Serviços Personalizados

Artigo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares em Google

Similares em Google

Compartilhar

South African Journal of Enology and Viticulture

versão On-line ISSN 2224-7904

versão impressa ISSN 0253-939X

S. Afr. J. Enol. Vitic. vol.43 no.1 Stellenbosch 2022

http://dx.doi.org/10.21548/43-1-4931

ARTICLES

Technological Advances in Winery Wastewater Treatment: A Comprehensive Review

D.E. Vlotman*; D. Key; B.J. Bladergroen

South African Institute for Advanced Materials Chemistry (SAIAMC), University of the Western Cape, Robert Sobukwe Road, Bellville, Cape Town 7535, South Africa

ABSTRACT

The commercial production of wine is directly linked to the use of large amounts of fresh water coupled with the generation of copious amounts of wastewater containing significant amounts of organic and inorganic substances. The impact of this waste stream on the environment has required the wine industry to implement certain protocols in wastewater management to comply with respective effluent discharge regulations as set out by local authorities. Reduced accessibility to good quality water resources in recent years has forced wineries to consider more efficient wastewater management strategies to improve water recovery and re-use, thereby promoting more sustainable wine production and minimizing the impact on stressed water resources. This review presents a comprehensive overview of established and emerging, physicochemical, biological, advanced oxidation and hybrid wastewater treatment technologies specifically applicable to the wine producing industry. Herein, winery wastewater composition and treatment techniques, environmental implications, knowledge gaps, technological operational challenges, alternative disposal and recycling options of treated winery wastewater are critically evaluated.

Key words: Winery wastewater treatment, biological wastewater treatment, inorganic contaminants, COD reduction, hybrid wastewater treatment, sustainability, sodium, potassium

INTRODUCTION

Agriculture accounts for roughly 70% of all freshwater withdrawals worldwide, and up to 95% in developing countries, with the wine industry covering three sectors of the economy: agriculture, manufacture and trade. (FAO, 2011; Gebrehiwot & Gebrewahid, 2016). In 2018, South Africa exported 420 million litres of wine which were equivalent to €663m of revenue. South Africa's wine industry also contributes to the country's Gross Domestic Product (GDP), covering 9% of total GDP for the whole country (Amfori., 2018). The wine production sector produces large volumes of contaminated wastewater consisting of significantly high concentrations of organic and inorganic substances (Iloms et al., 2020). In general, 3 to 5 m3 of winery wastewater is produced per ton of grapes crushed (Kookana & Kumar, 2006). To put this into context, the South African wine industry crushed a total of 1.2 million tons of grapes in the 2018 to 2019 season indicating that the total volume of wastewater generated during this vintage season was approximately 3.6 to 6 million m3 (SAWIS, 2019). In comparison, the Californian wine production sector in the USA crushed a total amount of 3.5 million tons of grapes during 2020, indicating a total volume of wastewater generated during this specific vintage season of approximately 10.5 to 17.5 million m3 (United States Department of Agriculture, 2020). This is a cause for concern since limited water resources, and an ever-increasing population growth have made the scarcity of adequate quality water a challenge throughout the world (Zeng et al., 2013; Ahmadi & Merkley, 2017). The increasing volume of winery wastewater being generated also presents additional challenges related to sustainable discharge which is exacerbated by the quantity, quality and consistency of winery wastewater which fluctuates seasonally and often contains materials hazardous to the environment thus making proper disposal an essential task (Devesa-rey et al., 2011).

Wineries operate as individual entities with their size and winemaking procedures often differing significantly which subsequently correlates to the variation in amount and quality of wastewater generated during the vinification process. Winery wastewaters have high chemical oxygen demand (COD), high levels of total suspended solids (TSS), low pH and fluctuations in salinity and nutrient levels, all of which indicate that these wastewaters may potentially pose an environmental threat (Mosse et al., 2011). The variations in the levels of these parameters are discussed later in this review.

The notable environmental impacts of winery wastewater are related to the pollution of water streams, soil degradation, vegetation damage due to wastewater disposal practices and foul odour mainly due to high organic load present in these wastewaters (Chatzilazarou et al., 2010). Most wineries have some form of treatment in place for processing their wastewater, however, alternative methods are continuously being researched and proposed which are aimed at (i) maximizing both efficiency and flexibility of the treatment process in handling fluctuations in impurity concentrations (organic and inorganic species) and effluent volumes, (ii) capital cost moderation, (iii) ease of operation and maintenance, (iv) a smaller footprint and finally (v) meeting specified discharge requirements for winery effluents (Maicas & Mateo, 2020).

Wineries are encouraged to irrigate their wastewater by the Department of Water and Sanitation (DWS) in South Africa however the intended end-use must be registered before irrigation can commence. Upon successful application of intent to irrigate wastewater, the guidelines as stipulated by the General Authorization (Table 1) must be adhered to (Department of Water Affairs, 2013). These authorizations also states that no ground or surface water contamination may take place and over-irrigation waterlogging and destruction of soil properties must be prevented at all times (Howell & Myburgh, 2018).

As different wineries generate vastly different volumes and contaminants concentrations of wastewater, plans to adopt common environmentally friendly and sustainable waste management systems are practically unfeasible and a "one size fits all" universal treatment technique that can be used by all wineries does not seem to exist. It is therefore imperative to have a fundamental understanding of the sources and fate of winery wastewaters to have a realistic approach to the selection of specific treatment technologies to be implemented. This can be managed by having control of what gets into the flow of the waste stream from the winery in the first place, which will then allow control of the quality of wastewater. In order to be able to manage winery wastewater and their potential environmental impacts, wineries should identify what the potential pollutants are, how and where they are generated and which management options are available to minimize their impacts (Chapman et al., 2001). The following section provides a description of the contaminants and their detection parameters commonly found in winery wastewater. The identification of winery wastewater characteristics will give insight to the types and concentration of contaminants to be aware of and subsequently allow wineries to adopt a suitable treatment technology based on the average level of contaminant concentration found in their respective wastewater.

WINERY WASTEWATER CHARACTERISTICS

Wastewater produced during commercial winemaking is diverse in terms of the constituents commonly found therein and these also differ between different sized wineries. The wine making process has five well-defined stages: (i) harvesting, (ii) crushing, (iii) fermenting, (iv) racking and clarification as well as (v) aging and bottling. During the harvest period, 80% of winery wastewater is generated in small wineries whereas medium to large wineries with continuous production generate roughly 50% of their wastewater in the same period (Howell et al., 2016).

The amount of winery wastewater generated on average ranges from 0.2 to 4 L to produce 1 L of wine (Welz et al., 2016). Winery effluents are usually characterized by their low pH (pH 4 to 5) which is mainly attributed to the presence of organic acids such as lactic, tartaric, citric and malic acid and succinic acid (Smagghe et al., 1992; Conradie et al., 2014). Electrical conductivity (EC) of winery wastewater is reported to be in the range of 1.62 to 6.15 mS/cm (Mulidzi et al. , 2018). Total nitrogen and total phosphorous nutrient levels in winery wastewater range between 100 to 640 mg/L and 240 to 657 mg/L, respectively (Melamane, Strong, et al., 2007; Bustamante et al., 2008). The chemical oxygen demand (COD) is an important parameter used to quantify organic pollution in wastewater. In winery wastewaters, the COD mostly consist of highly soluble alcohols, sugars, recalcitrant compounds (e.g., polyphenols), acids, tannins, and lignin (Bolognesi et al., 2020). The concentration of COD commonly found in winery wastewater have been documented to have a minimum concentration of 340 mg/L, mean concentration of 11 554 mg/L and reaching maximum concentration levels up to 296 119 mg/L (Shepherd, et al., 2001; Mosse et al., 2011; Bolognesi et al., 2020). Detailed studies on winery wastewater composition have concluded that 90% of the organic load is represented by ethanol and sugars (glucose and fructose) (Masi et al., 2015).

The presence of these previously mentioned organic and inorganic compounds in untreated winery wastewaters may cause salination and eutrophication of water resources (natural streams, rivers, dams) and also lead to soil salinity and contamination of soil with a wide range of chemicals if untreated wastewater is discharge via irrigation (Van Schoor, 2005). Generally, the quality of treated winery wastewater largely depends on the composition of chemicals added during wine-making operations and the efficacy of the wastewater treatment plant (Pedrero et al., 2010).

Winery waste can be categorized in two sections: (i) solid wastes (seeds, pomace, lees etc.) produced during destemming, pressing and settling and (ii) wastewater (wash and rinse water, as explained below) (Howell et al., 2016). Solid wastes (grape pomace) are made up of skin, stem, residual pulp, seed, stalks, and yeast cells from the fermentation process (Christ & Burritt, 2013). The polluting compounds found in winery wastewaters can be further divided into organic and inorganic pollutants. To create a better understanding of the complexity of winery waste, the different chemical constituents found in wine (which contribute both to organic and inorganic pollution in wastewater) are illustrated in Table 2.

