Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

South African Journal of Enology and Viticulture

versión On-line ISSN 2224-7904

versión impresa ISSN 0253-939X

S. Afr. J. Enol. Vitic. vol.42 no.2 Stellenbosch 2021

http://dx.doi.org/10.21548/42-2-4542

ARTICLES

Effect of Oxygen and Nitrogen Sparging during Grape Fermentation on Volatile Sulphur Compounds

X. LyuI; L.D. AraujoI; S.-Y. QuekI; W.J. du ToitII; P.A. KilmartinI, *

ISchool of Chemical Sciences, University of Auckland, Private Bag 92019, Auckland, New Zealand

IIInstitute for Grape and Wine Sciences/Department of Viticulture and Oenology, Stellenbosch University, Private Bag X1, Matieland 7602, South Africa

ABSTRACT

Elemental sulphur is a common fungicide applied in vineyards before harvest, and has been found to increase the production of desirable polyfunctional mercaptans, but also H2S and unwanted reductive sulphur aroma compounds. This paper investigates the effectiveness of oxygen and nitrogen sparging, applied during fermentation, on the removal of volatile sulphur compounds in Sauvignon blanc wines. Increasing the amount of elemental sulphur added to grapes after pressing, from nil to 10 to 100 mg/L, led to an increase in the formation of 3-mercaptohexanol (3MH), of 3-mercaptohexyl acetate (3MHA) for the 10 mg/L additions only, and of some unwanted reductive compounds. Few changes were observed in the concentrations of aroma compounds when the juices were sparged with nitrogen during fermentation. Additions of oxygen during fermentation led to some decrease in the concentration of polyfunctional mercaptans for the 10 mg/L sulphur additions, but did not significantly remove reductive aroma compounds. Few differences were observed in the concentration of wine phenolics or of further wine aroma families with any of the treatments.

Key words: Sauvignon blanc, gas sparging, oxygen, nitrogen, reductive aroma compounds

INTRODUCTION

Volatile sulphur compounds (VSCs) have an important influence on the sensory profile of wine and greatly affect wine quality and consumer preferences (Kreitman et al., 2016). Generally, these compounds have extremely low aroma-detection thresholds (from μg/L to ng/L). Depending upon their chemical structure, VSCs can be divided into two different types (Kreitman et al., 2016). Some VSCs are responsible for the pleasant aromas in wine, such as the polyfunctional mercaptans 3-mercaptohexanol (3MH), 3-mercaptohexyl acetate (3MHA) and 4-mercapto-4-methylpentan-2-one (4MMP), described as "passionfruit", "grapefruit" and "blackcurrant" (Roland et al., 2011). On the other hand, the "reductive" sulfidic off-odours can result in faulty wines; these include hydrogen sulphide (H2S), methanethiol (MeSH), ethanethiol (EtSH) and dimethyl sulphide (DMS), which are associated with undesirable odours such as "rotten egg", "putrefaction", "sewage" and "rubber" (Mestres et al., 2000; Siebert et al., 2010).

Elemental sulphur (S0) is commonly used in the vineyard before harvest and has various commercial formulations. S0 is used to combat the grape disease, powdery mildew (García et al., 2003), and has some advantages such as low cost and low risk of developing resistance (Savocchia et al., 2011). However, the use of S0 has long been associated with reduced sulphur aroma characters in finished wines, as S0 residues are reduced by yeast to hydrogen sulphide (H2S) (Siebert et al., 2010; Kwasniewski et al., 2014). The importance of H2S in causing wine reductive off-odours has been emphasised in recent studies, as it often appears in faulty wines at levels above its sensory threshold (> 1 μg/L) (Siebert et al., 2010).

H2S can be formed not only by the reduction of S0, but also by yeast metabolism from sulphite or sulphates (Schütz & Kunkee, 1977; Jiranek et al., 1995). Previous studies show that a lack of yeast assimilable nitrogen (YAN) can inhibit biomass formation and lose sugar-transport capabilities, and hence fermentation activity, and lead to the formation of H2S (Gardner et al., 2002). Genetic analyses of yeast strains have shown that H2S biogenesis is associated with the sulphur assimilation pathway from sulphite, where H2S production is an interim step in the reduction of sulphate or sulphite before incorporation into the amino acids methionine and cysteine (Masselot & De Robichon-Szulmajster, 1975; Kinzurik et al., 2016). Efforts have been made to develop new commercial yeast strains to produce less H2S (Scerri & Heinrich, 2009; Berlese-Noble et al., 2014; Kinzurik et al.,, 2016). Must turbidity and associated chemical composition can also affect H2S formation in certain wines (Karagiannis & Lanaridis, 1999).

