Servicios Personalizados

Articulo

Indicadores

Links relacionados

-

Citado por Google

Citado por Google -

Similares en Google

Similares en Google

Compartir

South African Journal of Industrial Engineering

versión On-line ISSN 2224-7890

versión impresa ISSN 1012-277X

S. Afr. J. Ind. Eng. vol.34 no.4 Pretoria dic. 2024

http://dx.doi.org/10.7166/34-4-2877

GENERAL ARTICLES

The critical success factors for lean six sigma implementation in small-and-medium-sized enterprises

M.T. Attar

Natural sciences and Engineering Department, University of Jeddah, Jeddah, Saudi Arabia

ABSTRACT

Lean six sigma (LSS) is an important business strategy for organisations, including small and medium-sized enterprises (SMEs). Over the years, SMEs have had a potentially significant impact on various countries' gross domestic product (GDP). The main purpose of this research is to investigate the critical success factors (CSFs) for lean six sigma (LSS) implementation in the Kingdom of Saudi Arabia's SMEs, and to contribute to discovering the factors that lead to business success, increase revenue, and enhanced competitive advantages. The study identified 29 factors from previous research in order to guide the successful implementation of LSS in the SME sector in Saudi Arabia in particular. The CSFs were refined, producing a consolidated list of 14 factors. A principal components analysis (PCA) identified four main factors: leadership support and management structure, technological capabilities, knowledge acquisition, and creativity and innovation. These factors could influence the success of SMEs in Saudi Arabia by adopting LSS in their business processes.

OPSOMMING

Lean six sigma (LSS) is 'n belangrike besigheidstrategie vir organisasies, insluitend klein en mediumgrootte ondernemings (KMO's). Oor die jare het KMO's 'n potensieel beduidende impak op verskeie lande se bruto binnelandse produk (BBP) gehad. Die hoofdoel van hierdie navorsing is om die kritieke suksesfaktore (CSF's) vir lean six sigma (LSS) implementering in die Koninkryk van Saoedi-Arabië se KMO's te ondersoek, en om by te dra tot die ontdekking van die faktore wat lei tot besigheidsukses, verhoogde inkomste en verbeterde mededingende voordele. Die studie het 29 faktore uit vorige navorsing geïdentifiseer ten einde die suksesvolle implementering van LSS in die KMO-sektor in veral Saoedi-Arabië te lei. Die CSF's is verfyn, wat 'n gekonsolideerde lys van 14 faktore opgelewer het. 'n Hoofkomponent-analise (PCA) het vier hooffaktore geïdentifiseer: leierskapondersteuning en bestuurstruktuur, tegnologiese vermoëns, kennisverkryging, en kreatiwiteit en innovasie. Hierdie faktore kan die sukses van KMO's in Saoedi-Arabië beïnvloed deur LSS in hul besigheidsprosesse aan te neem.

1. INTRODUCTION

Lean six sigma (LSS) has been widely used by numerous organisations worldwide as a continuous improvement method for cost reduction, process enhancement, and value creation for customers. According to [1], quality improvement and operational excellence can be achieved by using LSS. Leading companies in different countries, such as General Electric (GE) and Motorola, have reported several notable successes in LSS implementation. This results in reduced quality cost, improved process efficiency, satisfied customers, reduced defects and waste, increased revenue and market share, and continuous improvement strategies [2,3,4,5,6].

Since LSS is affected by Industry 4.0, it can generate huge benefits in improving business performance and achieving a competitive advantage [7]. Small and medium-sized enterprises (SMEs) are given much attention by different countries' governments as leading innovation and competition, increasing the rate of employment, and achieving long-term gains [8],[9]. This is owing to the potential impact of SMEs on a country's gross domestic product (GDP). Many studies have illustrated the potential value of SMEs in supporting the economic growth of a country through entrepreneurship and innovation, and by providing job opportunities.

In the Kingdom of Saudi Arabia (KSA) in particular, SMEs play an important role in economic development, and they contribute significantly to increasing employment opportunities [10]. The government has announced the Saudi Vision 2030, which includes several strategic plans to reduce economic dependence on oil and to utilise the available resources with multiple objectives. These objectives include transforming the SMEs sector into a basic engine for economic growth, increasing the SMEs' current contribution to GDP from 20 per cent to 35 per cent, and providing about 70 per cent of jobs in the private sector [11].

The exact nature of lean six sigma in Saudi Arabia is still evolving, as companies are still learning how best to implement these methodologies in their own culture and context.

Indeed, there is no single definitive answer to the question of what qualifies a company to be referred to as an LSS company. However, some common characteristics of LSS companies are a commitment to continuous improvement, a focus on data-driven decision-making, a strong emphasis on employee engagement, creativity and innovation, and a track record of success in implementing LSS projects.

There is a growing interest in lean six sigma among SMEs in Saudi Arabia. However, there is still a lack of understanding of what it means to be an LSS company. Some SMEs may believe that they need to have a full LSS programme in place in order to be considered an LSS company [12].

SMEs in Saudi Arabia could still benefit from LSS principles and techniques, even if they did not have a formal LSS programme in place. The authors believe that SMEs could implement LSS through training employees on LSS tools and techniques, using the Kaizen methodogy to identify and eliminate waste, implementing six sigma projects to improve specific processes, measuring and tracking performance metrics, and creating a culture of continuous improvement. If a company exhibits these qualities, then it can be considered an LSS company.