Briefly, wine consists of water, alcohols, sugars, acids, phenols nitrogenous compounds, vitamins and volatile compounds each of which contribute to the unique aromas and taste sensation of the wine which eventually affects its perceived quality. The wastewater generated during wine making procedures are abundant in potassium (K+) and sodium (Na+) salts mainly due to the naturally occurrence of K+ (Buelow et al., 2015). The concentration of K+ and Na+ in winery wastewater is of particular importance when the wastewater is intended to be used for irrigation in vineyards since these ions significantly contribute (with K+ contributing more than Na+) to soil fertility but in excess are harmful to plant growth. The prevalence of these ions is also related to caustic cleaning agents used during wine production. A typical cleaning process involves the use of caustic cleaning agents such as NaOH and KOH to remove solid deposits of tartrate and other organic acids typically stuck on the inside of vessels and equipment. Thereafter, dilute citric/tartaric acids are used as acidic agents to wash out caustic residues. Finally, clean water is used to remove traces of the cleaning agents (Chapman et al., 2001).

Table 3 displays a summary of common pollutants and detection parameters found in winery wastewater. Apart from the organic matter, nitrogen and phosphorous are of major concern since their presence in the wastewater (if released) may lead to eutrophication, and the demise of aquatic organisms (Welz et al., 2016).

The commonly found classes of contaminants in winery wastewater, their sources and environmental effects is described below in Table 4. Sources of organic contaminants such as phenols, ethanol and sugars arise from grape juice, wine and lees which also contribute to the prevalence of nutrients such as nitrogen and phosphorus in winery wastewater. Their environmental effects include foul odours, and an excess of nutrients in the wastewater.

Cleaning processes significantly contribute towards wastewater volumes generated from wineries. The primary winemaking processes effects on winery wastewater generation and the impact on wastewater quality are summarized in Table 5. Herein, possible environmental effects which impinge on legal wastewater quality parameters are also illustrated (Van Schoor, 2005). Based on the contribution of these processes to winery wastewater, it is clear that at least one form of treatment is required to meet environmental standards as discussed in the following section.

WINERY WASTEWATER TREATMENT

When water-use and the contaminants in waste streams are well understood, measures can be put in place to enhance the quality of the wastewater and reduce its quantity. This will determine which treatment technology is best suited for a specific winery's needs (treated wastewater end use). In order to select which treatment technology to adopt, it is important to take note of the following:

I. Winery wastewater characteristics,

II. effluent quality requirements (e.g., irrigation/ municipal discharge etc.),

III. space availability of the winery, capital and annual budget and the technical expertise required to operate the treatment system.

If the above factors are critically evaluated by wineries, the treatment options discussed below may provide adequate information on the selection of a "fit for purpose" treatment technology based on the end use of the treated wastewater.

WINERY WASTEWATER TREATMENT TECHNOLOGIES

Various wastewater treatment methods have been investigated with the aim of attempting to alleviate wastewater disposal issues faced by wineries (Mosse et al., 2011; Mosse et al., 2012; Adesoji & Joseph, 2016; Johnson & Mehrvar, 2020). The re-use of winery wastewater via irrigation of agricultural land is becoming a common practice. However, these wastewaters contain dissolved potassium and sodium ions, which can adversely affect the soil chemistry and physical structure as well cause a reduction in hydraulic conductivity in soil (indication of ease of passage of water through soil). Lower hydraulic conductivity denotes less permeable soil (Yu & Ahmedna, 2013). Irrigation using potassium rich water has been reported to benefit the overall soil fertility, however, long-term application can lead to a transformation of the soil physicochemical properties (Chapman et al., 2001; Yu & Ahmedna, 2013). Elevated concentration levels of potassium and sodium (800 to 1 000 mg/L) in winery wastewater reduce the infiltration rates of water and oxygen due to swelling and dispersion (which leads to soil crusting and slaking). In addition, long term irrigation with winery wastewater leads to poor aeration which ultimately results in oxygen deficiency and restriction of plant root growth (Arvanitoyannis et al., 2006).

In most cases, wineries adopt a combination of treatment phases which include preliminary, primary, secondary and tertiary treatment phases. A final clean up step is also commonly used for disinfection of the treated effluent, which is largely dependent on its end use. This paper will focus on three basic treatment variations with a range of derivative methods which can accomplish wastewater treatment objectives if used in a suitable combination: (i) physicochemical treatment, (ii) biological treatment and (iii) advanced oxidation treatment. Fig. 1 below illustrates typical practices during winery wastewater collection and treatment options.

Preliminary Winery Wastewater Treatment

Most wastewater treatment involves at least one physical treatment stage primarily to settle out the solid substances present in the wastewater. This is a straightforward step being simple, effective and also aids in the prevention of primary and secondary treatment equipment from becoming clogged with solids like seeds, stalks and leaves (Mosse et al., 2011). This preliminary treatment phase involves the use of screens/ grits to remove large matter (skins, pips, stems and lees) for particle sizes greater than 500 urn, whereas filters are used for particles in the range of 100 to 500 (Day et al., 2011).

Primary Physicochemical Treatment Methods

Physicochemical treatment methods (a combination of physical and chemical treatment methods) involve the use of chemicals to change the physical state of colloidal particles, altering their stability and making these particles more coagulable for further treatment (Bellie et al., 2015). This treatment method may have a substantial effect on organic material's biodegradation potential in winery wastewater. Chemically assisted settling by means of flocculation is widely used for fine particles with particle size less than 10 nm (Kyzas et al., 2016). Physicochemical treatment can separate suspended solids/matter from wastewater using coagulation/flocculation, sedimentation tanks, centrifugation and microfiltration. Physicochemical treatment has most commonly been used as pre-treatment to reduce organic load and turbidity (increase clarity) of winery wastewater prior to biological treatment (Prajapati & Chaudhari, 2015). Some of the advantages of physicochemical treatment methods are: (i) reduction of sludge build-up and wear on treatment pumps, (ii) reducing BOD concentration before discharge or reuse and (iii) the enhancement of treatment efficacy via the addition of chemicals (e.g., pH adjustment can rapidly settle solids) as well as improvement of the suitability of the wastewater for disposal on land (Kyzas et al., 2016).

Various other physicochemical treatment methods have been implemented in winery wastewater treatment and include chemical precipitation with chelating agents, coagulation/ flocculation, electrocoagulation and sedimentation (Ioannou et al., 2015). Coagulation and flocculation are among the most used primary treatment methods of winery wastewater.

Coagulation and flocculation

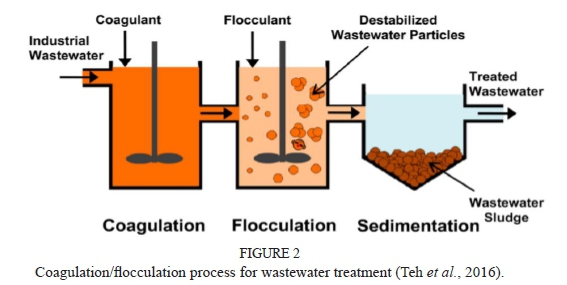

In this treatment technology, the typical parameters assessed to evaluate the treatment efficiency are TSS, turbidity and COD. The aim of coagulation/flocculation is to agglomerate fine particles into flocs of large particles which can be removed to reduce turbidity, natural organic matter and inorganic matter present in the wastewater (Malik et al., 2017). This process involves (i), rapid mixing of dispersed coagulant into the liquid matrix via harsh agitation and (ii), agglomeration of small particles into well-defined flocs via flocculation with moderate agitation. Thereafter, flocs are settled out (via sedimentation) and removed as sludge while the treated water may either be discharged or transferred to a further (upstream) treatment process (Teh et al., 2016). Coagulation occurs when a coagulant, for example aluminium and iron salts (e.g., aluminium sulphate, aluminium chloride, ferric chloride, ferrous sulphate etc.) is added and rapidly mixed with the winery wastewater (Bellie et al., 2015). The coagulant's role is to neutralize and destabilize the (usually) negative charges on the surface of colloidal particles. Without these coagulants, colloids may form a stable suspension with particle sizes in the range 0.01 to 1 μm (Braz et al., 2010). Following the destabilization of colloidal suspensions and the addition of flocculants, sedimentation has been historically employed and has been reported as an effective pre-treatment process that can lower TSS, turbidity and in some cases the COD of winery wastewater (Lofrano & Meric, 2015). Sedimentation involves the separation of particles in suspension based on gravitational force, derived from the difference in density between particles and the fluid. Sedimentation can either be used before coagulation to reduce the amount of coagulant chemicals needed or after coagulation or flocculation where its purpose is to reduce the concentration of solids in suspension and thereby subsequently reducing the concentration load prior to upstream processes like filtration (Carlsson, 1998). Fig. 2 illustrates a typical coagulation/ flocculation and sedimentation process.

