Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

South African Journal of Industrial Engineering

versión On-line ISSN 2224-7890

versión impresa ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.34 no.4 Pretoria dic. 2024

http://dx.doi.org/10.7166/34-4-2898

GENERAL ARTICLES

Variation orders during execution of construction infrastructure projects: case study of an electricity company

T. MashambaI, ; M.G. Kanakana-KatumbaII; R. MaladzhiIII

IDepartment of Mechanical and Industrial Engineering, University of South Africa, Pretoria, South Africa

IIDepartment of Industrial Engineering, Tshwane University of Technology, Pretoria, South Africa

IIIDepartment of Mechanical Engineering, Durban University of Technology, Durban, South Africa

ABSTRACT

Electricity plays a fundamental role in efforts towards sustainable development and poverty alleviation. The South African government resolved to build new power-generating plants, but the completion of these projects has been affected by different variation orders. An investigation was conducted using the compensation events and variation committee records from different stations in the SAP database to determine the trend of the variation orders that were raised during the execution of the new stations and at existing plants. The results showed that factors such as scope change, integration between packages, design errors, and expedited schedules contributed to the variation orders during the execution of the infrastructure projects.

OPSOMMING

Elektrisiteit speel 'n fundamentele rol in die volhoubare ontwikkeling en armoedeverligtingspogings. Die Suid-Afrikaanse regering het besluit om nuwe kragopwekkingsaanlegte te bou, maar voltooiing van hierdie projekte is beïnvloed deur verskeie omvangsveranderings. 'n Ondersoek is uitgevoer met behulp van die vergoedingsgebeurtenisse en variasiekomiteerekords van verskillende stasies in die SAP-databasis om die neiging van goedgekeurde omvangsveranderingsbestellings wat tydens die uitvoering van die nuwe kragstasies en bestaande aanlegte geopper is, te bepaal. Die resultate toon dat faktore soos die omvangverandering, integrasie tussen pakkette, ontwerpfoute, en versnelde skedule bygedra het tot die variasiebestellings tydens die uitvoering van die infrastruktuurprojekte.

1. INTRODUCTION

The International Energy Agency (IEA) estimates that 1.1 billion people do not have access to electricity, most of them living in rural areas [1]. According to [2], electricity plays a fundamental role in sustainable development and poverty alleviation efforts; its accessibility impacts the lives of underprivileged people and their ability to escape poverty. Lacking reliable access to electricity is considered a limit on people's opportunities and quality of life. As an emerging economy, South Africa faces the double challenge of chasing economic growth and environmental protection. It is noted that the economy of South Africa is primarily organised around large-scale energy-intensive mining and the associated beneficiation industries, raising its energy intensity levels to above-world-average levels, even when compared with developed countries.

According to [3], improving energy efficiency in South Africa would help both the citizens and the economy. The energy sector is critical in the economic growth perspective, as it contributes 3.2% of the country's gross domestic product (GDP). The power utility has seen a substantial growth in demand for power supplies from both industrial and domestic power consumption bases over the past 20 years owing to economic growth. According to [4], the power utility is currently executing various capital expansion building programmes to address the supply constraint requirements. This expansion takes the form of new generation plants that are needed to boost electricity generation capacity, transmission grids, electricity distribution lines, and needed substations. The new infrastructure is mostly procured and executed as projects awarded to winning bidders by government agencies.

The projects include new builds and generation projects. The role of engineering in the utility's generation division is to ensure the maintainability, operation, and sustainability of its generation assets. The role of engineering in new builds and generation refurbishment projects is to develop the full cycle of the design process, which is the core engineering function. The engineering role involves developing and reviewing the concept designs, basic designs, detailed designs, and technical specifications.

According to [5], the electric power construction business is complex, has less staff, and has many difficulties in its management. The focus of the organisation is changing from one of 'operate and maintain' to one of undertaking major new capacity projects, including building new plants and returning mothballed plants to service. According to [3], key projects such as the construction of power stations A, B, and C are currently in progress to upgrade and grow the energy sector infrastructure. The power utility has not implemented projects of this nature for more than 20 years, and these projects need to be fast-tracked. During the previous build programme, the power utility depended on superior technical capability as the core competence to ensure successful implementation. The construction projects of power stations A, B, and C have run into delays, quality problems, cost overruns, and systems designs not being integrated that can be traced to the project dynamics plan. However, the completion of these projects has also been affected by different variation orders.

