Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

Journal of the Southern African Institute of Mining and Metallurgy

versión On-line ISSN 2411-9717

versión impresa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.111 no.11 Johannesburg nov. 2011

JOURNAL PAPER

The evaluation of whole-body vibration in a South African opencast mine

S.A. Aye; P.S. Heyns

Dynamic Systems Group, Department of Mechanical and Aeronautical Engineering, University of Pretoria

SYNOPSIS

Vibration levels on a variety of equipment in a South African opencast mine were measured in this study. The well-established ISO 2631-1 (1997) standard methodology was used for the computation of weighted root mean square (WRMS) and vibration dose value (VDV). This method was used to evaluate the wholebody vibration (WBV) on a wide range of equipment in the opencast mine using the two main parameters, namely the daily exposure A(8) which is based on the WRMS concept and the VDV which measures shocks. The results obtained show that while the majority of the equipment rendered exposure levels that are below the exposure limit value (ELV), exposure levels on about half of the equipment do exceed the exposure action levels. The study also highlights the importance of shock in the observed responses.

Keywords: whole-body vibration, opencast mine, LHDs, excavators, other equipment.

Introduction

Heavy equipment and vehicles used in mining activities may expose operators to significant levels of shock and vibration over extended periods. These vibration exposures could be detrimental and lead to discomfort, interference with activities, and impaired health1. These multifaceted and varied effects on the human body are usually dealt with by considering human vibration as either a whole-body vibration (WBV) problem, which occurs when the body is supported on a surface that is vibrating, or a hand-arm vibration (HAV) problem, which occurs when the hand is in contact with a vibrating surface such as hand-held equipment2. This work deals with WBV.

Numerous epidemiological studies have been conducted all over the world, documenting the detrimental effects of high levels of vibration exposure on human beings. Occupational health and safety issues have been investigated in several countries including British Columbia3, Croatia4, Finland5 and Spain6 amongst others. In South Africa Van Niekerk et al.2,7 reported on vibration levels on some typical equipment in South African mines8.

Different international standards have been developed that regulate the way in which human vibration should be measured and reported, as well as provide indications of the health risk involved. In this regard ISO 2631 (1997)9 is well known. More recently European Parliament legislation10 stipulated minimum standards for the health and safety of workers exposed to WBV. Unlike Europe, South Africa does not have legislation that governs maximum acceptable vibration levels. However, it might be expected that the European Union (EU) initiative may gradually start to influence the situation in South Africa11.

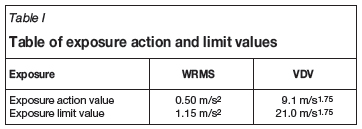

The EU legislation specifies daily vibration exposure levels (exposure action value (EAV) and exposure limit value (ELV)) in terms of weighted root mean square (WRMS) acceleration and vibration dose value (VDV) over an 8 hour period as shown in Table I. In addition, it requires employers to reduce worker vibration exposure levels wherever it is practically possible. Where an operator is likely to be exposed to vibration, an assessment of the likely daily vibration exposure is to be made. If the exposure level is above the EAV, a range of actions must be taken to reduce exposure and decrease risks. If the ELV is exceeded, immediate action must be taken to reduce vibration exposure below the ELV and procedures implemented to prevent it being exceeded again.

To assist employers in the evaluation and assessment of risks arising from WBV, the EU published a guide12. This guide suggests that employers should perform an assessment of the risk, including estimation of worker daily vibration exposure level, to determine whether the EAV or ELV are likely to be exceeded during normal work on vibrating equipment. It is therefore of considerable importance that a comprehensive database of WBV levels and daily exposure data be generated to encompass a wide range of equipment and operations.

This work aims to provide such a database for South African opencast mines. The study considers 34 different pieces of equipment in a very large South African mine. The equipment is roughly categorized as load haul dumpers (LHDs), excavators, and other equipment.