Andreoletta et al. (2007) investigated the efficacy of a pre-treatment procedure derived from chemical precipitation with chelating agents (2,4,6-trimercaptotriazine (TMT)) and monitored the reduction in concentration of suspended solids and heavy metals (Cu and Zn) with raw winery wastewater COD concentration in the range of 3 090 to 7 438 mg/L. The authors conducted lab-scale experiments based on jar tests to determine optimum TMT dosages and metal removal efficiency, followed by a pilot scale investigation. In their study, chemical precipitation was achieved by adding (1) NaOH for pH correction; (2) TMT at dosage of 0.84 mL of TMT (15%) for 1 mg of Cu removed; (3) cationic polymer and polyelectrolyte (flocculants) and finally settling. The authors reported significant reduction of TSS from 281 to 28 mg/L (90% reduction) and heavy metals with Cu averaging from 1.09 to 0.041 mg/L (96% reduction) and Zn from 0.68 to 0.154 mg/L (76% reduction). This was an important finding since the discharge limit into public sewage as stipulated by Italian regulations for Cu and Zn at the time of their research were 0.4 mg/L and 1.0 mg/L, respectively. The removal of COD values using TMT in their study was however less than 9% (from 4 720 to 4 302 mg/L). This reduction of approximately 418 mg/L was attributed to the reduction of COD particulate matter and the precipitation of suspended solids. The authors stated that the reason why only 9% reduction of COD was achieved may be due to roughly 92% of organic matter in the winery wastewater being in soluble form, and that chemical precipitation is ineffective in removing dissolved compounds (Andreottola et al., 2007). An economic study was also conducted to evaluate the treatment cost of winery wastewater which include factors such as chemical dosages, plant management, electricity, sludge disposal effluent quality control and taxes (discharge to municipality). The average treatment cost of winery wastewater using the previously mentioned factors was estimated to be € 14.6 (roughly R260) per cubic meter of wastewater treated for high-quality wineries located in the Province of Trento, Italy.

Rytwo et al. (2011) used a two-step process with raw sepiolite (0.1%) and crystal violet modified sepiolite (0.1%) for the reduction of dispersed solids in winery effluents, bringing about large particles. The authors investigated the effect of the two-step procedure comparing both raw (pH 4.9, COD 4 940 mg/L) and pH corrected (pH 7.0, COD 2 120 mg/L) wastewater. This method reduced TSS by 96% (from 1 600 mg/L to 70 mg/L) for pH corrected effluent and by 98% (from 1 400 mg/L to 10 mg/L) for raw effluent. The turbidity of the treated effluent was also decreased between 55 to 65% of the original values for pH corrected (initial value of 163.3 NTU) as well as raw effluent (initial value of 130.3 NTU). The COD reduction was between 20 to 40% for both treated and untreated samples and the authors stated that this may be due to a significant amount of dissolved organic matter present in the wastewater that does not coagulate (Rytwo et al., 2011).

In a different study conducted by Rizzo et al. (2010), the treatment of winery wastewater using chitosan as a natural organic coagulant was investigated as an alternative to conventional metal-based coagulants and evaluated its potential to generate reusable organic sludge. The chitosan reduced turbidity (92%, with an initial turbidity of 180 NTU), COD (73%, with an initial COD of 1 550 mg/L) and TSS (80%, with an initial TSS of 750 mg/L) all of which occurred at an optimum chitosan dosage of 20 mg/L with pH 6.8. In their study, lower than optimum chitosan dosage (<20 mg/L) was also investigated where bridging of particles occurred and aggregates were still observed to be effectively settled. In contrast, an excess of chitosan dosage caused an inversion of particle charge in suspension due to a higher positively charged chitosan-solid aggregate formation rate. This resulted in an electrostatic repulsion which subsequently led to less effective settling (Rizzo et al., 2010).

Braz et al. (2010) reported on the treatment of winery wastewater using four different coagulants (ferric sulphate, ferric chloride, alum and calcium hydroxide). Experimental conditions were as follows: initial COD (31 369 to 38 391 mg/L) aluminium sulphate (alum): pH 5 to 7, coagulant volume 20 mL (5% w/v), ferric chloride and ferrous sulphate: pH 5 to 8, coagulant volume 10 mL (5% w/v) and calcium hydroxide: pH 5 to 8, coagulant volume 20 mL (5% w/v). In their study, optimal pH of 5 and coagulant dosage allowed an efficient reduction of turbidity (92.6%) with aluminium sulphate and TSS removal of 95.4% using calcium hydroxide. Although the reduction of TSS and turbidity using these coagulants were generally above 60%, apart from ferric chloride, the reduction in COD for all coagulants used were on average less than 30%. The authors then evaluated the long-term aerated storage combined with the coagulation/flocculation process. Results showed that a COD reduction of 84.5% was obtained, 96.6% for turbidity, 98.7% for volatile suspended solids (VSS) and 99.1% for TSS using calcium hydroxide as the most suitable coagulant to add to the long-term aerated storage effluent under optimum operating conditions.

A summary of different types of coagulants used in this section, and their effect on the reduction of total suspended solids (TSS), turbidity, volatile suspended solid (VSS) and chemical oxygen demand (COD) are shown in Table 6.

Apart from chemical coagulation, electrocoagulation has been an area of interest in winery wastewater treatment. The following section describes electrocoagulation process and discusses reported literature on its use in winery wastewater treatment.

Electrocoagulation

Electrocoagulation occurs when direct current electrolysis is used with metallic electrodes of iron or aluminium (i.e., anode and cathode) being submerged in wastewater. The two primary electrochemical reactions taking place in this treatment technology involves the cation (Fe2+ or Al3+) being released into the solution at the anode and water being reduced to hydrogen gas in the form of bubbles and hydroxyl ions at the cathode (Barrera-Díaz et al., 2018). During electrocoagulation, the highly charged cations formed at the anode destabilize colloidal particles by forming mono- and polymeric hydroxo complex species (Kabdas.li et al., 2012). These metal hydroxo complex species have significant adsorption properties, forming strong aggregates with pollutants in wastewater (Kabdasli et al., 2012). This process has been extensively used in industrial wastewater treatment and has been receiving increasing interest in agricultural wastewater treatment (Holt et al., 2005). Kirzhner et al. (2008) studied the implementation of electrocoagulation for the treatment of winery wastewater, prior to further processing. Their study indicated that up to 42% of COD (initial influent 1 500 to 17 000 mg/L) was removed whereas BOD (initial influent 1 500 to 2 500 mg/L) was only partially removed (28%). Their experimental set up consisted of two aluminium electrodes, spaced 1.5 cm apart, and connected to a DC-power supply operated at 2.5A and 10 V, with operating times ranging between 10 and 40 minutes. The authors then added ozone (1 L/min) which slightly enhanced COD reduction from 42% to 48%. The addition of 2.5% H2O2 adversely increased the COD from 11 172 mg/L to 21 700 mg/L after 40 minutes. A two-stage process was then investigated to enhance COD removal efficiency where the effluent was treated by electrocoagulation in the first stage, followed by purification via aquatic plants (salt marshes with rushes) in the second stage. This configuration combined with aeration showed a BOD reduction of 97.5% and a COD reduction of 98.2% after 23 days of treatment (Kirzhner et al., 2008). This reduction in COD and BOD was attributed to the aquatic plants having high sorption characteristics and high reproduction rate as compared to using electrocoagulation as a stand-alone technique.

Kara et al. (2013) investigated the treatment of winery wastewater using electrocoagulation with Al and Fe electrodes. Optimized operating conditions for Fe electrode: pH 7, current density of 300 A/m2, operating time of 90 min and for the Al electrode: pH 5.2, current density of 300 A/m2, operating time of 120 min were established. The removal efficiencies under these conditions of COD (initial influent 25 200 to 28 640 mg/L) and turbidity (initial influent 24 to 90 NTU) were found to be 46.6% and 92.3%, respectively for the Fe electrode whereas that of Al was 48.5% and 98.6%, respectively. The COD values after treatment with both electrodes were still too high (Al: 13 180 mg/L and Fe: 15 200 mg/L) for disposal, thus indicating that electrocoagulation may be inadequate at reducing COD values to legal discharge limits (Kara et al., 2013).

