Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

Journal of the Southern African Institute of Mining and Metallurgy

versão On-line ISSN 2411-9717

versão impressa ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.111 no.10 Johannesburg Out. 2011

TRANSACTION PAPER

The history and development of the pyrometallurgical processes at Evraz Highveld Steel & Vanadium

W.S. SteinbergI; W. GeyserI; J. NellII

IEvraz Highveld Steel & Vanadium, Emalahleni, South Africa

IIHatch, Johannesburg, South Africa

SYNOPSIS

In 1963, the full-scale engineering study for the development of an iron, steel, and vanadium plant was initiated. This was the birth of Evraz Highveld and its process flow as it is known today. Highveld started out as a steelworks that produced steel and vanadium-bearing slag from a titaniferous magnetite iron ore mined from its own mine site near Steelpoort. The process utilized co-current rotary kilns for prereduction, and submerged-arc furnaces for the production of pig iron with approximately 1.15% vanadium.

Because of various technical challenges that the submerged-arc furnaces experienced over the years, a decision was taken in 2004 to convert the furnaces to open slag bath (OSB) operation, in order to enable the maximum production of iron and vanadium while improving the control over operational parameters.

The conversion proved to be highly successful and, since 2005, three furnaces have been converted to OSB operation. The fourth furnace will be converted in the first half of 2011. The conversion to OSB furnaces not only yields higher vanadium recovery to the metal at the iron plant, but also improves the overall throughput of the steel plant. This is the result of the higher carbon content of the liquid iron from the OSB furnaces, eliminating the need for anthracite addition to the shaking ladle process. This reduces the blowing time by approximately 60%.

The conversion of the furnaces to OSB configuration is seen as an enabling technology change and a prerequisite to the implementation of other plant improvements that are envisaged. The longterm vision of EHSV is to convert five furnaces to OSB mode, and permanently decommission the two remaining submerged-arc furnaces. This will allow EHSV to maintain current steel and vanadium production but at a significantly improved overall efficiency.

Keywords: pyrometallurgy, furnace, open slag bath, Evraz, Highveld.

Introduction

The Evraz Highveld Steel & Vanadium (EHSV) process flowsheet was developed in the early 1960s, based on the research done by Dr William Bleloch in 1949. He showed that Bushveld complex magnetite ore could be melted using submerged-arc furnace (SAF) technology in a process that controls the carbon addition to selectively reduce vanadium and iron while leaving titania dissolved in the slag. In March 1963, a decision was taken to start with a full-scale engineering study to develop an iron, steel, and vanadium plant based on prior pilot-plant testwork. The engineering study was done by Davy and the United Engineering Company of Sheffield1.

The engineering study resulted in a rotary kiln-electric furnace (RKEF) flowsheet for the iron plant. The purpose of the kilns is to reduce the magnetite ore 'as much as possible' by utilizing a cheap form of energy such as pulverized coal, fired through a continuous burner at the feed end. The reason for the decision at the time to construct co-current kilns is unknown. Discussions with one of the original commissioning engineers, working for Lurgi at the time, revealed that it was decided by Highveld to have all material flow directed in a single direction. The use of a RKEF flowsheet is well founded, as the use of conventional blast furnace technology poses the risk of blocking the hearth and tuyeres with highly refractory titanium carbide. Today, a successful blast furnace operation with similar ore (10.6% TiO2 versus 12.6% TiO2 in Highveld ore) is run by Panzhihua Iron and Steel in China2. They do, however, blend their magnetite with high quality haematite sourced from Australia to dilute the TiO2, hence reducing the risk of hearth precipitation. In the 1960s, this was not deemed possible.

The smelting of hot prereduced titaniferous magnetite iron ore to produce pig iron and a vanadium rich slag was started in the 1960s by both Highveld and New Zealand Steel. New Zealand Steel (NZS) selected partially open bath technology and a foamy slag practice, while Highveld went for the submerged-arc smelting mode. In the 1980s, New Zealand Steel rebuilt their iron plant with two six-inline rectangular furnaces. They also introduced multi-hearth calciners ahead of the kilns, and do not utilize pulverized coal burners inside the kilns at all. Instead, NZS rely on the gas-fired multi-hearth calciners to ignite the coal in the feed, and sustain the combustion by controlling air flow inside the kilns. NZS also use waste-heat boilers for the generation of approximately 60% of their internal electricity requirements3.