The excessive production of H2S can also lead to the formation of other sulphur compounds, for instance methanethiol (MeSH), ethanethiol (EtSH) and their acetates (König et al., 2009). H2S is highly volatile, meaning that most of the generated H2S can be removed by CO2 sparging during the fermentation process (Jastrzembski et al., 2017). However, the remaining H2S in the finished wine still influences wine quality. Winemakers have employed various methods to remove excessive VSCs in wine, for example copper finning, aeration and the addition of lees (Franco-Luesma & Ferreira, 2016). In particular, oxygen applications during the fermentation process have been reported to have positive effects in preventing or remediating the generation of reductive aromas (Day et al., 2015).

Oxygen additions during fermentation can lead to the oxidation of phenolic compounds and effects on polyfunctional mercaptans and other volatile aroma compounds, while with red wines it can improve wine colour, taste and texture (Gómez-Plaza & Cano-López, 2011). Oxygen may also improve yeast vitality and enhance nitrogen assimilation efficiency and, in the process, lower the concentration of H2S to below its odour threshold value (McCord, 2003; Gómez-Plaza & Cano-López, 2011). Oxygen additions during fermentation have been reported to oxidise the generated H2S to elemental sulphur, leaving S at the bottom of the tank as a way to remove H2S (Gómez-Plaza & Cano-López, 2011). Oxygen can also decrease the concentration of other VSCs, possibly through the oxidation of thiol compounds to their respective disulphides, which have higher odour threshold values (Zoecklein, 2007).

The optimum time for the addition of oxygen to fermentation has also been studied. A controlled addition at the end of the exponential growth phase of the yeast (approximately 36 h to 48 h after inoculation) has been shown to be the most useful for stimulating fermentation (Salmon, 2006; Day et al., 2015). On the other hand, the early addition of oxygen has been beneficial for the quality of white wine through effects on chemical composition (Bertrand & Torres-Alegre, 1984). The mitigation of VSCs by using micro-oxygenation has also been undertaken after the primary fermentation has been completed (Gómez-Plaza & Cano-López, 2011).

The aim of this study was to evaluate the influence of gas sparging (pure O2 and N2), starting from about one-third of the way into the fermentation of Sauvignon blanc wines. The early formation of H2S has been enhanced by the addition of elemental sulphur prior to fermentation. The effect of O2 sparging on mitigating VSCs is compared with the physical displacement of VSCs through N2 sparging, and to controls with no gas sparging.

MATERIALS AND METHODS

Samples

All the samples were free-run juices and were collected from two tanks at the winery, labelled Sauvignon blanc sample 1 (SB1) and Sauvignon blanc sample 2 (SB2). These samples were taken from the Drylands Winery (Constellation Brands) in Marlborough, New Zealand on 2019-04-04. The juices were collected in several 5 L containers, with a corresponding amount of potassium metabisulphite (PMS) added to the juice for a target SO2 level of 70 mg/L. This high level of SO2 addition was to keep a certain level of free SO2 in the juices for long-distance transportation and storage prior to fermentation. The juices were stored in a cool room (4°C) in the winery before being transported to Auckland in a cool environment (packed with dry ice) on a 90 min flight on 2019-04-05.

After arrival, the juices were stored in a -4° cool room for cold settling until the fermentation started on 2019-05-22 and 2019-05-23. The free SO2 was measured before fermentation, on 2019-05-21, for one representative container each for SB1 and SB2, and values of 25 mg/L and 28 mg/L were obtained, respectively. There was a delay between juice collection and starting fermentation due to the time needed to complete the construction of the gas sparging equipment. After cold settling, the juices were racked into labelled 750 mL wine bottles for fermentation. Three levels of elemental sulphur were added to each juice sample before yeast inoculation - nil, 10 mg/L and 100 mg/L. After yeast inoculation and for each level of elemental sulphur, the juices were sparged with different gases for a period of time during fermentation, namely O2, N2 and control (no gas sparging), creating nine treatments for each Sauvignon blanc wine. Each treatment was performed in triplicate.

Fermentation process

Each treatment was fermented in triplicate. The juices were first moved from the cool room (-4°) and allowed to reach room temperature (25°). After adding elemental sulphur, the rehydrated yeast (VIN 7) was added to the grape must following the manufacturer's instructions to start fermentation. The juices were then moved to a temperature-controlled room (15°) for fermentation. The weight of every bottle was monitored daily using a scale, as the yeast metabolism led to the production of CO2, which was released from the bottles, causing the overall weight to go down (Belda et al., 2017). The dissolved oxygen already present in the must was expected to be depleted rapidly during the early stages of fermentation and consumed through yeast activity (Han et al., 2017).