The power utility's engineering team investigated major problems in the construction sector, such as high costs, general quality-related problems, general problems, and the reduction of costs in constructing new buildings. Little research has investigated non-value-adding activities connected to changes or variations made during the construction stage. According to academics and practitioners, variation orders are prevalent in the construction industry, but their potential impact on project performance has been overlooked. Variation continues to pose a serious threat to the construction industry [6]. This study investigated the trend of the variation orders that were raised during the execution of the new power stations and at existing coal-fired power stations, and made recommendations for future projects.

2. OBJECTIVES

The objective of the study was to conduct an investigation using the compensation events and variations committee records from different stations in the SAP database to determine the trend of variation orders that were raised during the execution of the new stations and at existing coal-fired power stations, and to come up with recommendations. Variation orders involve additions, omissions, alterations, and substitutions in respect of quality, quantity, and schedule of works.

3. LITERATURE REVIEW

According to [7], construction and the development of infrastructure are important for economic growth. As described by [8], a construction contract is a business agreement that is subject to variability. The general conditions of contracts for construction works use variation orders (VOs) to deal with scope changes. Contractual provisions for adjustments permit parties to a contract freely to request variations within the boundaries of the work's scope without changing the terms of the original agreement. As defined by [9], a variation is any deviation from an established and clearly defined scope and schedule. A variation order is the formal document that is used to modify the original contractual agreement, and it becomes part of a project's documents. Variation orders arise for a variety of reasons, some of which are predictable and others are not [10]. However, [11] note that variation orders happen because construction projects include complicated procedures that cannot be fully specified in advance. It is unusual to complete projects exactly on time owing to factors such as business condition changes, delivery slips, and design modifications. According to a review of the literature, every member of a project contributes to such variances [12].

According to various researchers, including [13], variation orders cause cost overruns. Cost and schedule overruns are common occurrences in construction projects, despite the many studies that have been done on the subject. While [14] state that scope modification is a recurring theme in research into the causes and effects of overruns, cost and schedule overruns are among the most important effects of changes to scope. This was confirmed in a study of the effects of scope change by [15]. Many researchers have identified various causes of variation orders [16]. A total of 11 causes were identified from the literature review, as discussed below.

• Change of schedule: During the project construction phase, a change in schedule could require a substantial reallocation of resources. The contractor would need either to supply more resources or to leave certain resources idle because of changes to the timeline. In both situations, additional costs are incurred [17].

• Scope change: One of the biggest causes of variation in construction projects is a change in the project's scope. It usually happens because of poor front-end planning [18].

• Owner's financial problems: The owner's financial problems can affect project progress. This issue often leads to changes in work schedules and specifications, affecting the quality of the construction [10].

• Change in specifications by the owner: Specification changes are a frequent occurrence in construction projects with insufficient project objectives [9].

• Integration between packages: A lack of an integrated plan during the inception of the project causes delays [19].

• Change in design by the consultant: Changes in design are frequent in projects where construction starts before the design has been finalised [17]. Such changes affect the project in various ways, depending on the timing of the changes.

• Design complexity: Complex designs require exceptional skills and construction methods [20].

• Inadequate working drawing details: To convey the complete concept of the project design, the working drawings must be clear and brief [21].

• Shortage of skilled manpower: Skilled manpower is required during construction projects, and a shortage thereof can lead to project delays [22].

• Poor workmanship: Poor workmanship leads to the reworking of construction projects [13].

• Conflicts between contract documents: It is essential that the contract documents are clear and precise. Insufficient details may result in delays in the project's completion or may cause variations in cost [23].

According to [24], [17], [10], [18], [23], and [13], the major causes of variations fall into three broad categories:

• Design errors and omissions (65 per cent)

• Design changes (30 per cent)

• Unforeseen conditions (5 per cent)

3.1. Impact of variation orders on project performance

According to [23], maximum project performance would be achieved, given a well-structured schedule of works, if the job consistently proceeded without glitches within the allocated time frames and projected financial restrictions. According to [9], a study of the effects of variation orders on academic building projects, variation orders significantly increased the cost of construction projects [24]. It was discovered by [22] that variation orders issued at different project phases had a negative impact on the project's completion time and costs. Time and cost overruns and disputes had a major impact on project performance.

Variation orders not only affect project performance in respect of time and cost, but also unfavourably affect quality, health, safety, and professional relationships. However, factors influencing the occurrence of variation orders and their adverse impact on project performance vary from one project to another. Such factors include the nature of the work, the complexity of the project, and the procurement method. Although it is unlikely that variation orders could be avoided completely, they could be minimised if their origin and causes were clearly known [25].