According to the KSA's General Authority for Statistics [10], the number of SMEs in the Makkah Region (Western Region) by the end of 2021 accounted for about 27 per cent of the total number of SMEs in the KSA. Indeed, little research has been conducted on LSS implementation in SMEs [13]. Previous research has explained that few publications are available on LSS implementation in the manufacturing and non-manufacturing sectors [14]. Not many studies have been conducted on the critical success factors (CSFs) for LSS implementation [15]. Furthermore, few researchers have addressed the use of LSS in SMEs [16]. Thus this research aimed to identify the CSFs for a successful implementation of LSS in Saudi SMEs.

The study has been organised systematically. First, LSS, SMEs, and CSFs are introduced and described. Second, a review of CSF for LSS implementation in SMEs is presented. Third, the research methodology and the details of the questionnaire, along with some analytical tools used in this research, are explained. Fourth, the research findings focus on the underlying description of the identified factors. The last section provides a conclusion and directions for future research.

1.1. Lean six sigma

Lean six sigma (LSS) is a method of quality improvement by integrating lean manufacturing and six sigma (SS). It relies on removing waste, improving performance, and achieving zero defects by identifying value-added and non-value-added activities in the workplace. According to [13], LSS is a methodological tool that plays a significant role in improving quality and services, increasing customer satisfaction, and reducing costs. It can be achieved by implementing the tools and principles of lean and six sigma. The term 'lean' focuses on eliminating several types of waste (Muda), whereas SS focuses on improving the quality of the process by identifying the causes of defects, thus leading to reduced variability in the process. By implementing LSS, organisations can identify and reduce waste and save money [16]. According to [1], the implementation of LSS in SMEs has several benefits, including reducing non-value-added activities and lead times, achieving on-time delivery, and saving money.

1.2. Small and medium-sized enterprises

Small and medium-sized enterprises (SMEs) make a major contribution to modern economies by creating job opportunities, improving productivity, increasing income, and boosting innovation [17,18]. SMEs can be categorised into various groups according to the number of employees, annual revenue, and business assets [19]. Several countries use different classifications to define the term 'small business'. For instance, a small business enterprise in the United States has 500 employees or fewer, whereas in European countries a business enterprise is classified as 'small' if it has fewer than 50 employees. The KSA describes a small business as having three to 49 employees and a total annual revenue of around US$1.3 million or less.

1.3. Quality and customer satisfaction

Quality pioneers have developed quality management practices to improve quality and achieve customer satisfaction. Indeed, using quality tools, concepts, and techniques is important for satisfying customer needs. This is because of the increased level of competition in the business environment. Edwards and Deming [20] focused on management's responsibility for building a good quality system, and proposed 14 points in implementing quality improvement. Juran [21] strongly emphasised the top management's commitment and support in promoting the concept of quality to employees. Feigenbaum [22] viewed quality as total quality management (TQM) that involves everyone in the organisation. Crosby [23] stated that there was a traditional trade-off between the cost of improving quality and the cost of poor quality, and he promoted the 'zero defects' concept.

1.4. Critical success factors

'Critical success factors' (CSFs) is a term used to identify the key factors that are required to ensure the success of an organisation and to achieve a competitive advantage. [24] defined CSF as several elements that should be considered to achieve organisational objectives. The factors should be constantly evaluated against competitors to ensure an SME's success. However, there is no collective agreement among researchers on a specific set of factors that could influence the success of SMEs [25].

1.5. Importance of the study in the Kingdom of Saudi Arabia context

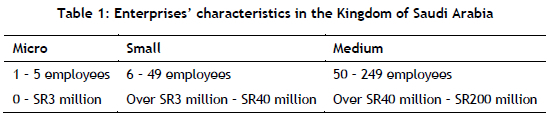

Enterprises in the KSA face several difficulties as a result of globalisation and increased numbers of foreign products from multiple countries in local markets. Moreover, there is a high level of demand from customers to buy products of better quality, a fast mode of delivery, and reasonable prices. Thus entrepreneurs seek to respond to customers' requirements and to give satisfaction by using advanced technology or tools such as mobile applications, internet-based tools, and integrated database-based technologies [12]. Saudi Arabia has been concerned about expanding the role of SMEs in its economy. In 2020, the government offered small enterprises financial support of around SR50 billion to overcome the crisis of COVID-19. This action was taken to attain the goal of Saudi Vision 2030, which includes increasing SMEs' contribution to GDP from 20 per cent to 35 per cent and raising the private sector's contribution from 40 per cent to 65 per cent. The KSA used the following characteristics of enterprises [26]:

[27] stated that the main CSFs of SMEs in Saudi Arabia are their business characteristics, the business environment, their management factors, their individual factors, business support, and capital investment. These factors led the authors of this study to use quality improvement techniques such as LSS.

1.6. Lean implementation in small and medium-sized enterprises

The main objective of lean implementation in SMEs is to reduce waste and to optimise operational processes [28],[29]. A literature research showed that the success of lean implementation in SMEs depends on several sets of factors. For instance, Moeuf et al. [28] identified three CSFs of lean in SMEs: leadership, experience, and decision-making power. Nguyen [30] identified the following CSFs for lean implementation in SMEs: management's involvement and direction; employee engagement; culture change; resource allocation; training; coaching and consulting; teaching; and measuring key performance indicators. Singh and Jain [31] studied the CSFs in British manufacturing SMEs, and listed the following: management's involvement and commitment; communication; cultural change; and education and training. Alefari et al. [32] explored the success factors affecting United Arab Emirates (UAE) SMEs' performance in the manufacturing sector, and identified financial motivations; leadership; managerial support; teamwork; recognition; and training.