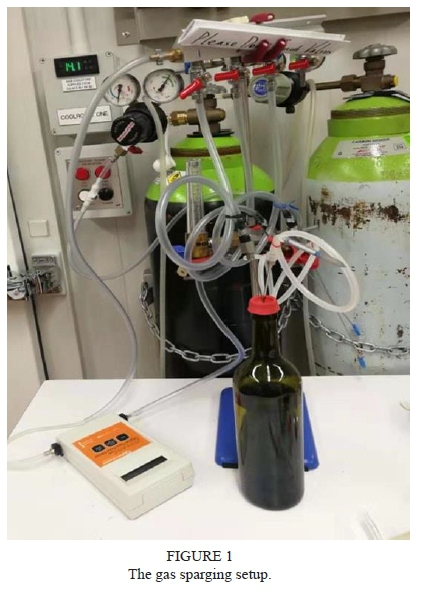

The gas sparging was undertaken after one-third of the fermentation, determined by the extent of weight loss. Based on previous experience, each bottle of Sauvignon blanc with a starting Brix of around 20 will lose approximately 53 g of weight by the end of fermentation. When the bottles had lost about one third of this weight, gas sparging was undertaken at a flow rate of 50 mL/min for 5 min every other day, for a total of five times. The setup of the gas sparging equipment is shown in Fig. 1. The gas came from a gas cylinder through a gas regulator. The gas then went through plastic tubes before passing a digital gas flowmeter (Phenomenex®, ZEPHYR™ 500HR), which monitored the flow rate of the whole gas system. This was connected to a manual gas flowmeter that regulated the flow rate and made it stable. After that, the gas went through a gas manifold and eventually reached the bottom of the wine bottle via a plastic tube connected with a long hypodermic needle. The wine bottle was sealed using a rubber stopper with only an inlet (a long hypodermic needle) and an outlet (a short hypodermic needle) to make sure the gas was sparged into the wine under a sealed system and was able to be released into the outside environment.

When the fermentation was complete, as determined by the weight of the bottles remaining stable for more than three days, 25 mg/L SO2 (45 mg/L PMS) was added to the wines to ensure that no yeast activity would continue. The wines were then cold stabilised in a -4°C cool room for two weeks. After cold stabilisation, samples were collected from each wine bottle and stored in a -20°C freezer until the analysis of the various chemical compounds.

Chemicals

Saccharomyces cerevisiae Lalvin VIN7 was purchased from Lallemand (Anchor Yeast Biotechnologies, Cape Town, South Africa). Elemental sulphur Sulgran (80% w/w, water-dispersible granule) was supplied by Fruitfed Supplies (Auckland, New Zealand). PMS was purchased from Enartis (Trecate, Italy).

The internal standards, d2-3-mercaptohexanol and d2-3-mercaptohexyl acetate, were synthesised at the University of Auckland (Hebditch et al., 2007). The polyfunctional mercaptan 3-mercaptohexanol (98%) was sourced from Acros Organics (Geel, Belgium), and the 3-mercaptohexyl acetate (98%) was from Oxford Chemicals (Hartlepool, UK). The sulphur-containing compounds methanethiol, carbon disulphide, sodium sulphide, dimethyl sulphide and diethyl sulphide were supplied by Sigma-Aldrich (Castle Hill, Australia), and were all at a purity of 98%. Dimethyl sulphide-d6 was from Sigma-Aldrich (Castle Hill, Australia). For the analysis of the C6 compounds, hexanal (98%), trans-2-hexenal (98%), trans-2-hexenol (96%), cis-2-hexenol (95%) and cis-3-hexenol (98%) were purchased from Aldrich (Castle Hill, Australia); 1-hexanol (99.5%) was from Fluka (Castle Hill, Australia); and the trans-3-hexenol (97%) was from Lancaster (Morecambe, England). The deuterated internal standards, d11-n-hexanol and d12-n-hexanal, were purchased from CDN isotopes (Pointe-Claire, Canada). The phenolic compounds gallic acid, caffeic acid, p-coumaric acid, catechin, epicatechin, rutin and quercetin-glucuronide were all of high purity and were supplied by Sigma-Aldrich (Castle Hill, Australia). The other aroma compounds, such as esters, terpenes, C13-norisoprenoids, higher alcohols, aldehydes, C6 compounds, fatty acids, phenols and cinnamates, were supplied by Sigma-Aldrich (Benkwitz et al., 2012; Jouanneau et al., 2012).

Juice analysis

Standard juice chemical analytical parameters

The juices taken from the winery tanks were also sent to the winery laboratory for immediate analysis of standard juice parameters. The analyses were undertaken using a FOSS WineScan™ SO2 instrument (FOSS, Denmark) for total soluble solids (Brix), pH, titratable acidity as tartaric acid (TA), yeast assimilable nitrogen (YAN), free sulphur dioxide (F-SO2), total sulphur dioxide (T-SO2), and the absorbance at 420 nm (A420).

Wine analysis

The polyphenol compounds in the wines were quantified using an Agilent 1100 HPLC instrument, equipped with an ESA CoulochemIIIelectrochemical detector (Chelmsford, USA), a diode-array UV-Vis detector (Agilent, USA), and a Phenomenex Luna C18 column (250 * 4.6 mm ID, 5 μm particle size) (Torrence, CA). The procedure was based on a method developed previously (Maggu et al., 2007).

