Services on Demand

Article

Indicators

Related links

-

Cited by Google

Cited by Google -

Similars in Google

Similars in Google

Share

African Entomology

On-line version ISSN 2224-8854

Print version ISSN 1021-3589

AE vol.30 Pretoria 2022

http://dx.doi.org/10.17159/2254-8854/2022/a13587

RESEARCH ARTICLE

Development and evaluation of a tractor-operated automatic gun sprayer for cotton crops

Nagesh Kumar TI; M AnantacharII; M VeerangoudaII; KV PrakashII; S NadagoudaIII; BG KoppalkarIV; Sushilendra Advi RaoII; M MuraliII; V RaghavendraII

IICAR-National Institute on Natural Fibre Engineering and Technology, Kolkata, India

IIDepartment of Farm Machinery and Power Engineering, College of Agricultural Engineering, UAS, Raichur, India

IIIDepartment of Entomology, College of Agriculture, UAS, Raichur, India

IVDepartment of Agronomy, College of Agriculture, UAS, Raichur, India

ABSTRACT

A tractor-operated automatic gun sprayer was developed for a cotton crop. The unit consists of frame structure, spray tank, horizontal triplex pump, control valves, spray gun nozzle, pressure gauge, strainer, hydraulic agitator and actuating mechanism. The power to drive the HTP pump was taken from the tractor power take off (PTO) through a belt and pulley. The actuating mechanism consists of motor and worm gear reduction. Two motors with 0.5 kW each (12 V dc) were used to provide oscillation motion to spray guns and motors get power from the tractor battery. The rotation angle of the spray gun is 30° horizontally. Provision was also made to fold the spray boom while in transport. The spray pattern could be adjusted based on the application of chemicals. This study was conducted to determine the suitable nozzle orientation (0°, 15° and 30° downwards) to field crops. The orientation of the spray nozzle was maintained by using the metal protractor. The laboratory experiments were carried out by using the actual cotton plant. The best nozzle orientation for maximum droplet density and droplet size as 15° downward. Leaf hopper [Amrasca biguttula (Ishida)] and aphids [Aphis gossypii (Glover)] control in the cotton crop after 7th day of spraying dinotefuran insecticide from the automatic gun sprayer and conventional tractor-operated gun sprayer was 87, 86 and 58 %, and 50 %, respectively. The total cost required to fabricate the sprayer was US$ 1008. The cost of operation of the tractor operated automatic gun sprayer was found to be US$ 4.7/ ha.

Keywords: cost of operation, droplet density, droplet size, leaf hopper and aphids, nozzle orientation

INTRODUCTION

A continuously growing population of the world is putting an increased pressure on the available agricultural land and demand for more intensive agriculture, especially in many developing countries. Some of the ways to increase crop yield include protecting the crop from insect pests, diseases and weeds. Oerke et al. (1994) reported that in the absence of control measures, an average production loss by pests, disease and weeds are 15, 14 and 13 % respectively in cereals. Among the various methods of pest control, pesticide application is widely used for controlling disease, insects and weeds in the crops.

The cotton crop is concentrated in semi-arid regions of the country and is one of the principal commercial crops in India with a 9.5 million ha cultivated area which is the largest in the world. Though, the average yield of cotton (440 kg/ha) is low against the world average of 667 kg/ha, which is due to poor control of pests and dryland farming conditions (Gholap & Mathur (2013)). The cotton crop is infested by various pests. Among the pests of cotton, sucking pests like leaf hopper [Amrasca biguttula (Ishida)], aphids [Aphisgossypii (Glover)] and whitefly [Bemisia tabaci (Gennadius)] are deleterious to crop growth. These start feeding on the cotton plant from the early stage of crop growth up to maturity causing a significant decline in boll production. Leaf hoppers impair the photosynthesis of plants by introducing salivary toxins while sucking sap (Mohan et al. 2014). Heavy infestation on younger plants may cause the death of plants. Dhawan et al. (1988) reported that the reduction of cotton yield from leaf hopper alone was 11.60 %. Aphids deposit honey dew on leaves which become darkened due to sooty mould growth (Mohan et al. 2014). Furthermore, contamination of lint with honeydew and associated fungi leads to poor quality cotton.