Methodology

Measured parameters and transducers

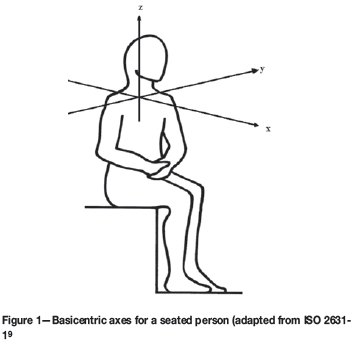

In accordance with ISO 2631-1 (1997)9, acceleration levels were measured on the operator's seat of the equipment under consideration along three basicentric (i.e. fixed to surfaces that come in contact with the body) axes (seat x longitudinal, seat y - transverse, seat z - vertical, see Figure 1) by means of a Dytran Model 5313A triaxial seat accelerometer.

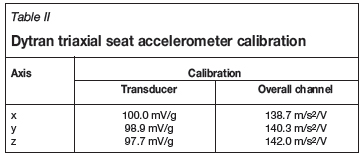

The seat accelerometer was attached to the seat cushion using duct tape to prevent it from slipping away during operation (see Figure 2). The instrumentation was calibrated in the laboratory before leaving for the measurement site, and again upon return. Transducer and overall calibration details are provided in Table II. A digital camera and laptop computer were also taken to the site for photograph and transfer of data respectively.

Data acquisitioning and recording

Signals from the triaxial accelerometer were passed to a Sound Vibration Analyzer 958 (SVAN958) Human Vibration Meter (HVM), where the data was digitally recorded (see Figure 2) using a 16GB external flash disk attached to the SVAN958 to enable it to store data of long duration.

The SVAN958 HVM samples at a fixed frequency of 48 kHz. Anti-aliasing filters are embedded in the system. The HVM was used to record raw acceleration time histories as well as unweighted root mean square (RMS) values of the acceleration signals. The data was downloaded to a personal computer (PC) for post-processing and further analysis in software such as MATLAB or OCTAVE. Since the interest is here primarily in frequencies of between 0 and 100 Hz, the data were resampled to 2 kHz.

A minimum of about 10 minutes was required for both the fitting and removal of the transducers and the data acquisition system. Hence, to reduce disruption of the mining activities, fitting and removal were performed during normal work breaks. This led to overall data recording periods that were generally between 30 minutes and 1 hour per station, and which is comfortably more than the minimum measurement time of 10 minutes13.

Data analysis

The data time histories were recorded in volts in WAV file format on the SVAN958 and subsequently downloaded to a PC. Dedicated software was used to enable reading the very large WAV files. The calibration factors reported in Table II for seat x, seat y, and seat z were then applied to obtain the equivalent acceleration-time history in m/s2 from the WAV format data.

The acceleration time histories recorded on the operator's seat of the target equipment were post-processed to compute the following:

Frequency and measurement axis-weighted acceleration time histories, processed in accordance with the requirements of ISO 2631-1 (1997)

Estimated operator daily vibration exposure, presented in 8-hour energy-equivalent continuous, frequency-WRMS acceleration A(8) and VDV forms

Crest factor (CF) for each piece of target equipment

Time to reach the EAV and ELV, when specified both in A(8) and VDV forms.

As a check on the integrity of the results the externally post-processed RMS and VDVs were computed and compared with the SVAN958 internally calculated values. The VDVs for an 8-hour exposure period defined in EU Directive 2002/44/EC (see Table I) were also computed. Plots of the weighted acceleration histories were also constructed from the data obtained.

The required parameters were then computed and extrapolated to cover the entire duration of exposure using dedicated software developed in the MATLAB environment. The acceleration was frequency-weighted based on ISO 26311 (1997), again using dedicated software. Subsequently the WRMS acceleration and VDV were computed.

Repeated exposure to vibration that exceeds the ELV based on A(8) could lead to low back pains. ISO 2631-1 (1997) recommends that if a CF higher than 9 is attained this indicates the presence of shocks and the A(8) approach is not sufficient. The VDV must then be computed. The VDV is a fourth-power value that takes into account the cumulative effect of vibration for the duration under consideration and therefore captures shocks better.