4. RESEARCH METHODOLOGY

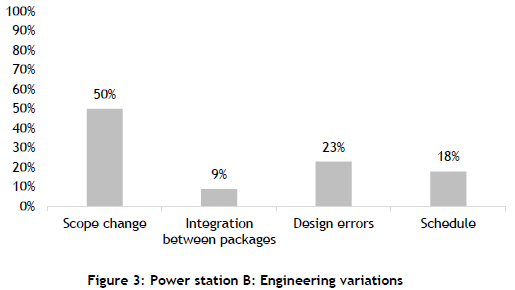

The research methodology for this study entailed conducting an investigation that used the compensation events and variations committee records from different stations in the SAP database in order to determine the trend of variation orders that were raised during the execution of the new power stations and at existing coal-fired power stations. The problem and the root causes of each variation were identified and analysed by the assessment team. The raw data from new builds and generation engineering reports were analysed and filtered, as shown in Table 1 below. Table 1 shows the variation orders that were raised during the period according to date. The new builds were stations A, B, and C, whereas 'generation engineering' was at existing coal-fired power stations.

5. RESULTS AND DISCUSSION

The investigation found that variation orders were based on the scope changes, integration between packages, expedited schedule, and design errors discussed below, according to [26]. The scope changes were related more to the scopes that were missed during the development of the works information, outdated drawings being issued, and a lack of detailed specification. The integration issue was related more to design interfaces between packages, while expedited schedules and design errors were caused by a lack of understanding of the requirements and not following verification process. The following were the root causes per researched station, with a causal analysis summary:

5.1. New build - Power station A

5.1.1. Scope changes

• Change of scope resulting from the heating ventilation air-conditioning plant layout being revised. The power electrical distribution design was changed from the original design.

• The installation of the earth mat at the surge shaft was not part of the original scope.

• The surge shaft area had a change of scope to the contractor's original scope.

• Scope was added for fibre-optic cables with two panels on each end of the cables for the power house-building management system.

• Scope was added for supplying and installing stainless steel supports to rectify the louvre installed at the capping structure. The scope was changed for temporarily installing a fan and associated ducting in the bifurcator area.

• Change to existing civil design for capping structure to minimise ventilation disruption during construction.

• Change of design by connecting the water and sewage to the permanent supply.

• Design change by raising the 22kV power line transecting the tailrace spoil area to give an assurance that the final landscaped levels would not impact the long-term maintenance of the line and fibre-optic cabling.

• Scope was added to install additional column supports and rip rap for sewer line pipe bridge.

• Scope was added for additional power cables for the distribution boards.

• Missed scope to supply fibre-optic patch leads on the communication network between 400V boards.

• Transition joints had to be used on common cooling water pumps, which was not included in the works information and was treated as addition to the existing scope.

5.1.2. Integration between packages

• Additional gas required for the 400kV cable testing and final termination was missed during engineering interface.

• Engineering interface for commissioning common cooling water system prior to the water being made available in the tailrace, adding additional plant/materials, people and time costs.

5.1.3. Design errors

• Reconstruction of beam 30 as a result of design errors, heating, design changes to ventilation and air-conditioning (HVAC), and diversion of main water pipeline to avoid stream crossings.

• Failure to design correct power supply to handle smaller Lot-D system such as back-flushing filters in the cooling water system and motorised valves.

• Crane gantry length was specified as 160 m, but the gantry length was 180 m on site. Failure to specify correct parameters.

• Missed scope for labelling the water and sewer system as detailed in the instructions.

• Missed scope for sealing works for HVAC openings. Various cable and pipe openings in the power complex required sealing to enable the balancing of air for the HVAC system to function properly.

5.1.4. Expedited schedules

• Schedule impacted by the relocation and installation of the ventilation system from auxiliary building capping structure to the turbine hall.

5.1.5. Power station A: Engineering variations, and cost variations orders charts

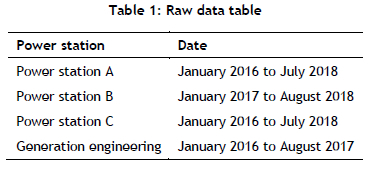

Figure 1 shows the results of the variations done at Power station A from January 2016 to July 2018. It is clear from the chart that 60% of the variations were because of scope changes, followed by 24% of the variations because of design errors, 12% because of lack of integration between packages, and 4% because of the expediting schedule.