This paper describes the process EHSV is following to adopt aspects of the current NZS process by converting all submerged-arc furnaces to open slag bath configuration (OSB). It also discusses the unique shaking ladle process used at the steel plant to extract vanadium. In order to stay competitive in the market following recent and expected future electricity price increases, EHSV are considering the installation of multi-hearth furnaces ahead of the kilns as well as the installation of modular waste-heat boilers for on-site generation of electricity. These concepts are also addressed in the paper.

Evraz highveld steel and vanadium process flow description

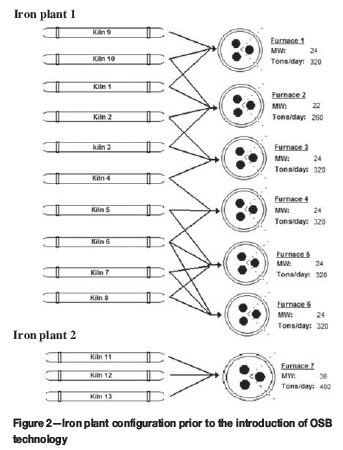

Evraz Highveld currently operates 13 refractory-lined rotary kilns, each 60 m long. The kilns feed seven arc furnaces with transformer ratings ranging between 45 and 65 MVA. Iron ore, fluxes, and coal are fed to the kilns, and the furnaces produce liquid vanadium-bearing pig iron, titania slag, and CO gas. The magnetite ore is received by rail from the opencast mine situated on the Bushveld Main Magnetite layer between Stofberg and Steelpoort. The typical ore composition is shown in Table I.

A typical metal output of 2400 t/day is obtained, together with a similar amount of slag. Slag condition is carefully controlled through the addition of fluxes to dilute titania and mitigate the risk of excessive titanium reduction. Typical metal and slag compositions are shown in Table II.

The slag is crushed, and entrained metal particles are magnetically removed and recycled through the process. The metal, with a vanadium content of approximately 1.20%, is transported to the steel plant for further processing.

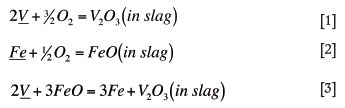

Vanadium is transferred from the liquid metal to slag using a shaking ladle process. The shaking ladle follows a soft oxygen blowing practice, where the following reactions take place:

Scrap is used as a coolant, and anthracite is used to replenish carbon that is unintentionally oxidized to CO and CO2. The metal is poured into the basic oxygen furnaces (BOFs), while the slag is retained and transferred to the vanadium plant for crushing and packaging.

The steel plant consists of four shaking ladles, three 70 t basic oxygen furnaces, two ladle furnaces, and four continuous casting machines. The steel plant has the ability to produce slabs, blooms, or billets at a typical rate of 2600 t/day.

The slabs are transferred to the flat products section of the plant, where plate or coils are produced, while the billets and blooms are transferred to the structural mill for production of structural steel.

Evraz Highveld currently produces approximately 900 000 tons of steel per year. The developments mainly at the iron plant are necessary in order to double their production in the next 10 years. Figure 1 shows a schematic process flow of the current layout.

Development at ironmaking

The iron plant is the focus of operational improvements because the two most important cost drivers (electricity and coal) are rooted in the operation of the arc furnaces (Figure 2).

Inefficiencies in the SAF technology with regard to hot metal production and vanadium recovery (see below) prompted Evraz Highveld to investigate open slag bath smelting as an alternative technology.

The main technical problems associated with submerged arc smelting are4:

Low vanadium yield-the average vanadium content in pig iron from the SAF for October 2008 was 1.00%. Over the same period, metal from the OSB furnaces contained 1.16% V

Low iron yield-mainly due to lower iron temperatures, causing more skulling of ladle and launders

Low productivity owing to low power input due to the inability to maintain the coke bed-this is a result of erratic carbon content of the batching recipes. The average metal production for the SAFs for July 2008 was 284 t/day. During the same period, the OSB furnaces produced 344 t/day

Erratic product quality-higher sulphur values in the liquid iron. The average sulphur content of the metal from the SAF was 0.092%, while for the OSB furnaces it was 0.037%. The higher slag basicity in the OSB furnaces permits more desulphurization during smelting.