Weighted root mean square (WRMS) is the square root of the average of the squares of the weighted values. The WRMS acceleration is expressed in m/s2 for translational vibration and calculated as follows:

where aw (t) is the weighted acceleration time history and T is the duration of the measurement.

The daily exposure (A(8)) is the daily exposure (8-hour energy-equivalent continuous, frequency-WRMS acceleration).

The crest factor (CF) is the ratio of the maximum weighted acceleration value to the WRMS.

Vibration dose value (VDV) is the fourth root of the integral of the fourth power of acceleration after it has been frequency weighted. The frequency-weighted acceleration is measured in m/s2 and the time over which the VDV is measured is in seconds, yielding VDVs in m/s1.75. The VDV is computed as follows:

where aw(t) is the weighted instantaneous acceleration magnitude and T is the duration of the measurement. The fourth power in the expression for VDV emphasizes the presence of shocks in the data.

Results

Summary of equipment WBV levels based on ISO 2631-1 (1997) using WRMS parameter

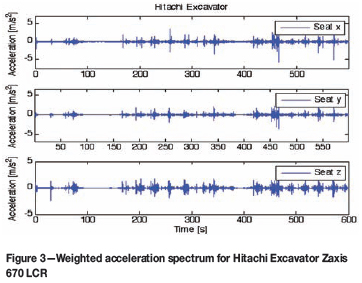

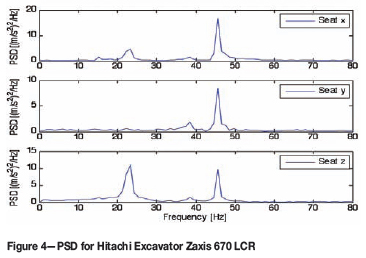

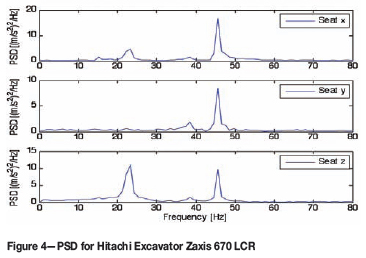

The recorded data consisted of WBV levels measured with respect to time along the three basicentric axes (x, y, and z) on the operator's seat. This data was weighted as shown in Figures 3 and 4 for a Hitachi Excavator Zaxis 670 LCR. The highest vibration magnitude computed from the weighted acceleration history of the excavator was obtained as 0.41 m/s2 and in the z-direction, which is below the EAV. From Figure 3 one can observe the presence of shocks. The CF would therefore need to be computed, and if higher than 9 then the VDV would have to be computed for evaluation of risk to health. The Hitachi Excavator Zaxis 670 LCR has CF higher than 9 in all three directions (x-, y-, and z-axes) as shown in Table IV. This indicates the presence of shocks in the data collected for the equipment. The equipment excavates top soil or coal and loads into LHDs operating over a rough surface. This leads to the multiple recurring highmagnitude transient shocks as shown in Figure 3.

In Figure 4 the peaks are at 22 and 45 Hz indicate the dominant frequencies. From the literature the frequency range of 4-20 Hz is known to be the most uncomfortable for humans1. Hence, in this particular case the peak response frequencies are close to the range of maximum sensitivity, which indicates that small changes in the configuration could easily lead to significantly increased exposure. The WRMS, CF, and time to EAV (A(8)) and ELV (A(8)) were calculated and tabulated separately for each equipment combination identified, and the results shown in Tables III, IV, and V.