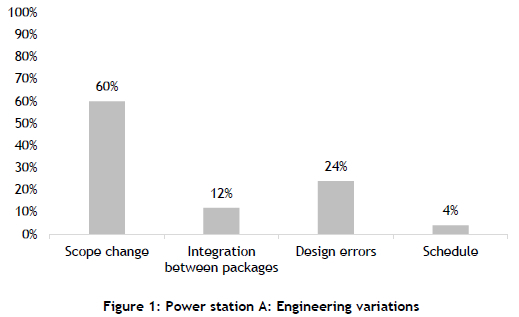

Figure 2 shows the results of the variations at Power station A, looking at the impact on the costs from January 2016 to July 2018. It is clear from the chart that more money was spent on integrating the packages, as the budget of this variation was high. The variation cost changes because of design errors were 10%.

5.1.6. Findings

• It was found that most of the variations at Power station A were a result of changes in scope during construction.

• The cause of design errors was a result of engineers not confirming and verifying the correct parameters on site.

• The integration engineers failed to interface the different packages to complete as planned.

5.2. New build - Power station B

5.2.1. Scope changes

• Exclusion of work in the employer's requirements.

• Equipment design changes as a result of change in power contract supplier.

• Additional cores - control and instrumentation: auxiliary bay 2 simulator.

• Unit 1 - Modification to pipe support.

• Additional chemical supply.

• Auxiliary bay loading.

• Engineering scope omission for coal bunker lightning.

• Unit 1 - C elevator intercom system and telephone booth cable from fibre to copper.

• Procurement of piping and fittings for the lime silo; scope gap was created when the waste water treatment plant (WWTP) was de-scoped from the Package 17 water treatment plant.

• Design, supply, and installation of the missing secondary steel for the low pressure services piping.

• Procurement of pressure testing equipment; scope gap was created when the WWTP was de-scoped from the P17 water treatment plant.

• Changes to the design as a result of revised load schedules from engineering.

5.2.2. Integration between packages

• Misalignment of design information exchange between the two packages (Package 17 and Package 12).

• Interface between the packages not clearly defined for the bundled take-up.

• Small power electrical changes to the WTP; layout showing position of the equipment was not issued to the designer for the WTP lab building, which resulted in some of the electrical points not aligning with the equipment.

5.2.3. Design errors

• Dirty water collected from the stockyard could not be channelled to the nearest manhole.

• Modification to drain pipework required for chemical cleaning, calculation error from power utility engineering during storm water drainage verification process.

5.2.4. Expedited schedule

• Bad housekeeping in Unit 1 owing to multiple contractors working in the same area.

• Contractor working over December 2016.

• Outage works caused a temporary interruption to the construction power supply.

• Access delay for crane pad backfill.

• Additional cartridge filters for resin plant commissioning; lessons learnt from power station C to mitigate delays during initial commissioning of the resin plant.

• Amendment of P20A schedule to meet key milestones; difficulties experienced by Siemens, leading to de-scoping on Units 1-6 and common plant.

5.2.5. Power station B: Engineering variations and engineering variation costs charts

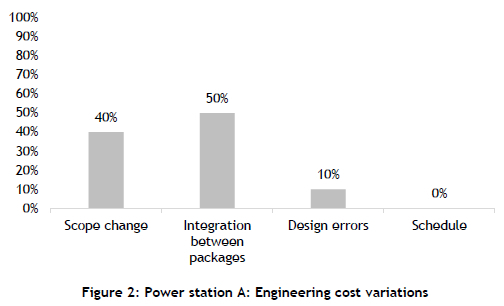

Figure 3 shows the results of the variations at Power station B from January 2017 to August 2018. It is clear from the chart that 50% of the variations were the result of scope change, followed by 23% as a result of design errors, 18% as a result of expediting schedules, and 9% as a result of lack of integration between packages.

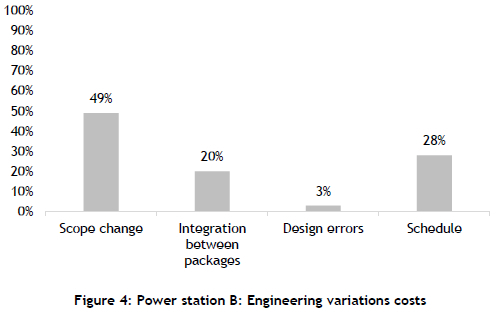

Figure 4 shows the results of the variations at Power station B, looking at their impact on costs from January 2017 to August 2018. It is clear from the chart that the variations owing to scope changes had a greater impact on cost, as 49% was spent on scope changes. Three per cent of variation cost changes were from design errors.

