Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

Journal of the Southern African Institute of Mining and Metallurgy

On-line version ISSN 2411-9717

Print version ISSN 2225-6253

J. S. Afr. Inst. Min. Metall. vol.111 n.8 Johannesburg Aug. 2011

TRANSACTION PAPER

Annual mine planning and execution buffering-a safety imperative

R.C.D. Phillis; H. Gumede

Ukhozi Project Management

SYNOPSIS

The annual mine planning process is one of the most important tactical/operational steps towards achieving strategic goals. These tactical plans are part of a very comprehensive Mineral Resource Management process, with the natural sequel to planning being execution. The execution of an underground hard rock mine plan is a multi-project environment that comprises many development construction-equipping-stoping single project paths, which are referred to as 'stoping paths'. The uncertainty that typifies execution of projects comes in the form of untimely disruptions to constituent tasks and/or project paths. Annual mining plans also include quantified objectives for occupational health and safety, production, quality, cost, employee morale, environment, and corporate social investment. Such objectives make for a highly complex environment that management must contend with- complex in the sense that all the paths and objectives have interdependent constraints. Furthermore, at the time of this paper, Sections 54* and 55** of the MHSA*** put the onus on management to ensure legislative adherence.

It stands to reason that planning estimates allow excess capacity-buffers-that cushions the impact of untimely disruptions. This paper concerns the fact that despite all the buffers allowed for, time, scope, and budget creeps impact on mine planning and threaten its successful execution. As a consequence, the paper deals with buffer management, the essence of Critical Chain Project Management (CCPM). Effective buffer management provided strategic (executive level) updates without losing the tactical/operational detail necessary for job card creation, especially where professional skills and experience are in short supply. Indicative bottom-line results showed CCPM to be highly effective.

Keywords: CCPM, buffer.

Introduction

The annual tactical plans on mines are normally successors of feasibility studies and, life of mine (LOM) plans, and predecessors of operation plans. These plans are part of a comprehensive Mineral Resource Management (MRM) process, which is beyond the scope of this paper. By their nature, annual hard rock tactical plans fall within the realm of project management.

It is generally acknowledged that mining is beset by uncertainties. In order to deliver realistic estimates that are used to derive the annual mine plan, tactical plans must consider these high levels of uncertainties-those that result from both internal and external factors.

External factors for 2008-2009 (the time period during which several of the studies took place) included:

Volatility of electricity supply from Eskom (South Africa's national electricity supplier)

Mine stoppages by the Department of Mineral Resources (DMR) Inspectorate due to safety and health (Section 54 of the MHSA)

The effects of an increased number of public holidays on monthly production momentum.

Internal factors included:

Geological risks (poor grade levels, reef rolls etc.)

Geotechnical risks (bad ground)

Machine availability

Skills shortages (level of individual competence, proportion of individuals with necessary skills)

Human resources availability (absenteeism and turnover).

Regardless of the uncertainties and the complexities that plague the mining industry, management is expected to deliver annual mine plans. In simple terms, annual tactical plans are a form of contract between a mine/shaft and the stakeholders. The planned targets must be achieved because annual plans form a significant part of the embodiment of the returns on investment (ROI) that informs both major capital investment decisions and company strategy and tactics.

Conventionally, and rightly so, most of the effort goes to finding solutions that attempt to reduce the uncertainty of every individual input. The authors of this paper have observed that most publicly listed mining companies reported shortfalls in periodic production results in 2008, although the same companies may have reported favourably on profitability for the 2008 financial year. Various and mostly valuable internal and external uncertainties were cited for the lower periodic production results, despite the tactical plans having inbuilt contingencies (protective capacity to cater for things that go wrong). This implies two things: that business plans are either unrealistic; or that the inbuilt protective capacities and contingencies are inadequate. However, since mining by its nature will always be accompanied by high levels of uncertainties, it is worthwhile to explore alternative approaches that attempt to systematically manage contingences in a holistic manner.

The alternative approach applied in this work is underpinned by the Theory of Constraints (TOC) and, in particular, by Critical Chain Project Management or CCPM principles. CCPM was used in seven studies (one pilot study and six studies in different shafts of two South African hard rock mines) to complement and enhance the existing business processes and to protect the business plan to increase the probability of its successful realization. Some of the studies were six months in duration. CCPM focuses more on the way contingencies and protective capacities are managed. As a consequence, this paper concentrates on the systematic management of inbuilt contingencies through a process known as 'buffer management'.

Mine planning takes place in a project management environment and many uncertainty factors jeopardize its delivery. The following sections will focus on the technicalities and practicalities of instituting buffers in annual mining plans.