Orescanin et al. (2013) applied electrocoagulation for the treatment of winery wastewater as a pre-treatment step using electrode sets consisting of stainless steel, iron and eventually aluminium combined with sonication with a sodium chloride support electrolyte. Removal efficiencies of their experiment were 55% COD reduction (initial influent 10 240 mg/L vs final treated effluent: 4 580 mg/L), 98% reduction in turbidity (initial influent: 3 190 NTU vs final treated effluent: 61 NTU) and 98% reduction in suspended solids (initial influent 2 680 mg/L vs final treated effluent: 52 mg/L). The authors postulated that the removal of suspended solids may have been due to coagulation/flocculation with Fe2+, Fe3+ and Al3+ ions released into the treated solution via electrochemical corrosion of the sacrificial steel, Fe and Al electrodes, precipitation of hydroxides and finally co-precipitation of Fe and Al hydroxides. Electrocoagulation has major advantages which include having a small footprint, a high degree of automation as well as no chemical addition is required in this process resulting in minimal secondary pollution and sludge volumes in comparison to chemical coagulation. In contrast, the 'sacrificial anodes' need to be replaced periodically and energy requirements presents another challenge to successfully operate this process (Islam, 2019). Therefore, in countries prone to electricity shortages, this may not be a feasible treatment option unless renewable energy can be used as a source of power to the electrodes.

Based on the previously mentioned electrocoagulation treatment studies, it can be concluded that the use of conventional Al and Fe electrodes are substantially effective for removing suspended solids and turbidity, but not for significantly reducing COD values with COD reduction generally less than 60% in all the above cases (Refer to Table 7). Hence, this method may be suitable as a pre-treatment step to slightly reduce organic concentration of the wastewater prior to the incorporation of secondary treatment methods such as biological treatment to further remove (soluble) organic constituents in the wastewater, as will be discussed later.

Highly soluble alcohols, acids, sugars and compounds such as tannins and polyphenols contribute towards the organic matter in winery wastewater which may not be removed solely by physicochemical techniques (Lucas et al., 2010). Therefore, a common secondary treatment phase is utilized which involves biologically treating the dissolved organic pollutants in winery wastewater. The following section will highlight biological treatment as applied to winery wastewater. The preceding treatment phases (preliminary and primary) are essential steps to condition the wastewater to be effectively treated via biological processes.

Biological Treatment Methods

In biological treatment methods, aerobic, anaerobic and combined anaerobic/aerobic systems are most commonly used and generally take place during secondary the treatment phase. These methods are often classed to be environmentally friendly, since the organic matter contained in winery wastewater is readily biodegradable. Biological winery wastewater treatment plants rely on the selection of a mixture microbial flocs using recycled settled biomass and developing high performance reactors by increasing the concentration of biomass inside the reactors (Eusébio et al., 2004). The following sections will discuss the application of aerobic and anaerobic biological treatment techniques in winery wastewater.

Aerobic Treatment

Aerobic systems are one of the most widely used technologies in wastewater treatment as a whole and consists of lagoons equipped with large pumps where natural aerobic bacteria growth in wastewater is facilitated by way of air circulation (Kyzas et al., 2016). Aerobic processes may often be adequate to comply to legal discharge regulations, however, foul odours and ground water pollution are commonly known to occur (Bories et al., 2007). Most large wineries treat their wastewater on site with aerated ponds being the simplest, most common and least expensive (Storm, 2001). However, these systems have been reported to have reduced rates of biological activity during cold weather which is a concern for wineries with year-round operations (Alisawi, 2020).

Activated sludge process

Fumi et al. (1995) were one of the first groups of researchers to employ conventional (long term) activated sludge (LTAS) as a treatment technology for winery wastewater. The authors stated that this process allows for a simple and flexible treatment of winery wastewater. Since winery wastewater is low in nutrient content, urea and phosphate salts addition is needed to ensure that the process of cellular synthesis occurs (Lofrano & Meric, 2015). Their reactor consisted of a series of polyester reinforced vertical tanks with one equalization tank, three fully mixed aeration tanks and one conical, up-flow settlement tank equipped with a rotating-drum filter and providing oxygen via a diffused-aeration membrane-plate located at the bottom of each tank. With this configuration, the authors obtained an average of 98% COD reduction with raw (untreated) influent water having COD values of 2 000 to 9 000 mg/L and final COD values ranging between 50 to 130 mg/L. (Fumi et al., 1995). Furthermore, total suspended solids ranged between 200 to 12 00 mg/L in untreated effluent to below 60 mg/L in the treated effluent.

Petruccioli et al. (2000) evaluated organic load reduction of winery wastewater using activated sludge through the operation of an air bubble column bioreactor (ABB), fluidized-bed reactor (FBB) and a packed-bed bioreactor (PBB). A trend was observed where an increase in COD removal rates occurred with increasing organic loads. Under optimal operating conditions, the FBB achieved a COD reduction of 88.7%, with a hydraulic retention time (HRT, average time that a soluble compound remains in the bioreactor) of 2.2 days, PBB's COD reduction was 91.1% with 1.2 days' retention and ABB, which yielded the best results, where the COD reduction was 92.2% with 0.8 days retention. The ABB was then subjected to prolonged treatment (280 days, (COD range, 2 700 to 6 600 mg/L) with the maximum organic loading rate applied at 8 800 mg/L per day. The COD reduction during this period was routinely higher than 90% but decreased to a minimum of 80% when operated above critical loading rate 8 240 mg/L per day.

Brucculeri et al. (2005) evaluated the feasibility of co-treating municipal and winery wastewaters using conventional activated sludge process. Their treatment plant consisted of an extended-oxidation process during vintage and a pre-denitrification/oxidation step for the remainder of the year. They showed that COD and nitrogen reduction, was obtained in both cases: with COD reduction of 90% with initial influent having COD value of 200 to 400 mg/L (during vintage) and 87% (non-vintage). Nitrogen reduction of 65%, during both vintage and non-vintage periods were observed with initial concentrations between 20 to 25 mg/L and treated effluent generally below 15 mg/L (Brucculeri et al., 2005).

Petruccioli et al. (2002) made use of a jet-loop reactor (JLR) to aerobically treat winery wastewater (see Fig. 3). A JLR essentially consists of, as the name suggests, a jet and a loop reactor. The function of the jet loop reactor involves recycling a part of the reaction medium after reintroducing it back to the feed at the entrance of the reactor (Warmeling et al., 2016). This configuration offers simple construction, ease of operation and superior mixing performance at relatively low energy consumption rates making it a useful application of mass transfer limited multi-phase reaction systems (Warnecke, 1989). According to the results obtained by the authors, at organic loading rates ranging from 400 to 5 900 mg/L per day, the COD reduction ranged between 96% to 98% with final effluents consistently reaching COD values below 200 mg/L. The experiment was then continued for a period of 12 months and loading rate occasionally altered with a varied hydraulic retention time of 2.3 to 4.4 days. The COD reduction within 12 months averaged at 90%. Based on the excellent reactivity of the system to rapid variations in loading rate, the authors concluded that this system will be well adaptable and flexible enough to treat winery wastewater, known for its wide seasonal variability due to the fluctuations in organic matter and volume. However, if homogenization is not adequate, the selectivity of the reaction is reduced. Therefore, the balance between mixing and mass transfer in JLR's is a crucial design aspect (Weber et al., 2019).

Eusébio et al. (2004) made use of a JLR spanning over a year using winery wastewaters collected in different seasons which brought about the selection of different acclimatized microorganisms obtained from a variety of activated sludge (winery wastewater, pulp and paper wastewater, biomass from a thermal natural spring and freeze-dried commercial inoculum) preserving a high degree of productivity and conversion. The results showed the development of a specific consortium of microbes which, after a lengthened operation time (390 days) and stringent bioreactor conditions, yielded a COD reduction of 80% (initial value of 3 100 to 27 200 mg/L). There were however some issues faced with this system which includes pump breakage and sporadic foaming events and changes in effluent composition which were responsible for some variations observed during COD reduction (40 to 95%) within the 390-day operation period (Eusébio et al., 2004). The predominant bacterial isolates which reduced organic load belonged mostly to the genera Bacillus and Pseudomonas. Whereas the absence of Spirillum (microaerophile) found in this study confirmed the exceptional aeration rate obtained in the JLR, assessed by the dissolved oxygen levels (which maintained levels between 75-90% saturation). A tabulated summary of the aerobically treated winery wastewater methods is shown in Table 8.

Advancement of aerobic treatment methods have been well documented in the past 20 years. Amongst these technological advances, membrane technology has become one of the most widely used biological treatment methods throughout the agricultural industry.