Equipment used to control the pest infestation by Indian farmers are lever operated or power operated knapsack sprayer, tractor drawn boom sprayer and bullock or tractor operated gun sprayer. Spraying with a knapsack sprayer is an energy consuming operation because the operator has to carry the weight of fluid throughout entire covering area. During the spraying operation, the operator's body assumes an awkward position giving severe discomfort to the body (Tamilselvi & Krishnan 2016). Currently, in India tractor-operated boom sprayers have short boom lengths, need more number of tracks for tractor travelling which leads to less cultivation area and more damage to rows (Nalavade et al. 2008). In a conventional method of gun spraying, two persons are required to swing the gun from side to side during operation behind the bullock cart or tractor. A hand-operated gun sprayer leads to excessive application of chemicals and less uniformity of application which leads to excessive operational cost and environmental pollution. Uneven distribution is a major drawback from conventional spraying due to varying swing speed and distance by an operator. It is impossible to maintain a constant height during swinging of the lance. Availability of labour for farm work is also decreasing daily. The main drawback of the conventional gun sprayer is fatigue to the operator's hand because of the continuous swinging of the gun sprayer behind the tractor or bullock cart. On the other hand, the operator is also affected by the chemical being sprayed in front of him. To overcome the drawbacks of the conventional sprayer, the present study was undertaken to develop a tractor-operated automatic gun sprayer for a cotton crop and the performance of the sprayer was evaluated in the laboratory and field conditions. The biological efficacy of the sprayer was compared with a conventional tractor operated gun sprayer.

MATERIALS AND METHODS

A prototype of the tractor-operated automatic gun sprayer for spraying of chemicals for a cotton crop has been developed and fabricated by considering crop and machine parameters. The development of tractor-operated automatic gun sprayer was carried out in the central workshop, Department of Farm Machinery and Power Engineering, CAE, University of Agricultural Sciences, Raichur, Karnataka, India. The essential components of the sprayer are the frame structure, spray tank, horizontal triplex pump, control valves, spray boom, pressure gauge, strainer, hydraulic agitator and actuating mechanism for spray guns. Rear view of the tractor-operated automatic gun sprayer is shown in Figure 1. The power to drive the 3 hp (horsepower) horizontal triplex pump was taken from tractor PTO through a belt and pulley. For cotton and red gram, application rate ranges from 125 to 450 l/ha depending on the equipment used (Shukla et al. 1987). A plastic chemical tank of 500 l capacity was selected to avoid frequent refilling. The pressure regulator maintains working pressure on the discharge end of the system but moves the overflow back into the tank.

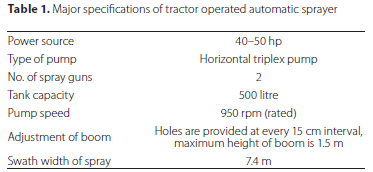

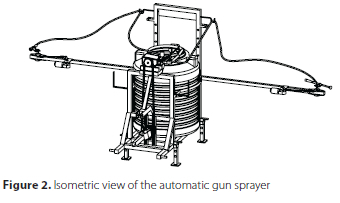

The specification of the developed sprayer is presented in Table 1. Isometric view of the automatic gun sprayer is shown in Figure 2.

Frame structure

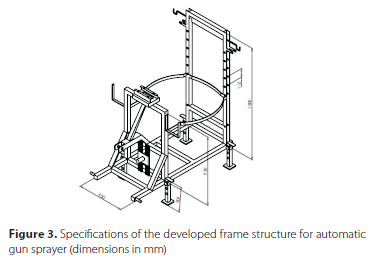

The frame has a box section at the bottom to hold the chemical tank. A frame of 1000 mm x 630 mm x 920 mm was fabricated from 50 mm x 50 mm hollow square mild steel. At the front end of the box, two hitches were provided for attachment to the tractor lower link. At the top of the front portion of the box, a rectangular frame was welded rigidly to serve as a support for the pump. Just below the rectangular frame, top hitch was provided to attach the tractor top link. The inner section of the box could accommodate 500 l chemical tank. Holes were provided at either side of the rear frame to attach the boom. For support and to hold the delivery pipes, hooks were provided at the top of the rear frame. Specifications of the developed frame structure for the automatic gun sprayer are shown in Figure 3.