5.2.6. Findings

• At Power station B it was found that 50% of the variation orders came from scope changes, followed by expedited schedules, lack of integration between packages, and design errors.

5.3. New build - Power station C

5.3.1. Scope changes

• Scope omission for where the pipes were to be placed (underground: bury the pipes and cover them with corrosion protection material, or in a concrete trench).

• There were changes to the design owing to revised load schedules from engineering.

• Changes to the design (new load schedules) recorded on engineering change number 1792.

• Replacement of the cable trenches by cable tunnels as per request from civil packages.

• Some of the loads that were on the original scope were not included in the raw water dam boards 1 and 2 load as scheduled. The new loads that had to be added were heat ventilation and airconditioning (HVAC), security lighting board, and sump pumps.

• 1 x 220V lockable isolators were required for 2 x air-conditioning units and 1 x fan motor. The scope for an unused portion of the balance of the plant at Power station A was not part of the initial DCS contract, and was only picked up during detailed design.

• Wrong flow meters were installed and, during the negotiations to correct, the employer asked that six more demineralised water consumption flow meters be added.

• There was no area lighting at the ash dump irrigation pump station because the scope for that lighting was missed and needed to be included.

• The original employer's requirement specified fault recording on all signals. In practice, this would have made it difficult for the generation operating personnel to perform fault finding. Therefore, the employer's requirements had to be adjusted to assist generation.

• There were changes in the engineering designs/requirements and problems with the interface during construction.

• Insufficient sockets were allocated during the design stage.

• The scope of work was never allocated to a certain contractor.

• Addition of an electrical office in the control room, which was not catered for in the initial design.

• Main civils (alternative drainage H01 design - new item).

• New scope to install a new drain line at the auxiliary bay basement.

• Cancellation, integration, and addition of load schedules, resulting in design and cost changes.

• Cast the spool pieces into the two additional wall sections.

• Scope was omitted to specify oily ash and coarse ash removal during unit start-up.

• Omission of scope by engineering for the supply and installation of hard wiring to the midpoint junction box that could accommodate the installation of reclaimer runback signal.

• Missed scope on P08, steel supports.

• Implement design change for cost savings from unit 5-1.

• Improvement of an accepted design as prescribed by the contract in order to lower the operating costs of the analyser network.

• Missed scope, installation of a steel crossover platform from the turbine hall to the auxiliary bay.

• Reversal of revision 1 cost. Engineers adopted contractor's proposal of a 6 m concrete pole instead of 9 m galvanised poles; but the 6 m poles started cracking.

• Construction of HVAC service trench scope was previously not allocated to any package.

5.3.2. Integration between packages

• De-scoping and reallocation of scope from P11 to either 08 or P18 owing to commercial issues.

• Fire water piping routes not considered to be integrated with transformer fire wall design.

• Handrails clash with soot blower pipe insulation.

• Because of clashes between services and existing constructed components of the access control building, it was necessary to revise the construction details of the services.

• There was no proper interface between the mine and Power Station A about how the belt would be tripped in the unlikely event of both mine level instruments failing.

• To eliminate the clash between ADV pipework and HVAC.

• Clash between two different civil structures.

• Cable racking routing from auxiliary bay along the turbine hall wall.

5.3.3. Design errors

• There was a need to adjust the steel structure with longer bolts to accommodate the out-of-tolerance foundation levels.

• Level of stabilised coal layer.

• Too little pressure, as the potable tank was situated on the southern side of the power station, and water was needed on the northern side.

5.3.4. Expedited schedule

• Unavailability of detailed design at tender stage.

• Work to be done at Unit 6: lighting.

5.3.5. Power station C: Engineering variations and engineering variation costs charts

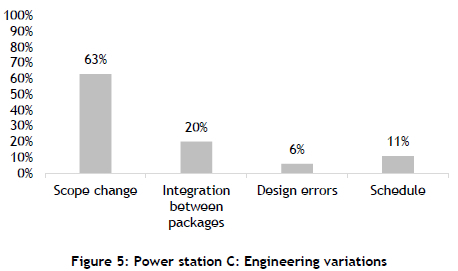

Figure 5 shows the results of the variations at Power station C from January 2016 to July 2018. It is clear from the chart that 63% of the variations were owing to scope changes, followed by 20% owing to lack of integration between packages, 18% because of design errors, and 6% owing to schedule expediting.