Summary of equipment WBV levels based on ISO 2631-1 (1997) using VDV parameter

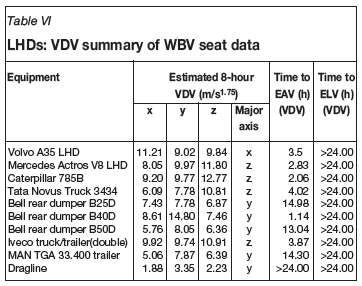

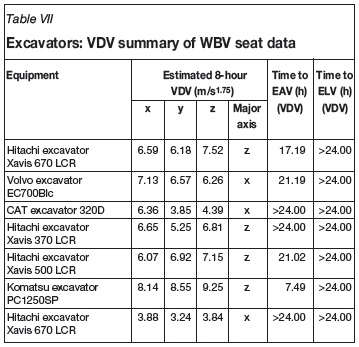

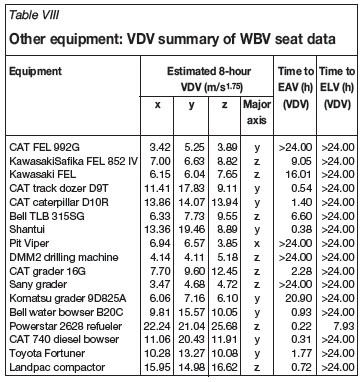

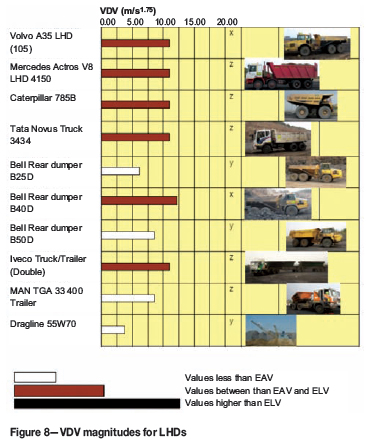

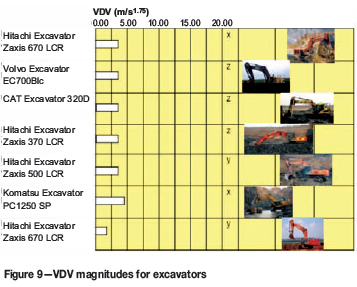

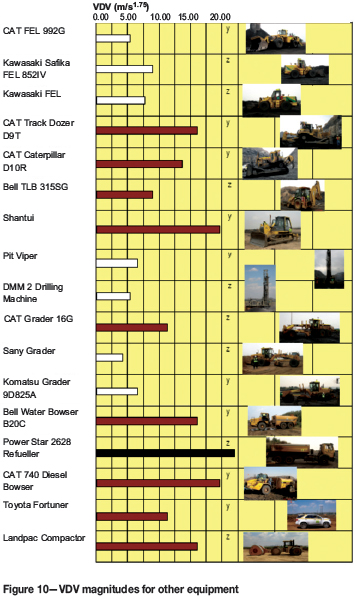

A summary overview is shown in Tables VI, VII and VIII for VDV analyses for LHDs, excavators, and other equipment respectively.