Supporting frame for pump

The rectangular frame of 180 x 240 x 50 mm (W x L x H) was fabricated by using mild steel L-channel. The supporting frame was welded at the top of the frame structure. The pump was mounted on the supporting frame by using nuts and bolts.

Spray boom

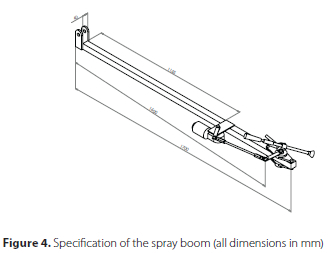

The boom was attached to the rear portion of the frame structure. The boom was fabricated using 35 mm x 35 mm hollow square mild steel with a thickeness of 3 mm. One side of the boom has a locking arrangement. The boom of 1.7 m was provided on either side of the frame separately. The actuating mechanism and spray guns were provided at the ends of the boom. Boom height can be adjusted to the required height by attaching the boom to holes provided on the bottom frame structure. Holes were provided at 150 mm intervals. Provision was also made to fold the spray boom while in transport. Specification of the spray boom is shown in Figure 4.

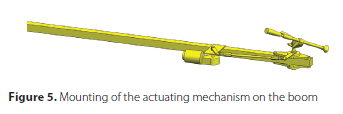

Actuating mechanism for spray guns

The actuating mechanism provides power to the spray guns to move back and forth. The actuating mechanism consists of motor and worm gear reduction. A worm gear is attached to the output shaft of the motor. This worm gear spins around as the motor turns. The worm gear is connected to a long rod, as the gear rotates it moves the rod and in turn provides an oscillation motion to the spray guns. The worm gear and rod convert the rotational output of the motor into a back and forth motion to spray guns. Two motors with 0.5 kW each (12 V dc) were selected based on the power required to move the spray gun. The motors are powered from the tractor battery. Mounting of the actuating mechanism on the boom is shown in Figure 5.

Spray guns

Two spray guns are mounted on the boom at either side of the frame structure. These get a swinging action by the actuating mechanism. Nozzles are mounted on the 45 cm lance. The spray pattern can be adjusted as required. The angle of rotation of each spray gun is 30° horizontally. Pesticide was supplied to each gun separately to reduce the hydraulic losses.

Control valves

The delivery from the pump is provided with two control valves, i.e. two-way cock, pressure relief valve. The pressure regulator maintains working pressure on the discharge end of the system but moves the overflow back into the tank at lower pressure. The chemical fluid is supplied to the two spray guns by a two-way cock.

Laboratory evaluation of the tractor-operated automatic gun sprayer

The laboratory calibration of the sprayer was carried out in the same way as prescribed by the BIS code of IS: 11429 (1985): Methods for calibration of sprayers. The tractor PTO was 400 rpm and speed at the pump was 950 rpm (rated). It was operated at half throttle as the power required for the HTP pump was low. The sprayer was calibrated in the laboratory at a pump speed of 950 rpm and varying supply pressures. Discharge from individual spray guns was collected separately and analysed for variation. Length of throw was measured from the nozzle tip to the last point where the water reaches. Length of throw was measured by using a steel tape.

A separate study was conducted to determine the suitable nozzle orientation (0, 15 and 30° downward) to field crops. The orientation of the spray nozzle was maintained by using a metal protractor. The operating pressure of 20 kg/cm2 was maintained throughout the experiment. The laboratory experiments were carried out by using the actual cotton plant. The cotton plants were raised in polyethylene bags and after a certain age were placed in pots (Gholap et al. 2012). This was an attempt to establish an actual plant canopy in the laboratory to get the correct results. The droplet density and diameter of the spray with 2 mm nozzle size were measured. Height of the spray nozzle was maintained at 300 mm above the plant canopy. Methylene blue MS dye mixed @ 5 g/1 in water and glossy paper were the same as that used by Jassowal et al. (2016). The dye mixed with water was sprayed on the crop. When the sprayed material dried, the glossy paper strips (7.5 x 2.5 cm) were collected for analysis in the laboratory using DepositScan software.