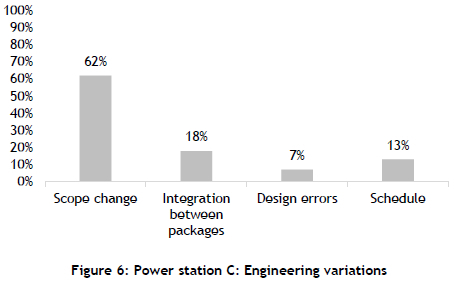

Figure 6 shows the results of the variations at Power station C, looking at the impact on costs from January 2016 to July 2018. It is clear from the chart that the variations caused by scope change had more of an impact on cost, as 62% was spent on scope changes. The variation cost changes caused by design errors made up 7%.

5.3.6. Findings

• It is evident that the trend of scope being missed in the packages was the greatest contributor to the number of variations being issued at the electricity company.

• The interfaces between packages were not well managed: it was discovered that, when the scope of other packages changed, the engineers did not do an impact assessment to see what impact the changes might have on the interfacing packages.

5.4. Generation engineering projects

5.4.1. Scope changes

• The change in engineering was as a result of underestimating the quantities from civil engineering, and the geotechnical report initially indicating that all of the G6 material was available from the basin; however, only the basin was available.

• Because of an additional scope of work, modifications were needed to the flexibility of the swirl and flange.

• Removals of activities from the works information resulted in a contract credit, as these items were no longer required.

• The works information did not include the protection of the culverts crossing road embankments; hence the need to apply hydro seeding to prevent erosion of the embankments.

• The battery room was delayed by incorrect scan results of the underground conditions, which did not identify everything underground. Therefore, after finding cables and other things, the contractor had to change their excavation method to a more labour-intensive one, which took much longer than expected.

5.4.2. Integration between packages

• As a result of the changes from the engineering change management, 40 defective scrolls could not be used in their current condition to accommodate the tilling and, therefore, they had to be re-manufactured. These formed part of the 164 burners specified in the contract.

• The interface was not updated on the as-built design documents.

5.4.3. Design errors

• The design dimensions for the wind box flange and the fitting component were wrong.

• There were mistakes in the design of the boiler package.

• Incorrect measurement of floor by engineering.

• Incorrect measurements of the cooling capacity on the detailed designs by engineering.

5.4.4. Expedited schedule

• Not adhering to the reply periods of the contract (engineering updated drawing requested late).

• Poor quality check of documentation during pre-contract stage owing to the urgency of the contract.

• Late acceptance of design by the power utility company's engineering team, owing to the resignation of the civil engineer who was assigned to the project.

• Delays in acceptance of designs prevented the contractor from completing the work within the contract period.

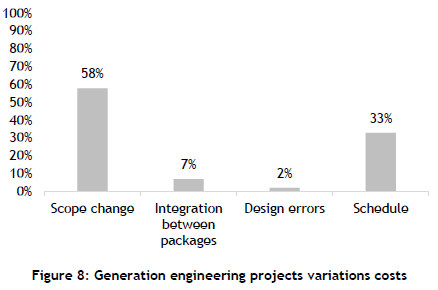

5.4.5. Generation engineering projects, engineering variations, and engineering variation costs charts

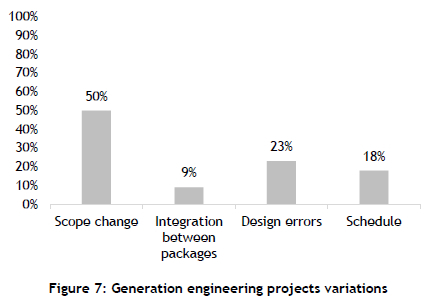

Figure 7 shows the results of the variations at generation engineering projects form January 2016 to August 2017. It is clear from the chart that 50% of the variations were caused by scope change, followed by 23% owing to design errors, 18% owing to expediting the schedule, and 9% as a result of lack of integration between packages.

Figure 8 shows the results of variations in the generation engineering projects, looking at the impact on costs from January 2016 to August 2017. It is clear from the chart that the variations caused by scope change had the greatest impact on cost, as 58% was spent on scope change. Variation cost changes caused by design errors made up 2%.

5.4.6. Overall findings on generation engineering projects

• It was found that the lack of comprehensive works information was the common root cause of scope change.

• The project that led to additional scope being issued during the execution was caused by the lack of information, missed during the development of the works information.