To achieve these metallurgical improvements with OSB smelting, process control had to be improved. This necessitated better equipment and higher-skilled operators.

The OSB furnaces have an inherently higher power consumption because of the open-arc configuration. Initially, a higher vanadium recovery compensated for the power consumption, but recent increases in electricity costs have, unfortunately, negated the value of a higher vanadium recovery. Increasing electricity costs led to many small continuous improvement projects related to both equipment and operational practices. To reduce the specific power consumption of the OSB furnaces, the following drivers were identified:

Poor metallurgical performance and plant instability, arising from the sourcing of coal from numerous suppliers. In response, a decision was taken to limit coal suppliers to a maximum of two, and to improve quality control over the coal delivered to site

Poor metallurgical control over the OSB furnaces. In response, the furnace energy balance is managed in more detail with specific reference to the charge inventory in the furnaces. An empty furnace leads to high losses of energy, unstable bath chemistry, and low vanadium recoveries

Inconsistent prereduction in the kilns. In response, finer ore is fed to the kilns. As the degree of prereduction improves, furnace power consumption and coal consumption decrease.

Figure 3 shows the future configuration of the iron plant. The latest furnace is number 7 at Iron Plant 2. The conversion is almost complete where the first tap is expected towards the end of October 2011. The Furnace 7 design aims to minimize losses of energy from the furnace by using a revised centre-feeding system. At some time in the future, Furnace 2 will also be converted to OSB operation, at which stage Furnaces 3 and 4 will be decommissioned.

The main reasons for converting to OSB furnaces at EHSV are:

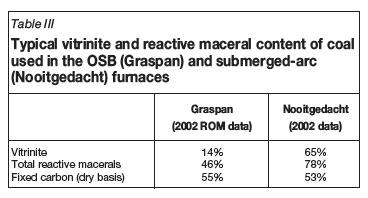

The ability to use cheaper coal-because of the lower average operating temperature, only the more reactive, and expensive, Seam 5 coal can be used in the SAFs. The OSB furnaces, on the other hand, operate at a higher average temperature, and less reactive and cheaper Seam 2 coal can be used. Coal reactivity can be related to the reactive maceral content, and Table III shows the significant difference in composition between the coal used in the OSB and submerged-arc furnaces.

Reduced coal consumption-due the lower reactivity of the Seam 2 coal used in the OSB furnaces, kiln combustion losses are lower compared to the SAFs, which use the more reactive Seam 5 coal

Reduced power consumption-the OSB furnaces have an inherently higher power consumption because of the higher losses of energy through the roof. In practice, it is found that the actual power consumption per ton of metal produced is higher for the SAFs because their availability is lower than that of the OSB furnaces. Metal production is further affected by variability in electrode immersion owing to inconsistent feed composition

Reduction in electrode paste consumption-due to the fact that the tip of the OSB electrode is not submerged in the burden (as happens with the SAF), the electrode is less prone to oxidation through bath reactions or mechanical damage.

The advantages of OSB operation described above are well demonstrated by the OSB/SAF comparison in Table IV. The data used to compile this comparison represents averages for the 12 months before conversion and for 12 months after hot commissioning. Averages for the 'past 6 months' represent the period from June 2010 to November 2010, both months inclusive.

A closer look at the open slag bath operation5

In the past two years, EHSV have built their confidence in operating the OSB furnaces, and although there are still many challenges, OSB technology has become a sustainable part of the process.

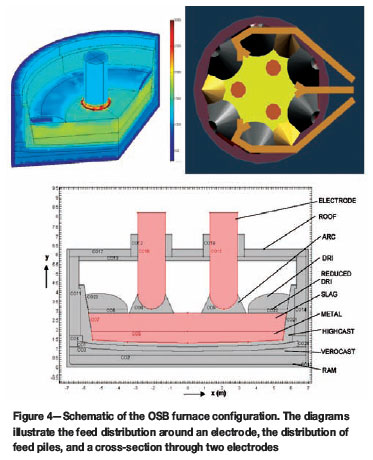

Figure 4 demonstrates some of the characteristics of the OSB melting operation. The arc is struck between the electrode tip and the liquid slag bath. This superheats the slag, which melts the furnace feed as it slides into the bath. The furnace is charged through 12 charge ports on the perimeter of the furnace. The charge forms banks that protect the sidewall refractories.