Arabi et al. [33] explained the success factors in implementing lean and in promoting change in and the development of SMEs. These were the involvement and commitment of the top management; the involvement and participation of employees; the ability and willingness to change the organisational structure; training the employees; communicating goals and objectives; and developing employees' skills.

1.7. Lean six sigma in small and medium-sized enterprises

LSS in SMEs combines the principles of lean with the tools and techniques of six sigma. This provides a more comprehensive and powerful approach to improvement than conventional lean. LSS can help SMEs to improve their work efficiency, productivity, and quality in a way that is sustainable over time. In addition, LSS provides a clear roadmap for improvement that could help SMEs to avoid costly mistakes [16].

In fact, LSS uses a broader range of tools and techniques in incorporating the tools and techniques of lean and the statistical tools of six sigma. This gives SMEs a more powerful set of tools for their improvement efforts. LSS is a more complex approach to improvement than conventional lean, and it requires a stronger commitment from leaders to be successful.

The literature reveals that several factors lead to the successful implementation of LSS in SMEs. A list of published papers related to the implementation of LSS in SMEs is given in Table 2. Previous research showed that there were limited studies of using LSS in SMEs in developing countries, including the KSA. Thus the objective of this study was to identify the critical success factors for LSS implementation in Saudi Arabian SMEs.

2. RESEARCH METHODOLOGY

This section describes the steps involved in the research methodology.

First, a list of CSFs for LSS implementation in SMEs was identified, based on the extensive literature review. Second, two academics and two entrepreneurs related to SMEs in the KSA were invited to a focus group discussion to provide the most important CSFs that would apply to SMEs in the Saudi environment. Third, a survey questionnaire was designed that contained closed-ended questions. Quantitative data were measured by a five-point Likert scale, ranging from one to five - 'strongly agree' to 'strongly disagree' respectively. Fourth, the principal components analysis (PCA) method was used to discover the relationships among the factors. The last step was to identify the main CSFs for implementing LSS in Saudi SMEs.

3. RESULTS

3.1. List of CSFs for LSS implementation in SMEs

The review of the literature on LSS implementation in SMEs initially resulted in identifying 29 CSFs after excluding duplicate factors with similar meanings. The identified factors needed further investigation and evaluation to explore their importance in influencing the successful implementation of LSS in SMEs.

3.2. Focus-group discussion

The 29 CSFs were identified from a literature review. To validate the 29 CSFs, a survey was designed and administered to two academics and two entrepreneurs with good knowledge and work experience in LSS applications. The survey asked the participants to recommend the inclusion or exclusion of each CSF. A focus-group discussion was conducted, and a total of 13 CSFs were selected out of the 29 that had been first identified. The considered factors were consistent with the KSA SME context and expected to influence and contribute to the successful implantation of LSS in Saudi Arabian SMEs. As recommended by the participants, 'adoption of Quality 4.0 in the context of Industry 4.0' was an important factor that could help SMEs to compete with larger companies and to improve their overall performance. Thus this factor was added to the final list.

'Quality 4.0' refers to the integration of advanced technologies to improve efficiency, quality, and productivity in order to remain competitive in today's rapidly changing business environment. It can be adopted by SMEs by facilitating the implementation of digital transformation and development of their IT structure. Furthermore, the automation of lean leads to several benefits for SMEs in supplier support, greater customer satisfaction, improved process control systems, and the management of the human factors [56].

The final set of recommended factors was included in the questionnaire items, and is listed below:

1. Top management support and commitment

2. Advanced tools for communication and information flow

3. Teamwork and collaboration

4. Organisational culture and structure

5. Employees' development and engagement

6. Understanding customer requirements

7. Cooperative supplier relationships

8. Strategic quality planning

9. Linking LSS with customer satisfaction and business strategy

10. Adopting a recognition and reward system

11. Managers' and employees' awareness of LSS tools and techniques

12. Project management skills

13. Prioritise business quality

14. Adoption of Quality 4.0 within Industry 4.0.

3.3. Survey questionnaire

The study undertook a survey of 104 SMEs located in Jeddah City (in the Western Region of the KSA). A self-administered questionnaire was developed, based on an extensive review of the literature related to the CSFs for LSS implementation in SMEs. The study targeted the managers and owners of SMEs. All of the respondents provided written informed consent prior to participating in the study. The enterprise business types covered in this study were the wholesale and retail trade, accommodation and food services, and education services.

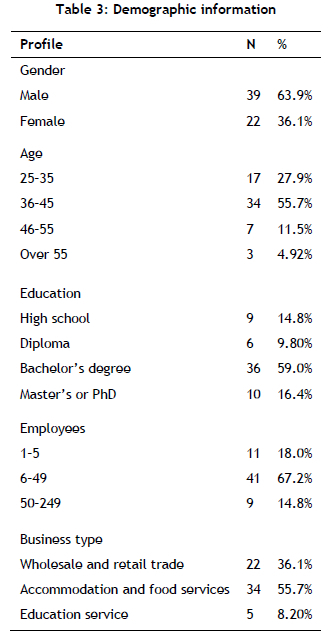

The online questionnaire included a short introduction and the overall purpose of the study. It had two parts, and was provided in both English and Arabic. The first part sought the demographic characteristics of the respondents, such as gender, age, educational level, number of employees, and business type (Table 3).