CCPM and annual mine planning

Simply stated, CCPM is a TOC way of managing projects (Leach, 2004). The CCPM methodology was chosen by the authors of this paper because it both explicitly acknowledges the uncertainties associated with projects and provides a systematic way of managing inherent contingencies in a manner that ensures project success. CCPM is based on the premise that successful project management is constrained neither by unrealistic project commitments of time, scope, and cost, nor by the fact that contingencies (i.e. the sum total of implicit and explicit protective capacities) are insufficient to absorb all things that go wrong. Instead, CCPM is concerned with how contingencies are (mis)managed. With the use of a CCPM perspective, the following observations were made after the authors had participated in the planning processes of two major mining houses.

Tactical plans have inherent protective capacities (buffers):

The annual average month has 23 working days (excluding non-working days). The average daily stoping advance rate is 1 m, with an effective drill length of 1.2 m per hole; Monthly targets are set at between 12 and 17 m. This translates to a time buffer range of 26% to 47% per month.

There are many other inherent buffers that increase in relation to the experience of line management who make estimates, and these buffers reside with line management.

Annual tactical plans and Parkinson's Law

Parkinson's Law refers to the principle of dividing planned work over available time. In a typical mining tactical planning and execution environment, the Law will reveal itself in the following chronological manner:

Monthly targets are annual targets divided by 12 months

Daily targets are monthly targets divided by the annual average 23-day month

Stoping shift work is divided among resources over an 8-hour shift.

This reductionism is necessary for fiscal measurements, but also has the potential for adverse effects. If time is lost early in the plan or project, the outstanding work must be divided over the time remaining, which implies additional effort and pressure. The sense of urgency to achieve tactical goals increases in proportion to consumption of time; for instance, as periodic milestones fall short of delivery so does the pressure to improve performance increase (periodic milestones include monthly, quarterly, half-yearly, and annual milestones).

If, for example, targets are not met in the first quarter, then the shortfall is carried over to the remaining three. At this early stage, the urgency might not surface, especially as line management idealizes future executions and the resolving of all the problems they have been working on. What happens in reality is that time continues to creep as line management works on elusive solutions to these problems. Ultimately, more work must be done in less time and the ability to mobilize the mine becomes increasingly difficult as year-end approaches.

Annual tactical plans and the 'Student Syndrome'

In CCPM, the 'Student Syndrome' is the tendency of individuals to delay getting down to work. This happens especially when people know that they have inherent buffers and are busy with something else at the time; they tend not to start work immediately. If individuals start late and if the work rate remains unchanged, then it is highly likely that the work will finish late. An implication for back-to-back stoping schedules is that if one stoping task runs late it jeopardizes the successful realization of the annual mining plan-not all the planned stoping can then be completed in the available time.

Task interdependency and integration

Structural activities that precede stoping are development, equipment, and construction. Back-to-back scheduling means that a delay in one of these activities would jeopardize the readiness of the stope and, ultimately, the success of the mining plan. Figure 1 shows the linear integration of a stoping path. It is also important to remember that task efficiencies in these activities do not average out-on the contrary, they reduce exponentially. Similarly with vertical integration, the probability of successful integration reduces exponentially in proportion to the number of tasks being integrated. Table I is an attempt to highlight the amount of linear (lateral) and vertical integration that must be borne in mind in the managing of annual mining plans.

Table I presents a summary of different but interdependent tasks (taking cognisance of resource allocation) that must integrate prior to having a single path as shown in Figure 1. Each stoping path has both vertical and lateral dependencies that must integrate. Vertical dependencies between stoping paths could expand to between ten (10) to more than a thousand (+1000) lines on software such as MS Projects. Furthermore, the probability of a successful integration decreases significantly with an increase in vertical dependencies because stoping path integration is a conditional-dependency probability.

Annual tactical plans make up a multi-project environment

Many stoping paths and half-levels run concurrently and often without a clearly defined critical path or paths. In the shafts where the studies were carried out, the implications of the multi-project nature of the tactical plans were numerous:

Execution scheduling of virgin ground (new mining ground) often involved separate development and stoping schedules that were not linked. This made it easy for mine overseers to manage their respective areas of responsibility. This also meant that development schedules were managed semi-independently from the stoping schedules

The construction and equipping schedules were often under-estimated during planning and execution

It was difficult for line management and stakeholders to maintain a holistic view of the annual mining execution, because of the division of work and labour, and the related incentives promoting local efficiencies

Arguments erupted over priorities, without a dispassionate mechanism for effective conflict resolution and decision-making existing.