• The drawings are not pre-identified or verified prior finalising the contracts.

• Engineers did not expedite the review of the design drawings that were issued during engineering.

• Lack of communication between the project manager, project engineer, and design engineer. This could have been because the roles and responsibilities were not clearly defined at the inception of the project.

Table 2 highlights the causal analysis summary based on variation orders at Projects A, B, and C and at the generation engineering projects. It includes recommendations that are based on the variation order reports that were analysed.

6. CONCLUSION

It is evident from the investigation that a number of factors contributed to the variation orders, as highlighted in the causal analysis summary. They can be summarised as follows:

• Lessons learnt from engineers doing designs for Power stations A, B, and C were ineffective.

• Engineers did not expedite the review of the design drawings issued during the engineering phases.

• There was no proper transition between technical specification and works information that involved engineers.

• The works information did not include all of the design requirements.

• Lack of an integrated plan at the inception of the project.

• Poor quality check of documentation during pre-contract stage owing to the urgency of the contract.

• The engineers did not fully understand the system's requirements.

• Lack of intervention by system integration during design development.

• Lack of sufficient time to do proper quality checks of documentation.

• Improper planning of activities.

The investigation showed that scope modification is a reoccurring theme in the causes and effects of overruns. Cost and schedule overruns are among the most important effects of scope change. In addition to the recommendations in the causal analysis summary, it is recommended that cross-functional teams be established for new building projects, and that due diligence be conducted. The recommendations are based on the literature review, and include the involvement of the contractor during the design phase, constant coordination and direct communication, proper management of variation orders, thorough design or design details, and teamwork among all project team members to control variation orders. These recommended solutions could be helpful in reducing the adverse effects of variation orders. However, this study looked only at new construction projects and generation engineering projects; therefore, it would be important that future research focus on generation capital projects and on distribution and transmission infrastructure projects. Such projects are often delayed; and this study could lead to better project delivery in respect of cost and schedule management.

REFERENCES

[1] International Energy Agency, "Key world energy statistics 2020," 2020. [Online]. Available: https://www.iea.org/reports/key-world-energy-statistics-2020 [ Links ]

[2] A. Fabio and J.M. Peiro, "Human capital sustainability leadership to promote sustainable development and healthy organizations: A new scale," Sustainablility, vol. 10, no. 7, 2413, 2018. doi: 10.3390/su10072413 [ Links ]

[3] Department of Mineral Resources and Energy, "Integrated resource plan," 2019. https://www.energy.gov.za/irp/2019/IRP-2019.pdf [ Links ]

[4] N.O. Ogano and L. Pretorius, "Front end project planning model for the electricity utility industry in sub-Saharan Africa," Conference: IAMOT 2013, Porto Alegre, Brazil, April 14-18,17 pp, 2012. ISBN 0-9815817-6-5: Porto Alegre, Brazil [ Links ]

[5] X. Zhang, Y. Wu, L. Shen, and M. Skitmore, "A prototype system dynamic model for assessing the sustainability of construction projects," International. Journal of Project Management., vol. 32, no. 1, pp. 66-76, 2014. doi: 10.1016/j.ijproman.2013.01.009 [ Links ]

[6] Z. Osman, A. Omran, and C.K. Foo, "The potential effects of variation orders in construction," J. Eng., vol. 2, no. October, pp. 141-152, 2017. https://doi.org/10.48084/etasr.3168 [ Links ]

[7] O.M. Motta, O.L.G. Quelhas, J.R. de F. Filho, S.Franga, and M. Meirino, "Megaprojects front-end planning: The case of Brazilian organizations of engineering and construction," Am. J. Ind. Bus. Manag., vol. 04, no. 08, pp. 401-412, 2014. doi: 10.4236/ajibm.2014.48049 [ Links ]

[8] The Construction Industry Institute (CII), "Pre-project planning handbook, special publication 39-2," Construction, .pp.30-35. April, 1995. [ Links ]

[9] F.M. Arain, S. Assaf, and L.S. Pheng, "Causes of discrepancies between design and construction," Archit. Sci. Rev., vol. 47, no. 3, pp. 237-249, 2004. doi: 10.1080/00038628.2000.9697530 [ Links ]

[10] A.H. Memon, I.A. Rahman, M. Faris, and A. Hasan, "Significant causes and effects of variation orders in construction projects," Res. J. Appl. Sci. Eng. Technol., vol. 7, no. 21, pp. 4494-4502, 2014. [ Links ]