Membrane bioreactors

Membrane bioreactors are also amongst the most used aerobic treatment methods world-wide. These systems offer an efficient secondary treatment option. In comparison to conventional activated sludge processes, membrane filtration is used instead of a secondary clarifier. These compact wastewater treatment systems produce high quality treated water. Furthermore, solids concentration is more efficiently controlled in an MBR since membranes retain the usually washed-out fraction of suspended solids contained in systems with secondary settlers (Van Dijk & Roncken, 1997). Artiga et al. (2005) studied the treatment of winery and tannery wastewater, using a membrane biological reactor. The experiment was conducted over 120 days where the first 50 days were assigned to treat winery wastewater and the balance dedicated for tannery wastewater treatment. For the winery wastewater, soluble COD influent ranged between 1 000 to 4 000mg/L and tannery, 350 to 2 000 mg/L. The authors obtained a COD reduction of 97% for winery wastewater and 86% for tannery wastewater. The organic matter concentration in the effluent was generally less than 100 mg/L and quite similar during the treatment process, despite the differences in the nature and COD of both wastewaters studied.

Melamane et al. (2007) described a study where a combination of a submerged membrane bioreactor (SMBR) and a secondary digester was tested for the treatment of wine distillery wastewater in Worcester, South Africa. Their setup consisted of four individual reactors and the testing period lasted for 30 days. pH buffering was achieved using 1 000 mg/L CaCO3 and K2HPO4 for the first 10 days and then increased to 8 000 mg/L CaCO3 and 4 000 mg/L K2HPO4 for the remainder of the study. The first reactor (reactor A), a balancing tank supplied reactor B (the SMBR) with wastewater which subsequently fed the treated effluent (from the SMBR) to a permeate balancing tank (reactor C) and finally the effluent contained in reactor C was fed to a secondary digester (reactor D). With this configuration, a COD reduction of 76% (average influent of 4 840 mg/L) could be obtained after 22 days, prior to the inoculation of the secondary digester (reactor D), with 25% COD removal occurring in the first 10 days. Secondary digestion and buffering COD reduction remained constant between 72 and 76% after 16 days of treatment with treated wastewater having COD values of roughly 1 100 mg/L. The treated effluent did however, not meet the standards required for crop irrigation (due to constant phosphate levels of 100 mg/L throughout the study) (Melamane et al., 2007).

Valderrama et al. (2012) conducted a case study where winery wastewater treatment was compared using conventional activated sludge as well as a membrane bioreactor. The reduction of COD (influent 100 to 8 000 mg/L) was marginally higher for the MBR (97%) than for the CAS (95%). The high-quality treated effluent in their study met the requirements for reuse in agricultural practices based on Spanish legislation. Although both systems displayed high reduction in COD values, the MBR outperformed the CAS simply because of its design simplicity, process flexibility towards influent changes and smaller footprint.

Vergine et al. (2020) made use of self-forming dynamic membrane bioreactors (SFD-MBR) to treat canning and winery wastewater. Their system showed good reduction of COD (94%.) for the canning wastewater with the soluble COD fraction not exceeding 100 mg/L (initial COD of 1 000 mg/L). Similarly, the COD reduction in winery wastewater was 95% (initial COD of ± 2 000 mg/L). Feed composition and operating conditions of the SDF-MBR adversely affected the filtration performance of this system which required constant cleaning (once every 4 days for 80 days). Furthermore, it can be concluded that the filtration performance which was influenced by membrane fouling resulted in an increase in energy consumption due to more intense aeration of the membrane, consequently increasing operational costs of this system.

MBR technology has the advantage of its flexibility in terms of influent loading, small footprint, reduction in sludge produced and a compact system with greater capability of solid removal and disinfection (Jeison & van Lier., 2007; Tewari et al., 2010). But as with many membrane systems, fouling, decrease in flux and ultimately membrane replacement should be considered when applying this technique. Fouling in membrane processes, occurs via solids, colloids and solutes being deposited onto or into the membrane pores by way of various mechanisms such as adsorption, pore-clogging and pore-blocking. When membranes are fouled, their permeability substantially decreased, but can be restored by cleaning procedures (backwashing) however this directly affects the operational downtime of MBR systems (Guglielmi et al., 2007).

Fixed bed biofilm reactor

Andreottola & Foladori (2005) used a full-scale two-stage fixed bed biofilm reactor (FBBR) filled with plastic carriers to treat winery wastewater. The FBBR consisted of a first stage divided in two parallel reactors which offered flexibility in flow rate during vintage and non-vintage periods of the year and reduced the COD values by 70% (about 7 000 mg/L influent COD as annual average). A third FBBR was then used to enhance the quality of the wastewater with a total average COD reduction of 91% throughout a year of operation. The first stage in the FBBR system largely contributed to the oxidation of biodegradable COD, whereas the second stage essentially refined the effluent arising from the first stage having slowly biodegradable COD or flow rate peaks. It was however, observed that any further reduction was not possible due to the non-biodegradable soluble COD fraction (approximately 10% which was not explicitly identified by the authors) in which FBBR and settling was not equipped to remove. Importantly, back-washing of the FBBR was not required during seasonal period (Sept-March) due to the high empty space offered by the plastic carriers.

Rotating biological contactor

Implementation of a pilot-scale rotating biological contactor (RBC) was investigated to treat winery wastewater by Coetzee et al. (2004). Their results indicate that this biological system is not efficient enough at removing organic matter since it only reduced the COD (influent: 4 000 to 8 000 mg/L) by an average of 23% and a maximum reduction of 43% (Coetzee et al., 2004). Although the authors stated that this could be an effective pre-treatment technique, the application of RBC to winery wastewater is limited. If compared to other methods mentioned earlier in this review (refer to Table 8), conventional activated sludge, JLR and MBR's would be more suitable selections in terms of total organic load removal efficiency.

Table 9 compares the advantages and drawbacks of aerobic wastewater treatment technologies as applied to winery wastewater which includes activated sludge, jet loop reactors, membrane bioreactors and fixed bed biofilm reactors.

Based on the comparison, it can be concluded that MBR systems are most suitable and adaptable to the variation in influent flow as well as treatment of wastewater with high organic content to discharge/re-use quality standards. Membrane fouling should however be taken into account when considering this type of treatment technology.

Anaerobic Treatment

As mentioned previously, winery wastewater is high in organic content, it is therefore worthwhile to consider energy generation from anaerobic digestion processes combined with wastewater treatment. Anaerobic digestion occurs without the presence of oxygen and is dependent on alternative metabolic pathways used by a group of disparate microorganisms (Mosse et al., 2012). The basis of this technique involves the consumption of dissolved organic matter via a group of anaerobic micro-organisms (in the winery wastewater), with biogas being the main product of this treatment method (Basset et al., 2016). Thus, a major advantage of anaerobic treatments methods is the generation of energy (in the form of biogas) which can be used to maintain operational process requirements.

Distillery wastewater treatment was studied by Wolmarans & de Villiers (2002) using an up flow anaerobic sludge blanket (UASB) as pre-treatment and monitored its performance of a three-year period (1998 to 2000). This system achieved a high reduction of COD (average influent of 26 669 mg/L, treated effluent 2 814 mg/L) of more than 90%. The start-up procedure of the UASB system was carefully monitored (for three weeks) where volumetric loading rates (defined as the kilograms of COD fed to the reactor per cubic meter of total reactor volume per day) of 4 000 and 18 000 mg/L per day were applied. Generally, this technique requires an initial start-up procedure which can take between one week to two months. The start-up of the UASB used by the authors took 7 to 8 days before process stability was achieved for operations in 1998 and 1999, with temperature and pH of the reactor being constant with average values of 35°C and 5.8, respectively. During these two seasons (1998 and 1999), the COD removal was maintained at roughly 90%. Conversely the start-up procedure during the 2000 season required 25 days to reach similar conditions and COD removal efficiencies. During the first week of the 2000 season, COD removal efficiency increased from 60 to over 90%. However, a sharp decrease was observed when the authors increased the loading rate from 6 000 mg/L per day to 12 000 mg/L per day (from >90% to 65%). The authors then decreased the loading rate to below 8 000mg/L per day for the following 19 days until stabilization was achieved. Thereafter the loading rate was dramatically increased to 18 000 mg/L per day with no significant decrease in COD removal efficiency (>90%). During this rapid decrease and increase in COD loading for the 2000 season, it was noted that care must be taken when using UASB systems since a decrease in granule stability may be experienced with fluctuating COD loadings, consequently resulting in a decrease in UASB reactor performance.