Major infrequent disruptions such as accidents caused major discontinuities of pre-planning cycles.

Qualitative observations

Apart from these implications, qualitative observations were made by the study team. The first of these is that mine planning commitments were converted into bonus contracts as an incentive for management. Second, getting mining plans authorized was a mammoth task. It involved a constant contest between the managers and their executives supervising them regarding acceptable mining rates and targets: managers preferred conservative mining rates to increase their chances for a bonus, while executives insisted on rates that improved the return on assets managed (ROAM) for shareholders.

A third observation was the idealization of the mine planning execution. The belief existed that the best way to meet and exceed planned commitments is through 'realistic' estimates (i.e. plans with adequate contingencies) coupled with a full kit of resources-human, material, engineering, technical intelligence, and budget.

A further observation was the short-term orientation of mine managers. Over a four-year period, managers were mostly rotated within a two-year period. This meant that often managers inherited annual mining plans that had been committed by another manager, and that resentment grew as the inheriting manager's performance regressed.

It was, therefore, a logical conclusion that annual mine plan execution at the mines studied was too complex-with too many uncertainties, interdependencies, variations, and constraints competing for line management attention. (The fact that managers did as well as they did was commendable). The effectiveness of applied CCPM at several shafts had to take cognisance of both logical and psychological factors affecting mine planning. The following section discusses the methodology of the implementation of the solution.

CCPM applied to annual mine planning

A mine tactical plan is derived through both a bottom-up approach (an inductive approach, which results in the summation of the goals of the organization) and a top-down process derived through reductionism, where goals are broken down into constituent components. As mentioned earlier, a typical annual mining plan is derived through a comprehensive MRM process. The MRM process is usually facilitated by mine planning technologies, such as CADSMINE/Mine 2-4D. The output data could further be configured for export to basic MicrosoftTM Excel® or any other software. More often than not, the output of the MRM process marked the end of the planning phase. Subsequent phases include resource allocations and costing, which results in annual mining budgets. When the mine planning and budgeting processes have been authorized, the mine planners' role often switches to mine plan execution, monitoring, and reconciliation.

Mine plan execution was the point where CCPM was applied to the study sites in the following sequence:

Identifying the annual mining plan stoping critical chain (i.e. a schedule inclusive of a stoping critical path and crews, using basic project management technology), and establishing stoping priorities

Scheduling stoping paths backwards, according to priorities

Instituted buffers onto stoping paths (protecting each path holistically)

Configuring basic schedules for CCPM technology

Inducing active collaboration and buy-in of line management

Implementing CCPM: agreeing on cultivating a work ethic analogous to a relay race among task managers in accordance with CCPM principles, which was facilitated by technology.

Each of these items is discussed below.

Identifying the stoping critical chain

Most planners have detailed stoping plans and the corresponding crew/resource movement plans. At the study sites, the output from mine planning information was sorted and captured onto MS Projects® and the process continued as follows:

Individual stoping tasks were linked to the tactical plan cycle, and so too were the development tasks

Development and stoping schedules were integrated as a single project

Detailed construction and equipping schedules were reinvented with mine overseers and shift supervisors (including contractors) to ensure process credibility and link responsible persons for timely communication

Resources were tabulated and allocated to various development/construction/equipping/stoping tasks for the entire tactical plan

Mine plans were classified according to half-levels, defined by stoping paths for buffers to be instituted

Buffer institution and buffer management were to cater for mis-estimation and mis-considerations.

As regard the second last of these points, the stoping path comprised related tasks that had to be carried out in order to ensure stoping readiness (i.e. detailed development, construction plus equipping, and the actual stoping schedules, which were usually drafted on 1:200 plans in 'war rooms' on surface). Table I is an attempt to create a more vivid picture of the detail.

Scheduling the stoping paths backward according to priorities

Each stoping path end-date was recorded as a milestone date. These stoping end-dates were named and treated as contractual milestones (CMSs). CMS dates were pinned as fixed end-dates. The start-dates of various stoping paths were pushed out earlier, due to resource contention (automatically and dispassionately resolved according to priorities). Line management was able to receive early warnings and take decisive action to ensure that CMSs were met.

Instituting buffers onto stoping paths

Buffer institution onto stoping paths may be classified into two parts-first, agreeing on the sum of contingencies that would be used to buffer the stoping path, and second, the metrics necessary for critical information such as the rate of buffer consumption vis-à-vis stoping path completion.