3.4. Sample

Of the 104 questionnaires that were distributed, 61 were received after their completion (a response rate of 59 per cent). The results showed that the majority of the participants (63.9 per cent) were males, while 36.1 per cent were females. In respect of the entrepreneurs' age, the majority of the participants (55.7 per cent) were between 36 and 45 years; the rest were between 25 and 35 years (27.9 per cent) or between 46 and 55 years (11.5 per cent); only 4.92 per cent were over the age of 55. This indicated that the SMEs depended mainly on young people.

The participants' educational level indicated that some of them were educated at the high school level (14.8 per cent), and some held a diploma (9.80 per cent). However, the majority of them were bachelor's degree holders (59 per cent) and Master's or PhD graduates (16.4 per cent).

The survey data revealed that 18 per cent of the SMEs had one to five employees, 67.2 per cent had six to 49 employees, and 14.8 per cent or the enterprises had 50 to 249 employees. The business types of the SMEs showed that 36.1 per cent of them were in the wholesale and retail trade, 55.7 per cent were related to accommodation and food services, and only 8.2 per cent were in education services.

The second part of the questionnaire contained closed-ended questions. A total of 56 items were developed, based on the factors selected and recommended by the focus group members (Table 4).

To assess the content validity of the items, two academics reviewed the questionnaire's items. They assessed the questions based on clarity, length, and the time required to complete the survey. Then the final version of the questionnaire items was finalised.

A reliability test was used to evaluate the questionnaire items. The results showed that the Cronbach's alpha value was greater than 0.7, which indicated that the measurement scale used in this study was consistent, as shown in Table 5.

3.5. Principal component analysis

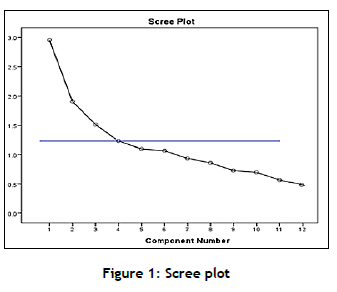

The Statistical Package for Social Sciences (SPSS) software was used to perform the principal component analysis (PCA). According to Fodor [57], PCA is a statistical technique for variable reduction that obtains uncorrelated variables and identifies strong components in the data. The components with eigenvalues greater than 1.0 should be considered [58]. Table 6 shows that four components extracted from the data accounted for 76 per cent of the total variation.

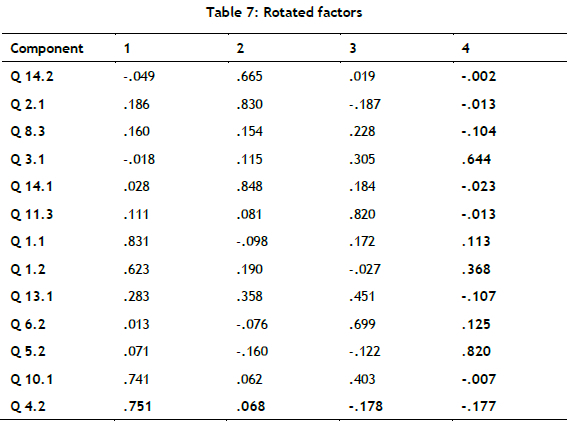

The Kaiser-Meyer-Olkin (KMO) test was used to check sampling adequacy. The cut-off value should be equal to or greater than 0.6 [50]. The estimated KMO test result was 0.77, indicating that the PCA could extract the common factors. The results in Table 7 show that four components made significant contributions to the total variability. The first component contributed 33.72 per cent of the total variance and included four items (Q1.1, Q1.2, Q10.1, Q4.2). These items related to 'Adopting a recognition and reward system', 'Organisational culture and structure', and 'Leadership support and management structure'. Thus the first factor was labeled 'Leadership support'. The second factor contributed 18.88 per cent of the total variance, and contained three items (Q14.2, Q2.1, Q14.1). These belonged to 'Adoption of Quality 4.0 within Industry 4.0' and to 'Advanced tools for communication and information flow'. Thus the second factor was labeled 'Technological capabilities'. The third factor contributed 12.55 per cent of the total variance and covered two items (Q11.3, Q6.2). This factor was subject to 'Managers' and employees' awareness of LSS tools and techniques' and to 'Understanding of customers' requirements'. Accordingly, the factor was identified as 'Knowledge acquisition'. Finally, the fourth factor contributed 10.43 per cent of the total variance, and was associated with the Q3.1 and Q5.2 items. This factor represented 'Teamwork and collaboration' and 'Employees' development and engagement'. So the factor was called 'Creativity and innovation'. A further explanation of these factors is given in the next section.

3.6. Identification of critical success factors for implementing lean six sigma in the Kingdom of Saudi Arabia's small and medium-sized enterprises

Based on the PCA results, the CSFs were divided into four main categories.