Ganesh et al. 2010 investigated the treatment of winery wastewater using three anaerobic fixed-bed reactors. In their study, three small polyethylene floating carriers (named: S9, S30 and S40 with organic loading rates corresponding to 42 000, 27 000 and 22 000 mg/L per day, respectively) were used as media for biomass immobilization and retention. This configuration was able to remove 80% of COD (influent COD value of18 000 to 21 000 mg/L). The authors mentioned that supplemental nutrients (nitrogen and phosphorus) to maintain a C:N:P ratio of 400:7:1 were required for cellular growth in the biological phase. The 80% reduction in COD highlights lower reactor volume, energy consumption (compared conventional activated sludge processes) and land area requirements for the implementation of this biological treatment process. However, a drawback of this technique is that it requires aerobic treatment (or a post treatment) to make the final effluent fit for disposal.

Laing (2016) investigated the feasibility of an anaerobic sequencing batch reactor (AnSBR) to treat synthetic winery wastewater in South Africa. In this study the treatment parameters for two types of synthetic effluent (1 000 to 4 000 mg/L and 4 000 to 7 000 mg/L COD, respectively) were optimized using lab-scale reactors (14.7 L, with granular mesophilic biomass kept at 35°C). During the first phase of the study (COD 1 000 to 4 000 mg/L), an average COD reduction of 88% was achieved whereas 80% COD reduction occurred in the second phase (4 000 to 7 000 mg/L) with both phases having controlled pH values of 7.2. The optimized parameters that were studied include the pH, feeding time and mixing frequency. This system used by the author produced biogas with the methane fraction forming more than 80% of the biogas (in the absence of nitrogen), compared to the typical biogas production which is made up of 70% methane and 30% carbon dioxide. This was achieved by increasing the COD:N fraction in the reactor, ultimately producing (according to the authors) an "upgraded biogas". During this step, when the mixing time in the reactor was optimized, less granule shearing occurred and better methanogen protection was observed. Based on these results, the author recommended that this reactor has the potential to be up scaled to a pilot scale set-up which could then be used to determine the feasibility and cost of the AnSBR process on a larger scale.

The feasibility of anaerobic membrane bioreactors (AnMBR) was recently studied by Basset et al. (2016). Specific organic loading rate in their study was kept below the methanogenic activity (300 mg/L per mixed liquor suspended solids (MLSS) per day whilst the wastewater had a total COD of 6 752 mg/L; and a soluble COD fraction of 4 040 mg/L. The AnMBR used in their study achieved a 96.7% COD reduction, producing 87.1% of methane in the process. Membrane fouling was however a limiting factor, especially inside the membrane pores, which decreased the membrane flux by 80%. Fouling in membranes is major limitation, as previously stated, since it affects treatment quality, efficiency and, also corresponds to more energy being needed to operate under fouled conditions.

Anaerobic treatment of winery wastewater generally displays COD reduction in the range of 80 to 98% with biogas production between 500 to 600 L per kilogram of COD removed, with 60 to 80% being methane (Moletta, 2005). Although anaerobic treatment produce biogas with less amount of sludge and are generally odour free, their COD/ BOD reduction efficiency and consistency is not sufficient to be released to water bodies without having undergoing post aerobic treatment (Bharathiraja et al., 2020). Table 10 compares aerobic and anaerobic treatment methods.

Constructed wetlands

A constructed wetland is an artificial shallow basin filled with substrate (i.e., soil or gravel) and planted with vegetation highly tolerant to saturated conditions which are designed to mimic the bioremediatory process occurring in natural wetlands (Welz et al., 2015). The plants contained in constructed wetlands metabolize available nutrients and may accumulate heavy metals and degrade certain organic contaminants (Welz et al., 2015). Provided adequate land space, constructed wetlands represent a cost-effective, ecologically friendly and aesthetically appealing option for wastewater remediation (Masi et al., 2002). The mechanisms involved in constructed wetlands to treat wastewater comprises of the settling of particulate matter, filtration and chemical precipitation through contact between water and the substrate (soil), adsorption and ion-exchange on the surfaces of plants and substrates as well as the breakdown and transformation of pollutants by microorganisms and plant uptake (Omondi & Navalia, 2016). In essence, constructed wetlands may fall into secondary/tertiary treatment but is often grouped to be a combination of primary, secondary and tertiary treatment methods.

Literature has shown that winery wastewaters may have phytotoxic effects on wetland plant species which is a fundamental rationale for the construction and design of constructed wetlands. Ideally, a constructed wetland plant should be able to tolerate high-organic loads and remove significant amounts of contaminants thereby purifying the effluent in a relatively short period of time (Arienzo et al., 2009a).

Shepherd et al. (2001) demonstrated the use of a pilot scale horizontal subsurface flow (HF) constructed wetland (6.1 m long x 2.4 m wide x 1.2 m deep) in a medium sized winery (producing 18 200 m3 wine per year) with flows ranging from 80 to 170 m3/day and COD organic loads of 500 to 45 000 mg/L. Their system had a surface area of 14.9 m2, filled with pea gravel with a hydraulic conductivity of 2 mm/s which received the effluent from an up-flow coarse sand filter used as pre-treatment with a 10-day hydraulic retention time. The CW was planted with Typha dominicus, Schoenoplectus acutus (referred to in original article as Scirpus acutus but the genus name has since changed) and some Sagittaria latifolia and the wastewater was diluted and fed to the CW at 500 L/day with an initial COD concentration of 993 mg/L which was then increased to COD values of 5 000 mg/L. During their experiment, a COD reduction efficiency of at least 97% with influent concentration less than 5 000 mg/L and 97% removal of TSS with influent values of 450 mg/L were obtained (Shepherd et al., 2001).

Grismer et al. (2003) studied the effect of retention time and treatment performance of a full-scale constructed wetland process when applied to winery wastewater. Two full-scale subsurface wetlands were evaluated during harvest crush and spring season with data collected from a medium sized winery near Hopland, California and another from a smaller winery near Glen Ellen, California. The wetland applied to Hopland displayed COD reductions of 49 to 79% and a tannin removal rate of 46 to 76%. An observation was made where pollutant removal was more efficient during non-crush season. At the Glen Ellen winery, the authors obtained a significant COD reduction where the influent had COD concentrations of 8 000 mg/L whereas the treated effluent was as low as 5 mg/L (Grismer et al., 2003).

Mulidzi et al. (2007) achieved an average COD reduction of 80% (influent average of 14 000 mg/L) with the treated effluent displaying COD values of 500 mg/L. The volume of winery wastewater used by the authors was 4 m3. The dimensions of the constructed wetland used during their study was 45 m long x 4 m wide x 1.2 m deep filled to a depth of 0.9 m with diatomic gravel with particle sizes between 20 to 30 mm. The gravel bed had a porosity of 35% with a total wetland volume of 162 m3 and a pore volume (with access to roots and wastewater) of 56.7 m3. In the same study during the years 2004 to 2005 a COD reduction using this system during winter was 83% and 80% COD reduction during summer using winery wastewater from Goudini, South Africa. Subsequently, constructed wetland treatment during 2005 and 2006 yielded an average COD reduction of 82%,

with 88% of the reduction occurring in winter and 77% COD reduction occurring during the summer months (Mulidzi, 2007). In a separate study, conducted by the same authors (Mulidzi et.al., 2010), the retention time was decreased by half with a winery wastewater volume of 8.1 m3 (7 days compared to the earlier study which had retention time of 14 days. The treated effluent displayed COD values of 5 000 mg/L with a removal efficiency of 60% within 7 days. This was an important finding since the treated effluent after 7 days met the minimum requirements for soil irrigation as per the South African guidelines (Mulidzi, 2010). A further essential comparison between the two studies (14-day retention time vs 7-day retention time) was that 60% of COD reduction was achieved in 7 days with a higher wastewater volume (8.1 m3 compared to 4 m3). Furthermore, it was observed that a pre-treatment for the removal of solids was crucial since the solids contained more than 40% of the COD load, which if unfiltered could cause clogging of the system.