Fifty per cent (50%) of task durations were used as buffers, primarily to negate the effects of both the Student's Syndrome and Parkinson's Law. Buffers were divided into three equal segments in order to provide colour-coded (green, yellow, and red) warnings of excessive rates of buffer consumption. CCPM focuses on time management as the active variable and leverage for improving cost and scope performance (passive variables)

Buffers from halved task durations were put back into the project plan as a mechanism for protecting each stoping path. Each stoping path buffer was integrated with half-level buffers. Stoping paths were simplified into stoping pipelines that enabled managers to view stoping progress against buffer consumption rates.

Configuring stoping paths for CCPM technology

The complexity of annual mine plan execution was reflected by the number of tasks that could easily be determined by the number of MS Project task numbers. When the annual mining plan was consolidated (including buffers and linkages) the network diagram was overwhelming. The need for a simplified picture and the ability to automatically track and recalculate buffers over a 24-month (2 years -the scope of annual mine plan) period necessitated the use of CCPM technology that is normally reserved for major capital project management: ConcertoTM. ConcertoTM had the ability to provide 24-hour Internet-based access for executives who had to leave the operations from time to time.

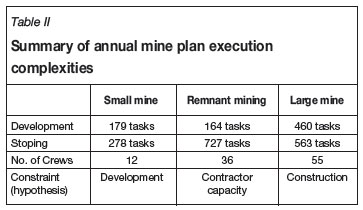

Simultaneously, ConcertoTM had to be able to provide detailed pockets of work (which we called 'job cards') for line management that covered a five-day window period (adjustable). Table II presents a summary of three mines where the MS Project® lines were quantified (only development and stoping outputs from mine planners) as a measure of execution complexity.

ConcertoTM was employed because it could easily handle the complexities without losing sight of the interdependencies. Stoping paths were configured as follows:

Half-level stoping paths from MS Projects were registered onto ConcertoTM

ConcertoTM simplified highly complex MS Project bar charts into stoping pipelines (Figure 2).

A few of the benefits Concerto brought about are listed below:

Executive-level view of projects and sub-projects with necessary details to create job cards (Figure 2)

Automatic recalculation of pipeline views

Graphs showing effective resource loading and warnings of future risk of resource overloading due to failure to complete their tasks on time

Interdependencies making it possible to detect a ripple before it became something much bigger.

At this stage the CCPM algorithms were applied to annual mine planning, and buffers were instituted in a way that protected stoping paths, half-levels and, ultimately, the entire annual mine plan. This would have been a waste of innovation if the work ethic could not be changed and buy-in from and collaboration with line management established. The buy-in process will be addressed only in brief, as it also does not form part of the scope of this paper.

Inducing buy-in from production line management

Buy-in was based on reaching consensus with line management on: whether a problem existed with managing execution of annual mine plans; whether a solution existed; and if line management was open to an alternative approach. This buy-in was started at the top of the line-the mine manager-and included stakeholders (mine unions). The process also involved empirical data gathering at the source in order to test whether the solution was appropriate for the problem.

Subsequent training was provided without disrupting work (on-site training that fitted into line management daily programmes) and was relevant to the different levels of line management. In the end broad consensus was reached to try a work ethic analogous to relay racing.

Shift supervisor buy-in and training

Training was done on a one-on-one basis by accompanying shift supervisors underground and customizing input sheets in the form of job card summaries for that particular day or week. Introductory training on CCPM was given to shift supervisors. Before the switch was made to Concerto, CCPM was applied to the shift supervisors' pre-planning and, after experiencing the simplicity of the innovation with corresponding successful realization of pre-planning, they became increasingly convinced of CCPM's usefulness.

Mine overseer training and buy-in

The buy-in process with mine overseers was made easy in that they were a party to all steps up to configuring CADSMine information for ConcertoTM. They went through the journey and appreciated the innovation. Concerto offered a valuable opportunity in that management could enjoy all the benefits of CCPM without having to learn its technicalities.

Implementing mine planning and execution buffering

As the business plan was now on project management principles, mine overseers were given project manager responsibilities, while shift supervisors were given task manager responsibilities.

Mine overseer (project manager) updates

Mine overseers had access to the overview of the half-levels that formed part of their responsibility. Figure 2 presents a screenshot of a project pipeline status that the overseers had access to. They also had access to shift supervisor screens but were not authorized to make changes. The software kept a record of all updates and changes (including who made them and when). In Figure 2 the date in purple is the original fixed end-date while the date in black is the projected date- i.e. the date based on specific work rates

Shift supervisor (task managers) updates

Figure 3 presents a screenshot of the shift supervisor screen in the form of job cards. There are only three updates a shift supervisor has to make. The first is an update in task status (as in 'NS' for 'not started', 'IP' for 'in progress', and 'CO' for 'complete); the second is an update of the remaining duration in days of the task; and the third is a comment on why the change in remaining duration needed to be made.