The first CSF is related to 'Leadership support and management structure'. This factor has the greatest influence on the value of a small business. [56] demonstrated that senior managers are responsible for a company's quality initiatives and deployment. According to [59], leaders can establish an organisational culture that facilitates the implementation of LSS. Indeed, because SMEs have limited capital investment and human resources compared with large ones, top management must use the benefits of LSS and collect the required resources to make it a success. This includes investing resources in training and in capabilities that could facilitate a culture of data-driven decision-making and the development of an internal data system to store and access information quickly. [13] showed that leaders in the SME context should involve all of their employees in process improvement projects by using LSS tools, which could lead to the development of personal skills in problem-solving. Leaders of SMEs could take advantage of the adaptability and flexibility of SMEs to create customer satisfaction. According to [60], the success of SMEs depends mainly on their leadership skills, unity, management, liability, and risk. To succeed in implementing LSS in SMEs, leaders have the main role of creating a good environment for creativity, innovation, and quality improvement. This would include encouraging employees to participate in LSS projects, providing good training and mentoring of projects through team leaders, establishing a reward and recognition system, allowing employees to focus on process-related improvements, and data-based decision-making.

The second CSF belongs to 'Technological capabilities'. Most SMEs do not adopt digital transformation in the business process, unlike large businesses. Several studies have shown the lack of the use of technology in SMEs, which hinders their success. For instance, [61] stated that SMEs should integrate advanced technologies into their operations and procedures in order to achieve a competitive advantage in the market. This would result in improved productivity, reduced costs, and effective communication, and would facilitate the decision-making process. Indeed, Industry 4.0 is driven by enormous changes in manufacturing practices, processes, and innovation. Thus SMEs should use advanced software/applications and tools such as the Internet-of-Things (IoT), artificial intelligence (AI), machine learning, data mining, and robotics through the digitalisation and automation of the business process to achieve improved quality, customer satisfaction, and business excellence [62,63]. [56] demonstrated that the technological dimension is a significant factor in the successful implementation of LSS in SMEs.

The third CSF is attributed to 'Knowledge acquisition'. Training and skills are less likely to be available to employees in SMEs than in large businesses. In addition, SMEs face many difficulties in the market, such as an inability to retain qualified employees, limited expenditure on research and development (R&D), a lack of advanced technological systems, low managerial capabilities, and a lack of knowledge of local and international enterprises [64]. The implementation of LSS in SMEs is impacted by the high costs of transitions, inadequate financial planning, and the unstable economic environment. Thus SMEs could overcome these problems by spreading the knowledge of LSS methodology and tools to their employees, identifying the specific training needs related to LSS, and being aware of the increasing demand for skilled labour. Indeed, enhancing knowledge and developing employees' skills and should be aligned with the organisation's strategic plans and improvement programmes.

The fourth factor is assigned to 'Creativity and innovation'. The growing number of SMEs that seek a competitive advantage have shaped different ways of innovating, including connecting business process development with automation and digitalisation. The failure to capture and manage innovation is one of the reasons that SMEs fail in business [65]. The absence of innovation prevents SMEs from reducing their operational complexity and from focusing on the core principles and objectives of the business. Managing innovation involves identifying the areas for continuous improvement, reducing costs and waste, creating an appropriate environment to assist in the use of LSS tools, and transforming creative ideas into new products and processes. According to [66], innovation is one of the main criteria for improving organisational performance. [67] identified two types of innovation in SMEs: incremental innovation and radical innovation. Incremental innovation aims to improve the existing characteristics of a product or service that is offered to customers. In contrast, radical innovation focuses on developing new products or services to create customer satisfaction. As a result, most SMEs focus mainly on incremental innovation because of the absence of product enhancement and the non-availability of technological resources [68].

SMEs could support and motivate their employees in generating creative ideas and forming a quality culture, and so achieving a competitive advantage and growth. [69] identified the relationship between innovation and business success, and concluded that companies' sales increased when they promoted new products in the market; that innovation has been the main factor in the success of Japanese companies; that double the profit can be obtained by using innovative ideas and making significant improvements to their performance by adopting innovation; and that SMEs can sustain their business and grow faster than noninnovative companies.

4. CONCLUSION

This study has proposed the main CSFs for the successful implementation of LSS in the KSA's SMEs. An initial list of 29 factors was identified from the extensive literature. These factors were refined to produce a list of 14 factors. Then a PCA was conducted to identify the CSFs for LSS implementation in the KSA's SMEs. The results showed that four main factors influence Saudi SMEs' success in adopting LSS in their business processes: leadership support and management structure, technological capabilities, knowledge acquisition, and creativity and innovation. The study suggests that success is tied to top management support and to the development of an organisation's management structure.

SMEs should make the effort to develop a standardisation of quality, improve their procedural methods to provide better services, and satisfy customers' expectations. This could be achieved by aligning their organisational goals with LSS projects. Resistance to change is indeed a hindrance to LSS implementation in SMEs, which means that the top management's involvement and employees' engagement is crucial to implementing LSS in SMEs.

Although much research has been conducted on the CSFs for LSS implementation in SMEs, this study specifically explores those in a Saudi context. The research data includes only one region of the KSA and represents the owners' or managers' points of view, which means that the interpretation of the results cannot be generalised. There is also a need to consider each country's characteristics while investigating the factors that lead to the successful implementation of LSS in SMEs.

The scope of the study has been limited to the Saudi context only; thus the results could vary if the identified CSFs were used in other countries.