Discussion of results

WBV results based on ISO 2631-1 (1997) using WRMS approach

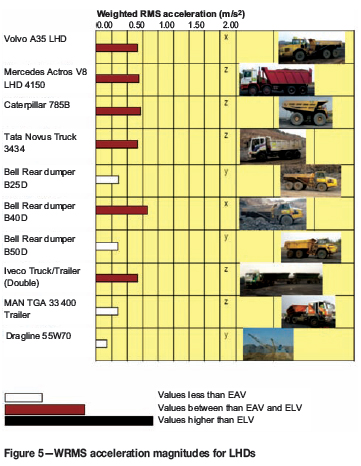

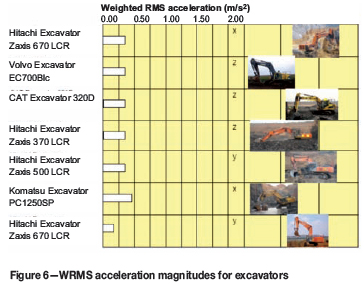

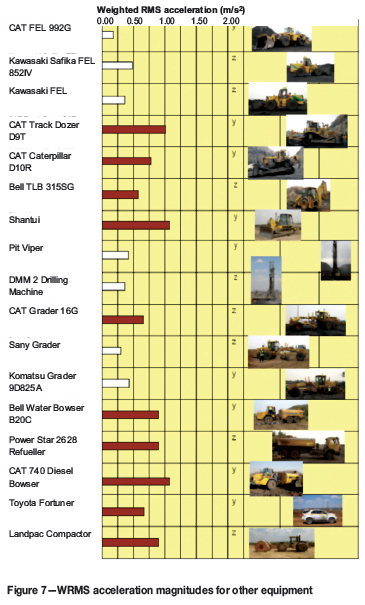

Figures 5, 6, and 7 schematically summarize the WRMS acceleration levels that were observed. Two groups can be identified, namely those where the vibration levels are less than the EAV of 0.5m/s2 and which constitute about half of the equipment considered, and the other half where the vibration levels exceed the EAV of 0.5 m/s2 but are still less than the ELV of 1.15 m/s2. In some equipment the highest value is in the z-direction whereas in others it is along either the y- or z- axis. None of the equipment displayed WRMS values exceeding the limit value of 1.15 m/s2, as shown in Tables III, IV, and V.

For each piece of equipment shown in Tables III, IV and V, the decision on the presence of shocks is taken based on the direction with the highest CF. 12% of the equipment have CF less than 9 in all three directions. The remaining 88% have CF above 9 in at least one direction. Of the four pieces of equipment with CF less than 9, the Landpac compactor in Table V has the lowest CF of 7.41 in the x-axis (worst direction). This is quite close to CF of 9 as any slight increase in vibration could result to CF above 9. This therefore again confirms the presence of shocks in the data collected. The equipment in Tables III, load, haul and dump top soil or coal operating over rough road resulting to transient shocks. Similarly, the equipment in Table IV and V operate over similar conditions leading to multiple recurring transient shocks.

As was observed before, the maximum accelerations can either be in the x-, y- or z-directions. This implies that one cannot assume that vertical acceleration will always be worst.

WBV results based on ISO 2631-1 (1997) using VDV approach

Figures 8, 9 and 10 give a summary of the equipment where the WBV levels are either below the VDV action value of 9.1 m/s1.75 or between the VDV action and limit values of 9.1 m/s1.75 and 21 m/s1.75 respectively, or above the VDV limit values of 21 m/s1.75 as shown in Tables VI, VII, and VIII. Half of the equipment had VDVs below the VDV action value. Forty seven per cent of the equipment had VDVs between the VDV action and limit value. The remaining three per cent of the equipment had VDVs above the VDV limit values. A significant proportion of the equipment has exposure values above the action value and as such action needs to be taken to reduce these exposures.

The number of equipment items with vibration values below the EAV and between the EAV and ELV is almost the same for both the A(8) and VDV, as shown in Figures 5 to 10. In Figure 10 the black bar indicates a case where the ELV has been exceeded and action should be taken to reduce the vibration level or reduce the operator exposure to the equipment. This again emphasizes the importance of shock in the evaluation of vibration exposure for some mining equipment. Even though the exposure limit value has not been exceeded for most of the equipment, it can be seen that the exposure values lie between the EAV and ELV. Hence, action has to be taken to mitigate the exposure to vibration. Berezan et al.14 found that aggressive driving patterns, rough and poorly maintained roads and pit floors, along with the occasional bump and poorly placed load from a shovel, can create intense and sometimes serious vibration levels on a heavy hauler. Ameliorative action for the mitigation of vibration levels includes the regular grading of roads to ensure they are level and training of operators on how to use the equipment effectively.

Conclusions

This study provides a WBV database for a large range of equipment typically found on South African opencast mines. The ISO 2631-1 (1997) standard methodology was used to evaluate typical WBV levels on these equipment, using the A(8) and VDV parameters. The results obtained from this standard indicate that some 95% of the equipment is associated with vibration levels below the exposure limit values. Typically some 50% of the equipment causes vibration exposures that exceed exposure action values. This is very significant and suggests the necessity for proper vibrational risk assessment and management in mining applications. Shocks can be important, as can be seen when using the VDV parameter; one of the pieces of equipment exceeds the ELV. Actions to reduce vibration levels are recommended. These include regular grading of roads and training of operators on how to use the equipment.