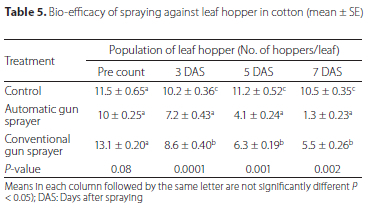

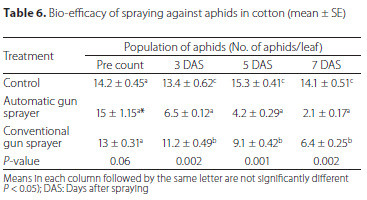

Biological efficacy of sprayer

The main sucking pests present in cotton were aphids [Aphis gossypii (Glover)] and leaf hopper [Amrasca biguttula (Ishida)]. Dinotefuran Insecticide was used to spray and it was mixed with water with a recommended dose of 150 g/500 l (Anon. 2017). For calculation of biological efficacy of insecticide, the number of pests in the field was counted from 10 randomly selected plants. The pests were counted from a total of three leaves of a plant, i.e., upper and lower side was recorded before and after the spray. The pests count was further recorded on 3rd, 5th and 7th day after spraying. The difference in the number of pests before and after the spray was noted to calculate the percentage reduction of pests. The insecticide used (dinotefuran (Osheen)) was mixed with water with a recommended dose 150 g/ 500 l. Duncan multiple range tests using the SPSS 9.0 program for significance and interaction effects.

RESULTS AND DISCUSSION

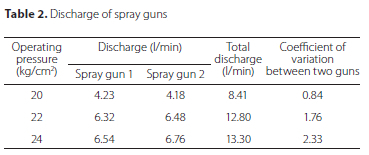

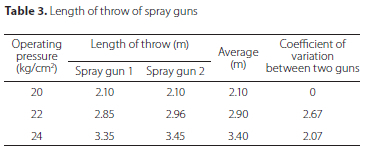

The discharge rate and length of throw from the spray guns and their variation is presented in Tables 2 and 3. The total discharge varied from 8.41 to 13.30 l/min as operating pressure was varied from 20 to 24 kg/cm2. The maximum coefficient of variation (2.33) was observed for 24 kg/cm2 which was acceptable under field conditions. The maximum length of throw was 3.40 m from the tip of the nozzle. The length of throw and pattern of spray can be changed by adjusting the handle to 180° from shutoff to maximum flow position. Spray pattern could be changed from mist or jet depending on the application of chemicals.

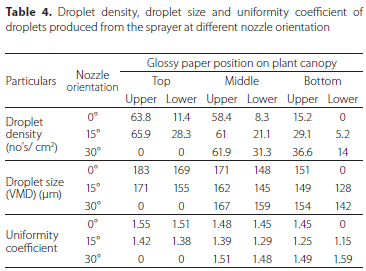

The effect of three different nozzle orientations on the droplet characteristics (droplet size, density and uniformity) is shown in Table 4. The droplet density received on the lower side of the leaves at 0° orientation of nozzle was less compared to other angles. This is because the spray nozzle was over the plant canopy. Most of the spray droplets fall on the top surface of the plant than the lower surface. Plant leaves also offer some resistance of the spray to penetrate deep into the canopy when the spray nozzle was over the plant. The droplet deposition on both the upper and lower surfaces of the plant canopy was maximum when the orientation of the nozzle was 15°. Good deposition of droplets was attributed to nozzle orientation. The nozzle was inclined to the plant and height between the crop and nozzle was less. Both upper and lower leaves were directly exposed to spray deposition. Spray droplets penetrated to the various positions of the plant canopy due to the hydraulic energy of the spray droplets. As the orientation of the spray nozzle changed from 15 to 30°, most of the spray was directed to the middle and bottom positions of the plant. It was also observed that most of the spray solution reached the ground surface. For mobile insects, the droplet densities of 20-30/cm2 and in most cases sedentary pests would co-exist with other pests, a threshold limit of droplet density of 40/cm2 was considered necessary (Gupta et al. 2011). It may be seen that droplet densities obtained were sufficient to kill the pests and insects, except at the bottom of the canopy. Keeping in view of droplet density throughout the canopy, 15° orientation of the spray nozzle was chosen for field studies.