In spite of the fact that this paper aimed to identify the CSFs of LSS implementation in a specific sector in Saudi Arabia, the sample size of 104 was rather small for achieving a reliable and valid result. In addition, the paper focused only on identifying the CSFs for LSS implementation in Saudi SMEs, and did not consider large companies. The insights gained from this study should assist LSS practitioners and academics to understand better the adoption and implementation of LSS in SMEs.

It is recommended that further studies be conducted to develop a framework for LSS implementation in SMEs in the context of Industry 4.0.

ACKNOWLEDGEMENTS

This research was sponsored by a grant from the University of Jeddah, Jeddah, Saudi Arabia. The author would like to thank the University of Jeddah for the research funding and the participants in the surveys for their valuable contribution to this research.

RESEARCH METHODOLOGY

All of the procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki Declaration and its later amendments or comparable ethical standards.

The author has no conflicts of interest to disclose.

REFERENCES

[1] Thomas, A.J., Ringwald, K., Parfitt, S., Davies, A. & John, E. 2014. An empirical analysis of Lean Six Sigma implementation in SMEs - A migratory perspective. International Journal of Quality and Radiality Management, 31(8), 888-905. [ Links ]

[2] Akkerhuis, T.S., Spanjaard, C.M., Nuijten, S.E., Berendes, O.G. & Does, R.J.M.M. 2015. Quality quandaries: Realizing strategic focal points at a business school. Quality Engineering, 27(2), 67-273. [ Links ]

[3] Bhat, S., Gijo, E.V. & Jnanesh, N.A. 2014. Application of Lean Six Sigma methodology in the registration process of a hospital. International Journal of Productivity and Performance Management, 63(5), 613-643. [ Links ]

[4] Chakravorty, S.S. & Shah, A.D. 2012. Lean Six Sigma (LSS): An implementation experience. European Journal of Industrial Engineering, 6(1),118-137. [ Links ]

[5] Wang, F.-K. & Chen, K.-S. 2012. Application of Lean Six Sigma to a panel equipment manufacturer. Total Quality Management & Business Excellence, 24(4), 417-429. [ Links ]

[6] Zwetsloot, I.M. & Does, R.J.M.M. 2015. Quality quandaries: Improving revenue by attracting more clients online. Quality Engineering, 27(1),130-138. [ Links ]

[7] Brown, S.W. & Swartz, T.A. 1989. A gap analysis of professional service quality. Journal of Marketing, 53, 92-98. [ Links ]

[8] Yadav, N., Shankar, R. & Singh, S.P. 2021. Hierarchy of critical success factors (CSF) for Lean Six Sigma (LSS) in Quality 4.0. International Journal of Global Business and Competitiveness, 16(1),1- 14. [ Links ]

[9] Headley, D.E. & Miller, S.J. 1993. Measuring service quality and its relationship to future consumer behavior. Journal of Health Care Marketing, 4, 32-41. [ Links ]

[10] General Authority for Statistics (GaStat). 2021. The total number of enterprises 2021. Retrieved from: https://www.monshaat.gov.sa/ar/monshaat-reports (accessed 12 March 2022). [ Links ]

[11] General Authority for Statistics (GaStat). 2018. GCC SMEs contribution to private sector. Retrieved from: https://www.stats.gov.sa/en/news/323Jaccessed 20 February 2022). [ Links ]

[12] Albliwi, S.A. & Al-Harbi, B.D. 2020. The status of Lean Six Sigma application within SMEs in the Kingdom of Saudi Arabia: A high level technological tool for quality improvement. Bioscience Biotechnology Research Communication, 13(3), 1349-1355. [ Links ]

[13] Antony, J., Vinodh, S. & Gijo, E.V. 2021. Lean Six Sigma for small and medium sized enterprises: A practical guide. Boca Raton, FL: CRC Press. [ Links ]

[14] Laureani, A. & Antony, J. 2012. Standards for Lean Six Sigma certification. International Journal of Productivity and Performance Management, 61(1), 110-120. [ Links ]

[15] Jeyaraman, K. & Teo, L.K. 2010. A conceptual framework for critical success factors of Lean Six Sigma: Implementation on the performance of electronic manufacturing service industry. International Journal of Lean Six Sigma, 1(3), 191-215. [ Links ]

[16] Belhadi, A., Touriki, F.E. & Elfezazi, S. 2019. Evaluation of critical success factors (CSFs) to lean implementation in SMEs using AHP: A case study. International Journal of Lean Six Sigma, 10(3), 803-829. [ Links ]

[17] Arnheiter, E.D. & Maleyeff, J. 2005. The integration of Lean management and Six Sigma. The TQM Magazine, 17(1), 5-18. [ Links ]

[18] Kuzilwa, J.A. 2005. The role of credit for small business success: A study of the National Entrepreneurship Development Fund in Tanzania. The Journal of Entrepreneurship, 14(2), 131-161. [ Links ]

[19] Hertog, S. 2010. Benchmarking SME policies in the GCC: A survey of challenges and opportunities, Eurochambres, Brussels, Belgium. [ Links ]

[20] Deming, W.E. 1982. Quality, productivity, and competitive position (Vol. 183). Cambridge, MA: Massachusetts Institute of Technology. [ Links ]