References

1. GRIFFIN, M.J. Handbook of Human Vibration. Academic Press, London, 1990. [ Links ]

2. VAN NIEKERK, J.L., HEYNS, P.S., and HEYNS, M. Human vibration levels in the South African mining industry. Journal of the South African Institute of Mining and Metallurgy, July/August, vol. 100, no. 4, 2000. pp. 235-242. [ Links ]

3. TESCHKE, K., TRASK, C., VILLAGE, J., CHOW, Y., COOPER, J., DAVIES, H., DEMERS, P., HODGSON, M., HONG, K., HURRELL, C., JOHNSON, P., KNOTT, M., LUONG, N., MORRISON, J., WRIGHT, G., XU, F., and KOEHOORN, M. Back injuries in heavy industries: Risk Factor Exposure Assessment. Final Report to WorkSafeBC, 2008. [ Links ]

4. GOGLIA, V. and GRBAC, I. Whole-body vibration transmitted to the framesaw operator. Applied Ergonomics, vol. 36, 2005. pp. 43-48. [ Links ]

5. YRÄNHEIKKI, E. and SAVOLAINEN, H. Occupational safety and health in Finland. Journal of Safety Research, vol. 31, no. 4, 2000. pp. 177-183. [ Links ]

6. SESÉ, A., PALMER, A.L., CAJAL, B., MONTAÑO, J.J., JIMÉNEZ, R., and LLORENS N. Occupational safety and health in Spain. Journal of Safety Research, vol. 33, no. 4, 2002. pp. 511-525. [ Links ]

7. VAN NIEKERK, J.L., HEYNS, P.S., HEYNS, M., and HASSALL, J.R. The measurement of vibration characteristics of mining equipment and impact percussive machines and tools. Safety in Mines Research Advisory Committee SIMRAC Pretoria, South Africa. Report, GEN 503, January, 1999. [ Links ]

8. MINE HEALTH AND SAFETY COUNCIL (MHSC). Newsletter, Issue 2, 2004. pp. 1-4. [ Links ]

9. ISO 2631-1. Mechanical vibration and shock - Evaluation of human exposure to whole-body vibration. 1997. [ Links ]

10. European Commission. The European Parliament and the Council of the European Union, on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents (vibration) (sixteenth individual Directive within the meaning of Article 16(1) of Directive 89/391/EEC). Directive 2002/44/EC. Official Journal of the European Communities, 6 July 2002. L117/13-19. [ Links ]

11. HEYNS, P.S. Vibration. MHSC Handbook on Mine Occupational Hygiene Measurements. Stanton D.W., Kielblock, J. Schoeman, J.J., and Johnston, R.W.(eds.). Pretoria, Mining Health and Safety Council, South Africa, 2007. [ Links ]

12. EU Good Practice Guide WBV, Guide to good practice on whole-body vibration. 2006. Version 6.7h English. http://wwwnew.isvr.soton.ac.uk/hrv/VIBGUIDE/2008_11_08%20WBV_Good_practice_Guide%20v6.7h%20English.pdf. [ Links ]

13. MANSFIELD, N.J., ATKINSON, S., and PAYNE, G. Effect of increasing measurement duration on accuracy of whole-body vibration field measurements. 38th United Kingdom Conference on Human Response to Vibration, Institute of Naval Medicine, Alverstoke, Gosport, UK, 17-19 September 2003. [ Links ]

14. BEREZAN, J.J., JOSEPH, T.G., and DEL VALLE, V.D. Monitoring whole-body vibration effects on ultra-class haulers. CIM Bulletin, vol. 97, no. 1082, 2004. pp. 1-4. [ Links ] ♦

Paper received Jan. 2010; revised paper received Sep. 2011.

© The Southern African Institute of Mining and Metallurgy, 2011. SA ISSN 0038-223X/3.00 + 0.00.