In a more recent study conducted by Milani et al. (2020), the investigation of a multistage constructed wetland used for winey wastewater was conducted and analysed for its suitability for irrigation re-use. This multistage configuration consisting of vertical subsurface flow bed (VF), horizontal subsurface flow bed (HF) and a free subsurface flow unit (FSF) and treating 3 m3 of wastewater per day at the Marabino winery in Sicily, Italy achieved COD and TSS reduction of 81 and 69%, respectively. The wastewater used in their study was mixed with sewage produced by the ablution facilities used throughout the winery. The wastewater was screened, followed by an equalization tank (5 m3) and the constructed wetland (Milani et al., 2020). With this system, after the horizontal subsurface flow wetland, 96% of the samples met the legal Italian irrigation limit for COD which was further increased to 100% compliance after the final free subsurface flow unit (2 020 mg/L influent with a minimum of 3 mg/L after multistage treatment). Furthermore, only 34% of the samples exceeded TSS limits (10 mg/L) and 18% exceeded BOD limit (20 mg/L) after treatment. The reasoning for this observation was explained by algae growth which occurs in the FSF stage, subsequently increasing the TSS and BOD5 concentration of the effluent. Based on these results, the authors stated that the implementation of this multistage constructed wetland was a feasible treatment option for winery wastewater due to its high efficiency and compliance for irrigation guidelines as per the Italian legislation. Furthermore, it was noted that constructed wetlands are particularly suitable for small to medium wineries where the construction, operation and maintenance costs of conventional wastewater treatment plants may not be economically sustainable by the owners of the wine farm.

In contrast to the statement made by Milani et al., (2020), we do suggest that constructed wetland systems are more suitable for medium to large wineries largely based on the space requirements for constructed wetlands. Small wineries may usually adopt minimal treatment (preliminary and primary) and most often combine their wastewater with sewage before being treated at local municipalities in order to dispose of their effluent in an adequate manner.

Constructed wetlands are essentially simplified treatment systems with low energy requirements. It can provide aesthetic benefits to wineries, the design, construction and maintenance is simplistic, and the operational costs are low in comparison to many other winery wastewater treatment techniques (e.g., activated sludge and membrane technology). Albeit, that the constructed wetlands have the previously mentioned advantages, it is a significantly land intensive technology and would not be suitable for small wineries. In addition, the removal of suspended matter is crucial to the performance of the wetland system with a pre-treatment step being imperative to prevent clogging of the system.

Apart from the abovementioned treatment technologies, tertiary treatment such as advanced oxidation processes have been extensively researched in the past few decades and will be discussed further in the following section.

Advanced oxidation processes

Advanced oxidation processes have been receiving increasing attention to treat a variety of agro-industrial wastewaters (Chong et al., 2010). Winery wastewaters have been documented to be challenging to fully treat winery with biological methods alone. The emerging research on adopting advanced oxidation processes to treat the seasonal and flow varying wastewaters has been shown to produce promising results and can be used as a treatment step before subjecting the wastewater to aerobic biological treatment (Ovelleiro et al., 2006). The principal objective of advanced oxidation processes (AOPs) in wastewater treatment involves the partial or complete degradation of organic contaminants (Coha et al., 2021). After partial degradation, there may still be oxidisable but less harmful products and in the case where complete oxidation occurs, mineralization (transformation of all organic compounds into carbon dioxide and mineral salts) is attained (Coha et al., 2021). Here the main mechanism of oxidation in AOPs occurs via the production of highly reactive hydroxyl free radicals able to non-selectively react with oxidisable organic species with fast reaction kinetics (Coha et al., 2021). In general, O3 (ozone), H2O2 (hydrogen peroxide) and UV (ultraviolet) irradiation are used to generate hydroxyl radicals in the first step of oxidation. Thereafter, a reaction ensues between the radicals and organic contaminants finally producing precipitates (Jaiyela & Bwapwa, 2016). For the purpose of this paper, advanced oxidation processes based on Fenton process will be discussed.

Fenton Process

The Fenton reagent is widely used in wastewater treatment and is a combination of Fe2+ salts and hydrogen peroxide (H2O2). The implementation of the Fenton reagent is mainly due to its ability to easily oxidize organic compounds and form hydroxyl radicals in a simple way as shown in Eq. 1 and Eq. 2 below.

The effectiveness of this technique relates to the formation of strong hydroxyl radicals (OH) and the oxidation of Fe2+ to Fe3+and since both ions are coagulants, a Fenton process may have a synergistic effect, i.e., oxidation and coagulation (Ippolito et al., 2021).

Ippolito et al. (2021) studied the treatment of winery wastewater using a Fenton process. The main findings obtained in their study suggest that this process could reduce COD values by 54% (influent COD: 20 000 mg/L). This was achieved after pH adjustment from pH 4.6 (raw effluent), to a pH of 8 using hydrated lime (bentonite was used to promote the precipitation of suspended substances before pH adjustment with lime). This was accompanied by a 75% reduction in TDS from 4 680 mg/ to 1 170 mg/L. Furthermore, an analysis of variance (ANOVA) test was conducted to determine optimum concentrations of H2O2/ Fe2+ and a 60% reduction in COD values were obtained with 60 L/m3 of hydrogen peroxide and 30 kg/m3 of ferrous sulphate heptahydrate. Lastly, a study of the influence of pH was carried out and the optimum concentrations as mentioned above were used on raw effluent (pH 3.5 to 4.5). The reduction in COD value during this experiment ranged from 40% at pH 3, to 52% at pH 4 to 4.5 (Ippolito et al.,, 2021).

Besides stand-alone Fenton processes, photo Fenton processes have also been studied in winery wastewater treatment. Upon addition of UV/Vis light (i.e., photo-Fenton reactions) additional radicals are produced aiding the regeneration of the catalyst (Eq. 3 and Eq. 4) (Ovelleiro et al., 2006; Anastasiou et al., 2009). The photo-Fenton process is pH-dependent (with an optimal pH 2.8) due to precipitation of iron, thus strict pH control is required (Davididou & Frontistis, 2021).

Table 11 below shows a summary of Fe-based advanced oxidation processes as applied to winery wastewater.

Advanced oxidation processes based on Fe, shows great potential to be either used as a pre- or post-treatment step during the treatment of winery wastewater reaching reduction in COD values up to 90% in some cases (Lucas et al., 2009b). Photo Fenton for example has advantages such as (i) at low concentrations the ferrous catalyst is in abundance and nontoxic, (ii) hydrogen peroxide can easily be diluted, (iii) no mass transfer limitations exist due to all reagents being in the liquid phase (Ioannou et al., 2015). But as with many techniques, Fe-based advanced oxidation processes also suffer from various limitations which have been tabulated in Table 12.

CONCLUSIONS

The generation of varied quantities of winery wastewater coupled with fluctuations in the composition of winery wastewater throughout the wine making process presents a difficult task to wineries in selecting suitable treatment methods. Based on the literature cited for the treatment of winery wastewater, a common trend was observed where many techniques' shortfalls are related to the fluctuations in organic content and volume of the wastewater. Furthermore, the different phases (primary, secondary and tertiary) in wastewater management are essential to controlling the effluent quality and largely depend on its end use and relevant regulations. Importantly, winery wastewater treatment plants are not tasked to turn wastewater into potable water, but rather the treated water is aimed at being clean enough for it to be released into the natural cycle of water (through land application) without causing damage to the environment.

Physicochemical treatment methods (i.e., coagulation/ flocculation, electrocoagulation, sedimentation) have been identified as being effective pre-treatment steps. These methods are mainly successful in removing total suspended solids (TSS) up to 95%, reducing turbidity (up to 80%) of the wastewater and to a smaller extent reduction of the organic content (generally <40% COD reduction). This is an important step since the reduction of these organic contents of raw effluent facilitate further (and more manageable) treatment using biological treatment methods and advanced oxidation processes. However, during physicochemical processes varying quantities of chemical sludge is produced which is usually processed externally. These processing costs can escalate, particularly with increasing volumes of wastewater. Furthermore, the correct pH and dosage of chemicals are essential to make the process work effectively which is not a straightforward task due to the widely varying chemical composition of winery wastewater. Biological treatment is one of the most widely used methods with activated sludge process and its modifications being the most studied and adopted methods for winery wastewater treatment. The implementation of biological treatment methods in winery wastewater treatment is based on the high biodegradability of the effluent due to ethanol and sugars contained in the effluent, which justifies the use of this treatment method. Treatment technology based on biological processes is in most cases traditional and well understood. These methods generally produce high quality effluent achieving COD reduction values as high as 98%, but its energy requirements for air supply, excess sludge production and biomass settling difficulty affects its suitability (and future longevity) in wastewater treatment at smaller wineries and may be more suitable to larger wineries.

Constructed wetlands have long been used throughout the wine industry mainly based on their design and construction simplicity, they do not have a high demand for electrical energy as well as the proven potential of the treated wastewater to be fit for use as a source of irrigation. The main drawback of this treatment system is its large footprint and the requirement for a pre-treatment to filter out suspended solids and the need for longer retention times which may cause issues with the attraction of pests. Although the treatment efficiency of this technique is substantial (60 to 100% reduction in COD), the long retention times may cause issues particularly during harvest when there is a major influx of wastewater that requires treatment.