[21] Juran, J. 1974. Quality Handbook: The Guide to Performance Excellence, New York, New York: McGraw-Hill. [ Links ]

[22] Feigenbaum, A. 1983. Total quality control. New York: McGraw-Hill. [ Links ]

[23] Crosby, P. 1979. Quality is free: The art of making quality certain. New York: McGraw-Hill. [ Links ]

[24] Brotherton, B. & Shaw, J. 1996. Towards an identification and classification of critical success factors in UK Hotels Plc. International Journal of Hospitality Management, 15(2), 113-135. [ Links ]

[25] Chong, W.Y. 2012. Critical success factors for small and medium enterprises: Perceptions of entrepreneurs in urban Malaysia. Journal of Business and Policy Research, 7(4), 204-215. [ Links ]

[26] Monshaat. 2020. Other service activities sector. Retrieved from: https://www.monshaat.gov.sa/ar/monshaat-reports [ Links ]

[27] Al-Tit, A., Omri, A. & Euchi, J. 2019. Critical success factors of small and medium-sized enterprises in Saudi Arabia: Insights from sustainability perspective. Administrative Sciences, 9(2), 32. [ Links ]

[28] Dora, M., Van Goubergen, D., Kumar, M., Molnar, A. & Gellynck, X. 2013. Application of lean practices in small and medium-sized food enterprises. British Food Journal, 116(1), 125-141. [ Links ]

[29] Hu, Q., Mason, R., Williams, S.J. & Found, P. 2015. Lean implementation within SMEs: A literature review. Journal of Manufacturing Technology Management, 26(7), 980-1012. [ Links ]

[30] Nguyen, D.M. 2018. Critical success factors of lean implementation in Vietnam manufacturing enterprises. Journal of Production Engineering, 21(1), 1-5. [ Links ]

[31] Singh, V. & Jain, P. 2017. Implementation of lean manufacturing in small and medium enterprises. International Journal of Advance Research and Innovative Ideas in Education, 3(2), 4756-4761. [ Links ]

[32] Alefari, M., Almanei, M. & Salonitis, K. 2020. Lean manufacturing, leadership and employees: The case of UAE SME manufacturing companies. Production & Manufacturing Research, 8(1), 222-243. [ Links ]

[33] Arabi, S., Chafi, A., Bajjou, M.S. & El Hammoumi, M. 2021. Exploring lean production system adoption in the Moroccan manufacturing and non-manufacturing industries: Awareness, benefits and barriers. International Journal of Automotive and Mechanical Engineering, 18(4), 9312-9332. [ Links ]

[34] Spanyi, A. & Wurtzel, M. 2003. Six Sigma for the rest of us. Available at: www.qualitydigest.com/july03/articles/01_articles/ (accessed 12 February 2022). [ Links ]

[35] Antony, J., Kumar, M. & Madu, C.N. 2005. Six sigma in small- and medium-sized UK manufacturing enterprises: Some empirical observations. International Journal of Quality and Reliability Management, 22(8), 860-874. [ Links ]

[36] Achanga P., Shehab E., Roy R. & Nelder G. 2006. Critical success factors for lean implementation within SMEs. Journal of Manufacturing Technology Management, 17(4), 460-471. [ Links ]

[37] Kumar, M. 2007. Critical success factors and hurdles to Six Sigma implementation: The case of a UK manufacturing SME. International Journal of Six Sigma and Competitive Advantage, 3(4), 333-351. [ Links ]

[38] Nonthaleerak, P. & Hendry, L. 2008. Exploring the Six Sigma phenomenon using multiple case study evidence. International Journal of Operations and Production Management, 28(3), 279-303. [ Links ]

[39] Bakás, O., Givaert, T. & Van Landeghem, H. 2011. Challenges and success factors for implementation of lean manufacturing in European SMEs. NTNU Engineering Series, 4(2), 397-408. [ Links ]

[40] Panizzolo, R., Garengo, P., Sharma, M.K. & Gore, A. 2012. Lean manufacturing in developing countries: Evidence from Indian SMEs. Production Planning and Control, 23(10-11), 769-788. [ Links ]

[41] Brun, A. 2011. Critical success factors of Six Sigma implementations in Italian companies. International Journal of Production Economics, 131(1), 158-164. [ Links ]

[42] Zhou, B. 2016. Lean principles, practices, and impacts: A study on small and medium-sized enterprises (SMEs). Annals of Operations Research, 241(1), 457-474. [ Links ]

[43] Timans, W., Antony, J., Ahaus, K. & Van Solingen, R. 2012. Implementation of Lean Six Sigma in small- and medium-sized manufacturing enterprises in The Netherlands. The Journal of the Operational Research Society, 63(3), 339-353. [ Links ]

[44] Habidin, N.F. & Yusof, S.M. 2013. Critical success factors of lean six sigma for the Malaysian automotive industry. International Journal of Lean Six Sigma, 4(1), 60-82. [ Links ]

[45] Rymaszewska, A. 2014. The challenges of lean manufacturing implementation in SMEs.Benchmarking: An International Journal, 21(6), 987-1002. [ Links ]

[46] Alaskari, O., Ahmad, M.M. & Cuenca, R.P. 2014. Critical success factors for Lean tools and ERP systems implementation in manufacturing SMEs. International Journal of Lean Enterprise Research, 1(2), 177-183. [ Links ]