The orientation of the spray nozzle did affect the droplet size and uniformity of droplets (Table 4) but they largely affected the deposition on different positions of the plant canopy. The droplet size produced at different nozzle orientations varied from 128-183 |im which is recommended size for suppressing most of the insect pests in cotton crop. Jain et al. (2006) stated that recommended droplet size for control of most pests and diseases in the cotton crop is 100-200 |im. The droplet size observed at 15° orientation of the spray nozzle was within the recommended values. Uniformity of coefficient of spray droplets ranged from 1.15-1.55 indicates sprayer produces a narrow droplet spectrum.

The performance of the tractor-operated automatic gun sprayer was carried out in the farmer's field by considering the 15° orientation of the spray nozzle. The field capacity, field efficiency, application rate and fuel consumption of the tractor was 1.25 ha/h, 80 %, 435 l/ha and 3.2 l/h, respectively.

Biological efficacy of the sprayer for control of leaf hopper and aphids in cotton

The biological efficacy of dinotefuran recommended dose of 150 g/500 l for control of leaf hopper and aphids in cotton by using two sprayers are shown in Tables 5 and 6. The leaf hoppers ranged from 11.5, 10, and 13 per leaf a day before spraying and there was no significant difference among treatments. All the sprayers were effective in reducing the population of aphids and leaf hoppers of cotton over control. There was a significant decrease in the population of leaf hopper and aphids that were recorded in automatic tractor-operated gun sprayer compared to a conventional gun sprayer. Leaf hopper and aphids control in the cotton crop after 7 days of spraying from the automatic gun sprayer and conventional tractor-operated gun sprayer was 87 %, 86% and 58%, 50%, respectively. Nageshkumar et al. (2018) reported that the highest decrease of population of leaf hopper and aphids was found from the automatic gun sprayer compared to a conventional gun sprayer due to higher level of deposition on the leaves. The deposition of spray on the leaves depends on the orientation, type of nozzle, spray volume and speed of operation. Other important spray characteristics influencing the efficacy of spray particle is spray angle, spray shape and volume distribution pattern (Minov et al. 2014). The degree of coverage on the target with individual droplets determines biological efficacy. The more droplets per unit area, the better will be the efficacy of the spray. The developed sprayer produced recommended droplets for suppressing pests compared to the conventional tractor-operated sprayer.

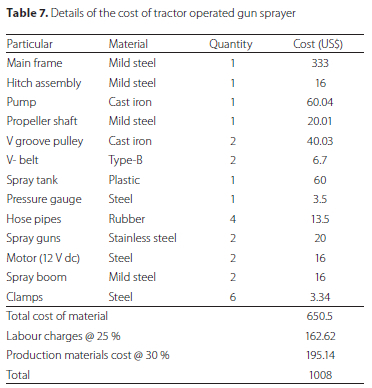

Cost of operation

Cost for material and construction of the tractor-operated automatic gun sprayer was estimated (Table 7) as around US$ 1008 (1 US$ = 74.95 INR). The cost of operation of the tractor-operated automatic gun sprayer was found to be US$ 4.7/ha. The breakeven point and payback period of the sprayer in cotton was 87.8 hours per annum and 1.48 years, respectively.

CONCLUSION

The best nozzle orientation for maximum deposition was optimised as 15°. The droplet size and droplet density produced were maximum when nozzle orientation as 15°. By adjusting the control valve position, the quantity of chemical can be varied. The coefficient of variation of discharge and length of throw was in an acceptable range. The droplet size produced satisfies the requirement for maximum deposition. The leafhopper control in the cotton crop, in contrast to conventional tractor operated gun sprayer 7 days after spraying by using dinotefuran insecticide had a biological efficacy of 87 %. It was also observed from the study that bioefficacy not only depends on the sprayer parameters but also depends on the type of Insecticide and concentration. The cost of operation of the tractor-operated automatic gun sprayer was found to be US$ 4.7/ ha. The developed sprayer could be used for spraying orchard crops by mounting the spray boom vertically

ACKNOWLEDGEMENT

We wish to acknowledge the university grant commission (India) for providing financial support to carry out the experiment.