Advanced oxidation processes (based on Fe in this study) showed treatment removal efficiencies with reduction in COD values reaching 40 to 80% as a standalone method and up to 95% when combined with biological pre-treatment processes (such as membrane bioreactors) in relatively short treatment times (average of 4 h). Advanced oxidation processes generally have high reaction rates, high oxidation potentials and a non-selective nature. Due to the high oxidation potential of the generated hydroxyl radical in this system, a much smaller footprint is maintained as compared to techniques such as activated sludge and constructed wetlands. These techniques may however require more extensive pre-treatment steps (especially in the photo Fenton process) as well as energy requirements to operate the light source as well as to improve light transmission in the reactor. This can be overcome by using sunlight as an irradiation source (i.e., energy efficient implementation of photo-assisted advanced oxidation processes). Advanced oxidation systems using hydrogen peroxide should be carefully monitored and controlled since H2O2 may have potential adverse effects on later treatment steps (careful system design, may mitigate such occurrences).

In summary, treatment technologies best suited for small wineries include chemical treatment (physicochemical) combined with aerated lagoons which is adequate for either land application or municipal co-treatment, whereas for medium to large wineries, activated sludge, constructed wetlands, and anaerobic digestion would suffice based on its suitability for biogas capture and usage for energy demands required by the biological plants. Advanced oxidation processes have the potential to alleviate many constraints faced by wineries in terms of the quality of the treated effluent however this technique has not been applied to the South African wine industry and future research should therefore be dedicated towards its implementation in this country. The feasibility of normalized costs should be included in such studies which may then be grounds to select a treatment option such as advanced oxidation as opposed to the already applied techniques used as discussed in this review. The current study is limited to published results. Important parameters needed to make a fair comparison are not frequently available, such as system capital costs, running cost, and hydrodynamic conditions (such as retention times) for studies discussed in this paper. The literature cited and discussed in this study should be useful for the wine industry to be able to compare what has been done, what is currently being done and what the future looks like in terms of winery wastewater treatment.

LITERATURE CITED

Adesoji, J. & Joseph, B., 2016. Treatment technology for brewery wastewater in a water-scarce country : A review. Brew. Wastewater Treat. Technol. 112, 3, 1-8. [ Links ]

Ahmadi, L. & Merkley, G.P., 2017. Wastewater reuse potential for irrigated agriculture. Irrig. Sci. 35, 4, 275-285. [ Links ]

Alisawi, H.A.O., 2020. Performance of wastewater treatment during variable temperature. Appl. Water Sci. 10, 89, 1-6. [ Links ]

Amfori. 2018. Environmental Hotspots in the South African wine industry. Available: https://www.amfori.org/sites/default/files/amfori-2019-08-16-Sustainable-Wine-Programme.pdf. Accessed 07/01/22 [ Links ]

Amaral-Silva, N., Martins, R. C., Paiva, C., Castro-Silva, S. & QuintaFerreira, R. M., 2016. A new winery wastewater treatment approach during vintage periods integrating ferric coagulation, Fenton reaction and activated sludge. J. Environ. Chem. Eng. 4, 2, 2207-2215. [ Links ]

Anastasiou, N., Monou, M., Mantzavinos, D. & Kassinos, D., 2009. Monitoring of the quality of winery influents / effluents and polishing of partially treated winery flows by homogeneous Fe (II) photo-oxidation. Desalination 248, 1-3, 836-842. [ Links ]

Andreottola, G. & Foladori, P., 2005. Treatment of winery wastewater in a full-scale fixed bed biofilm reactor Treatment of winery wastewater in a full-scale fixed bed biofilm reactor. Water Sci Technol 51:71-79. [ Links ]

Andreottola, G., Cadonna, M., Foladori, P., Gatti, G., Lorenzi, F. & Nardelli, P., 2007. Heavy metal removal from winery wastewater in the case of restrictive discharge regulation. Water Sci. Technol. 56, 2, 111-120. [ Links ]

Andreottola, G., Foladori, P., & Ziglio, G., 2009. Biological treatment of winery wastewater : An overview. Water Sci. Technol. 60, 5, 1117-1125. [ Links ]

Arienzo, M., Christen, E.W. & Quayle, W.C., 2009a. Phytotoxicity testing of winery wastewater for constructed wetland treatment. J. Hazard. Mater. 169, 94-99. [ Links ]

Arienzo, M., Christen, E.W., Quayle, W., & Kumar, A., 2009b. A review of the fate of potassium in the soil-plant system after land application of wastewaters. J. Hazard. Mater. 164, 2-3, 415-422. [ Links ]

Artiga, P.,Ficara, E., Malpei,F., Garrido, J.M., & Mendez, R., 2005. Treatment of two industrial wastewaters in a submerged membrane bioreactor. Desalination 179, 161-169. [ Links ]

Arvanitoyannis, I.S., Ladas, D., & Mavromatis, A., 2006. Wine waste treatment methodology Int. J. Food Sci. \& Technol. 41, 10, 1117-1151. [ Links ]

Barrera-Díaz, C.E., Balderas-Hernández, P., & Bilyeu, B., 2018. Chapter 3 - Electrocoagulation: Fundamentals and Prospectives In: C.A. Martínez-Huitle, M.A. Rodrigo, & O. Scialdone (eds). Electrochem. Water Wastewater Treat. Butterworth-Heinemann 61-76. [ Links ]

Basset, N., Santos, E., Dosta, J., & Mata-álvarez, J., 2016. Start-up and operation of an AnMBR for winery wastewater treatment Ecol. Eng. 86, 279-289. [ Links ]

Beck, C., Prades, G., & Sadowski, A., 2005. Activated sludge wastewater treatment plants optimisation to face pollution overloads during grape harvest periods. Water Sci. Technol. 51, 1, 81-88. [ Links ]

Bellie, P.N., Sockan, V., & Jayakaran, P., 2015. Waste Water Treatment by Coagulation and Flocculation Int. J. Eng. Sci. Innov. Technol. 3, 2. [ Links ]

Bharathiraja, B., Iyyappan, J., Jayamuthunagai, J., Kumar, R.P., Sirohi, R., Gnansounou, E., & Pandey, A., 2020. Industrial Crops & Products Critical review on bioconversion of winery wastes into value-added products. Ind. Crop. Prod. 158, 112954. [ Links ]

Bolognesi, S., Cecconet, D., & Capodaglio, A.G., 2020. 5 - Agro-industrial wastewater treatment in microbial fuel cells In: R. Abbassi, A.K. Yadav, F. Khan, & V. Garaniya (eds). Integr. Microb. Fuel Cells Wastewater Treat. Butterworth-Heinemann 93-133. [ Links ]

Bories, A., Guillot, J.M., Sire, Y., Couderc, M., Lemaire, SA., Kreim, V., & Roux, JC., 2007. Prevention of volatile fatty acids production and limitation of odours from winery wastewaters by denitrification. Water Res. 41, 13, 2987-2995. [ Links ]

Braz, R., Pirra, A., Lucas, M.S., & Peres, J.A., 2010. Combination of long term aerated storage and chemical coagulation/flocculation to winery wastewater treatment. Desalination 263, 226-232. [ Links ]

Brucculeri, M., Bolzonella, D., Battistoni, P., & Cecchi, F., 2005. Treatment of mixed municipal and winery wastewaters in a conventional activated sludge process: A case study. Water Sci. Technol. 51, 1, 89-98. [ Links ]

Buelow, M.C., Steenwerth, K., Silva, L. C.R., & Parikh, S.J., 2015. Characterization of Winery Wastewater for Reuse in California. Am. Soc. Enol. Vitic. 3, 66, 302-310. [ Links ]

Bustamante, M., Moral, R., Paredes, C., Perez-Espinosa, A., Moreno-Caselles, J., & Perez-Murcia, M.D., 2005. Uses of winery and distillery effluents in agriculture: characterisation of nutrient and hazardous components. Water Sci. Technol. 51, 1, 145-151. [ Links ]

Bustamante, M., Moral, R., Paredes, C., Perez-Espinosa, A., Moreno-Caselles, J., & Perez-Murcia, M.D., 2008. Agrochemical characterisation of the solid by-products and residues from the winery and distillery industry. Waste Manag. 28, 372-380. [ Links ]

Butnariu, M. & Butu, A., 2019. 11 - Qualitative and Quantitative Chemical Composition of Wine In: A.M. Grumezescu & A.M. Holban (eds). Qual. Control Beverage Ind. Vol.17, 385-417. [ Links ]

Candia-onfray, C., Espinoza, N., Sabino, E.B., & Salazar, R., 2018. Chemosphere Treatment of winery wastewater by anodic oxidation using BDD electrode. Chemosphere 206, 709-717. [ Links ]