The polyfunctional mercaptans, 3-mercaptohexan-1-ol (3MH) and 3-mercaptohexan-1-ol acetate (3MHA), were quantified using a solid-phase extraction with the GC-MS method, as reported previously (Herbst-Johnstone et al., 2013).

Further volatile compounds were quantified using a headspace solid phase microextraction (HS/SPME) with GC-MS method, as reported previously (Herbst-Johnstone et al., 2012). The analysis was undertaken on an Agilent 7890A GC System coupled to a mass selective detector model 5975C inert XL (Santa Clara, CA, USA). A 2 cm, 23-gauge, 50/30 μm, DVB/CAR/PDMS fibre was used with an automated holder, grey, notched (SUPELCO, Bellefonte, Pennsylvania, USA; #57299_U).

The reductive compounds were quantified using a headspace solid-phase microextraction and gas chromatography-mass spectrometry (HS-SPME/GC-MS) method previously developed by Nguyen et al. (2012). The analysis was undertaken on the same system as the analysis of further volatile compounds.

More details of the calibrations of these analytical methods can be found in our recently published paper (Lyu et al., 2021).

Statistical data analysis

The analysis was undertaken using Microsoft Excel 365 (Microsoft, Redmond, USA) and R 3.5.2 (R Core Team, The University of Auckland, New Zealand). The data analysis used a one-way ANOVA test. Different treatments, different levels of elemental sulphur addition and different gas sparging treatments were used as a single fixed factor and were analysed separately. The significance level was set at 5% and the pair-wise comparison of means was undertaken using Tukey's test. The Tukey test assumes a normal distribution and, while such a distribution was not able to be established for the small dataset, it can be applied to "real-valued random variables whose distributions are not known" (Casella & Berger, 2001).

RESULTS AND DISCUSSION

Standard juice chemical analytical parameters

Standard juice chemical measurements were done when the juices were collected from the tanks at the winery. There was little difference between SB1 and SB2 in terms of these measurements, and they can be regarded as typical of commercial Sauvignon blanc juices from the Marlborough region (with average values of 20.25°Brix, pH 3.15, TA 8.8 g/L, YAN 256 mg N/L, F-SO2 28 mg/L, T-SO2 60 mg/L and an A420 of around 0.11). The YAN, F-SO2 and T-SO2 in SB1 were a little lower than those in SB2, while the other values were very similar.

Wine analysis

Phenolic compounds

Table 1 shows the concentrations of the phenolic compounds in the final wines. Changes in the concentrations of phenolic compounds can show differences in wine oxidation history. Several phenolic compounds were not detected in the wines, e.g. the grape reaction product (GRP), p-coumaric acid, ferulic acid and quercetin-glucoside, while syringic acid was only detected in some of the samples. No consistent trend was found in the concentrations of the phenolic compounds between different gas sparging treatments under the same level of elemental sulphur addition. While the N2 (an inert gas) sparging treatment was not expected to affect the phenolic compounds in the wines, O2 sparging was expected to lead to lower concentrations of some phenolic compounds, as the oxidation reaction of these compounds was expected to occur in the must (Du Toit et al., 2006). A rapid uptake of O2 by the yeasts may have occurred in preference to the oxidation of phenolic compounds during fermentation and at the time of gas sparging (Du Toit et al., 2006). Furthermore, the lack of influence of O2 on the oxidisable phenolic compounds needs to be borne in mind when reviewing the results of the sulphur-containing aroma compounds in the wines.

Polyfunctional mercaptans

Figs 2 and 3 shows the concentrations of 3MH and 3MHA, respectively, in the two Sauvignon blanc wines following the various treatments. There was a clear increase in the concentrations of polyfunctional mercaptans when elemental sulphur was added to the juices before fermentation. This is expected to occur through the reduction of elemental sulphur to H2S, and the formation of extra 3MH through a 1,4 addition of H2S to certain C6 compounds during yeast metabolism (Schneider et al., 2006). This trend is consistent with the results of our recently published research (Araujo et al., 2017; Lyu et al. 2021), in that extra increases in polyfunctional mercaptans were observed when elemental sulphur was included with grapes soon after harvest. Lacroux et al. (2008) reported that the application of a combination of elemental sulphur and foliar nitrogen fertilisation to Sauvignon blanc vines prior to véraison enhanced the levels of polyfunctional mercaptans in the finished wines, which were preferred by a professional panel in a blind tasting. It is worth noting that 3MHA was not detected in the wines to which 100 mg/L elemental sulphur had been added. This may be due to some unknown influence of the high level of elemental sulphur addition in the grape must on the conversion rate from 3MH to 3MHA, and is worthy of further investigation. At the same time, no similar declines with further acetate esters were observed (see below).