The furnace energy balance proved to be the most important control measure to maintain furnace productivity, because of the large impact that the furnace condition has on bath chemistry. There are three main aspects influencing the furnace chemistry:

1. The furnace feed material chemistry, which in turn is controlled by the raw material quality and the kiln operation

2. The effective energy available in the furnace (energy balance)

3. Melting phenomena in the furnace. Operational experience has shown that material with a low melting point is preferentially taken up in the slag bath. Unless an even feed rate is maintained, more refractory material accumulates in the banks, leading to fluctuations in bath chemistry.

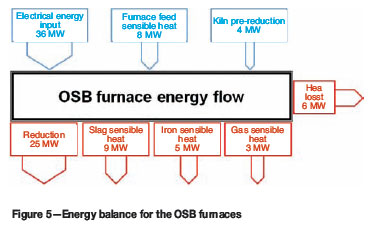

A Sankey diagram for the OSB furnaces is given in Figure 5. It is important to control the balance by adjusting feed rate and power input to optimize vanadium recovery and minimize titania reduction from the slag.

Impact of the OSB furnaces on steel plant operation and vanadium extraction

Vanadium recovery is an extremely important aspect of EHSV's business and is the main motivation for converting to OSB operation. For the same reason, it is important to optimize the performance of the shaking ladle process.

In the shaking ladle process, hot metal from the iron plant is subjected to a 'soft' oxygen blow while being mechanically stirred. Although C, Si, Ti, Mn, Cr, and V have a higher affinity for oxygen than Fe, most of the oxygen blown into the ladle reacts to form FeO.

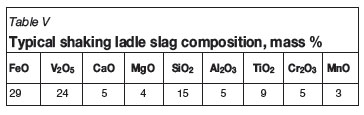

The FeO, in turn, reacts with Si, Ti, Mn, V, and Cr in the hot metal to form oxides that dissolve in an iron oxide slag. The temperature of the slag is controlled below 1400ºC. The slag is viscous and has the consistency of a paste because the temperature is below the liquidus. In the 'soft' oxygen blow it is important to minimize the formation of Fe2O3, which will increase the liquidus temperature and cause the slag to be excessively 'dry'. A typical slag composition is given in Table V. The liquidus phase is a vanadium-bearing spinel belonging to the Fe3O4-FeV2O4 solid-solution series. Using the current blowing practice, vanadium recovery to the slag is between 90 and 92%.

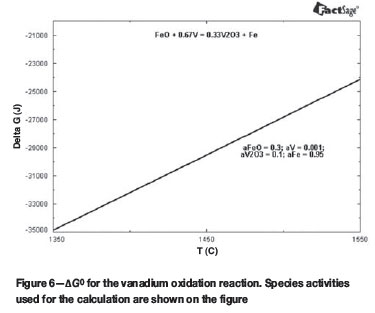

The oxidation of vanadium is promoted by low bath temperatures (see Figure 6), and EHSV controls the temperature to below 1400ºC with scrap and iron ore additions.

Apart from serving as a coolant, iron ore additions are beneficial for increasing the activity of FeO in the slag, thereby promoting the oxidation of vanadium from the metal.

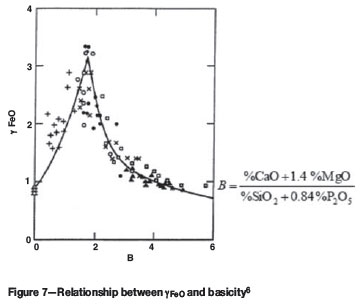

Slag basicity has a large effect on FeO activity (as shown in Figure 7). To maximize the activity of FeO, the basicity would have to be increased from the current value of about 0.7 (as per the current slag composition) to 2. Currently basicity is not controlled, because of customer constraints. High amounts of CaO and MgO in the vanadium slag cause the formation of an insoluble vanadate in the salt roasting stage, in turn causing a reduction in yield.

During blowing, most of the dissolved carbon is oxidized to carbon monoxide/dioxide. If too much carbon is oxidized there is a risk that the metal could start to solidify because the temperature is controlled to below 1400ºC.

To replenish the carbon, anthracite is added in batches during the blow. The anthracite additions have a negative effect on vanadium recovery to the slag, since anthracite tends to reduce vanadium oxide back to the hot metal.

