent fluidized bed. Fluididization V. Proceedings Of The Fifth Engineering Foundation Conference On Fluidization. Ostergaard, K. and Sorensen, A. (eds.). Engineering Foundation, New York, 1986, pp. 305-312. [ Links ]

11. GELDART, D. and POPE, D.J. Interaction of fine and coarse particles in the freeboard of a fluidized bed. Powder Technology, vol. 34, no. 1, 1983. pp. 95-97. [ Links ]

12. PELL, M. Handbook of Powder Technology, volume 8. Gas Fluidization. 1st edition. Elsevier Science Publishing Company, Amsterdam, 1990. [ Links ]

13. PERRY, R.H. and GREEN, D.W. Perry's Chemical Engineers Handbook, 7th edition. New York, McGraw-Hill, 1998. [ Links ]

14. SPIRA, P. A radioactive tracer test in No.1 roaster at Canadian Electrolytic. Noranda Research Centre, Internal report No.187, Montreal, February 1970. [ Links ]

15. ZINCOR LIMITED. Zincor Internal Report, 1992. [ Links ] ♦

Paper received Jun. 2009; revised paper received Jul. 2011.

© The Southern African Institute of Mining and Metallurgy, 2011. SA ISSN 0038-223X/3.00 + 0.00.