In relation to the different gas sparging procedures, for both Sauvignon blanc samples without added elemental sulphur there were small, but not significant, decreases in the concentrations of 3MH and 3MHA in the wines with both N2 and O2 gas sparging compared to the control wines (Figs 2 and 3). A clearer decrease in the concentrations of polyfunctional mercaptans from gas sparging was seen with the wines made with the 10 mg/L elemental sulphur additions, particularly with O2 sparging in both Sauvignon blanc samples. In this case, the introduction of oxygen during fermentation could have produced some quinones from the oxidation of phenolic compounds, which in turn could gave reacted with the polyfunctional mercaptans. Quinones are important intermediates that can affect wine quality through interactions with nucleophilic compounds, such as 3MH, resulting in the loss of desirable aromas (Nikolantonaki et al., 2014). However, the lack of observable changes in phenolic levels with O2 application suggests that a different mechanism could be at work, leading to the lower 3MH and 3MHA concentrations. Another explanation could be the quinones formed due to oxygen sparging during fermentation caused the loss of the polyfunctional mercaptans. However, some of the quinones could have been reduced back to their original phenolic forms when SO2 was added postfermentation, a process that occurs very rapidly in wines (Makhotkina & Kilmartin, 2009).

In contrast, with the addition of 100 mg/L elemental sulphur, both of the gas sparging trials allowed a higher formation of 3MH in the wines compared to the wines with no gas sparging, while the large error bars associated with some values should be noted (Figs 2 and 3). The increasing effect of 3MH on the N2 sparging treatment applied to Sample 2 was even stronger than the O2 sparging treatment. The reason why the gas sparging increased 3MH formation when 100 mg/L of elemental sulphur was applied needs to be investigated in future studies.

Reductive aroma compounds

Table 2 shows the concentrations of the reductive compounds quantified in the Sauvignon blanc wines according to differences in gas sparging treatments and elemental sulphur additions. Methanethiol was detected at concentrations above its perception threshold in most of the wines. Carbon disulphide, 2-(methylthio)-1-ethanol and benzothiazole were detected in the wines at concentrations below their perception thresholds. Ethanethiol, dimethyl sulphide and diethyl disulphide were not detected in some wines when elemental sulphur was added at 0 or 10 mg/L. Other compounds were present in the wines at higher or lower than their perception thresholds, with increases seen as more elemental sulphur was added to the juices.

There were no significant differences among the gas sparging treatments on the concentrations of the reductive sulphur compounds compared with the control treatments (Table 2). The inclusion of N2 or O2 sparging occasionally removed some unwanted reductive sulphur compounds, but the effects were not consistent. Bekker et al. (2016) reported that, with O2 treatment (40% O2 and 21% O2) during fermentation, the negative effect of volatile sulphur compounds caused by reductive winemaking was decreased. At the same time, there was an increase in positive red fruit aromas in the Shiraz wine being investigated in that study, while the physical displacement treatment (N2) did not lower the reductive aromas. More recent research with Shiraz wines undertaken by Bekker et al. (2021) showed that macro-oxygenation during fermentation (sparged with compressed air at a rate of 1 L/min for two hours for each of five consecutive days) can assist in lessening reductive aromas in sensory tests.

Volatile aroma compounds

Several families of aroma compounds were quantified in this paper, including esters, higher alcohols and aldehydes, terpenes, C13-norisoprenoids, C6 compounds, fatty acids, cinnamates and phenols. The values were consistent with our recent publication on Sauvignon blanc wines (Lyu et al., 2021). While the gas sparging treatments were targeted at sulphur-containing aroma compounds, it was considered important to check the effects of the treatments on these additional important aroma compounds. Across the different treatments, few significant or consistent trends were found in the wines between different gas sparging treatments or different levels of elemental sulphur additions. The occasional increase or decrease in the concentration levels of particular aroma compounds that were consistent across both SB1 and SB2 will be noted here.

Among the esters, no significant differences were found among gas sparging treatments or elemental sulphur treatments, except for isobutyl acetate and ß-phenylethyl acetate, which were present at the highest levels in the wines treated with 100 mg/L S0 (two to three times higher than 0 mg/L S0). This occurred despite the fact that the acetylation of 3MH to 3MHA seemed to be inhibited at such a high level of S0. The increase in isobutyl acetate with the addition of 100 mg/L S0 was diminished when gas sparging was applied (a decrease of around 38% for oxygen sparging and 20% for nitrogen sparging).

Regarding the terpenes and C13-norisoprenoids, for most of the samples, ß-citronellol and trans-geraniol were found at higher levels in the wines with O2 sparging (around 37% higher for ß-citronellol and 17% higher for trans-geraniol compared to the controls). In contrast, cis-geraniol was found at lower levels with O2 sparging (around 38% lower compared to the controls). A significant decrease in ß-damascenone was observed with increased S0 additions to the wines (around 61% decrease with 10 mg/L S0 and 93% decrease with 100 mg/L S0 additions).