From the foregoing, it is clear that the efficiency of the shaking ladle operation depends on careful control over iron oxide activity in the slag, temperature, and the carbon content of the metal. These variables are not independent, and the relationship between the iron oxide content of the slag and carbon in metal is of particular importance. [5]

In practical terms this means that blowing rate and the ore and anthracite additions have to be carefully balanced to optimize vanadium recovery while retaining a sufficiently fluid metal product.

Proposed change to the shaking ladle process after complete conversion to OSB furnace operation The OSB furnaces have the ability to produce liquid iron with a higher carbon content than that produced by the SAFs. This will reduce, or even eliminate, the need to add anthracite to the shaking ladle. The steel plant will then focus on adding larger amounts of FeO to the shaking ladle in the form of fine ore and eliminate the addition of scrap. Scrap addition will be optimized at the BOFs.

This change seems subtle but has a large impact on the throughput of the steel plant. Preliminary tests indicate that the blowing time at the shaking ladle can be reduced from 75 minutes to 30 minutes by eliminating anthracite and scrap additions.

Conclusions

Over the past four years, Evraz Highveld has been in the process of converting 5 of the 7 furnaces in the iron plant to open slag bath configuration. On completion of the conversion, the two remaining SAFs will be decommissioned. Conversion to OSB operation is motivated by improved vanadium recovery, reduced coal consumption, reduced electrode consumption, reduced power consumption per ton of metal produced, and the ability to use less-reactive coal and a larger fraction of fine ore.

Iron from the OSB furnaces has a higher carbon content, which impacts significantly on the efficiency of the shaking ladle process at the steel plant. Blowing time in the shaking ladle process can be reduced by as much as 45 minutes by eliminating scrap and anthracite additions. The steel plant will focus on the addition of fine ore, in order to increase the FeO content in the slag to improve overall vanadium recovery in a shorter blowing time.

It is the objective of Evraz Highveld to ultimately increase their yearly output by approximately 50%. To achieve this objective, the prereduction process will have to be improved, potentially through the use of multi-hearth furnaces upstream of the kilns. By improving prereduction, more iron will be produced from the same overall power input in the arc furnaces. The use of waste-heat boilers for the generation of electricity is also under investigation to further reduce the overall cost per ton of steel.

Acknowledgements

This paper is published by permission of Evraz Highveld Steel & Vanadium. The contributions of our colleagues are gratefully acknowledged, as well as the design and operational inputs by Hatch.

References

1. ROHRMANN, B. Vanadium in South Africa. The Metals and Minerals Industry in South Africa, Part 1, H.W. Glen (ed.). Journal of The Southern African Institute of Mining and Metallurgy, Johannesburg. 1989, pp. 27-36. [ Links ]

2. ZHANG, L., ZHANG, L.N., WANG, M.Y., LI, G.Q., and SUI, Z.T. Recovery of titanium compounds from molten Ti-bearing blast furnace slag under the dynamic oxidation condition. Minerals Engineering, vol. 20, 2007. pp. 684-693. [ Links ]

3. KELLY, B.F. Ironmaking at BHP New Zealand Steel Limited, Glenbrook, New Zealand. Australasian Mining and Metallurgy. The Sir Maurice Mawby Memorial Volume, vol. 2, Australasian Institute of Mining and Metallurgy, Victoria, Australia, 1993. pp. 348-353. [ Links ]

4. SUTHERLAND, J.J. Final technical report of the open slag bath trial, Internal Highveld Steel & Vanadium document, 3 September 2003. [ Links ]

5. STEINBERG, W.S. Development of a control strategy for the open slag bath furnaces at Highveld Steel and Vanadium Corporation Ltd. M.Eng. thesis, University of Pretoria, Department of Metallurgical Engineering and Materials Science, December 2008. [ Links ]

6. Wakelin, D.H. (ed.). The Making, Shaping and Treating of steel. 11th edition. AISE Steel Foundation, Pittsburgh, PA, 1999. p. 88. [ Links ]

This paper was first presented at the Southern African Pyrometallurgy Conference, 6-9 March 2011, Misty Hills, Muldersdrift.

© The Southern African Institute of Mining and Metallurgy, 2011. SA ISSN 0038-223X/3.00 + 0.00.