AUTHORS' CONTRIBUTIONS

This work is carried out in collaboration with all authors. Author Nageshkumar carried out the experiment and prepared a draft copy of the research paper. Anatanachar and Veerangouda helped in the preparation of the manuscript. Author Prakash corrected the manuscript and suggested vital inputs to the manuscript and Sushilendra corrected the manuscript and suggested vital inputs to the manuscript. Murali, M and V Raghavendra conducted statistical analysis and data interpretation. Sushil Nadagouda and Koppalkar helped me to measure the droplet size and droplet density. All the authors read and approved the manuscript.

ORCID IDs

Nagesh Kumar, T - https://orcid.org/0000-0003-2566-9109

REFERENCES

Anonymous. 2017. Package of practice for crops. University of Agricultural Sciences, Raichur. Karnataka, India.

Dhawan AK, Sidhu AS, Simwat GS. 1988. Assessment of avoidable loss in cotton (Gossypium hirsutum and G. arboreum) due to sucking pests and bollworms. Indian Journal of Agricultural Sciences 58(4): 290-292. [ Links ]

Gholap B, Mathur R. 2013. Field evaluation of tractor operated boom sprayer of cotton crop. International Journal of Agricultural Engineering 6(2): 372-374. [ Links ]

Gholap B, Mathur R, Dande KG. 2012. Laboratory performance evaluation of 12 m tractor mounted boom sprayer for cotton crop. International Journal of Agricultural Engineering 5(1):31-36. [ Links ]

Gupta P, Sirohi NPS, Kashyap PS. 2011. Effect of nozzle pressure, air speed, leaf area density and forward speed on spray deposition in simulated crop canopy. Annals of Horticulture 4(1): 63-71. [ Links ]

Jain SK, Dhande KG, Aware VV, Jaiswal AP. 2006. Effect of cone angle on droplet spectrum of hollow cone hydraulic nozzles. Agricultural Mechanization in Asia, Africa and Latin America 37(1): 51-53. [ Links ]

Jassowal NS, Singh SK, Dixit AK, Rohinish K. 2016. Field evaluation of a tractor operated trailed type boom sprayer. Agricultural Engineering Today 40(2): 41-52. [ Links ]

Minov V, Cointault F, Pieters JG, Nuyttens D. 2014. Spray nozzle characterization. Aspects of Applied Biology 122: 353-363. [ Links ]

Mohan S, Monga D, Kumar R, Nagrare V, Nandini G, Vennila S, Tanwar RK, Sharma OP, Someshwar B, Meenu A, et al. 2014. Integrated Pest Management Package for Cotton. National Centre for Integrated Pest Management, New Delhi: India.

Nageshkumar T, Anantachar M, Veerangouda M, Prakash KV, Nadagouda S, Koppalkar BG. 2018. Bio-efficacy of tractor operated automatic gun sprayer. International Journal of Current Microbiology and Applied Sciences 7(8): 3174-3177. https://doi.org/10.20546/ijcmas.2018.708.339 [ Links ]

Nalavade PP, Salokhe VM, Jayasuriya HPW, Hiroshi N. 2008. Development of a tractor mounted wide spray boom for increased efficiency. Journal of Food, Agriculture and Environment 6(2): 164-169. [ Links ]

Oerke EC, Dehne HW, Schoenbeck F, Weber A. Crop Production and Crop Protection. Amsterdam, The Netherlands: Elsevier; 1994. [ Links ]

Shukla LN, Sandhar NS, Singh S, Singh J. 1987. Development and evaluation of wide-swath tractor-mounted sprayer for cotton crop. Agricultural Mechanization in Asia, Africa and Latin America 18(2): 33-36. [ Links ]

Tamilselvi P, Krishnan A. 2016. Ergonomic evaluation of conventional agricultural sprayers with respect to human performance. Journal of Agricultural Science Digest 36(3): 179-184. [ Links ]

Correspondence:

Correspondence:

Nagesh Kumar T

Email: nagesha.kumar88@gmail.com

Received: 25 November 2020

Accepted: 1 October 2021