Among the higher alcohols, lower levels of 1-butanol were found in the wines with O2 addition (around 26% lower). Regarding the C6 compounds, cis-3-hexenol was present at lower levels in the wines that were subject to O2 (18% lower). In contrast, hexanal was present at higher levels in the wines with O2 (26% higher). Hexanol was present at higher levels in the wines treated with 100 mg/L S0 (33% higher), while both cis-3-hexenol and trans-3-hexenol were present at lower levels in the wines with 100 mg/L S0 (around 16% lower for cis-3-hexenol and 33% lower for trans-3-hexenol).

CONCLUSIONS

Sauvignon blanc wines treated with variable concentrations of elemental sulphur before fermentation, followed by sparging with different gas treatments during fermentation, resulted in wines with distinctive chemical profiles. Elemental sulphur significantly increased the concentrations of sulphur-containing compounds and polyfunctional mercaptans. This indicates that elemental sulphur created an environment that favoured the formation of these compounds, likely through an increase in H2S levels early in fermentation. However, the elemental sulphur additions had little effect on other chemical compounds, such as the phenolics or other volatiles.

The oxygen applied during fermentation did not result in the removal of undesirable reductive aroma compounds, nor did it lead to the considerable oxidation of phenolic compounds. However, the added oxygen did decrease the concentrations of 3MH and 3MHA compared to the control wines. The physical sparging with N2 only removed unwanted volatile sulphur compounds from some of the wines occasionally, but did not otherwise significantly affect the chemical composition of the wines. The addition of oxygen during fermentation seems to be a viable option to influence the content of certain sulphur-derived compounds of Sauvignon blanc wines.

Further trials are needed to examine increased oxygen as well as nitrogen dosages during fermentation, and their effects on the reductive compounds. The level of dissolved oxygen in the wines should also be monitored. Such trials should include sensory analysis to evaluate the changes in perception of polyfunctional mercaptans caused by the application of oxygen, and whether the influence of unwanted reductive aroma compounds can be removed. Other trials could also focus on the influences of oxygen and nitrogen sparging on pressed juice, which contains more phenolics that could possibly lead to a different outcome in terms of reductive sulphur compounds, as only free-run juice was used in this present study. Large-scale fermentation under practice-relevant conditions should also be considered in future studies.

LITERATURE CITED

Araujo, L.D., Vannevel, S., Buica, A., Callerot, S., Fedrizzi, B., Kilmartin, P.A. & Du Toit, W.J., 2017. Indications of the prominent role of elemental sulfur in the formation of the varietal thiol 3-mercaptohexanol in Sauvignon blanc wine. Food Res. Int. 98, 79-86. [ Links ]

Bekker, M., Day, M., Holt, H., Wilkes, E. & Smith, P.A., 2016. Effect of oxygen exposure during fermentation on volatile sulfur compounds in Shiraz wine and a comparison of strategies for remediation of reductive character. Aust. J. Grape Wine Res. 22(1), 24-35. [ Links ]

Bekker, M., Espinase Nandorfy, D., Kulcsar, A., Faucon, A., Bindon, K. & Smith, P., 2021. Comparison of remediation strategies for decreasing 'reductive' characters in Shiraz wines. Aust. J. Grape Wine Res. 27(1), 52-65. [ Links ]

Belda, I., Ruiz, J., Esteban-Fernandez, A., Navascues, E., Marquina, D., Santos, A. & Moreno-Arribas, M.V., 2017. Microbial contribution to wine aroma and its intended use for wine quality improvement. Molecules 22(2), 189. [ Links ]

Benkwitz, F., Nicolau, L., Lund, C., Beresford, M., Wohlers, M. & Kilmartin, P.A., 2012. Evaluation of key odorants in Sauvignon blanc wines using three different methodologies. J. Agric. Food Chem. 60(25), 6293-6302. [ Links ]

Berlese-Noble, J., Raynal, C., Silvano, A., Granes, D., Bonnefond, C. & Ortiz-Julien, A., 2014. New research, new yeast, new selection tool. Aust. N.Z. Grapegrow. Winemak. 602, 48-53. [ Links ]

Bertrand, A. & Torres-Alegre, V., 1984. Incidence de l'action de l'oxygene sur la formation des produits secondaires de la fermentation alcoolique du moüt de raisin. Sci Aliments. 4(1), 45-64. [ Links ]

Burdock, G. (2005). Fenaroli's Handbook of Flavor Ingredients. In: Boca Raton, FL: CRC Press. [ Links ]

Casella, G., & Berger, R. L., 2001. Statistical Inference (2nd ed.). Duxbury. 102. [ Links ]

Day, M., Schmidt, S., Smith, P. & Wilkes, E., 2015. Use and impact of oxygen during winemaking. Aust. J. Grape Wine Res. 21, 693-704. [ Links ]

Du Toit, W., Marais, J., Pretorius, I. & Du Toit, M., 2006. Oxygen in must and wine: A review. S. Afr. J. Enol. Vitic. 27(1), 76-94. [ Links ]