[47] Jadhav, J.R., Mantha, S.S. & Rane, S.B. 2015. Analysis of interactions among the barriers to JIT production: Interpretive structural modelling approach. Journal of Industrial Engineering International, 11(3), 331-352. [ Links ]

[48] Dora, M., Kumar, M. & Gellynck, X. 2015. Determinants and barriers to lean implementation in food-processing SMEs - A multiple case analysis. Production Planning and Control, 27(1), 1-23. [ Links ]

[49] Lande, M., Shrivastava, R.L. & Seth, D. 2016. Critical success factors for Lean Six Sigma in SMEs (small and medium enterprises). TQM Journal, 28(4), 613-635. [ Links ]

[50] Belhadi, A., Touriki, F.E. & El Fezazi, S. 2016. A framework for effective implementation of lean production in small and medium-sized enterprises. Journal of Industrial Engineering and Management, 9(3), 786-810. [ Links ]

[51] Dash, B. & Tripathy, S. 2017. Study of critical success factors of Indian manufacturing industries: A case study. International Journal of Management & Business Studies, 7(1), 42-49. [ Links ]

[52] Tyagi, D., Soni, V.K. & Khare, V.K. 2017. Evaluation of critical success factors for Six Sigma implementation in Indian manufacturing SMEs. International Journal of Mechanical and Production Engineering Research and Development, 7(6), 489-500. [ Links ]

[53] Kumar, M. & Antony, J. 2018. Comparing the quality management practices in UK SMEs. Industrial Management & Data Systems, 108(9), 1153-1166. [ Links ]

[54] Sahoo, S. & Yadav, S. 2018. Lean implementation in small- and medium-sized enterprises: An empirical study of Indian manufacturing firms. Benchmarking, 25(4), 1121-1147. [ Links ]

[55] Wassan, R.K., Shaikh, S.A., Shaikh, I.K., Memon, M.S., Rahman, A. & Shah, S.F.H. (2022). Initial screening of critical success factors for Green, Lean and Six Sigma implementation in Pakistani small and medium enterprises. Journal of Applied Engineering Science, 20(3), 946-956. [ Links ]

[56] Saraswat, P., Agrawal, R. & Meena, M. L. 2021. An analysis of critical success factors using analytical hierarchy process for implementation of Lean with Industry 4.0 in SMEs. In Agrawal, R., Jain, J.K., Yadav, V.S., Manupati, V.K. & Varela, L. (eds), Recent advances in smart manufacturing and materials, Singapore: Springer, 255-262. [ Links ]

[57] Fodor, I.K. 2002. A survey of dimension reduction techniques (Lawrence Livermore National Laboratory Technical Report UCRL-ID-148494). Livermore, CA: Center for Applied Scientific Computing. Retrieved from: https://www.osti.gov/biblio/15002155 (accessed December 18, 2021). [ Links ]

[58] Kaiser, H.F. 1960. The application of electronic computers to factor analysis. Educational and Psychological Measurement, 20(1), 141-151. [ Links ]

[59] Juran, J.M. & Godfrey, A.B. 1999. Juran's quality handbook. New York: McGraw Hill. [ Links ]

[60] Asian, Diken, A. & Sendogdu, A.A. 2011. Investigation of the effects of strategic leadership on strategic change and innovativeness of SMEs in a perceived environmental uncertainty. Procedia: Social and Behavioral Sciences, 24, 627-642. [ Links ]

[61] Prasanna, S.V. 2013. Lean Six Sigma in SMEs: An exploration through literature review. Journal of Engineering, Design and Technology, 11(3), 224-250. [ Links ]

[62] Park, S.H., Dahlgaard-Park, S.M. & Kim, D.C. 2020. New paradigm of Lean Six Sigma in the 4th Industrial revolution era. Quality Innovation Prosperity, 24(1), 1-16. [ Links ]

[63] Rajput, S. & Singh, S. 2019. Identifying Industry 4.0 IoT enablers by integrated PCA-ISM- DEMATEL approach. Management Decision, 57(8),1784-1817. [ Links ]

[64] Rowley, C. & Cooke, F.L. 2014. The changing face of management in China. New York: Routledge. [ Links ]

[65] Alexander, P., Antony, J. & Rodgers, B. 2019. Lean Six Sigma for small- and medium-sized manufacturing enterprises: A systematic review. International Journal of Quality & Reliability Management, 36(3), 378-397. [ Links ]

[66] Sink, D.S. 1991. The role of measurement in achieving world-class quality and productivity. Industrial Engineering, 23(6), 23. [ Links ]

[67] Klewitz, J. & Hansen, E.G. 2014. Sustainability-oriented innovation of SMEs: A systematic review. Journal of Cleaner Production, 65, 57-75. [ Links ]

[68] Prajogo, D. & McDermott, C.M. 2014. Antecedents of service innovation in SMEs: Comparing the effects of external and internal factors. Journal of Small Business Management, 52(3), 521-540. [ Links ]

[69] Vyas, V. 2014. Low-cost, low-tech innovation: New product development in the food industry. London: Routledge. [ Links ]

Submitted by authors 25 Feb 2023

Accepted for publication 24 Oct 2023

Available online 14 Dec 2023

* Corresponding author: mtattar@uj.edu.sa

ORCID® identifiers

M.T. Attar: https://orcid.org/0000-0003-0365-6964