[11] R. Ndihokubwayo and T. Haupt, "Waste reduction through lean and agile thinking: Case of variation orders," , pp. 1-11, . 2010. http://hdl.handle.net/11189/1091 [ Links ]

[12] A.A. Oladapo, "Article information: A quantitative assessment of the cost and time impact of variation orders on construction projects," J. Eng. Des. Technol., vol. 5, no. 1, pp. 35-48, 2007. doi: 10.1108/17260530710746597 [ Links ]

[13] P.E.D. Love, G.D. Holt, L.Y. Shen, H. Li, and Z. Irani, "Using systems dynamics to better understand change and rework in construction project management systems," Int. J. Proj. Manag., vol. 20, no. 6, pp. 425-436, 2002. doi: 10.1016/S0263-7863(01)00039-4 [ Links ]

[14] S.M.E. Sepasgozar, M.A. Razkenari, and K. Barati, "The importance of new technology for delay mitigation in construction projects," American Journal of Civil Engineering and Architecture.., vol. 3, no. 1, pp. 15-20, 2015. doi: 10.12691/ajcea-3-1-3 [ Links ]

[15] S. Tariq, N. Ahmad, M.U. Ashraf, A.M. Alghamdi, and A.S. Alfakeeh, "Measuring the impact of scope changes on project plan using EVM," IEEE Access, vol. 8, pp. 154589-154613, 2020. [ Links ]

[16] B.A. Mokhtar, C. Bédard, and P. Fazio, "Collaborative planning and scheduling," J. Archit. Eng., vol. 6, no. 2, pp. 66-75, 2000. [ Links ]

[17] E. Fisk, Construction project administration, 5th ed. Upper Saddle River, NJ: Prentice Hall, 1997. [ Links ]

[18] G.E. Gibson, E. Bingham, and C.R. Stogner, "Front end planning for infrastructure projects," Proc. Constr. Res. Congr. 2010: Innov. Reshaping Constr. Pract., pp. 1125-1135, 2010. doi: 10.1061/41109(373)113 [ Links ]

[19] X. Xu and P.X.W. Zou, "System dynamics analytical modeling approach for construction project management research: A critical review and future directions," Front. Eng. Manag., vol. 8, no. 1, pp. 17-31, 2021. doi: 10.1007/s42524-019-0091-7 [ Links ]

[20] A. Kazaz, S. Ulubeyli, and N.A. Tuncbilekli, "Causes of delays in construction projects in Turkey," J. Civ. Eng. Manag., vol. 18, no. 3, pp. 426-435, 2012. doi: 10.3846/13923730.2012.698913 [ Links ]

[21] K. Reichelt and J. Lyneis, "The dynamics of project performance: Benchmarking the drivers of cost and schedule overrun the nature of project problems," Eur. Manag. J., vol. 17, no. 2, pp. 135-150, 1999. [ Links ]

[22] A.S. Hanna, R. Camlic, P.A. Peterson, and E.V. Nordheim, "Quantitative definition of projects impacted by change orders," J. Constr. Eng. Manag., vol. 128, no. 1, pp. 57-64, 2002. doi: 10.1061/(asce)0733-9364(2002)128:1(57) [ Links ]

[23] H.A.M. Albtoosh and T.M. Alkhamis, "Administrative policies to reduce the negative impact of variation orders on Jordanian construction projects," AJIBM, pp. 329-340, 2021. doi: 10.4236/ajibm.2021.114021 [ Links ]

[24] F.M. Arain and L.S. Pheng, "The potential effects of variation orders on institutional building projects," Facilities, Vol. 23, No. 11/12, pp. 496-510, 2005. doi: 10.1108/02632770510618462 [ Links ]

[25] R.U. Halwatura and N.P.N.P. Ranasinghe, "Causes of variation orders in road construction projects in Sri Lanka," ISRN Constr. Eng., vol. 2013, pp. 1-7, 2013. doi: 10.1155/2013/381670 [ Links ]

[26] Name withheld, "New builds & generation engineering projects variation orders assessment report," South Africa, 2018. [ Links ]

Submitted by authors 25 Apr 2023

Accepted for publication 4 Sep 2023

Available online 14 Dec 2023

* Corresponding author: takimashamba38@gmail.com

ORCID® identifiers

T. Mashamba: https://orcid.org/0000-0002-8074-1532

M.G. Kanakana-Katumba: https://orcid.org/0000-0001-7475-2131

R. Maladzhi: https://orcid.org/0000-0003-3773-8538