Fang, Y. & Qian, M.C., 2005. Sensitive quantification of sulfur compounds in wine by headspace solid-phase microextraction technique. J. Chromatogr. A 1080(2), 177-185. [ Links ]

Franco-Luesma, E. & Ferreira, V., 2016. Reductive off-odors in wines: Formation and release of H2S and methanethiol during the accelerated anoxic storage of wines. Food Chem. 199, 42-50. [ Links ]

García, E., Chacón, J., Martínez, J. & Izquierdo, P., 2003. Changes in volatile compounds during ripening in grapes of Airén, Macabeo and Chardonnay white varieties grown in La Mancha region (Spain). Food Sci. Technol. Int. 9(1), 33-41. [ Links ]

Gardner, J.M., Poole, K. & Jiranek, V., 2002. Practical significance of relative assimilable nitrogen requirements of yeast: A preliminary study of fermentation performance and liberation of H2S. Aust. J. Grape Wine Res. 8(3), 175-179. [ Links ]

Gómez-Plaza, E. & Cano-López, M., 2011. A review on micro-oxygenation of red wines: Claims, benefits and the underlying chemistry. Food Chem. 125(4), 1131-1140. [ Links ]

Han, G., Webb, M.R., Richter, C., Parsons, J. & Waterhouse, A.L., 2017. Yeast alter micro-oxygenation of wine: Oxygen consumption and aldehyde production. J. Sci. Food Agric. 97(11), 3847-3854. [ Links ]

Hebditch, K.R., Nicolau, L. & Brimble, M.A., 2007. Synthesis of isotopi-cally labelled thiol volatiles and cysteine conjugates for quantification of Sauvignon blanc wine. J. Label. Compd. Radiopharm. 50(4), 237-243. [ Links ]

Herbst-Johnstone, M., Araujo, L., Allen, T., Logan, G., Nicolau, L. & Kilmartin, P., 2012. Effects of mechanical harvesting on 'Sauvignon blanc' aroma. Acta Hortic. 978, 179-186. https://doi.org/10.17660/ActaHortic.2013.978.18 [ Links ]

Herbst-Johnstone, M., Piano, F., Duhamel, N., Barker, D. & Fedrizzi, B., 2013. Ethyl propiolate derivatisation for the analysis of varietal thiols in wine. J. Chromatogr. A 1312, 104-110. [ Links ]

Jastrzembski, J.A., Allison, R.B., Friedberg, E. & Sacks, G.L., 2017. Role of elemental sulfur in forming latent precursors of H2S in wine. J. Agric. Food Chem. 65(48), 10542-10549. [ Links ]

Jiranek, V., Langridge, P. & Henschke, P., 1995. Regulation of hydrogen sulfide liberation in wine-producing Saccharomyces cerevisiae strains by assimilable nitrogen. Appl. Environ. Microbiol. 61(2), 461-467. [ Links ]

Jouanneau, S., Weaver, R.J., Nicolau, L., Herbst-Johnstone, M., Benkwitz, F. & Kilmartin, P. A., 2012. Subregional survey of aroma compounds in Marlborough Sauvignon blanc wines. Aust. J. Grape Wine Res. 18(3), 329-343. [ Links ]

Karagiannis, S. & Lanaridis, P., 1999. The effect of various vinification parameters on the development of several volatile sulfur compounds in Greek white wines of the cultivars Batiki and Muscat of Hamburg. Am. J. Enol. Vitic. 50(3), 334-342. [ Links ]

Kinzurik, M.I., Herbst-Johnstone, M., Gardner, R.C. & Fedrizzi, B., 2016. Hydrogen sulfide production during yeast fermentation causes the accumulation of ethanethiol, S-ethyl thioacetate and diethyl disulfide. Food Chem. 209, 341-347. [ Links ]

König, H., Unden, G. & Fröhlich, J., 2009. Biology of microorganisms on grapes, in must and in wine. Springer-Verlag, Heidelberg. [ Links ]

Kreitman, G.Y., Danilewicz, J.C., Jeffery, D.W. & Elias, R.J., 2016. Reaction mechanisms of metals with hydrogen sulfide and thiols in model wine. Part 1: Copper-catalyzed oxidation. J. Agric. Food Chem. 64(20), 4095-4104. [ Links ]

Kwasniewski, M.T., Sacks, G.L. & Wilcox, W.F., 2014. Persistence of elemental sulfur spray residue on grapes during ripening and vinification. Am. J. Enol. Vitic. 65(4), 453-462. [ Links ]

Lacroux, F., Trégoat, O., Van Leeuwen, C., Pons, A., Tominaga, T., Lavigne-Cruège, V. & Dubourdieu, D., 2008. Effect of foliar nitrogen and sulphur application on aromatic expression of Vitis vinifera L. cv. Sauvignon blanc. OENO One, 42(3), 125-132. [ Links ]

Landaud, S., Helinck, S. & Bonnarme, P., 2008. Formation of volatile sulfur compounds and metabolism of methionine and other sulfur compounds in fermented food. Appl. Microbiol. Biotechnol. 77(6), 1191-1205. [ Links ]