Any changes or updates needed to be validated and updated for the technology to work. Once the shift supervisor had updated the software, the changes were then applied to all task predecessors as well as task successors. The software automatically recalculated the remaining buffers, including the new projected completion date. Overseers and supervisors could then visualize the future impact of their actions and decisions to the half-level as well as to the annual mining plan at the time of update, which catered for the dynamics of execution management.

Also shown in Figure 3 are red and green colour codes on the left-hand side of the screen, which serve as urgency indicators on the basis of tasks that are consuming most of the buffers. The colour codes assisted the shift supervisors in our study to limit bad multitasking and kept them focused on critical tasks, and freed them to concentrate on other responsibilities such as adherence to occupational health and safety standards.

Mine managers had access to all the views and could evaluate and determine which activities were causing significant penetrations into contingencies/buffers and provide leadership on them. Managers were also able to give early warning about the impending risks on the business plan and to pinpoint where they needed assistance.

Figure 4 shows a resource loading graph. This screen helped management determine the resource loading and improve decision making regarding the reallocation of resources. The red bars indicated that the consumption rate of a buffer was faster than the rate of stoping pipeline completion. Also shown is the load-to-capacity ratio. If this ratio is more than 100%, it indicates a capacity constraint caused by resource overloading. Resource bars without colour indicate that resources are working on a task too far into the future, which is tantamount to waste (e.g. excessive off-reef development at the expense of on-reef development and holing).

Figure 5 presents a bird's eye view of effective task completion versus resource allocation. It can be seen from this figure that on April 21 limited resources were directed to completing critical tasks.

Annual mine plan buffering was applied to several shafts for up to three months. Early indications are that the buffering was successful, in support of which we have both qualitative surveys completed by line management as well as productivity performance that exceeded planned estimates.

Conclusion

The piloting of mine planning and execution buffering was based on the premise that the mining environment will always be impacted by high levels of uncertainty, interde pendency, and complexity. This paper posits that mine planning and execution were within the realms of project management. We have excluded inbound and outbound logistical considerations for the sake of brevity. The CCPM methodology and technology were applied to mine planning and execution because it focused on both project algorithms and human factors that had adverse effects on project performance. Based on the applications of this innovation at various platinum mines, within two platinum majors, the following was concluded:

Drawing of Gantt charts (bar charts) flagged misestimations and mis-considerations related to mining tasks and durations for line management before the execution phase (i.e. before the start of the annual business cycle), and necessary adjustments were made

Backward scheduling (i.e. planning from prioritized stoping) assisted in highlighting the fact that most plans should have started earlier, especially if resource allocation and costs had to be preserved, which was a key competitive advantage and in some cases critical for survival of a shaft/mine

CCPM technology was capable of managing the dynamic nature of mine planning and execution while providing visibility of buffers, both in terms of local stoping paths for shift supervisors, and holistically for the annual mining plans for senior management and executives-available on the internet/intranet on a 24hour basis

CCPM technology provided a measure of effective resource allocation, which was used for reallocation decisions to help with the recovery of the critical chain progress where this was necessary

Line management was able to isolate job cards from the whole mining plan in weekly scopes, and thereafter provide simplified updates. These updates, in turn, served to readjust the whole mining plan in accordance with current reality

Shaft queuing could be resolved dispassionately, because CCPM provided a mechanism for decision making according to the effectiveness of the annual mining plan

Line management could focus more on interpersonal issues, especially miners' empowerment to work safely

CCPM methodology and technology proved versatile as it was successfully applied to a major Enterprise Resource Program (SAP) project.

Buffering (Institution and Management) was, therefore, an effective way to manage multi-project environments such as mine planning and execution, especially after a comprehensive MRM process.

References

LEACH, L.P. Critical Chain Project Management, Artech House, Boston USA. 2004. [ Links ]

Paper received Oct. 2009; revised paper received Jun. 2011.

© The Southern African Institute of Mining and Metallurgy, 2011. SA ISSN 0038-223X/3.00 + 0.00.

* Section 54- Stoppage of mining operations after an incident or accident.

** 2Section 55-Personal liability for holders of legal appointments, guilty of MHSA contravention.

*** MHSA-Mine Health and Safety Act 29 of 1996.