Lyu, X., Dias Araujo, L., Quek, S.-Y. & Kilmartin, P.A., 2021. Effects of antioxidant and elemental sulfur additions at crushing on aroma profiles of Pinot Gris, Chardonnay and Sauvignon blanc wines. Food Chem. 346, 128914. [ Links ]

Maggu, M., Winz, R., Kilmartin, P.A., Trought, M.C. & Nicolau, L., 2007. Effect of skin contact and pressure on the composition of Sauvignon blanc must. J. Agric. Food Chem. 55(25), 10281-10288. [ Links ]

Makhotkina, O. & Kilmartin, P.A., 2009. Uncovering the influence of anti-oxidants on polyphenol oxidation in wines using an electrochemical method: Cyclic voltammetry. J. Electroanal. Chem. 633(1), 165-174. [ Links ]

Masselot, M. & De Robichon-Szulmajster, H., 1975. Methionine biosynthesis in Saccharomyces cerevisiae. Mol. Gen. Genet. 139(2), 121-132. [ Links ]

McCord, J., 2003. Application of toasted oak and micro-oxygenation to ageing of Cabernet Sauvignon wines. Aust. N.Z. Grapegrow. Winemak. 474, 43-53. [ Links ]

Mestres, M., Busto, O. & Guasch, J., 2000. Analysis of organic sulfur compounds in wine aroma. J. Chromatogr. A 881(1-2), 569-581. [ Links ]

Mestres, M., Busto, O. & Guasch, J., 2002. Application of headspace solidphase microextraction to the determination of sulphur compounds with low volatility in wines. J. Chromatogr. A 945(1-2), 211-219. [ Links ]

Nguyen, D.-D., Nicolau, L. & Kilmartin, P.A., 2012. Application of an automated headspace solid phase micro-extraction for the GC-MS detection and quantification of reductive sulfur compounds in wines. In: Salih, B. (ed.). Gas chromatography in plant science, wine technology, toxicology and some specific applications. InTech, Rijeka, Croatia. pp. 171 - 195. [ Links ]

Nikolantonaki, M., Magiatis, P. & Waterhouse, A.L., 2014. Measuring protection of aromatic wine thiols from oxidation by competitive reactions vs wine preservatives with ortho-quinones. Food Chem. 163, 61-67. [ Links ]

Ribéreau-Gayon, P., Glories, Y., Maujean, A. & Dubourdieu, D., 2006 (2nd ed). Handbook of enology: The chemistry of wine stabilization and treatments, vol. 2. John Wiley & Sons Ltd, Chichester, UK. [ Links ]

Roland, A., Schneider, R., Razungles, A. & Cavelier, F., 2011. Varietal thiols in wine: Discovery, analysis and applications. Chem. Rev. 111(11), 7355-7376. [ Links ]

Salmon, J.-M., 2006. Interactions between yeast, oxygen and polyphenols during alcoholic fermentations: Practical implications. LWT 39(9), 959-965. [ Links ]

Savocchia, S., Mandel, R., Crisp, P. & Scott, E., 2011. Evaluation of 'alternative' materials to sulfur and synthetic fungicides for control of grapevine powdery mildew in a warm climate region of Australia. Australas. Plant Pathol. 40(1), 20-27. [ Links ]

Scerri, D. & Heinrich, A.J., 2009. Winemaking trials prove new yeast strains produce no detectable hydrogen sulfide. Aust. N.Z. Grapegrow. Winemak. 545, 53-55. [ Links ]

Schneider, R., Charrier, F., Razungles, A. & Baumes, R., 2006. Evidence for an alternative biogenetic pathway leading to 3-mercaptohexanol and 4-mercapto-4-methylpentan-2-one in wines. Anal. Chim. Acta 563(1-2), 58-64. [ Links ]

Schütz, M. & Kunkee, R.E., 1977. Formation of hydrogen sulfide from elemental sulfur during fermentation by wine yeast. Am. J. Enol. Vitic. 28(3), 137-144. [ Links ]

Siebert, T.E., Solomon, M.R., Pollnitz, A.P. & Jeffery, D.W., 2010. Selective determination of volatile sulfur compounds in wine by gas chromatography with sulfur chemiluminescence detection. J. Agric. Food Chem. 58(17), 9454-9462. [ Links ]

Spedding, D. & Raut, P., 1982. The influence of dimethyl sulphide and carbon disulphide in the bouquet of wines. Vitis 21, 240-246. [ Links ]

Zoecklein, B., 2007. Factors impacting sulfur-like off odors in wine and winery options. 8th Annual Enology and Viticulture British Columbia Wine Grape Council Conference, Penticton, BC, Canada. [ Links ]

Submitted for publication: February 2021

Accepted for publication: June 2021

* Corresponding author: p.kilmartin@auckland.ac.nz [Tel: +64 9 923 8324]